Professional Documents

Culture Documents

Mechanical Symbols and Coating Code Guide

Uploaded by

ahmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Symbols and Coating Code Guide

Uploaded by

ahmadCopyright:

Available Formats

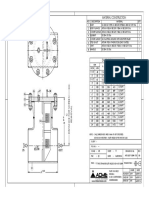

8 7 6 5 4 3 2 1

MECHANICAL SYMBOLS COATING / INSULATION CODE NOTES

MAIN PROCESS LINE. INTERNAL TREATED + EXTERNAL COATED LINE A

ARROW INDICATES DIRECTION OF FLOW ANTI-SWEAT AS

EXTERNAL COATED LINE ONLY B

SECONDARY PROCESS OR UTILITY LINE INSULATED EQUIPMENT ELECTRIC TRACED LINE + INSULATED + PAINTED E GENERAL NOTES FOR ALL P&ID

FIRE PROTECTION FP

F

EXISTING LINE FLUSH BOTTOM VALVE COLD INSULATED LINE + PAINTED F

HOT INSULATED LINE + PAINTED I

PACKAGE BOUNDARY NOT PAINTED / INSULATED LINE N

"FALL" OR SILENCER INTERNAL TREATED + EXTERNAL PAINTED LINE S

"RISE" 1:100 STEAM TRACED LINE + INSULATED + PAINTED T

INDICATION FOR FALL OR RISE 1. DEFINITIONS :

EXTERNAL PAINTED LINE ONLY (NOT INSULATED) V

MIXING CHAMBER VORTEX BREAKER

STEAM JACKET + INSULATED + PAINTED W

VB GRAVITY FLOW - ELEVATIONS DOWNSTREAM NEVER EXCEED INLET ELEVATION. LINE MAY CONTAIN POCKETS.

DUCT PERSONNEL PROTECTION + PAINTED PP

IN-LINE MIXER ACOUSTIC ATTENUATION INSULATION + PAINTED AA

0 SLOPE - ELEVATIONS CHANGES ARE CONSTAITLY DOWNWARD ONLY, NO POCKETS

STEAM\ELECTRICAL TRACED LINE SPECIAL APPLICATIONS X

(INCLUDES TRACING ON VALVE) ORIFICE MIXER HOT INSULATED+ACOUSTIC ATTENUATION INSULATION+PAINTED IAA ARE PERMITTED. SPECIFIC SLOPES REQUIRED ARE SHOWN BY SYMBOL ;

STEAM JACKETED VALVE STATIC MIXER XXXXX YYYYY PIPELINE IDENTIFICATION

JACKETED LINE (HEATING MEDIUM IS STEAM PIPING CLASS SPLIT 1

MULTI RESTRICTION ORIFICE PLATE X

UNLESS OTHERWISED NOTED).

LINE JUNCTION WHERE X HAS UNIT THE SAME AS I (SLOPE IS m/m, ETC)

6" - XXXX - XX - XXX - XXXXXX - XXX

E.G. MIN. DISTANCE

INJECTION QUILL COATING/INSULATION CODE (3 DIGITS MAX)

LINE CROSSING, NOT CONNECTED

PIPING SERVICE CLASS (7 DIGITS MAX) FREE DRAINING - GRAVITY FLOW -

ECCENTRIC REDUCER - TOP FLAT SCOPE SPLIT- LINE SEQUENCE NUMBER (001 - 999)

NO POCKET - NO LIQUID POCKET IN THE LINE. WHEN NECESSARY TO PREVENT VAPOR POCKET

VENDOR (WHITE SIDE) / PURCHASER (BLACK SIDE)

ECCENTRIC REDUCER - BOTTOM FLAT CALIBRATION POT FLUID CODE

THE NOTE WILL READ "NO VAPOR POCKET"

UTILITY DRAIN CONNECTION

E

Y PLANT NUMBER (4 DIGITS)

CONCENTRIC REDUCER OPC NO. XX = UTILITY ABBREVIATION (SEE FLUID CODE)

XX

Y = HYDROCARBON DRAIN / FLUSHING OIL ABBREVIATION NOMINAL PIPE SIZE (IN INCHES)

FLANGED END WITH BLIND FLANGE H : HEAVY

C : CRACKED 2. 6mm WEEP HOLES ARE PROVIDED AT LOW POINTS OF RELIEF VALVE DISCHARGE LINES TO VENT TO ATMOSPHERE.

END CAP. BUTT WELDED

PULSATION DAMPENER L : LIGHT FLUID CODES:

CC P PROCESS BGA BREATHING AIR

SPADE BLIND HBW HP BOILER FEED WATER HY HYDROGEN 3. PROVIDE SPECIAL SUPPORT FOR ALL TWO PHASE LINES TO AVOID VIBRATIONS.

CORROSION COUPON

MBW MP BOILER FEED WATER IA INSTRUMENT AIR

SC

LBW LP BOILER FEED WATER UA SERVICE AIR

RAM TYPE SAMPLE VALVE FCWR FRESH COOLING WATER RETURN LN LIQUID NITROGEN 0

SPECTACLE BLIND, OPEN POSITION 4. BASE PLATE DRAIN FOR PUMPS SHALL BE PROVIDED AS FOLLOWS :

(STRAHMAN) FCWS FRESH COOLING WATER SUPPLY UN NITROGEN (INERT GAS)

1 DWG NO. DW DRINKING WATER PA PROCESS SERVICE AIR

SAMPLE COOLER OFF PAGE CONNECTOR

MW DISTILLED WATER DA DRY PROCESS AIR

SPECTACLE BLIND, CLOSED POSITION sc (TO BE USED FOR DRAINS WHICH REQUIRE COOLING) PW PROCESS WATER VA VENT GAS (ATM)

SWS SEA WATER SUPPLY FG FUEL GAS

CONNECTOR NO. CONTINUATION NUMBER SWR SEA WATER RETURN 0 2" NPT

FLG FLUE GAS

RING SPACER TW FRESH WATER (DESALINATED) BASE PLATE

FILTER OR STRAINER (GENERAL) NG NATURAL GAS

SAMPLE POINT UW UTILITY WATER TG TAIL GAS

SC X - SEE SAMPLE CONNECTION CODE LISTING (THIS DRAWING) WA SOUR WATER

NON - PROCESS SPACER X WD DEMINERALIZED WATER FO REFINERY FUEL OIL

DRIP RING FOR APPLICABLE LETTER CODE

WS SOFTENED WATER

TWW TREATED WASTE WATER CH CHEMICALS (GENERAL)

NON - PROCESS BLIND SPECIALITY ITEM CODE (NOT STANDARD PART OF LINE) WW WASTE WATER FC FRESH CAUSTIC

SC SPENT CAUSTIC

FLANGED CONNECTION WITH STEAM RING YYY = SEQUENCE NUMBER FW FIREWATER BA BOILER WATER BLOWDOWN

QUICK RELEASE CLOSURE

BD BLOWDOWN SY

CONICAL STRAINER HS HIGH PRESSURE STEAM CBD COLD BLOWDOWN

KS VERY HIGH PRESSURE STEAM

SWING ELBOW ("WITCHES HAT".

D

LS VERY LOW PRESSURE STEAM AF ACID GAS FLARE 5. PROCESS TRAP DETAIL.

USE ONLY WHERE PERMANENTLY INSTALLED) LINE NUMBER BREAK EXPANSION JOINT CF COLD FLARE 0

MS MEDIUM PRESSURE STEAM

HF HIGH PRESSURE FLARE

HOSE CONNECTION "Y"-TYPE STRAINER (WELDED) LF LOW PRESSURE FLARE P&ID REFRESENTATION ACTUAL REPRESENTATION

LC LP STEAM CONDENSATE LLF LOW LOW PRESSURE FLARE

MC MP STEAM CONDENSATE

SPOOL PIECE (REMOVABLE) "Y"-TYPE STRAINER (FLANGED) HP STEAM CONDENSATE AD AMINE DRAIN

HC

SP

PC PURE CONDENSATE AY ACCIDENTALLY OILY SEWER

DESUPERHEATER CC CLOSED CHEMICAL SEWER STEAM LINE

TC TREATED CONDENSATE STEAM CONDENSATE

CY ACID SEWER

OPEN DRAIN TO FUNNEL OR TRENCH RC RECOVERED CONDENSATE

BASKET TYPE STRAINER FI FOAMING LIQUID

PIPELINE INSULATION JOINT FS FOAMING SOLUTION STEAM LINE LC

FL FLUSHING OIL HD HYDROCARBON DRAIN

"T" TYPE STRAINER (WELDED) DWG STA

LO LUBE OIL NY SANITARY SEWER

OPEN VENT NO.

FRENCH DRAIN SY OILY SEWER

"T" TYPE STRAINER (FLANGED) TY SLUDGE CONCENTRATE 3/4"

WAD SOUR WATER DRAIN STA

0

OPEN VENT WITH BIRD SCREEN WY NON-OILY SEWER

CT CATALYST SERVICE 3/4"

BASKET FILTER HYDRANT FIREWALL SD SULFURIC ACID DRAIN

VENT WITH CHINESE HAT AB ACID BRINE 0 3/4"

0

BALL VALVE

MONITOR WITH

H HOSE REEL

GATE VALVE (WEDGE TYPE) CARTRIDGE FILTER HYDRANT CONNECTION PIPING ABBREVIATIONS 6. FULL BORE VALVE TO BE CONSIDERED TO COMPRESSOR AND TURBINE INLET AND PSV INLET/OUTLET.

C

DIAPHRAGM VALVE

THE FOLLOWING ABBREVIATIONS ARE TO BE USED TO SUPPLEMENT THE

GLOBE VALVE Y-TYPE GLOBE VALVE FIRE MONITOR SPRAY NOZZLE GRAPHICAL REPRESENTATIONS OF PIPING COMPONENTS, WHERE REQUIRED.

PLUG VALVE

NEEDLE VALVE PITCH CONTROL PITCH CONTROL LP - LOW PRESSURE

AAV -

AUTO AIR VENT

CARBON FILTER LUB - LUBRICATED

MIN. COOLING ON FAILURE MAX. COOLING ON FAILURE AG -

ABOVE GROUND

BUTTERFLY VALVE AT -

AIR TRAP M - MOTOR/DRIVER

ATM -

ATMOSPHERE MAX - MAXIMUM

YYY

STREAM TAG No. BDV -

BLOW DOWN VALVE MH - MAN HOLE

KNIFE GATE VALVE SLIDE VALVE MIN - MINIMUM

YYY = MAX. 3 DIGITS (NUMERICAL) BL -

BLOCK LIMIT (BATTERY LIMIT)

BS -

BIRD SCREEN MOV - MOTOR-OPERATED VALVE

CHECK VALVE OUTSIDE C -

CLOSED MP - MEDIUM PRESSURE

CAF -

CARBON FILTER (CANISTER) MR - MANUAL RESET

DIAPHRAGM MROP - MULTI RESTRICTION ORIFICE PLATE

CC -

CABLE CONTROL

STOP CHECK VALVE CM -

COLLECTING MANIFOLD MV - MEASURED VARIABLE

COF -

CENTRE OF FLOAT NC - NORMALLY CLOSED

FLEXIBLE HOSE NNF - NORMALLY NO FLOW

CP -

CONDENSATE POT

OTHERS CPL -

COUPLER / ADAPTER NO - NORMALLY OPEN

VALVE WITH SPINDLE FOR LINES IN AND OUT OF REFINERY CS -

CARBON STEEL NOZ - SPRAY NOZZLE

EJECTOR CONTRACTOR CSC -

CAR SEAL CLOSED NSC - NON SLAM CHECK VALVE

CSO -

CAR SEAL OPEN O - OPENED

XXX P&ID DRAWING NUMBER (LAST 3 DIGITS OF SEQUENCE NUMBER)

B

D -

DRAIN PDM - POSITIVE DISPLACEMENT METER 0 11 Apr 14 ISSUED FOR CONSTRUCTION USYS SML WGK HSL

AUTOMATIC YYY TIE-IN NUMBER DCS -

DISTRIBUTED CONTROL SYSTEM PIP - PIPING

FOOT VALVE B 20 Mar 13 ISSUED FOR APPROVAL JYC SHH WGK ECS

RECIRCULATION VALVE REFINERY DE -

DE-ENERGIZED PLC - PROGRAMMABLE LOGIC CONTROLLER

STEAM TRAP ASSEMBLY DH -

DIP HATCH POV - POWER OPERATED VAVLE A 08 Nov 12 ISSUED FOR REVIEW AND COMMENT JYC SHH WGK ECS

STA (PNEUMATIC OR HYDRAULIC)

(FOR DETAILS SEE STANDARD HOOK-UP DRAWING) PG DTV -

DISSIMILAR TYPE CHECK VALVE

EH -

EXHAUST HEAD RB - REDUCED BORE REV. DATE DESCRIPTION PRED CHKD REVD APPRD COMPANY

LEVER OPERATED VALVE, B/L

EJT -

EXPANSION JOINT RSP - RING SPACER DRAWN: CHECKED: SCALE:

SPRING-LOADED TO CLOSE (BASIC SYMBOL)

ES -

EXTENDED SPINDLE RTU - REMOTE TERMINAL UNIT

X" X" ESD -

EMERGENCY SHUTDOWN RV - RELIEF VALVE

TYPICAL BATTERY LIMIT ARRANGEMENT

ETr -

ELECTRIC TRACE SC - SAMPLE CONNECTION

ANGLE VALVE EXCESS FLOW VALVE (VALVES TO BE ACCESSIBLE) SL - SILENCER

DRIPLEG ASSEMBLY WITH STEAM TRAP FA -

FLAME ARRESTOR

STA FAB -

FABRICATION SO - STEAMING - OUT

(FOR DETAILS SEE STANDARD HOOK-UP DRAWING)

FB -

FULL BORE SP - SPOOL PIECE

MIN. FG -

FLOW GLASS SRP - STEAM RING PIPE SAMSUNG ENGINEERING CO., LTD. SAMSUNG ENGINEERING

FI -

FOAM INLET SS - STAINLESS STEEL

BELLOW FLX -

FLEXIBLE HOSE STM - STEAM TRACING MANIFOLD

FTA -

FLOAT TRAP ASSEMBLY SSEW - SAFETY SHOWER/EYE WASH

FOUR-WAY VALVE THREE-WAY VALVE STEAM/LIQUID RELEASE TRAP GH -

GAUGE HATCH ST - STEAM TRACE PROJECT No. : 5636

FLAME ARRESTOR STA - STEAM TRAP ASSEMBLY

SAMSUNG JOB No. : SO 2542

FA GO -

GEAR OPERATED AGREEMENT No. : 11-5636-E-1

HC -

HOSE CONNECTION STR - STRAINER PERMANENT

DH HH -

HAND HOLE TP - TIE POINT PROJECT TITLE

HP -

HIGH PRESSURE TSO - TIGHT SHUT OFF

DIPHATCH EYE BATH (SELF CONTAINED) HS -

HOSE STATION UC - UTILITY CONNECTION CARBON BLACK AND DELAYED COKER PROJECT

SLIDING BLIND/GUILLITONE BLIND IA -

INSTRUMENT AIR UG - UNDERGROUND

UHR - UTILITY HOSE RACK

A

IH -

INSPECTION HOLE DRAWING TITLE

INST -

INSTRUMENTS US - UTILITY STATION PIPING & INSTRUMENT DIAGRAM

SUCTION FILTER AND HOOD I/P -

INSTRUMENT/PIPING V - VENT LEGEND SHEET

KI -

KEY INTERLOCKING SYSTEM VB - VORTEX BREAKER

L/R -

LOCAL / REMOTE VF - VENDOR FURNISHED PIPING SYMBOLS & ABBREVIATIONS

DIP NOZZEL EMERGENCY SHOWER AND EYE BATH LC -

LOCKED CLOSED (KEY LOCKING SYSTEM, WE - WITH EQUIPMENT REVISION

FUEL POT WITH ALARM ON OPERATOR WH - WEEP HOLE SHEET NO.

LOCKABLE IN CLOSED POSITION) 0

LO - LOCKED OPEN (KEY LOCKING SYSTEM, 5636-9000-PRP-D-101

US UTILITY STATION LOCKABLE IN OPEN POSITION)

DRAWING NO. SHEET SIZE

1 OF 1 A1

You might also like

- STP Piping BoqDocument4 pagesSTP Piping Boqdhanu_lagwankarNo ratings yet

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Document28 pagesSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaNo ratings yet

- Technical Data Sheet and Ga of Condenser Water Pumps (Ac System)Document15 pagesTechnical Data Sheet and Ga of Condenser Water Pumps (Ac System)Ashok reddyNo ratings yet

- Cooling and Sealing P&IDDocument2 pagesCooling and Sealing P&IDrahul_choubey_9No ratings yet

- Cable Schdule For ReferenceDocument22 pagesCable Schdule For ReferenceNishi mallickNo ratings yet

- Steam & Water Analysis System As-Built DrawingsDocument92 pagesSteam & Water Analysis System As-Built DrawingsSurendra Kumar SumanNo ratings yet

- T Type Strainer Butt Weld 1 PDFDocument1 pageT Type Strainer Butt Weld 1 PDFprashant mishraNo ratings yet

- LT HT Power Control Cable Schedule-R1-16 05 2013 IrsaDocument34 pagesLT HT Power Control Cable Schedule-R1-16 05 2013 Irsaerkamlakar2234No ratings yet

- Natural Gas System Line & Valve List: I.P.D.CDocument10 pagesNatural Gas System Line & Valve List: I.P.D.CepbamdadNo ratings yet

- Purchase Spec. For Tubes (Sa213 TP321)Document5 pagesPurchase Spec. For Tubes (Sa213 TP321)Daison PaulNo ratings yet

- Hac DrawingDocument13 pagesHac Drawingabdulkidwai2009No ratings yet

- Dfe-B00-Ele-Dwg-Sld-001 - R0 - Single Line Diagram For MV DistributionDocument1 pageDfe-B00-Ele-Dwg-Sld-001 - R0 - Single Line Diagram For MV DistributionElectrical PCBL TeamNo ratings yet

- CABLE SIGNAL SECTIONDocument1 pageCABLE SIGNAL SECTIONvarunNo ratings yet

- Standard QA Plan for AC Starter ComponentsDocument9 pagesStandard QA Plan for AC Starter ComponentsMukeshNo ratings yet

- Subject: External Static Losses Summary: Al-Diyar ConsultantsDocument10 pagesSubject: External Static Losses Summary: Al-Diyar ConsultantsFasil ENo ratings yet

- PMS Rev 0Document36 pagesPMS Rev 0rami ghorbelNo ratings yet

- Yanbu Export Refinery Piping Material SpecificationsDocument6 pagesYanbu Export Refinery Piping Material SpecificationsJanakiraman MalligaNo ratings yet

- Pressure Transmitter Data SheetDocument2 pagesPressure Transmitter Data Sheetneurolepsia3790No ratings yet

- Lighting Cable Schedule Bunati 1Document16 pagesLighting Cable Schedule Bunati 1Bfboys EdissonNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- Forbes Marshall Consultancy specifications for compressed air accessoriesDocument2 pagesForbes Marshall Consultancy specifications for compressed air accessoriessppatilNo ratings yet

- Cable Tray Size As Per National Electrical Code-2002. Article 392 - Electrical Notes & ArticlesDocument1 pageCable Tray Size As Per National Electrical Code-2002. Article 392 - Electrical Notes & ArticleskakagoNo ratings yet

- LABELING AND WIRING INFORMATIONDocument64 pagesLABELING AND WIRING INFORMATION2003vinay0% (1)

- Single Line Diagram r6Document1 pageSingle Line Diagram r6Quảng Thành NamNo ratings yet

- Oil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Document6 pagesOil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Muhammad MahmudNo ratings yet

- Oil Soak PitDocument1 pageOil Soak PitSathish KumarNo ratings yet

- Gen All e 0116 - 0Document1 pageGen All e 0116 - 0Madhankumar100% (1)

- MTO Instr Cable TrayDocument22 pagesMTO Instr Cable TrayGuru KathirNo ratings yet

- Hal Ahu BoqDocument16 pagesHal Ahu Boqmdalt9180100% (1)

- Design of Incinerator Plant For Vasai-Virar RegionDocument4 pagesDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRINo ratings yet

- 13.8KV Electrical Equipment IO ListingDocument15 pages13.8KV Electrical Equipment IO ListingRahulNo ratings yet

- Electrical Unpriced BOQ-23 07 2019Document13 pagesElectrical Unpriced BOQ-23 07 2019Mitesh KhandwalaNo ratings yet

- Calcuation - Cable Tray Loading - Medium Voltage (NEC 2017)Document4 pagesCalcuation - Cable Tray Loading - Medium Voltage (NEC 2017)cshamil7507No ratings yet

- Valve List Rev 0 with 53 Manual Butterfly ValvesDocument2 pagesValve List Rev 0 with 53 Manual Butterfly Valvesmkchy12No ratings yet

- 145B9973 - Off Base Piping List of Lines PDFDocument4 pages145B9973 - Off Base Piping List of Lines PDFHumayun NawazNo ratings yet

- Pharma MCC Panel Manufacturing InstructionsDocument27 pagesPharma MCC Panel Manufacturing Instructionsp mahesh goudNo ratings yet

- Enxt P 84L WH CR PC SD-113307-220VDC PDFDocument1 pageEnxt P 84L WH CR PC SD-113307-220VDC PDFAwnish KumarNo ratings yet

- Boq r0 Reactor Gd1 and Gd2 190418Document52 pagesBoq r0 Reactor Gd1 and Gd2 190418UDayNo ratings yet

- M6 EL 6107 R0 - Cable Carrier SystemDocument13 pagesM6 EL 6107 R0 - Cable Carrier SystemyuvrajNo ratings yet

- Asco Feb23 PDFDocument176 pagesAsco Feb23 PDFAliirshad10No ratings yet

- INTERLOCK logic-ACC (18MW CPP)Document4 pagesINTERLOCK logic-ACC (18MW CPP)mohantysatyapriyaNo ratings yet

- Karet Single - Line A1Document1 pageKaret Single - Line A1priyoNo ratings yet

- Full+Technical+Guideline+28+Apr+2023 4Document61 pagesFull+Technical+Guideline+28+Apr+2023 4AE MGPYNo ratings yet

- Cable Sizing Rev.3Document13 pagesCable Sizing Rev.3nadeem UddinNo ratings yet

- Super Cool Technical Specification UniversalDocument5 pagesSuper Cool Technical Specification UniversalSunil SinghNo ratings yet

- Deluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVDocument5 pagesDeluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVmuthuvelaaNo ratings yet

- Manoj Report - Copy 2Document63 pagesManoj Report - Copy 2Shyam HambardeNo ratings yet

- Electrical Load Calculation and Energy Consumption (22.8.12) .Document274 pagesElectrical Load Calculation and Energy Consumption (22.8.12) .Gandhi Ono100% (1)

- ABB Project Electrical Typical Cable Galnd LugDocument6 pagesABB Project Electrical Typical Cable Galnd LugharryNo ratings yet

- Technical Specification for ElevatorDocument185 pagesTechnical Specification for Elevatorvishal100% (1)

- 1 00 561 U4089 - Rev 04 PDFDocument15 pages1 00 561 U4089 - Rev 04 PDFSandip SurNo ratings yet

- Technical Data Sheet for Condenser On Load Tube Cleaning SystemDocument46 pagesTechnical Data Sheet for Condenser On Load Tube Cleaning SystemSupriyaRongNo ratings yet

- 528 - Tank Weighing System - 0Document4 pages528 - Tank Weighing System - 0Nikhil KarkeraNo ratings yet

- 10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleDocument1 page10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleKrishna KnsNo ratings yet

- SP 211900035 TS 001Document1 pageSP 211900035 TS 001Shahid PervaizNo ratings yet

- Pipe and fittings document layout guideDocument28 pagesPipe and fittings document layout guidemhreteabNo ratings yet

- 12 - With Vent - Config - 2Document1 page12 - With Vent - Config - 2sunnyseriousNo ratings yet

- VVCMC - C&D - WASTE - TIMBER, GLASS & PLASTIC SHED 20X35 - 08-24-23-Layout2Document1 pageVVCMC - C&D - WASTE - TIMBER, GLASS & PLASTIC SHED 20X35 - 08-24-23-Layout2samir bendreNo ratings yet

- BATT0030Document1 pageBATT0030André Dantas MoreiraNo ratings yet

- 160 2499 983Document1 page160 2499 983Anonymous 3NDrQadzRNo ratings yet

- SEO Suite V8: User Guide ManualDocument74 pagesSEO Suite V8: User Guide Manualtriwidi1768No ratings yet

- Hart - 7 Data' PDFDocument4 pagesHart - 7 Data' PDFahmadNo ratings yet

- Safety data sheet for nitrogen, compressed gasDocument3 pagesSafety data sheet for nitrogen, compressed gastriwidi1768No ratings yet

- Safety Datasheet for Helium GasDocument2 pagesSafety Datasheet for Helium Gastriwidi1768No ratings yet

- Safety data sheet for nitrogen, compressed gasDocument3 pagesSafety data sheet for nitrogen, compressed gastriwidi1768No ratings yet

- Hirarc-Form CompressDocument1 pageHirarc-Form CompressahmadNo ratings yet

- Legend SymbolsDocument21 pagesLegend SymbolsFaJar FieLdenNo ratings yet

- Applied Sciences: Hazard Analysis For Escalator Emergency Braking System Via System Safety Analysis Method Based On StampDocument21 pagesApplied Sciences: Hazard Analysis For Escalator Emergency Braking System Via System Safety Analysis Method Based On StampahmadNo ratings yet

- Safety Data Sheet Nitrogen, Refrigerated, LiquidDocument2 pagesSafety Data Sheet Nitrogen, Refrigerated, Liquidtriwidi1768No ratings yet

- Engineering Symbology - Prints and Drawings 1Document120 pagesEngineering Symbology - Prints and Drawings 1Zander_No ratings yet

- Kisspng Periodic Table ChemicalDocument1 pageKisspng Periodic Table ChemicalahmadNo ratings yet

- CO2 Storage SolutionsDocument5 pagesCO2 Storage SolutionsahmadNo ratings yet

- Wetting of Hydrocarbon Liquid Surfaces B PDFDocument5 pagesWetting of Hydrocarbon Liquid Surfaces B PDFahmadNo ratings yet

- Hylar 5000 PVDF Intro - EN v2.1 - 0Document3 pagesHylar 5000 PVDF Intro - EN v2.1 - 0Phạm TháiNo ratings yet

- KADIN ALBDocument29 pagesKADIN ALBtoribieNo ratings yet

- Emerson Control Valve HB Ed 3Document295 pagesEmerson Control Valve HB Ed 3Ahmed SeliemNo ratings yet

- 20 Sandvik Welding Handbook - 30 September, 2015 - CHAPTERDocument403 pages20 Sandvik Welding Handbook - 30 September, 2015 - CHAPTERahmadNo ratings yet

- Roughness GraphDocument1 pageRoughness GraphahmadNo ratings yet

- Wetting of Hydrocarbon Liquid Surfaces B PDFDocument5 pagesWetting of Hydrocarbon Liquid Surfaces B PDFahmadNo ratings yet

- Valve Selection GuideDocument20 pagesValve Selection GuideGagandeep SinghNo ratings yet

- Pipeline Design Consideration and StandardsDocument50 pagesPipeline Design Consideration and StandardsahmadNo ratings yet

- Latihan Al Baqarah 10Document1 pageLatihan Al Baqarah 10ahmadNo ratings yet

- C1 Kerb and GutterDocument16 pagesC1 Kerb and GutterRicky ChangNo ratings yet

- CES522 RC BEAM - DESIGN - Topic 2b - CB Example (Lecturer Vers)Document11 pagesCES522 RC BEAM - DESIGN - Topic 2b - CB Example (Lecturer Vers)muizzey aufaNo ratings yet

- Stainless Steel Price-Jindal ERW Pipes-21-12-2020Document1 pageStainless Steel Price-Jindal ERW Pipes-21-12-2020SRINIVASAN TNo ratings yet

- Additional Details of Weir / Barrages / Anicut Required For The India-WrisDocument23 pagesAdditional Details of Weir / Barrages / Anicut Required For The India-WriskkodgeNo ratings yet

- Simpack Wind 2010 Swe LoadsimulationsDocument26 pagesSimpack Wind 2010 Swe LoadsimulationsRamon Gutierrez100% (1)

- Advantages and Disadvantages of Cast Iron Pipe FittingsDocument14 pagesAdvantages and Disadvantages of Cast Iron Pipe Fittingsjoel_made60% (5)

- Pipe Support Basic - Seminar III, G.palaniDocument67 pagesPipe Support Basic - Seminar III, G.palaniAnonymous Xy309m9Sm9100% (2)

- Penstock Thickness CalculationDocument2 pagesPenstock Thickness Calculationrakesh1987_careers100% (6)

- 9 in Situ StressesDocument48 pages9 in Situ StressesZYNNNNo ratings yet

- 2014 MPM Catalogue-Web PDFDocument56 pages2014 MPM Catalogue-Web PDFmzaimNo ratings yet

- Career GuidanceDocument49 pagesCareer GuidanceAshish MohodNo ratings yet

- BTM Soil Laboratory ProfileDocument36 pagesBTM Soil Laboratory Profilebtmsoil100% (1)

- Local Cement ProductsDocument5 pagesLocal Cement ProductsrahmaasamymohamedNo ratings yet

- Unit-V Moment Distribution Method: Carry Over Moment To B - 10/5 - 5 KNMDocument13 pagesUnit-V Moment Distribution Method: Carry Over Moment To B - 10/5 - 5 KNMPrithivi RajNo ratings yet

- PropertiesandapplicationsoffoamedconcreteareviewDocument17 pagesPropertiesandapplicationsoffoamedconcreteareviewEJ KooNo ratings yet

- TDS - Rheofinish 288 FDDocument2 pagesTDS - Rheofinish 288 FDVenkata RaoNo ratings yet

- Drainage Project Presentation Presented To Chief BWP (19!5!17)Document143 pagesDrainage Project Presentation Presented To Chief BWP (19!5!17)maazrasheed100% (2)

- On The Nature of The Yield Point PhenomenonDocument11 pagesOn The Nature of The Yield Point Phenomenonle hoangNo ratings yet

- MMUP EXAM 01/11/2020-MECHANICAL: (Not Sure, Need To Check)Document6 pagesMMUP EXAM 01/11/2020-MECHANICAL: (Not Sure, Need To Check)Rahmat KhanNo ratings yet

- The Practice of Civil Engineering and RA 9266 - Architecture ActDocument70 pagesThe Practice of Civil Engineering and RA 9266 - Architecture ActAlden CayagaNo ratings yet

- Papers Cimentaciones ProfundasDocument822 pagesPapers Cimentaciones Profundasjimmy Andres100% (1)

- Short Term Mechanical Properties of High Performance ConcreteDocument38 pagesShort Term Mechanical Properties of High Performance ConcretesakolkongNo ratings yet

- SG-APEC Engr Assessment Statement 010719Document37 pagesSG-APEC Engr Assessment Statement 010719Christian DellaNo ratings yet

- Plumbing Material Prices Philippines - PHILCON PRICESDocument33 pagesPlumbing Material Prices Philippines - PHILCON PRICESSolomon Risty Cahulogan0% (1)

- 17 Earthquake EngineeringDocument70 pages17 Earthquake EngineeringJoselo MontenegroNo ratings yet

- Column DesignDocument36 pagesColumn DesignGaurav KashyapNo ratings yet

- M/s. Abdul HakimDocument5 pagesM/s. Abdul Hakimmd. shaju ahamedNo ratings yet

- Typical Civil BOQDocument11 pagesTypical Civil BOQMuhammad Wazim AkramNo ratings yet

- 22gg0023 - MZ Builders - 90 CDDocument2 pages22gg0023 - MZ Builders - 90 CDJan JanNo ratings yet

- Unit - Iii: Srividya College of Engineering and Technology Question BankDocument8 pagesUnit - Iii: Srividya College of Engineering and Technology Question BankAravindNo ratings yet