Professional Documents

Culture Documents

Electronic Engine Controls - Gasoline Engines

Uploaded by

autoscanningOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electronic Engine Controls - Gasoline Engines

Uploaded by

autoscanningCopyright:

Available Formats

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

SPECIFICATIONS ................................................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

SPECIFICATIONS

Material

Item Specification Fill Capacity

High Temperature Nickel Anti-Seize Lubricant ESE-M12A4-A —

XL-2 (US); CXG-2-B (Canada)

Motorcraft SAE 5W-20 Premium Synthetic Blend WSS-M2C930-A —

Motor Oil

XO-5W20-QSP (US); Motorcraft SAE 5W-20 Super

Premium Motor Oil CXO-5W20-LSP12 (Canada); or

equivalent

Penetrating and Lock Lubricant — —

XL-1 (US); CXC-51-A (Canada)

Torque Specifications

Description Nm lb-ft lb-in

A/C compressor bolts 25 18 —

Air Cleaner (ACL) outlet pipe-to-Throttle Body (TB) adapter bolts 10 — 89

Camshaft position (CMP) sensor 10 — 89

cardiagn.com

Catalyst monitor sensor 46 34 —

Charge motion control valve (CMCV) bolts — 5.4L 6 — 53

Crankshaft position (CKP) sensor 10 — 89

Cylinder head temperature (CHT) sensor 10 — 89

Fuel rail pressure and temperature sensor 6 — 53

Heated oxygen sensor (HO2S) 46 34 —

Intake manifold runner control (IMRC) actuator bolt — 6.8L 6 — 53

Knock sensor (KS) 20 15 —

Mass air flow (MAF) sensor bolts 3 — 27

PCM nuts 7 — 62

Throttle position (TP) sensor screws 3 — 27

Variable camshaft timing (VCT) oil control solenoid — 5.4L 5 — 44

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

DESCRIPTION AND OPERATION

Electronic Engine Controls ............................................................................................................................................... 303-14A-2

Camshaft Position (CMP) Sensor .............................................................................................................................. 303-14A-2

Crankshaft Position (CKP) Sensor ............................................................................................................................. 303-14A-2

Cylinder Head Temperature (CHT) Sensor ................................................................................................................ 303-14A-2

Fuel Rail Pressure and Temperature Sensor ............................................................................................................ 303-14A-2

Heated Oxygen Sensor (HO2S) and Catalyst Monitor Sensor (CMS) ....................................................................... 303-14A-3

Intake Manifold Runner Control (IMRC) Sensor (6.8L 3V) ........................................................................................ 303-14A-3

Knock Sensor (KS) ..................................................................................................................................................... 303-14A-3

Mass Air Flow (MAF) Sensor ..................................................................................................................................... 303-14A-3

Throttle Position (TP) Sensor ..................................................................................................................................... 303-14A-3

Variable Camshaft Timing (VCT) Oil Control Solenoid (5.4L 3V) .............................................................................. 303-14A-3

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

DESCRIPTION AND OPERATION

Electronic Engine Controls

The electronic engine controls consist of the following:

• Camshaft Position (CMP) sensor

• Catalyst Monitor Sensor (CMS)

• Crankshaft Position (CKP) sensor

• Cylinder Head Temperature (CHT) sensor

• Heated Oxygen Sensor (HO2S)

• Intake Manifold Runner Control (IMRC) actuator (6.8L 3V)

• Knock Sensor (KS)

• Mass Air Flow (MAF) sensor

• PCM

• Throttle Position (TP) sensor

• Variable Camshaft Timing (VCT) oil control solenoid (5.4L 3V)

• Fuel rail pressure and temperature sensor

The PCM needs the following inputs to calibrate the engine correctly:

cardiagn.com

• Air temperature

• Amount of engine detonation

• Camshaft position

• Crankshaft position

• Cylinder head temperature

• Engine coolant temperature

• Engine rpm

• Fuel rail pressure and temperature

• Mass airflow

• Throttle position

Camshaft Position (CMP) Sensor

The CMP sensor:

• sends the PCM a signal indicating camshaft position used for fuel synchronization and coil firing.

For removal and installation, refer to Camshaft Position (CMP) Sensor — 5.4L or Camshaft Position (CMP) Sensor — 6.8L in this section.

Crankshaft Position (CKP) Sensor

The CKP sensor:

• sends the PCM a signal indicating crankshaft position.

• is essential for calculating spark timing.

For removal and installation, refer to Crankshaft Position (CKP) Sensor in this section.

Cylinder Head Temperature (CHT) Sensor

The CHT sensor:

• is mounted into the front of the left cylinder head and is not connected to any coolant passages.

• sends a signal to the PCM indicating the cylinder head temperature.

For removal and installation, refer to Cylinder Head Temperature (CHT) Sensor in this section.

Fuel Rail Pressure and Temperature Sensor

The fuel rail pressure and temperature sensor:

• measures the fuel pressure and temperature and sends these signals to the PCM.

• uses intake manifold vacuum as a pressure reference.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

DESCRIPTION AND OPERATION (Continued)

For removal and installation, refer to Fuel Rail Pressure and Temperature Sensor — 5.4L or Fuel Rail Pressure and Temperature Sensor — 6.8L in this

section.

Heated Oxygen Sensor (HO2S) and Catalyst Monitor Sensor (CMS)

The HO2S and CMS:

• have the ability to create a voltage signal dependent on exhaust oxygen content.

• provide feedback information to the PCM used to calculate fuel delivery.

For removal and installation, refer to Heated Oxygen Sensor (HO2S) and Catalyst Monitor Sensor — Exploded View and Heated Oxygen Sensor (HO2S) or

Catalyst Monitor Sensor in this section.

Intake Manifold Runner Control (IMRC) Sensor (6.8L 3V)

The 6.8L air induction system improves engine performance by using the IMRC as follows:

• The intake manifold has 2 runners per cylinder, feeding each of the intake ports in the cylinder heads.

• The IMRC assemblies are located between the upper intake manifold and cylinder heads, providing 2 air passages for each cylinder.

• The valve plates are opened and closed by the IMRC electric actuator, which is controlled by PCM.

• One air passage is always open and the other passage switches from closed to open by means of a valve plate.

— Below 1,500 rpm, this valve plate is closed to improve fuel economy and emissions.

cardiagn.com

For removal and installation, refer to Intake Manifold Runner Control (IMRC) Actuator — 6.8L in this section.

Knock Sensor (KS)

The KS:

• is located in the intake valley of the cylinder block.

• sends a signal to the PCM indicating engine detonation.

For removal and installation, refer to Knock Sensor (KS) — 5.4L or Knock Sensor (KS) — 6.8L in this section.

Mass Air Flow (MAF) Sensor

The MAF sensor:

• sends the PCM a signal indicating mass airflow rate of air entering the engine.

• incorporates the Intake Air Temperature (IAT) sensor.

For removal and installation, refer to Mass Air Flow (MAF) Sensor in this section.

Throttle Position (TP) Sensor

The TP sensor:

• sends the PCM a signal indicating the throttle plate angle.

• is the main input to the PCM from the driver.

For removal and installation, refer to Throttle Position (TP) Sensor — 5.4L or Throttle Position (TP) Sensor — 6.8L in this section.

Variable Camshaft Timing (VCT) Oil Control Solenoid (5.4L 3V)

The VCT oil control solenoid:

• is an electrically controlled hydraulic valve that directs engine oil to the variable camshaft. Once the PCM transmits a signal, the solenoid moves a

valve spool, directing oil into the camshaft phaser cavity. This action changes valve timing by either inducing an advance or retard condition. The

camshaft is, thereby repositioned in relation to crankshaft timing and allows for optimum engine performance and lower emissions.

For removal and installation, refer to Variable Camshaft Timing (VCT) Oil Control Solenoid — 5.4L in this section.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

DIAGNOSIS AND TESTING

Electronic Engine Controls ............................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

DIAGNOSIS AND TESTING

Electronic Engine Controls

Refer to the Powertrain Control/Emissions Diagnosis (PC/ED) manual.

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Camshaft Position (CMP) Sensor — 5.4L ......................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Camshaft Position (CMP) Sensor — 5.4L

Material

Item Specification

Motorcraft® SAE 5W-20 Premium Synthetic Blend Motor Oil (US); WSS-M2C945-A

Motorcraft® SAE 5W-20 Super Premium Motor Oil (Canada)

XO-5W20-QSP (US); CXO-5W20-LSP12 (Canada)

cardiagn.com

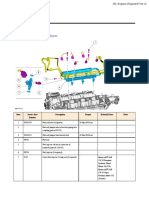

Item Part Number Description

1 — RH Camshaft Position (CMP) sensor electrical connector (part of

12B637)

2 N806155-S RH CMP sensor bolt

3 6B288 RH CMP sensor

4 6758 RH CMP sensor O-ring seal

5 — LH CMP sensor electrical connector (part of 12B637)

6 N806155-S LH CMP sensor bolt

7 6B288 LH CMP sensor

8 6758 LH CMP sensor O-ring seal

Removal and Installation

1. Disconnect the Camshaft Position (CMP) sensor electrical connector.

2. Remove the bolt and the CMP sensor.

• To install, tighten to 10 Nm (89 lb-in).

• Lubricate the O-ring seal with clean engine oil prior to installation.

3. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Camshaft Position (CMP) Sensor — 6.8L ......................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Camshaft Position (CMP) Sensor — 6.8L

Material

Item Specification

Motorcraft® SAE 5W-20 Premium Synthetic Blend Motor Oil (US); WSS-M2C945-A

Motorcraft® SAE 5W-20 Super Premium Motor Oil (Canada)

XO-5W20-QSP (US); CXO-5W20-LSP12 (Canada)

cardiagn.com

Item Part Number Description

1 — Camshaft Position (CMP) sensor electrical connector (part of

12B637)

2 N806155-S CMP sensor bolt

3 6B288 CMP sensor

4 6758 CMP sensor O-ring seal

Removal and Installation

1. Disconnect the Camshaft Position (CMP) sensor electrical connector.

2. Remove the bolt and the CMP sensor.

• To install, tighten to 10 Nm (89 lb-in).

• Lubricate the O-ring seal with clean engine oil prior to installation.

3. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Crankshaft Position (CKP) Sensor ................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Crankshaft Position (CKP) Sensor

Material

Item Specification

Motorcraft® SAE 5W-20 Premium Synthetic Blend Motor Oil (US); WSS-M2C945-A

Motorcraft® SAE 5W-20 Super Premium Motor Oil (Canada)

XO-5W20-QSP (US); CXO-5W20-LSP12 (Canada)

cardiagn.com

Item Part Number Description

1 N806184 A/C compressor bolt (3 required)

2 19703 A/C compressor

3 — Crankshaft Position (CKP) sensor electrical connector (part of

12B637)

4 N806155 CKP sensor bolt

5 6C315 CKP sensor

Removal and Installation

1. With the vehicle in NEUTRAL, position it on a hoist. For additional information, refer to Section 100-02.

2. Remove the accessory drive belt. For additional information, refer to Section 303-05.

3. Remove the 3 bolts and position the A/C compressor aside.

• To install, tighten to 25 Nm (18 lb-ft).

4. Disconnect the Crankshaft Position (CKP) sensor electrical connector.

5. Remove the bolt and the CKP sensor.

• To install, tighten to 10 Nm (89 lb-in).

• Lubricate the O-ring seal with clean engine oil prior to installation.

6. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Powertrain Control Module (PCM) ................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Powertrain Control Module (PCM)

Special Tool(s)

Vehicle Communication Module (VCM) and Integrated Diagnostic System (IDS) software

with appropriate hardware, or equivalent scan tool

cardiagn.com

Item Part Number Description

1 — PCM electrical connector (part of 12B637)

2 — PCM electrical connector (part of 12A581)

3 — PCM electrical connector (part of 15525)

4 N621905 PCM wiring harness support bracket nut (2 required)

5 14A206 PCM wiring harness support bracket

6 12A650 PCM

Removal and Installation

1. NOTE:

Refer to the Powertrain Control/Emissions Diagnosis (PC/ED) manual for correct Vehicle Communication Module (VCM) hook-up procedure.

If servicing the PCM, connect the scan tool to the vehicle. Allow the scan tool to identify the vehicle and obtain configuration data.

• All programmable module information will automatically be retrieved by the VCM.

2. Disconnect the 3 PCM electrical connectors.

3. Remove the 2 nuts and position the PCM wiring harness support bracket aside.

• To install, tighten to 7 Nm (62 lb-in).

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

(Continued)

4. Remove the PCM.

5. NOTE:

If the Instrument Cluster (IC) or the PCM is being replaced (or both), the parameters must be reset in both modules or the vehicle will experience a

Passive Anti-Theft System (PATS) no-start. This will occur even if the vehicle is not equipped with PATS. For additional information, refer to

Passive Anti-Theft System (PATS) Parameter Reset in Section 419-01.

To install, reverse the removal procedure.

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Throttle Position (TP) Sensor — 5.4L ............................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Throttle Position (TP) Sensor — 5.4L

Removal

1. Remove the Air Cleaner (ACL) outlet pipe. For additional information, refer to Section 303-12.

2. Disconnect the crankcase vent tube quick connect coupling from the ACL outlet pipe-to-Throttle Body (TB) adapter. For additional information, refer

to Section 310-00.

cardiagn.com

3. Disconnect the vacuum hose and wire harness retainer from the ACL outlet pipe-to-TB adapter and position aside.

4. Remove the 4 bolts and the ACL outlet pipe-to-TB adapter.

5. Remove the TB O-ring seal.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

(Continued)

6. Disconnect the Throttle Position (TP) sensor electrical connector.

cardiagn.com

7. NOTICE:

Do not put direct heat on the Throttle Position (TP) sensor or any other plastic parts because heat damage may occur. Damage may also

occur if Electronic Throttle Body (ETB) temperature exceeds 120°C (248°F).

NOTE:

Do not use power tools.

Remove the TP sensor.

1 Using a heat gun, apply heat to the top of the ETB until the top TP sensor bolt ear reaches approximately 55°C (130°F), this should take no more

than 3 minutes using an 1,100-watt heat gun. The heat gun should be about 25.4 mm (1 in) away from the ETB.

2 Monitor the temperature of the top TP sensor bolt ear on the ETB with a digital temperature laser or infrared thermometer, while heating the

ETB.

3 Using hand tools, quickly remove the bolt farthest from the heat source first and discard.

4 Using hand tools, remove the remaining bolt and discard.

5 Remove and discard the TP sensor.

Installation

1. NOTE:

When installing the new TP sensor, make sure that the radial locator tab on the TP sensor is aligned with the radial locator hole on the ETB.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-4 Electronic Engine Controls — Gasoline Engines 303-14A-4

(Continued)

NOTE:

Do not use power tools.

Install the new TP sensor.

• Using hand tools, install the 2 new bolts.

▪ Tighten to 3 Nm (27 lb-in).

2. Connect the TP sensor electrical connector.

cardiagn.com

3. Install the TB O-ring seal.

4. Install the ACL outlet pipe-to-TB adapter and the 4 bolts.

• Tighten to 10 Nm (89 lb-in).

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-5 Electronic Engine Controls — Gasoline Engines 303-14A-5

(Continued)

5. Connect the wire harness retainer and vacuum hose to the ACL outlet pipe-to-TB adapter.

cardiagn.com

6. Connect the crankcase vent tube quick connect coupling to the ACL outlet pipe-to-TB adapter. For additional information, refer to Section 310-00.

7. Install the ACL outlet pipe. For additional information, refer to Section 303-12.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Throttle Position (TP) Sensor — 6.8L ............................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Throttle Position (TP) Sensor — 6.8L

Removal

1. Remove the Air Cleaner (ACL) outlet pipe. For additional information, refer to Section 303-12.

2. Disconnect the Throttle Position (TP) sensor electrical connector.

3. NOTICE:

cardiagn.com

Do not put direct heat on the Throttle Position (TP) sensor or any other plastic parts because heat damage may occur. Damage may also

occur if Electronic Throttle Body (ETB) temperature exceeds 120°C (248°F).

NOTE:

Do not use power tools.

Remove the TP sensor.

1 Using a heat gun, apply heat to the top of the ETB until the top TP sensor bolt ear reaches approximately 55°C (130°F), this should take no more

than 3 minutes using an 1,100-watt heat gun. The heat gun should be about 25.4 mm (1 in) away from the ETB.

2 Monitor the temperature of the top TP sensor bolt ear on the ETB with a digital temperature laser or infrared thermometer, while heating the

ETB.

3 Using hand tools, quickly remove the bolt farthest from the heat source first and discard.

4 Using hand tools, remove the remaining bolt and discard.

5 Remove and discard the TP sensor.

Installation

1. NOTE:

When installing the new TP sensor, make sure that the radial locator tab on the TP sensor is aligned with the radial locator hole on the ETB.

NOTE:

Do not use power tools.

Install the new TP sensor.

• Using hand tools, install the 2 new bolts.

▪ Tighten to 3 Nm (27 lb-in).

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

(Continued)

2. Connect the TP sensor electrical connector.

cardiagn.com

3. Install the ACL outlet pipe. For additional information, refer to Section 303-12.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Fuel Rail Pressure and Temperature Sensor — 5.4L ....................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Fuel Rail Pressure and Temperature Sensor — 5.4L

Material

Item Specification

Motorcraft® SAE 5W-20 Premium Synthetic Blend Motor Oil (US); WSS-M2C945-A

Motorcraft® SAE 5W-20 Super Premium Motor Oil (Canada)

XO-5W20-QSP (US); CXO-5W20-LSP12 (Canada)

cardiagn.com

Item Part Number Description

1 — Fuel rail pressure and temperature sensor electrical connector (part

of 12B637)

2 9E498 Fuel rail pressure and temperature sensor vacuum connector

3 N808874 Fuel rail pressure and temperature sensor bolt (2 required)

4 9F972 Fuel rail pressure and temperature sensor

5 — Fuel rail pressure and temperature sensor O-ring seal

Removal and Installation

WARNING:

Do not smoke, carry lighted tobacco or have an open flame of any type when working on or near any fuel-related component. Highly flammable

mixtures are always present and may be ignited. Failure to follow these instructions may result in serious personal injury.

WARNING:

Before working on or disconnecting any of the fuel tubes or fuel system components, relieve the fuel system pressure to prevent accidental spraying

of fuel. Fuel in the fuel system remains under high pressure, even when the engine is not running. Failure to follow this instruction may result in

serious personal injury.

1. Release the fuel system pressure. For additional information, refer to Section 310-00.

2. Disconnect the battery ground cable. For additional information, refer to Section 414-01.

3. Disconnect the fuel rail pressure and temperature sensor electrical and vacuum connectors.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

(Continued)

4. Remove the 2 bolts and the fuel rail pressure and temperature sensor and discard the O-ring seal.

• To install, tighten to 6 Nm (53 lb-in).

• Install a new O-ring seal.

• Lubricate the new O-ring seal with clean engine oil prior to installation.

5. To install, reverse the removal procedure.

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Fuel Rail Pressure and Temperature Sensor — 6.8L ....................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Fuel Rail Pressure and Temperature Sensor — 6.8L

Material

Item Specification

Motorcraft® SAE 5W-20 Premium Synthetic Blend Motor Oil (US); WSS-M2C945-A

Motorcraft® SAE 5W-20 Super Premium Motor Oil (Canada)

XO-5W20-QSP (US); CXO-5W20-LSP12 (Canada)

cardiagn.com

Item Part Number Description

1 — Fuel rail pressure and temperature sensor electrical connector (part

of 12B637)

2 9E498 Fuel rail pressure and temperature sensor vacuum connector

3 W705870 Fuel rail pressure and temperature sensor bolt (2 required)

4 9F972 Fuel rail pressure and temperature sensor

5 — Fuel rail pressure and temperature sensor O-ring seal

Removal and Installation

WARNING:

Do not smoke, carry lighted tobacco or have an open flame of any type when working on or near any fuel-related component. Highly flammable

mixtures are always present and may be ignited. Failure to follow these instructions may result in serious personal injury.

WARNING:

Before working on or disconnecting any of the fuel tubes or fuel system components, relieve the fuel system pressure to prevent accidental spraying

of fuel. Fuel in the fuel system remains under high pressure, even when the engine is not running. Failure to follow this instruction may result in

serious personal injury.

1. Release the fuel system pressure. For additional information, refer to Section 310-00.

2. Disconnect the battery ground cable. For additional information, refer to Section 414-01.

3. Disconnect the fuel rail pressure and temperature sensor electrical and vacuum connectors.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

(Continued)

4. Remove the 2 bolts and the fuel rail pressure and temperature sensor and discard the O-ring seal.

• To install, tighten to 6 Nm (53 lb-in).

• Install a new O-ring seal.

• Lubricate the new O-ring seal with clean engine oil prior to installation.

5. To install, reverse the removal procedure.

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Variable Camshaft Timing (VCT) Oil Control Solenoid — 5.4L ......................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Variable Camshaft Timing (VCT) Oil Control Solenoid — 5.4L

NOTE:

LH shown, RH similar.

cardiagn.com

Item Part Number Description

1 6C260 Variable Camshaft Timing (VCT) oil control solenoid bolt

2 6C297 VCT oil control solenoid

Removal and Installation

1. Remove the valve cover. For additional information, refer to Section 303-01A.

2. Remove the bolt and the Variable Camshaft Timing (VCT) oil control solenoid.

• To install, tighten to 5 Nm (44 lb-in).

3. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Mass Air Flow (MAF) Sensor ........................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Mass Air Flow (MAF) Sensor

cardiagn.com

Item Part Number Description

1 — Mass Air Flow (MAF) sensor electrical connector (part of 12B637)

2 W505562 MAF sensor bolt (2 required)

3 12B579 MAF sensor

Removal and Installation

1. Disconnect the Mass Air Flow (MAF) sensor electrical connector.

2. Remove the 2 bolts and the MAF sensor.

• To install, tighten to 3 Nm (27 lb-in).

3. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Heated Oxygen Sensor (HO2S) and Catalyst Monitor Sensor — Exploded View ............................................................ 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Heated Oxygen Sensor (HO2S) and Catalyst Monitor Sensor — Exploded View

NOTE:

5.4L shown, 6.8L similar.

cardiagn.com

Item Part Number Description

1 — Heated Oxygen Sensor (HO2S) and Catalyst Monitor Sensor (CMS)

electrical connectors (part of 14A464)

2 9F472 HO2S (2 required)

3 9G444 CMS (2 required)

1. For additional information, refer to the procedures in this section.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Heated Oxygen Sensor (HO2S) ....................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Heated Oxygen Sensor (HO2S)

Special Tool(s)

Socket, Exhaust Gas Oxygen Sensor

303-476 (T94P-9472-A)

Material

Item Specification

High Temperature Nickel Anti-Seize Lubricant —

XL-2

Penetrating and Lock Lubricant (US); Penetrating Fluid (Canada) —

XL-1 (US); CXC-51-A (Canada)

cardiagn.com

Removal

1. With the vehicle in NEUTRAL, position it on a hoist. For additional information, refer to Section 100-02.

2. Disconnect the Heated Oxygen Sensor (HO2S) electrical connector.

3. Using the Exhaust Gas Oxygen Sensor Socket, remove the HO2S.

• Apply penetrating lubricant to the HO2S to assist in removal.

Installation

1. Install the HO2S.

• Apply a light coat of high temperature nickel anti-seize lubricant to the HO2S threads prior to installation.

• Calculate the correct torque wrench setting for the following torque. Refer to the Torque Wrench Adapter Formulas in the Appendix.

• Using the Exhaust Gas Oxygen Sensor Socket, tighten to 46 Nm (34 lb-ft).

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

(Continued)

2. Connect the HO2S electrical connector.

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Catalyst Monitor Sensor ................................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Catalyst Monitor Sensor

Special Tool(s)

Socket, Exhaust Gas Oxygen Sensor

303-476 (T94P-9472-A)

Material

Item Specification

High Temperature Nickel Anti-Seize Lubricant —

XL-2

Penetrating and Lock Lubricant (US); Penetrating Fluid (Canada) —

XL-1 (US); CXC-51-A (Canada)

cardiagn.com

Removal

1. With the vehicle in NEUTRAL, position it on a hoist. For additional information, refer to Section 100-02.

2. Disconnect the Catalyst Monitor Sensor (CMS) electrical connector.

3. Using the Exhaust Gas Oxygen Sensor Socket, remove the CMS.

• Apply penetrating lubricant to the CMS to assist in removal.

Installation

1. Install the CMS.

• Apply a light coat of high temperature nickel anti-seize lubricant to the CMS threads prior to installation.

• Calculate the correct torque wrench setting for the following torque. Refer to the Torque Wrench Adapter Formulas in the Appendix.

• Using the Exhaust Gas Oxygen Sensor Socket, tighten to 46 Nm (34 lb-ft).

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-3 Electronic Engine Controls — Gasoline Engines 303-14A-3

(Continued)

2. Connect the CMS electrical connector.

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Knock Sensor (KS) — 5.4L ............................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Knock Sensor (KS) — 5.4L

Item Part Number Description

1 — RH Knock Sensor (KS) electrical connector (part of 12B637)

2 W500225 RH KS bolt

3 12A699 RH KS

cardiagn.com

4 14A464 LH KS electrical connector

5 W500225 LH KS bolt

6 12A699 LH KS

Removal and Installation

1. Remove the intake manifold. For additional information, refer to Section 303-01A.

2. Disconnect the Knock Sensor (KS) electrical connectors.

3. Remove the 2 bolts and the 2 KS.

• To install, tighten to 20 Nm (177 lb-in).

4. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Knock Sensor (KS) — 6.8L ............................................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Knock Sensor (KS) — 6.8L

cardiagn.com

Item Part Number Description

1 — Knock Sensor (KS) electrical connector (part of 12B637)

2 W500225 RH KS bolt

3 12A699 RH KS (grey wire)

4 W500225 LH KS bolt

5 12A699 LH KS (black wire)

Removal and Installation

1. Remove the intake manifold. For additional information, refer to Section 303-01B.

2. Disconnect the Knock Sensor (KS) electrical connector.

3. Remove the 2 bolts and the RH and LH KS.

• To install, tighten to 20 Nm (177 lb-in).

4. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Cylinder Head Temperature (CHT) Sensor ...................................................................................................................... 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Cylinder Head Temperature (CHT) Sensor

Material

Item Specification

High Temperature Nickel Anti-Seize Lubricant —

XL-2

cardiagn.com

Item Part Number Description

1 — Cylinder Head Temperature (CHT) sensor electrical connector (part

of 12B637)

2 6G004 CHT sensor

Removal and Installation

1. Remove the intake manifold. For additional information, refer to Section 303-01A (5.4L) or Section 303-01B (6.8L).

2. Disconnect the Cylinder Head Temperature (CHT) sensor electrical connector.

3. Remove the CHT sensor and discard.

• To install, tighten to 10 Nm (89 lb-in).

• Coat the new CHT sensor threads with high temperature nickel anti-seize lubricant prior to installation.

4. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Charge Motion Control Valve (CMCV) — 5.4L .................................................................................................................. 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Charge Motion Control Valve (CMCV) — 5.4L

Material

Item Specification

Motorcraft SAE 5W-20 Premium Synthetic Blend Motor Oil WSS-M2C930-A

XO-5W20-QSP (US); Motorcraft SAE 5W-20 Super Premium Motor Oil

CXO-5W20-LSP12 (Canada); or equivalent

cardiagn.com

Item Part Number Description

1 9B841 Charge motion control valve (CMCV) RH rod

2 9B842 CMCV LH rod

3 W709084 CMCV stud bolt

4 W708165 CMCV bolts (2 required)

5 9L490 CMCV

Removal and Installation

1. Remove the intake manifold. For additional information, refer to Section 303-01A.

2. Disconnect the charge motion control valve (CMCV) RH and LH rods from the intake manifold.

• Lubricate the CMCV RH and LH rod ends with clean engine oil prior to installation.

3. Remove the stud bolt, the 2 bolts and the CMCV.

• To install, tighten to 6 Nm (53 lb-in).

4. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-i Electronic Engine Controls — Gasoline Engines 303-14A-i

SECTION 303-14A Electronic Engine Controls — Gasoline Engines

CONTENTS PAGE

Intake Manifold Runner Control (IMRC) Actuator — 6.8L ................................................................................................. 303-14A-2

cardiagn.com

2008 F-250, 350, 450, 550 Super Duty, 7/2007

303-14A-2 Electronic Engine Controls — Gasoline Engines 303-14A-2

Intake Manifold Runner Control (IMRC) Actuator — 6.8L

Material

Item Specification

Motorcraft® SAE 5W-20 Premium Synthetic Blend Motor Oil (US); WSS-M2C945-A

Motorcraft® SAE 5W-20 Super Premium Motor Oil (Canada)

XO-5W20-QSP (US); CXO-5W20-LSP12 (Canada)

cardiagn.com

Item Part Number Description

1 — Intake Manifold Runner Control (IMRC) actuator electrical

connector (part of 12B637)

2 W503917-S IMRC bolt (3 required)

3 — IMRC rod pivot pin

4 9J559 IMRC

Removal and Installation

1. Remove the air cleaner outlet pipe. For additional information, refer to Section 303-12.

2. Disconnect the Intake Manifold Runner Control (IMRC) actuator electrical connector.

3. Remove the 3 bolts.

• To install, tighten to 6 Nm (53 lb-in).

4. Disconnect the IMRC rod pivot pin from the intake manifold rod and remove the IMRC.

• Lubricate the IMRC rod pivot pin with clean engine oil prior to installation.

5. To install, reverse the removal procedure.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Manual Porsche CayenneDocument631 pagesManual Porsche CayenneRogério Moreno100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Heat Exchangers Hydrostatic Test ProcedureDocument1 pageHeat Exchangers Hydrostatic Test Procedureqaisarabbas900288% (17)

- Hydrogen Sulfide Analyzer Model 330S & 331S Model 330SDS & 331SDSDocument87 pagesHydrogen Sulfide Analyzer Model 330S & 331S Model 330SDS & 331SDSDavidNo ratings yet

- Sevice Manual MaseratiDocument98 pagesSevice Manual Maseratijorge Angel Lope100% (4)

- Lighter & Charging Socket Washing SystemDocument10 pagesLighter & Charging Socket Washing Systemjorge Angel LopeNo ratings yet

- PL Trans - SgmldiagDocument208 pagesPL Trans - SgmldiagArmando_SotoNo ratings yet

- BrakesDocument87 pagesBrakesautoscanningNo ratings yet

- Knock Sensor 2.4LDocument4 pagesKnock Sensor 2.4LautoscanningNo ratings yet

- BrakesDocument87 pagesBrakesautoscanningNo ratings yet

- 09a JF506 PDFDocument155 pages09a JF506 PDFСергей ЕсиповNo ratings yet

- (W) Wiring DiagramsDocument236 pages(W) Wiring Diagramsokolowicz100% (3)

- Module Communications NetworkDocument87 pagesModule Communications NetworkautoscanningNo ratings yet

- M11 SM Print Ready File PDFDocument1,168 pagesM11 SM Print Ready File PDFFrancisco Gustavo Moncada100% (9)

- Automatic TransaxleTransmission - TorqShift®Document466 pagesAutomatic TransaxleTransmission - TorqShift®autoscanningNo ratings yet

- Module Communications NetworkDocument87 pagesModule Communications NetworkautoscanningNo ratings yet

- Ford y Mazda Immo Ct-l1007 - enDocument70 pagesFord y Mazda Immo Ct-l1007 - enAnibal Chaccha Yauri100% (4)

- Service Manual Tiggo 2009Document1,903 pagesService Manual Tiggo 2009Felipe Andrino75% (12)

- Intake Air Distribution and FilteringDocument18 pagesIntake Air Distribution and FilteringautoscanningNo ratings yet

- Fuel Charging and Controls - 3.5L Ti-VCTDocument8 pagesFuel Charging and Controls - 3.5L Ti-VCTautoscanningNo ratings yet

- Starting SystemDocument84 pagesStarting SystemautoscanningNo ratings yet

- Electronic Engine ControlsDocument44 pagesElectronic Engine ControlsautoscanningNo ratings yet

- En 1434-4Document47 pagesEn 1434-4onebluelineNo ratings yet

- 2.SV Maintenance Technology PracticeDocument134 pages2.SV Maintenance Technology PracticeWeihan KhorNo ratings yet

- BMW 1 Series Coupé/Cabrio (E81/E82/E87/E88), 3 Series (E90/E92/E93), Z4 (E89) OBDII + ECU ConnectionDocument7 pagesBMW 1 Series Coupé/Cabrio (E81/E82/E87/E88), 3 Series (E90/E92/E93), Z4 (E89) OBDII + ECU Connectionabdull rehmanNo ratings yet

- Computer Science Paper Scheme (Marks Distribution)Document4 pagesComputer Science Paper Scheme (Marks Distribution)Honey BunnyNo ratings yet

- Routine Test Plan For Stator of 6fra 6068Document5 pagesRoutine Test Plan For Stator of 6fra 6068Ritesh YadavNo ratings yet

- Unit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsDocument6 pagesUnit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsCristina Garcia50% (2)

- Learning Management System (Lms Moodle)Document14 pagesLearning Management System (Lms Moodle)FantaNo ratings yet

- FIS Best Practice Guide Maintenance and Access Into Suspended CeilingsDocument24 pagesFIS Best Practice Guide Maintenance and Access Into Suspended CeilingsSameer KmNo ratings yet

- Chapt 1 Quy Dinh Lien Quan KD XNK - Ver2020Document9 pagesChapt 1 Quy Dinh Lien Quan KD XNK - Ver2020Thy NguyễnNo ratings yet

- Refrigeration Compressor Zr190kce Tfd.Document4 pagesRefrigeration Compressor Zr190kce Tfd.Mlayeh MohamedNo ratings yet

- PD Interview QuestionsDocument3 pagesPD Interview QuestionsChiranjeevi PandamaneniNo ratings yet

- Chapter 4 - Electricity Intake (2020 Edition)Document20 pagesChapter 4 - Electricity Intake (2020 Edition)bibinbibinNo ratings yet

- BPAG 172 Solved AssignmentDocument6 pagesBPAG 172 Solved AssignmentDivyansh BajpaiNo ratings yet

- Phy212 CH14 Worksheet-W07-KeyDocument5 pagesPhy212 CH14 Worksheet-W07-Keyangelyn tiongcoNo ratings yet

- Walworth Trunnion Ball 2011 1Document84 pagesWalworth Trunnion Ball 2011 1Andersson Benito HerreraNo ratings yet

- GBP CraneDocument1 pageGBP CraneHeldyApriandiNo ratings yet

- Seminar - MHD Raja Abou HarbDocument23 pagesSeminar - MHD Raja Abou HarbRaja Abo HarbNo ratings yet

- Self Service AnalyticsDocument20 pagesSelf Service AnalyticssniperrsbrNo ratings yet

- 3-The Four Dimensions of ServiceDocument13 pages3-The Four Dimensions of Serviceziad i alshowaiterNo ratings yet

- Torch (Machine Learning)Document4 pagesTorch (Machine Learning)levin696No ratings yet

- Endura UDI5000-CAM Configuration Software: Q U I C K S T A R TDocument8 pagesEndura UDI5000-CAM Configuration Software: Q U I C K S T A R TFranklin AlvaradoNo ratings yet

- ERAN Capacity Monitoring GuideDocument25 pagesERAN Capacity Monitoring Guidejkpllan3100% (5)

- GPC Browser GuideDocument11 pagesGPC Browser GuideAmr RizkNo ratings yet

- F300 Valves For API 641 TestingDocument3 pagesF300 Valves For API 641 TestingSyed AhmedNo ratings yet

- Sample Jayant 14Document12 pagesSample Jayant 14Shobhit PalNo ratings yet

- Array DSDocument10 pagesArray DSsriNo ratings yet

- FST-1 (E) 2015yrDocument3 pagesFST-1 (E) 2015yrRahulBhagatNo ratings yet

- Administrator's Guide For Oracle Internet DirectoryDocument820 pagesAdministrator's Guide For Oracle Internet Directorygleen lewisNo ratings yet