Professional Documents

Culture Documents

Ta27 43e

Ta27 43e

Uploaded by

Евгений Абрамов0 ratings0% found this document useful (0 votes)

4 views8 pagesOriginal Title

TA27-43E

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views8 pagesTa27 43e

Ta27 43e

Uploaded by

Евгений АбрамовCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

PRESSURE REGULATING VALVE, RE-

LIEF_ VALVE, SAFETY VALVE, ETC.

Every bridge has its own loading capacity. If trucks

heavier than the loading capacity of bridge should

cross it, it will be damaged earlier, giving a danger of its

breakage. To prevent such a danger, a sign board as

shown at right stood at each edge of bridges in the main

roads or in those dense in traffic, thereby limiting the

‘weight of trucks o vehicles capable of crossing a bridge.

"There is also a limit on the pressure to be applied to

the hydraulic or pneumatic circuit to insure its life and

operational safety. For this purpose, pressure regulat-

ing valve, relief valve, or safety valve is provided in the

circuit. Such a symbol as shown at right indicates a

relief valve used in the hydraulic cireuit.

a

Any of these valves will automatically open to permit the oil or air in the circuit to relieve

itself into the exhaust opening, if the pressure in the circuit increases, thereby preventing the

pressure from exceeding the set pressure. The set pressure, however, can be changed to an

optional value.

© A pressure regulating vlave serves to adjust the pressure in the circuit so as not to allow the

pressure to exceed the preset value and can be actuated whenever necessary.

¢ A relief valve is actuated only in such an abnormal conditions where the pressure in any

part of the circuit increases unexpectedly to an excessively high value and is kept closed in

the normal operating conditions of the circuit.

© A sefety valve is also actuated only when the pressure in an air tank, etc. increases to an

excessively high value.

These valves ate identical in fuction with each other, although their names are different

depending on their respective applications. That is, they open only when the pressure increases

and are called relief valves or escape valves from their same function.

Now, let us explain the functional princeple of these valves.

Each valve has a spring-loaded movable element (valve) held in contact with its seat when

the pressure in the circuit is lower than the thrust of spring (spring tension). The pressure

exerted on the opposite side to the spring tends to open the valve, but cannot overcome the

Spring tension, making it impossible for the oll (or ait in the cireuit to escape from around the

seat.

SS

Vale Pressure inthe

Seat Wrenn Higher presure

If the pressure in the circuit increases, the pressure tending to open the valve will overcome

the spring tension, pushing the seat to allow the oil or air to escape from around the seat

Thus, the pressure in the circuit will be prevenved from increasing further. This valve

accomplishes the same fuction on both the oil and air.

Hereinafter, the valves will be described as those used in the hydraulic circuit.

KOMAZSU— 2s —_

Training Aid @

>

sping

Amount of ol ex

‘through valve

‘Amount of ow

avthe set pressure

i

z

a

Set pressure

Leeknut

POPPET-TYPE VALVE

CONSTRUCTION AND FUNCTION

A valve remains closed, as long as the

pressure in the circuit cannot overcome the

spring tension in che valve. In a sketch at left, a

hole provided in the valve adjusting screw serves

to prevent the oil or air entered the spring

chamber from distrubing the valve function of

io, lepedtng tad tance so sity sakes, By

allowing the oil or air to escape tehrefrom.

If the pressure in the circuit increases, the

spring tension will be overcome by the oil

pressure, allowing the valve to open, which will

in turn allow the oil to escape through the

‘opening. So long as the oil does not sufficient!

flow out of the valve, the oll pressure will

increase continuously.

Thus, such an increase in the oil pressure in

the circuit will cause the oil pressure being ap-

plied to the valve to increase, which will in turn

compress the spring so as to enlarge the exhaust

opening until the pressure stops increasing,

allowing more oil to flow out of the valve.

‘The pressure (the set pressure) at which the

Pressure stops increasing is higher than the

pressure (valve opening pressure) at which the

valve opens, and a difference in pressure is larger

as more oil escapes. Accordingly, when the set

pressure is spoken of, the amount of oil flowing

through the valve must be considered. In che

hydraulic circuit, the set pressure is normally

meant by the pressure at which all the oil

discharged from a pump escapes through the

valve.

With the equal amount of oil flow, che

smaller the valve, the larger the pressure diffe-

rential will be. Such a large pressure differential is

the disadvantage of this type of valve.

ADJUSTMENT OF THE SET PRESSURE

If the valve opening pressure is upped by

increasing the spring tension in the valve in the

closed condition, the set pressure will also be

increased. To increase the spring tension, the

number of shims used should be reduced to

compress the spring. On the contrary, the spri

tension should be reduced for the lower set

pressure by increasing the shims in number.

In case of a valve provided with the adjusting

screw fixed by the locknut, the set pressure can

be adjusted by loosening the locknut and turn-

ing in or out the adjusting screw.

TROUBLES AND CORRECTIVE MEASURES

WEAK SPRING

If the spring is so weak as to give the low

deces wxdiaewlia\mcnikia Seems. the wales

will open under low pressure, reducing the set

oWhen the spring is not. much weak, the set

ressure can be restored to a desired degree

by increasing the spring tension with less

shims.

If the valve comes into contact with the

adjusting serew with less shims or if the valve

does not fully open with the spring in a close

contact with che valve, the spring should be

replaced with a new one.

If the spring is too weak to give a desired set

pressure even without shims, the spring

should be replaced. ‘

The spring tension may sometimes be

increased temporarily by means of a washer,

because no replacement spring is available.

In such a case, too, the valve opening must

not be limited.

LOOSENING OF THE ADJUSTING SCREW

If the adjusting screw is loosened, the set

pressure will be reduced. Re-tightening the screw

will restore the set pressure to the correct value.

POOR CONTACT OF VALVE WITH SEAT

If the valve does not come into a close

contact with its seat due to dust jammed

between both, scores on the contacting surfaces,

the rusted valve, etc., the oil will leak between

the contacting surfaces of both.

If such an oil leak is so much as to disturb

the oil pressure rise to the value required for the

circuit, the cylinder, hydraulic motor, etc. will

not be actuated in the worst case. Only a slight

oil leak usually causes the operating speed to

reduce or the cylinder to lower undee bs own

weight.

Dust should be washed off by flushing. Rust

should be removed to smoothen the valve

surface. Defective or scored parts should be

renewed.

UNSATISFACTORY VALVE OPENING

If the valve cannot fully open due to its

interference with foreign substance or to. the

rust, the oil will be unable to escape fully

through the valve, resulting in the abnormally

high set pressure, which will in turn deterio:

rate the valve function of pressure regulation or

prevention or relieving of excessively high pres-

sure.

|__Amount of flow atthe...

‘et pressure

sae a yBnone

Sudeoe po Jo tunowy

Exhaust port

Piston valve

eel)

FSreuit co

piston

VALVE CHATTERING

The valve may chatter or squeal in the

repeated opening or closing when the oil is

flowing out of the valve. The worn seat is one of

its causes. Such a mal-conditioned valve should

be replaced.

PISTON TYPE VALVE

EXAMPLE |

CONSTRUCTION AND FUNCTION

The pressure in the circuit applies to the end

of a piston, pushing the piston valve. The

pressure too low to overcome the spring thrust is

tunable to push the valve. If the pressure in-

creases so much a8 to overcome the spring

thrust, the piston will push the valve to open the

exhaust port, permitting the oil to flow through

the port until the pressure rise stops.

In this type of vlave, too, the more the oil

escapes through the valve, the larger the differ-

ence between the valve opening pressure and the

set pressure will be. As compared with a poppet

valve, the piston vaive has a really wide oil port

for its size, making it easy for the oil to flow

through and give a small pressure differential.

ADJUSTMENT OF THE SET PRESSURE

The set pressure can be adjusted by changing

the spring tension with the adjusting screw in

the same manner as in a poppet valve.

TROUBLES AND CORRECTIVE MEASURES

THE WEAKENED SPRING or THE

LOOSENED ADJUSTING SCREW will cause

the set pressure to drop as is the case with a

poppet valve.

INSUFFICIENT VALVE OPENING will

cause the set pressure to increase, disabling the

valve to accomplish its function of regulating the

pressure or relieving the excessive pressure as is

the ease with a poppet valve.

LEAKING VALVE

Similarly to a poppet valve, the poor contact

of valve with its seat in a piston valve results in

the mal-function and speed drop of cylinder or

hydradtic motor, and’ che cplindar’ lowering

under its own weight.

CLOGGED OIL PASSAGE INDICATED

BY AN ARROW-HEAD

If the oil does not flow to the piston due to

the clogged passage, the valve will not open.

icewe, ths all Hea bacealejcr eer

resistance, resulting in the delay in piston

movement. Thus, the valve opening or closing

cannot correspond to or keep up with the

variation in pressure in the circuit.

EXAMPLE 2 (PISTON VALVE)

The valve to be introduced hereinafter is a

combination of two valves of the same type as

described in the preceeding example. This valve

js actuated whenever the pressure in either the

red-colored or the blue-colored circuit reaches

the excessively high vale.

‘The abnormally high pressure built up in the

red_curcuit will be applied to the piston end

Surface. That pressure built up in the Blue circuit

will be applied to the stepped area of piston.

Thus, the piston valve will be pushed under such

an excessively high pressure, communicating the

red and blue circuits with each other, which will

allow the oil to flow from the high-pressure area

to the low-pressure area. The overflowing oil will

flow out of the area

BEFORE EXPLAINING

A PILOT-OPERATED VALVE

Look at a sketch at the right.

The oil levels in two containers are equal to

each other. No oil flow takes place in the pipe

connecting both containers, because the pres-

sures of an equal value are applied to the oil at

both ends of pipe.

If the oil levels in these containers vary, the

oil will flow from the container with a high level

to that with a low level, because both ends are

different in the pressure value from each other.

The larger the pressure differential, the more

the oil will flow.

Conversely speaking, where the oil does not

flow, the pressure values at both ends are equal

to each other.

Where the oil is flowing, the pressure at the

inlet port is higher than that at the outlet port.

‘The higher the flow rate, the larger the pressure

differential will be.

The above facts are applied to the main valve

to be described below.

©. If the oil does not flow through the balanc-

ing port, the valve will not be actuated,

because the pressure values on both sides of

valve are equal to each other.

© Where the oil is flowing, the pressure on the

inlet side will be higher and the valve is

thrusted on the inlet side. Then, the higher

the flow rate, the larger the thrust will be

given to the valve

PILOT-OPERATED VALVE

CONSTRUCTION AND FUNCTION

This type of valve has a pilot valve buit in. If

this pilot valve opens, a small amount of oil

will flow through its opening. By utilizing such a

small amount of oil flow is actuated the main

valve to let a large amount of oil to escape

through the main valve.

The pilot valve is one of poppet type valves

and its funetion is in the sime manner as

previously explained.

Where the main valve closes the main port

under the thrust of a weak spring, the pilot valve

is also under the pressure in the circuit through

the balancing port.

If the pressure in the circuit is low, the pilot

valve will close, blocking the oil flow to the

balancing port. Then, che main valve will not be

actuated because of the equal pressure values on

both sides.

If the pressure in the circuit rises so much as

to allow the oil to escape through the pilot

valve, the oil will flow into the balancing port,

giving rise to a difference in the pressure values

on both sides of the main valve.

If the pressure rise continues to increase the

Peer tobigt pi prchicsiagcvaorig ar toes a

the flow rate of oil in the balancing port will

also increase, which will in turn increase a

pressure differential on the main valve. For this

reason, the main valve will gradually open the

main port until the pressure rise ceases, increas-

ing the amount of oil flowing out.

This valve has the exactly same funciton

only with the pilot valve in a different position,

This valve is higher in operating efficiency,

because less oil escapes below the set pressure

due to a smaller difference between the main

port opening pressure and the set pressure. The

oil escaping through the pilot valve is trifle.

009d

ADJUSTMENT OF THE SET PRESSURE

The set pressure can be adjusted by changing

connection point

3 L--Amoun of tow a the spring tension with the pilot valve adjusting

z:) the set pressure screw in the same manner as in a poppet valve.

eS)

i TROUBLES AND CORRECTIVE MEASURES

3f :

$3] i The higher the flow rate of oll through the

F | Flowoutofthe pilot valve |! balancing port, the larger the pressure differen-

i 1 { tial (actuating force) on the main valve. The

enoeaw a flow rate is determined depending on the

Taentintheckeut 9g i amount of oil escaping through the pilot valve.

cee The higher the pressure in the circuit, the more

$45 the oil will escape through the pilot valve.

a4

a2

WEAKENED SPRING AND LOOSENED

ADJUSTING SCREW IN THE PILOT-OPERAT-

ED VALVE

Since the pilot vlave opens at a low pressure,

the set pressure will also drop.

For the repair of such a spring and screw,

refer to the paragraphs relating to a poppet

valve.

LEAKING PILOT VALVE

Poor contact of the valve with its seat or its

unsatisfactory buildup wll aus che ol leakage,

If much oil leaks, the main valve will be

actuated, allowing the oil to escape through the

port. (For the causes and repair of oil leakage,

refer to the poppet valve.)

UNSATISFACTORY OPENING OF PILOT

VALVE AND CLOGGED OIL PASSAGE

In order for the normal amount of oil to

flow, the pressure in the circuit must be higher

than the normal value because kof the resistance

(in the clogged passage) to the oil flow. In

consequence, the set pressure must be increased,

Unless the normal amount of oil flows, the

main valve will not open. (For the causes of

unsatisfactory valve opening, refer to the poppet

valve.)

CLOGGED BALANCING PORT

If the port becomes narrower, the main valve

will open earlier due to the increased pressure

differential and the set pressure will drop. Where

the port is fully closed, the main valve will fully

open under the pressure for opening the pilot

valve buit up in the circuit. Then, the main valve

will never close and remain fully opened because

of the negative pressure in the balancing cham-

ber.

WEAKENED SPRING IN THE MAIN VALVE

Since the main valve is actuated by the

smallest difference between the pressure values

on both sides, the set pressure will drop in this

case. Such a spring as permitting the valve to

move under the small pressure differential must

be replaced.

MAL-FUNCTIONING MAIN VALVE

If the main valve is not actuated due to the

jammed dust, the valve will remain fully opened

‘or closed.

The valve will open only under the pressure

differential over the normal value due to the

resistance by the dust, resulting in the increased

set pressure.On the contrary, the valve will close

only under the pressure differential below

the normal value. That is, the valve will begin

closing after the pressure in the circuit. is

lowered below the set pressure,

‘Amount of oil

owing out

Pressure in the

balancing chamber Circut/oressure

Pressure differential increases. Set oresure

corey |

Tie ressure rises,

——_Ser

Pilot valve opening pressure

eee

oe 4

Totaly clogged

DON'TS IN USE OF VALVES

The following are strictly prohibited for the inherent valve performance.

© Replacing a spring with the one out of the specification.

@ Working a seat to change ies diameter (in a poppet valve)

© Giving Soundsem or austen w the sdaon'of x beleceing poet

ADJUSTMENT OF THE SET PRESSURE

‘Afcer adjustement of the set pressure, be sure to make sure that the set pressure is,

correct by connecting an oil pressure gauge to the circuit. Then, proceed to the operation.

of the hydraulic system. In case of vehicles, too, the braking force must be measured

adter adjustment ot a brake,

Do not increase the set pressure without a justifiable reason. The set pressure is

provided for the purpose of operational safety and life of the hydraulic system. If the set

Pressure should be inereased wichout a justifiable reason, the valves provided inthe circuit

would be in vain, No body operates a vehicle by removing a brake because of its seizure

cor burning,

The set pressure is measured under the conditions where all the oil discharged from a

pump is being exhausted from the valve. In this case, if the cylinder or hydraulic motor is.

Operated, the oil will flow to the other part of circuit, resulting in the lower set pressure.

Such a pressure is not a true set pressure.

For this reason, the oil pressure should be measured with the cylinder kept extended

or contracted all the way to prevent the oil from flowing to the other part of circuit. In

measuring the lifting force of a shovel loader, the lift arm should be kept raised all the

way. In a cylinder where shocking is prevented by allowing the oil to escape with the

cylinder at its upward stroke end, the oil pressure should be measured with the outlet

port kept blind.

‘At the high oil temperature, the oil viscosity will be reduced, resulting in the lower set

pressure. At the lower oil temperature, the set pressure will be increased. The oil pressure

measurement should be made within the specified oil temperature range.

TROUBLESHOOTING GUIDE

Probable cause

Symptom

‘Vales of poppet and piston pe Pilocoperted valve

Valve remaining aly 7 Valve or piston impossible co move | > Vale imponible ro move (ame

opened {due to the jammed dus, seizure, cuneate

fing. et) + Mich ofl leaking thru the pilot

+ Totally clogged circuit tothe piston |” ae

“Totaly clogged balancing port

Low set presure + Weekened 4 + Weekened spring

1 Leossned aljaningsxew + Loosened ajunig screw

+ Partly clogged balancing port

High et pressure + Not fly opened valve + Not fully opened pilot valve

+ Partially clogged ercut tothe

pllorvalve

Valve remaining filly closed | + Valve o piston imposible ro + Valve imposible to move (same

none ao eed di, Pees “

seiturey rusting ee = Por valve ightened excessive

Valve ightenalexcesvely 1 Reece clogged cece to the

pilot ave

Unstable set presure (when + Valve subject to large resitance

pened the pesure wil Mrmr

SEerWhen closed, the

Printed in Ja

‘06-84(08)02

<

You might also like

- Ex200-3 Shop (2)Document230 pagesEx200-3 Shop (2)doan lucNo ratings yet

- Ex200-3 Shop (1)Document352 pagesEx200-3 Shop (1)doan lucNo ratings yet

- Lapping Powder FujimiDocument2 pagesLapping Powder Fujimidoan lucNo ratings yet

- Chuong 23-Hop So Tu DongDocument29 pagesChuong 23-Hop So Tu Dongdoan lucNo ratings yet

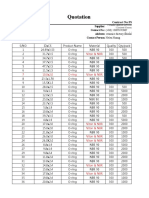

- QuotationDocument7 pagesQuotationdoan lucNo ratings yet

- Chuong 10-He Thong LaiDocument35 pagesChuong 10-He Thong Laidoan lucNo ratings yet

- Chuong 22-Hop SoDocument28 pagesChuong 22-Hop Sodoan lucNo ratings yet

- Chuong 21-Ly HopDocument28 pagesChuong 21-Ly Hopdoan lucNo ratings yet

- Chuong 9-He Thong TreoDocument23 pagesChuong 9-He Thong Treodoan lucNo ratings yet

- Chuong 1-Khai Quat Chung Ve OtoDocument9 pagesChuong 1-Khai Quat Chung Ve Otodoan lucNo ratings yet

- Chuong 7 - Cau Chu DongDocument13 pagesChuong 7 - Cau Chu Dongdoan lucNo ratings yet

- 5S - Hinh AnhDocument6 pages5S - Hinh Anhdoan lucNo ratings yet

- MK - Performance Management 2013Document36 pagesMK - Performance Management 2013doan lucNo ratings yet

- Chinh Sach Nhan Su SavicoDocument5 pagesChinh Sach Nhan Su Savicodoan lucNo ratings yet

- MK - Tieu Chuan Thuc Hien Tot 5SDocument9 pagesMK - Tieu Chuan Thuc Hien Tot 5Sdoan lucNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)