Professional Documents

Culture Documents

Chapter 12 - Hydraulic Track Tensioning System: Service Manual

Chapter 12 - Hydraulic Track Tensioning System: Service Manual

Uploaded by

Augusto OliveiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 12 - Hydraulic Track Tensioning System: Service Manual

Chapter 12 - Hydraulic Track Tensioning System: Service Manual

Uploaded by

Augusto OliveiraCopyright:

Available Formats

Service Manual

Chapter 12 - Hydraulic track tensioning system

Track tensioning system .................................................................................................................................. 12-3

1 Description........................................................................................................................................ 12-3

2 Fonction ............................................................................................................................................ 12-4

3 Temperature dependent pressure adjustment.................................................................................. 12-5

3.1 Increase in pressure ............................................................................................................... 12-5

3.2 To reduce pressure ................................................................................................................ 12-6

LFR/en/version: 08 / 2007

R 9250 from 13466 12 - 1

MJFCIFSS

Service Manual

LFR/en/version: 08 / 2007

12 - 2 R 9250 from 13466

MJFCIFSS

Service Manual Track tensioning system

Description

12 Track tensioning system

12.1Description

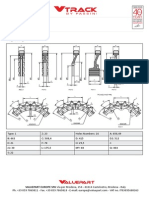

1 Housing 10 Check valve

2 Piston 11 Adapter fitting

3 Guide sleeve 14 Usit ring

4 Scraper ring 16 Cover

5 Piston guide ring 20 Allen head screw

6 Prop ring 21 Hex. head screw

7 Grooved seal ring 25 Spring ring

8 Support ring 26 Spring ring

9 Grooved seal ring

The hydro-spring unit (elastomer tensioner) consists of a cylindrical housing 1, a guide sleeve 3, which is

screwed in, and a cover 16, which is also screwed in.

Piston 2 is installed in the guide sleeve over piston guide rings 5. The piston is chromium plated. A grooved

ring with prop ring on each side seals , the piston and the threading on the guide sleeve.

The inserted cover is also sealed with a grooved ring 9.

LFR/en/version: 08 / 2007

The following components are located in the cover :

– 1 check valve 10 for a max. pressure of 2000 bar.

– 1 adapter fitting 11 with a R 1/4´´ threaded fitting to fill or drain the tensioner.

– 1 adapter 12 with pressure gauge 13.

The contents consists of a compressive fluid and is pumped via the check valve, described above, into the con-

tainer.

Guides (cross members) are screwed onto the hydro spring unit, making it possible for the unit to be pushed

into the extended idler guide on the side frame.

R 9250 from 13466 12 - 3

MJFCIFSS

Track tensioning system Service Manual

Fonction

The units is not connected to the side frame.

Caution!

The elastomer tensioner is a sealed unit under high pressure and may not be repaired or disassem-

bled for safety reason.

Defective or leaking elastomer tensioners should be remplaced as complete units.

Repairs on this component are only to be done by its manufacturer.

12.2Fonction

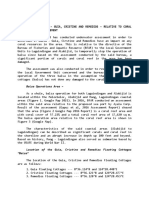

The elastomer tensioner is charged with a pre-tension of pV (nom.) at an ambient temperature of about +20°C.

The corresponding preload force is F1 (nom.).

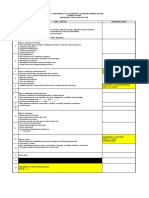

The table below shows the settings at different temperatures :

Temperature (°C) pV (bar) F1 (kN) Observation

-20 360 442

In this area, the hydraulic spring element

-10 470 577

must be replenish

0 580 712

5 pV (min.) = 630 773

10 695 853 The maintenance is free between +5°C and

20 pV (nom.) = 815 F1 (nom.) = 1000 +25°C

25 pV (max.) = 885 1086

30 960 1178

In this area, the pressure of filling must be

40 1120 1374

reduce

50 1300 1595

In the range pV (max.) / pV(min.), the hydro spring unit is maintenance free. This corresponds to temperature

between +5°C to +25°C.

At lower temperatures, or if pressure is below pV (min.) the tensioner must be refilled with elastomer via the

adapter 11 and using a hand pump (Id. no. : 5607896), until pressure pV (nom.) is reached.

At high temperature, or if pressure is over pV (max.) release some elastomer from the tensioner via adapter

11, using a special screw (Id. no. : 7366291), to have the pressure pV (nom.).

LFR/en/version: 08 / 2007

12 - 4 R 9250 from 13466

MJFCIFSS

Service Manual Track tensioning system

Temperature dependent pressure adjustment

12.3Temperature dependent pressure adjustment

For pressure adjustment, remove the cover A on the side frame of the undercarriage and verify the pressure.

12.3.1Increase in pressure

The idler is precharged at the factory and ready to be used.

However, if the machine is used at a temperature below the maintenance free range, the pressure in the hydro

spring unit has to be checked, and adjusted to pV(nom.) with the hand pump.

Proceed as follows to increase fluid :

– Relieve the track chain tension.

– Remove the cover from the appropriate side frame.

– Fill the hand pump container with elastomer.

– Slowly bleed the hose by pumping the hand pump slowly.

LFR/en/version: 08 / 2007

– Connect the pump to the adapter fitting 11 and fill the hydro spring unit to the correct pressure.

– Remove the pump from the adapter fitting after this procedure.

R 9250 from 13466 12 - 5

MJFCIFSS

Track tensioning system Service Manual

Temperature dependent pressure adjustment

12.3.2To reduce pressure

If the machine is changed from low operating temperature to warmer temperature (> +25°C), then the pressure

has to be changed also.

To do this, first relieve the pressure on the elastomer tensioner and then recharge the tensioner with the hand

pump to the correct pressure.

Proceed as follows :

– Relieve the track chain tension.

– Remove the cover from the appropriate side frame.

– Slowly turn the special screw into the valve seat until elastomer drains from the groove on the screw.

– Slowly remove the special screw. The valve closes by itself.

– Use the pump to pressurize the unit to the correct pressure.

LFR/en/version: 08 / 2007

12 - 6 R 9250 from 13466

MJFCIFSS

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- ZF Servocom EnglischDocument21 pagesZF Servocom EnglischSaša OljačaNo ratings yet

- American Code of Canon LawDocument154 pagesAmerican Code of Canon LawJay SmithNo ratings yet

- Service Parts Are Available For Pilot Valves Work ToolDocument8 pagesService Parts Are Available For Pilot Valves Work ToolAdal VeraNo ratings yet

- Troubleshooting Zaxis 3Document15 pagesTroubleshooting Zaxis 3jacklyn ade putra83% (18)

- A2 Electrical DiagramDocument16 pagesA2 Electrical Diagramjacklyn ade putra100% (14)

- Systematic Problem Solving: Mind Maps and Problem Solving ToolsDocument24 pagesSystematic Problem Solving: Mind Maps and Problem Solving Toolsthomasteepe50% (2)

- Hitachi Trouble ShootingDocument18 pagesHitachi Trouble Shootingjacklyn ade putra75% (4)

- HH220i Smaster ManualDocument60 pagesHH220i Smaster Manualjacklyn ade putra100% (1)

- HH220i Smaster ManualDocument60 pagesHH220i Smaster Manualjacklyn ade putra100% (1)

- TotalDocument98 pagesTotalengelberthmrNo ratings yet

- CP150 SMDocument50 pagesCP150 SMjacklyn ade putra100% (1)

- 06 WN Trackinfo Compact en 23 OkDocument23 pages06 WN Trackinfo Compact en 23 Oktazjuan1No ratings yet

- Front Mount HF TechdataDocument14 pagesFront Mount HF TechdataAlexandru NicuNo ratings yet

- Doosan Trauble ShootingDocument7 pagesDoosan Trauble Shootingjacklyn ade putra100% (1)

- Caterpillar - Steering Selenoid 785Document4 pagesCaterpillar - Steering Selenoid 785globalindosparepartsNo ratings yet

- Overhaul Engine NTA855 PR-37423Document4 pagesOverhaul Engine NTA855 PR-37423Hildan TvNo ratings yet

- Phast Europe: Fast Delivery ProgramDocument40 pagesPhast Europe: Fast Delivery ProgramDaveNo ratings yet

- Warn Winch 8274 Exploded View PartsDocument2 pagesWarn Winch 8274 Exploded View PartsORLANDO CASTILLONo ratings yet

- Sumitomo Error CodeDocument10 pagesSumitomo Error Codejacklyn ade putra100% (24)

- Best of BelgiumDocument215 pagesBest of Belgiumsven100% (1)

- Mark ViesDocument32 pagesMark ViesMauricio GuanellaNo ratings yet

- Barford TR5048 Manual + Parts List 2021 WITH MULCHDocument62 pagesBarford TR5048 Manual + Parts List 2021 WITH MULCHpggmarquesNo ratings yet

- Front Suspension Cylinder Cap Capscrew ImprovementDocument4 pagesFront Suspension Cylinder Cap Capscrew ImprovementSandro GastanagaNo ratings yet

- Hensley Blade ManualDocument520 pagesHensley Blade Manualkarol1177No ratings yet

- Wr430gb00b BMP Cat Discl EngDocument12 pagesWr430gb00b BMP Cat Discl EngY.EbadiNo ratings yet

- d65-15 Errors PDFDocument5 pagesd65-15 Errors PDFjacklyn ade putra100% (1)

- 325 329 General Duty Intro PELJ1792 - V01Document6 pages325 329 General Duty Intro PELJ1792 - V01robert0126No ratings yet

- Rollers & Idler - Korea Brand PartsDocument23 pagesRollers & Idler - Korea Brand PartsdefidhanNo ratings yet

- Copy of 8.6船EPA申請リスト-2Document58 pagesCopy of 8.6船EPA申請リスト-2RiotaNo ratings yet

- Om 501 A I LaDocument4 pagesOm 501 A I Lafrancisco1938No ratings yet

- PC3000-1 S - N 06174 - Idler AssyDocument2 pagesPC3000-1 S - N 06174 - Idler AssyM Ferry AnwarNo ratings yet

- P7000MIN HMP DigitalDocument45 pagesP7000MIN HMP DigitalOdrzavanje MPEUNo ratings yet

- BI6517010001 Procedure To Locate The Soft Spot On Slew Rings On Certain 6040-6090FS Hydraulic Mining ShovelsDocument3 pagesBI6517010001 Procedure To Locate The Soft Spot On Slew Rings On Certain 6040-6090FS Hydraulic Mining ShovelsVictor Marcos BautistaNo ratings yet

- 7 Series PDFDocument2 pages7 Series PDFVijay HatkarNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument8 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Crankshaft RepairDocument4 pagesCrankshaft RepairHichamNo ratings yet

- RODILLODocument35 pagesRODILLOfran100% (1)

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument3 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- I-Lock CT2 Coupler BrochureDocument2 pagesI-Lock CT2 Coupler BrochureW MoralesNo ratings yet

- MMT2 IT Strategic Solutiontask 4Document8 pagesMMT2 IT Strategic Solutiontask 4siddhartha_maity_440% (5)

- Manual LMCSSDocument311 pagesManual LMCSSenriqueNo ratings yet

- Gefran 500 PDFDocument4 pagesGefran 500 PDFajrandisi0% (1)

- Mantenimiento de Pines CartridgeDocument9 pagesMantenimiento de Pines CartridgeEduardo Vilca callaNo ratings yet

- Hydraulic System: Pantalla AnteriorDocument4 pagesHydraulic System: Pantalla AnteriorDiego VicenteNo ratings yet

- linkonepac4100xpcDocument1,215 pageslinkonepac4100xpcMiguel Angel Valencia ZegarraNo ratings yet

- Motores VickersDocument29 pagesMotores VickersHenry AvalosNo ratings yet

- Isi 29.00.00173Document66 pagesIsi 29.00.00173Do GyiNo ratings yet

- Technical Report BalsaDocument8 pagesTechnical Report BalsaVianney Anthony Abella GapuzNo ratings yet

- ForecastDocument69 pagesForecastInsannulNo ratings yet

- Powder Bushing ChartDocument4 pagesPowder Bushing ChartamigaflyerNo ratings yet

- Technical Description Hydraulic Excavator: LitronicDocument10 pagesTechnical Description Hydraulic Excavator: Litronicwalk01No ratings yet

- Hour Meter: Component Tracking - Lac Des Iles Mines LTDDocument7 pagesHour Meter: Component Tracking - Lac Des Iles Mines LTDgrtyyNo ratings yet

- 06 Undercarriage Tools PDFDocument108 pages06 Undercarriage Tools PDFMarco BacianNo ratings yet

- Eaton EZClipDocument72 pagesEaton EZClipReach HomeNo ratings yet

- Excavator BackhoeDocument7 pagesExcavator BackhoeleoNo ratings yet

- Catalouge Bucket Wearplate & AccessoriesDocument18 pagesCatalouge Bucket Wearplate & Accessoriesaribawayuni16No ratings yet

- Standard Equipment Optional Equipment: We Build A Better FutureDocument9 pagesStandard Equipment Optional Equipment: We Build A Better Futureyony choqueñaNo ratings yet

- Stieber Clutches Maincatalog en 2010Document92 pagesStieber Clutches Maincatalog en 2010Alice SunNo ratings yet

- Mida Casting IndustryDocument12 pagesMida Casting IndustryApip SallihNo ratings yet

- Samsung RS21HDTTS FridgeDocument24 pagesSamsung RS21HDTTS FridgeXiledNo ratings yet

- Chain Saw g5200 PDFDocument18 pagesChain Saw g5200 PDFaumaNo ratings yet

- KJIN Rockbreaker BrochureDocument8 pagesKJIN Rockbreaker BrochureRC SPARESNo ratings yet

- Dealer Stocking List PDFDocument6 pagesDealer Stocking List PDFMahmmod Al-QawasmehNo ratings yet

- At04222a2filter PDFDocument8 pagesAt04222a2filter PDFJoko SukarionoNo ratings yet

- Motor Assy - Track DriveDocument3 pagesMotor Assy - Track DriveDavid Apaza HurtadoNo ratings yet

- Smart BusDocument48 pagesSmart BussongoniNo ratings yet

- Rock DrillDocument75 pagesRock DrillElber Luis Chavez BarriosNo ratings yet

- F 12 ModifiedDocument10 pagesF 12 ModifiedEduardo CramerNo ratings yet

- Sheaves : With Cylindrical Roller BearingsDocument3 pagesSheaves : With Cylindrical Roller BearingsInhake AutechreNo ratings yet

- GTBZ40-42 Parts ManualDocument66 pagesGTBZ40-42 Parts ManualTesla EcNo ratings yet

- Supplement 1A:: Spare Parts List For Track System Type: 224T-DTS1-DB065BBDocument4 pagesSupplement 1A:: Spare Parts List For Track System Type: 224T-DTS1-DB065BBorlando chullo llaveNo ratings yet

- Montabert Blue LineDocument4 pagesMontabert Blue LineGeorge Kwamina Anaman0% (1)

- VR 762000Document1 pageVR 762000aleruhoNo ratings yet

- NTN RPL 2015 1st Oct 2015Document78 pagesNTN RPL 2015 1st Oct 2015Pankaj MittalNo ratings yet

- Installation, Start-Up and Service Instructions: 38AKS028-044 Air-Cooled Condensing Units 50/60 HZDocument24 pagesInstallation, Start-Up and Service Instructions: 38AKS028-044 Air-Cooled Condensing Units 50/60 HZalbertoaireNo ratings yet

- Engine CoolingDocument20 pagesEngine CoolingAlexandre Da Silva PintoNo ratings yet

- Spare Parts Pc3Document1 pageSpare Parts Pc3jacklyn ade putraNo ratings yet

- 307E Collage HYD SchemaDocument15 pages307E Collage HYD Schemajacklyn ade putraNo ratings yet

- Terbilang Untuk Pembayaran Pembayaran 1 (Satu) Unit Kubota Mini Excavator TIPE U-50-5 S/N 71772 E/N: 7GF7193Document1 pageTerbilang Untuk Pembayaran Pembayaran 1 (Satu) Unit Kubota Mini Excavator TIPE U-50-5 S/N 71772 E/N: 7GF7193jacklyn ade putraNo ratings yet

- Sticker Ready To ShipDocument1 pageSticker Ready To Shipjacklyn ade putraNo ratings yet

- Form Absen Unit Sheet1Document1 pageForm Absen Unit Sheet1jacklyn ade putraNo ratings yet

- Engine Stop DiagramsDocument2 pagesEngine Stop Diagramsjacklyn ade putra100% (2)

- D31PXDocument8 pagesD31PXjacklyn ade putraNo ratings yet

- Logo TKJDocument1 pageLogo TKJjacklyn ade putraNo ratings yet

- Measuring Fuel Spill Rate Pressure Limiter 2Document7 pagesMeasuring Fuel Spill Rate Pressure Limiter 2jacklyn ade putra100% (1)

- Dv300 STD MMDocument40 pagesDv300 STD MMjacklyn ade putraNo ratings yet

- DV100 SMDocument51 pagesDV100 SMjacklyn ade putraNo ratings yet

- QucryptoDocument28 pagesQucryptoMustafa_elecNo ratings yet

- Internet of Things For Smart CitiesDocument26 pagesInternet of Things For Smart CitiesCSE 44 Prajwal BhajeNo ratings yet

- Mainstream Deammonification WERF 2015Document304 pagesMainstream Deammonification WERF 2015UmutNo ratings yet

- Compvac (1) OffersDocument2 pagesCompvac (1) Offersagrocel_bhv5591No ratings yet

- Computer Ethics: Instructor: Anam ZaiDocument37 pagesComputer Ethics: Instructor: Anam Zaiayesha ambreenNo ratings yet

- Paper Presentation - Schedule - ISIPARM-2023Document7 pagesPaper Presentation - Schedule - ISIPARM-2023Subrahmanya G M BhatNo ratings yet

- FinalPräsi 06-01Document20 pagesFinalPräsi 06-01Joaquin DiazNo ratings yet

- KWHotel Configuration ModuleDocument30 pagesKWHotel Configuration Modulemaclans marketingNo ratings yet

- Nanotechnology in Biomedical ApplicationsDocument17 pagesNanotechnology in Biomedical ApplicationsAbhiroop KumarNo ratings yet

- Welding Lab Report # 1: Submitted To: Submitted byDocument6 pagesWelding Lab Report # 1: Submitted To: Submitted byAbrar HassanNo ratings yet

- Makalah Kelompok 10 Sistem Informasi AkuntansiDocument38 pagesMakalah Kelompok 10 Sistem Informasi AkuntansiDesy manurungNo ratings yet

- Unit 3 - CGW4U - Discussion 4 (Migration Response) - Afnan ShahidDocument6 pagesUnit 3 - CGW4U - Discussion 4 (Migration Response) - Afnan ShahidAfnan ShahidNo ratings yet

- Literature Review of Oyster MushroomDocument6 pagesLiterature Review of Oyster Mushroomewhknurif100% (1)

- Implementing The Government Accounting Manual (Gam) : (For National Government Agencies)Document25 pagesImplementing The Government Accounting Manual (Gam) : (For National Government Agencies)Joann Rivero-SalomonNo ratings yet

- Gateway CXDocument1 pageGateway CXArif Tawil PrionoNo ratings yet

- R T I ApplicationDocument3 pagesR T I Applicationthimmegowdatg1308No ratings yet

- List of Supported Oracle Hardware With Last Ship Dates AnnouncedDocument14 pagesList of Supported Oracle Hardware With Last Ship Dates Announcedaibot aibotNo ratings yet

- Eid 2014 Registration FormDocument3 pagesEid 2014 Registration FormGeorge ManuelNo ratings yet

- 212spflyer PDFDocument2 pages212spflyer PDFTulioLopezJNo ratings yet

- Sow CSC126 20224Document1 pageSow CSC126 20224Fatin AziraNo ratings yet

- Operation Manual: MODEL LS-R902 (N2, N3, N4, N5)Document12 pagesOperation Manual: MODEL LS-R902 (N2, N3, N4, N5)Gonzalo RiosNo ratings yet

- Annex 4.4 Audit Report Template (Model)Document45 pagesAnnex 4.4 Audit Report Template (Model)Gideon HilardeNo ratings yet