Professional Documents

Culture Documents

HDD Calculation For Gas Pipeline

Uploaded by

samotavijaypal26Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HDD Calculation For Gas Pipeline

Uploaded by

samotavijaypal26Copyright:

Available Formats

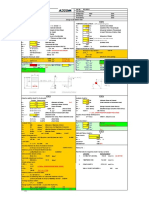

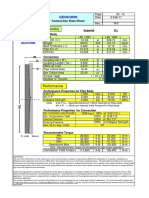

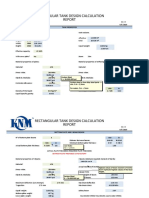

DESIGN CALCULATION FOR HDD -13 CH.

4+003 NEAR GANGA GARDEN NEW SANGANER ROAD 12"CGD JAIPUR

PROJECT : 12" CNG PIPELINE JAIPUR CGD

CLIENT : TORRENT GAS JAIPUR ,PVT. LTD.

CONTRACTOR LOGO TPI CLIENT

TPI : INTERNATIONAL CERT.SERV.PVT.LTD.

CONTRACTOR : M/S GL GOLDEN

Calculations required in accordance with ANSI code B31.8 for Gas transmissions across Pipelines for the installation of pipes by HDD are as

follows:

Outside Diameter Do - 323.85 mm

Inside Diameter Di - 311.05 mm

Wall Thickness T - 6.4 mm

SMYS of Materials SMYS 56000.0 PSI

Moment of Inertia I - 79805595.5700 mm4 0.0001 m

4

Weight of Pipe in Air Wt - 52.20 Kg / M

2

Cross Section of Pipe As Π/4(Do²-Di²) - 0.0064 M Area Calculated in (sq. meter)

Modulus of Elasticity E - 210000 N/mm2

Radius of Curvature R (Assumed) - 330.0 M

Co-efficient of Drag d - 239 N/M

2

3

Mud Density dm - 1050 Kg/m

Proposed Length L - 205.00 M

Entry Angle - 8.0000 Deg

Exit Angle - 8.0000 Deg

Maximum Depth of Profile D - 3.50 m

Hydrotest Pressure (1.5 X Design Pressure) pre test 73.5 Bars 7.34 N/mm2 (As Per Spec)

Hydrotest Pressure (1.5 X Design Pressure) post test 73.5 Bars 7.34 N/mm2 (As Per Spec)

Design Pressure p 49 Bars 4.89 N/mm2

Wt of one Drill Pipe (Length = 3.0 mtr) - 60.00 Kgs / 3.0 mtr

Total weight of Drill pipe to be used = 60x 205 / 3 = 4100.00 Kgs

Co-efficient of friction down hole t - 0.36

Static friction co-efficient 0n roller s - 0.2

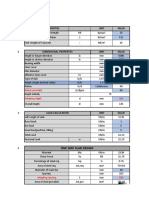

1. MAXIMUM LONGITUDIONAL STRESS DURING INSTALLATION

323.85 mm dia Pipeline

Buoyancy of Steel Pipe in Down Hole :

= ∏/4 x Do2 x Density of Drilling Fluid

= 0.7854 x 0.32385 2 x 1050

Wb = 86.49 Kg/M

Total Weight of Steel Pipe in Down Hole :

= (Wt. of Pipe) - (Buoyancy of Pipe in Down Hole)

= 52.20 - 86.49

= -34.29 Kg/M

Buoyancy Force :-

= FxN

= t(Buoyancy Factor x Proposed Length ) x N

= 0.36 x( 34.29 x 205.00 ) x 9.806

= 24815.08 N

Bending Moment :-

= EI/R

= 210000000000.00 x 0.0000798 / 330

= 50781.82 N-M

Pulling Force Calculation

Due to Buoyancy Force :-

F1 = FxN

Page 1 of 3

DESIGN CALCULATION FOR HDD -13 CH.4+003 NEAR GANGA GARDEN NEW SANGANER ROAD 12"CGD JAIPUR

PROJECT : 12" CNG PIPELINE JAIPUR CGD

CLIENT : TORRENT GAS JAIPUR ,PVT. LTD.

CONTRACTOR LOGO TPI CLIENT

TPI : INTERNATIONAL CERT.SERV.PVT.LTD.

CONTRACTOR : M/S GL GOLDEN

Calculations required in accordance with ANSI code B31.8 for Gas transmissions across Pipelines for the installation of pipes by HDD are as

= ( Buoyancy Factor x Proposed Length ) x N

= 0.36 x( 34.29 x 205.00 ) x 9.806

= 24815.08 N

Due to Curvature :-

F2 = 4 F x Bending Moment

1/2 x 2∏ /360 (Q entry R + Q Exit R)

= 4 x 0.36 x 50781.81818

0.008726646 ( 8.0000 x 330.0 + 8.0000 330.00 )

= 1587.05 N

Due to Cohesion :-

F3 = d x ∏ x Do x L

= 239.00 x 3.14 x 0.324 x 205.00

= 49822.48 N

Pulling Force :-

= F1 + F2 + F3

= 24815.08 + 1587.05 + 49822.48

= 76224.61 N

Considering Safety Factor & Drill pipes & Reamer Wt.

1.5 times x Pulling force + Drill Pipe + Reamer Wt.

=

= 11659.89275 + 4100.00 + 418

= 16.18 Tons 35591.36404 lbs

We are using HDD machine with 35 ton pulling capacity. (1 kg = 2.20 pound)

STRESS CALCULATIONS

Maximum Allowable Stress :-

S = 90% of SMYS

= 90% x 56000 PSI

= 50400 PSI

= 347.41 N/mm2

Bending Stress :-

= ED / 2R

= 2.10E+05 x 323.9 / 2 x 330000

= 103.04 N/mm2

Tensile Stress :-

= Pulling Force (N) / Cross Section Area (mm2)

= 76224.61 / 6400.000 (area Taken in Sq. mm)

= 11.91 N/mm2

Longitudional Stress during Installation :-

Allowable Stress > Tensile Stress + Bending Stress

> 11.91 + 103.04

347.41 > 114.95 N/mm2

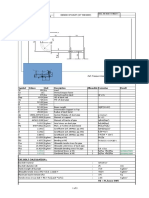

2. MAXIMUM EQUIVALENT STRESS DURING FINAL HYDROSTATIC TEST

Stress due to Hydrotest:-

= PD / 2t

= 7.34 x 323.9 / 2 x 6.4

2

= 185.71 N/mm

2

Bending Stress = 103.04 N/mm

Page 2 of 3

DESIGN CALCULATION FOR HDD -13 CH.4+003 NEAR GANGA GARDEN NEW SANGANER ROAD 12"CGD JAIPUR

PROJECT : 12" CNG PIPELINE JAIPUR CGD

CLIENT : TORRENT GAS JAIPUR ,PVT. LTD.

CONTRACTOR LOGO TPI CLIENT

TPI : INTERNATIONAL CERT.SERV.PVT.LTD.

CONTRACTOR : M/S GL GOLDEN

Calculations required in accordance with ANSI code B31.8 for Gas transmissions across Pipelines for the installation of pipes by HDD are as

Post Installation :-

Allowable Stress > Bending Stress + Hydrotest Stress

> 103.04 + 185.71

347.41 > 288.75 N/mm2

= which is lower than allowable stress, thus safe.

3. MAXIMUM EQUIVALENT STRESS DURING SERVICE

S = Allowable Stress

Allowable stress = Maximum allowable stress - bending stress - hydrotest stress

= 347.41 - 103.04 - 185.71 = 58.66 N/mm2

Minimum Allowable Radius of Curvature of Pipeline

R = E x Do

2S

= 210000 x 323.9

2 x 58.66 x 1000

= 68008500

323411.93

= 210.28 M

The calculated radius is less than the proposed radius of curvature

Pulling Stress when entire pipe in the roller

= SxWpxL = 0.2 X 52.20 x 205.00

As 0.0064

= 3278518.88 N/m2

= 3.28 N/mm2

CHECKED & VARIFIED BY

FOR G L GOLDEN FOR ICS FOR TORRENT GAS JAIPUR

NAME

SIGN

DATE

Page 3 of 3

You might also like

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- Base Plate Design Is 800 2007Document147 pagesBase Plate Design Is 800 2007pandian100% (1)

- HDD Calc As Per PRCDocument8 pagesHDD Calc As Per PRClive4sankar50% (2)

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Steel Truss Bridge 85 MT Bowarch Pedestrian BridgeDocument19 pagesSteel Truss Bridge 85 MT Bowarch Pedestrian Bridgeakshay kothiyalNo ratings yet

- ESR ST - DesignDocument33 pagesESR ST - DesignTarkeshwar Lal SrivastavaNo ratings yet

- Design Data-Conductor ACSR 240 40Document3 pagesDesign Data-Conductor ACSR 240 40Sara RamliNo ratings yet

- C7CH20050 - Wall - Reinforcement - WR2Document20 pagesC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- Rectangular Tank DesignDocument9 pagesRectangular Tank DesignMiguel EspañolNo ratings yet

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beagleNo ratings yet

- Design Excel SheetDocument17 pagesDesign Excel SheetbuntyNo ratings yet

- Lift Calculation DemoDocument4 pagesLift Calculation Demoa_toups0% (1)

- Davit design calculationsDocument12 pagesDavit design calculationsNaveen JeevaNo ratings yet

- Strip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNDocument13 pagesStrip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNkushaljp8989No ratings yet

- Steel Beam SpreadsheetDocument27 pagesSteel Beam SpreadsheetHugh McGilveray100% (1)

- Design of Steel Strcture, Is-800-2007Document48 pagesDesign of Steel Strcture, Is-800-2007srinivasNo ratings yet

- Piepline Thickness CalculationDocument6 pagesPiepline Thickness CalculationAneeq NaufalNo ratings yet

- Metal One Corp. Connection Data SheetDocument1 pageMetal One Corp. Connection Data SheetBalkis FatihaNo ratings yet

- Rectangular Tank Design Calculation: Tank Properties Tank Dimensions: Tank Volume: MM inDocument11 pagesRectangular Tank Design Calculation: Tank Properties Tank Dimensions: Tank Volume: MM inminov minovitchNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Blind Plate THK - Hydro PDFDocument3 pagesBlind Plate THK - Hydro PDFNaveen JeevaNo ratings yet

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- Design Calculation - KGPL SPUR INFRA CH 382.447 KMDocument18 pagesDesign Calculation - KGPL SPUR INFRA CH 382.447 KMRohit Kumar MishraNo ratings yet

- Calculation Cpi Tank: I. Design Parameters I.1 Design DataDocument5 pagesCalculation Cpi Tank: I. Design Parameters I.1 Design DataikramNo ratings yet

- HDD design calculations for 18Document23 pagesHDD design calculations for 18Binay Kumar100% (1)

- HORIZONTAL DIRECTIONAL DRILLING CALCULATIONDocument4 pagesHORIZONTAL DIRECTIONAL DRILLING CALCULATIONbulituk100% (1)

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Crane Load Capacity CalculationDocument11 pagesCrane Load Capacity CalculationsubudhiprasannaNo ratings yet

- HDD-LC-0001 Rev 0Document24 pagesHDD-LC-0001 Rev 0SAUGAT DUTTANo ratings yet

- 13-CAL AT CH 6.293 (27jan)Document4 pages13-CAL AT CH 6.293 (27jan)subudhiprasannaNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Dongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsDocument2 pagesDongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsSara RamliNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- Hl707 Adicg CR 001 r0 (Load Out Ramp)Document8 pagesHl707 Adicg CR 001 r0 (Load Out Ramp)dheeraj SureshNo ratings yet

- Dongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsDocument2 pagesDongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsSara RamliNo ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- Trunnion CalculationsDocument2 pagesTrunnion Calculationspmech consultantNo ratings yet

- 10T SWL Spreader Bar R2-Fos2.0Document8 pages10T SWL Spreader Bar R2-Fos2.0Snr Designer JayaNo ratings yet

- Design of Two Way Slab with Short Span of 3.62m and Long Span of 3.92mDocument1 pageDesign of Two Way Slab with Short Span of 3.62m and Long Span of 3.92mPipoy ReglosNo ratings yet

- R410A Tropical Split Technical Manual SpecsDocument1 pageR410A Tropical Split Technical Manual SpecsgrwgNo ratings yet

- PDF Installation Minimum Straight Section Between Curves A - CompressDocument2 pagesPDF Installation Minimum Straight Section Between Curves A - CompressJamie RichardsNo ratings yet

- GULF HEAVY INDUSTRIES SPREADER BEAM CALCULATIONSDocument2 pagesGULF HEAVY INDUSTRIES SPREADER BEAM CALCULATIONSSenthil KumarNo ratings yet

- One-Way Slab DesignDocument3 pagesOne-Way Slab DesignMoe Oo HtunNo ratings yet

- COLUMNDocument3 pagesCOLUMNGaneshalingam Ramprasanna2No ratings yet

- Design Report - Basement SlabDocument27 pagesDesign Report - Basement Slabsd.bushra91No ratings yet

- Base Ring - One Point - R0Document10 pagesBase Ring - One Point - R0Tushar MangratiNo ratings yet

- 1 DATA SHEET FOR ST BELT ST1600 CBT Brand 230329Document1 page1 DATA SHEET FOR ST BELT ST1600 CBT Brand 230329wycingenieriaNo ratings yet

- 1) Basic Data: Design of Cantilever Beam As Per IS 456-2000Document4 pages1) Basic Data: Design of Cantilever Beam As Per IS 456-2000khaniskhan03No ratings yet

- Acrylic PropertiesDocument1 pageAcrylic Propertiesmasood nazirNo ratings yet

- Geometry: Geoconn - TsDocument1 pageGeometry: Geoconn - TsPapa AinunNo ratings yet

- Shincoil CompressionDocument98 pagesShincoil CompressionVNK90No ratings yet

- Flange Calculation As Per BS - XLSX - 170111Document7 pagesFlange Calculation As Per BS - XLSX - 170111sandesh sadvilkarNo ratings yet

- S4 - Roof DeckDocument2 pagesS4 - Roof DeckJoemarie MartinezNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- 23132-E1A-XL-M: Spherical Roller BearingDocument2 pages23132-E1A-XL-M: Spherical Roller BearingvivianaNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Reynolds Experiment PDFDocument8 pagesReynolds Experiment PDFali najatNo ratings yet

- Cold Weld Cracking of HSLA SteelDocument3 pagesCold Weld Cracking of HSLA Steelarjun prajapatiNo ratings yet

- Curriculum Vitae: Career ObjectiveDocument5 pagesCurriculum Vitae: Career ObjectiveRavi Shankar ChakravortyNo ratings yet

- Dragonfly 112719 PDFDocument2 pagesDragonfly 112719 PDFdocturboNo ratings yet

- Holographic Data StorageDocument9 pagesHolographic Data Storagesamsaswat003No ratings yet

- Sand Replacement Lab ReportDocument16 pagesSand Replacement Lab Reportimran shakirNo ratings yet

- 03 Transforms 3 DDocument5 pages03 Transforms 3 DWafa ElgalhoudNo ratings yet

- BC546B, BC547A, B, C, BC548B, C Amplifier Transistors: NPN SiliconDocument6 pagesBC546B, BC547A, B, C, BC548B, C Amplifier Transistors: NPN SiliconNadia Ayelen GonzalezNo ratings yet

- GNS 121 by SalakoDocument26 pagesGNS 121 by SalakoAdesanya AbisolaNo ratings yet

- (Susol Metasol ACB) Catalog en 202104Document140 pages(Susol Metasol ACB) Catalog en 202104LUATNo ratings yet

- Smardt Chillers - The Global Leader in High Efficiency Oil-Free Cooling SolutionsDocument53 pagesSmardt Chillers - The Global Leader in High Efficiency Oil-Free Cooling SolutionsTùng Chu báNo ratings yet

- A2LA Accredited Laboratory for Mechanical TestingDocument6 pagesA2LA Accredited Laboratory for Mechanical TestingWaqar YounasNo ratings yet

- Diploma in Electrical Engineering Industrial Traning ReportDocument42 pagesDiploma in Electrical Engineering Industrial Traning ReportSathwik SinghNo ratings yet

- Energy Interactions With Earth Surface Features RemoteDocument24 pagesEnergy Interactions With Earth Surface Features RemoteZoro D. GhoulNo ratings yet

- 23xl 3ssDocument116 pages23xl 3ssHendra SyahputraNo ratings yet

- Research Paper - Beyond The Knee Point (CT Saturation)Document23 pagesResearch Paper - Beyond The Knee Point (CT Saturation)James BurtonNo ratings yet

- QP D15 De57 PDFDocument3 pagesQP D15 De57 PDFRajashekarBalyaNo ratings yet

- L-BL2 User ManualDocument40 pagesL-BL2 User ManualrubiodegoNo ratings yet

- NEW BENNI - Manual de ServicioDocument678 pagesNEW BENNI - Manual de ServicioSantiago CosNo ratings yet

- Crystal Field Stabilisation Energies of Octahedral Complexes (CFSEsDocument2 pagesCrystal Field Stabilisation Energies of Octahedral Complexes (CFSEsAyushi JoshyaNo ratings yet

- Siemens Arcadis Varic C ArmDocument2 pagesSiemens Arcadis Varic C ArmFady Sobhy AzizNo ratings yet

- Construction and Working Principles of BLDC MotorDocument24 pagesConstruction and Working Principles of BLDC Motormahadeva prasad m sNo ratings yet

- How Trust Impacts Organizational Learning and InnovationDocument14 pagesHow Trust Impacts Organizational Learning and Innovationerika31123100% (1)

- Prisms A Level PDFDocument28 pagesPrisms A Level PDFJeremiah NakibingeNo ratings yet

- A Conceptual Study of Finger-Type Slug Catcher For Heavy-Oil FieldsDocument8 pagesA Conceptual Study of Finger-Type Slug Catcher For Heavy-Oil FieldsfanziskusNo ratings yet

- Intensifying ScreenDocument20 pagesIntensifying ScreenLyht TVNo ratings yet

- Modeling Coastal Morphology: Virtual Reality or Realistic AnalogueDocument5 pagesModeling Coastal Morphology: Virtual Reality or Realistic AnalogueF. A. CB.No ratings yet

- Current Electricity - Revision Sheet (Part A) - Physics - Standard 10Document3 pagesCurrent Electricity - Revision Sheet (Part A) - Physics - Standard 10mNo ratings yet

- PLU Civil Engineering Department Midterm Exam ReviewDocument7 pagesPLU Civil Engineering Department Midterm Exam ReviewhaniiramosNo ratings yet

- Tac 12 CpaDocument27 pagesTac 12 CpaAlexandre BAUN TECNICO AUTOMACAONo ratings yet