Professional Documents

Culture Documents

SDZA01

Uploaded by

Faisal FaizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SDZA01

Uploaded by

Faisal FaizCopyright:

Available Formats

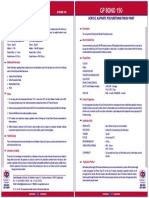

SD SABINITE ZINC

CHROMATE PRIMER A

Oil & Alkyd Based Anti-corrosive Primer

Zinc chromate pigment incorporated rust preventive primer for steel based on long oil alkyd resin

Steel structure at moderate corrosive environment

- Quick drying

- Applicable to light alloy surface

Colour Yellow

Finish Matt

Volume Solids 51 %

Typical Thickness Dry : 35 microns / coat

Theoretical Coverage 14.5 ㎡/L at 35 microns DFT

*Practical coverage vary depending on loss factors.

Flash Point 42℃

Specific Gravity 1.41 g/cm3

VOC 395 g/L

Temperature Resistance Non-continuous : 120℃, Continuous : 80℃

*These numerical values are subject to normal manufacturing tolerances,colours and testing variances.

- All surfaces to be coated should be completely clean, dry and free from contamination.

Surface preparation method shall be in accordance with ISO 8504: 2000.

- Remove salt and other water-soluble contaminants by fresh water.

- Remove oil and grease with suitable detergent or solvent (SSPC-SP-1).

- Remove rust, mill scale and other loose material completely by abrasive blasting (ISO

8501-1:2007 Sa 2 1/2 or SSPC SP-10) or power tool cleaning (ISO8501-1 St 3 or

SSPC SP3).

Application Conditions Ambient temperature shall be above 5℃ and relative humidity shall be below 85%. Surface

temperature shall be a minimum of 3℃ above dew point.

Adequate ventilation shall be provided in confined spaces to ensure proper drying.

Mixing Stir paint in container with power agitator well before using.

Mixing ratio -

Induction Time Not required

Application Method Airless spray

Thinner : Paint Thinner A (0-10% by weight)

Nozzle pressure: Not less than 10MPa

Nozzle Tip : No.163-515~619

Brush/Roller

Thinner : Paint Thinner A (0-5% by weight)

Power mix thinner if required.

*Too much thinning results sagging and slower cure.

SD SABINITE ZINC

CHROMATE PRIMER A

Clean Up Clean all the equipment with thinner immediately after use.

Pot Life 5 ℃ 20 ℃ 30 ℃

- - -

*Use all mixed paint within pot life.

Drying Time 5 ℃ 20 ℃ 30 ℃

Surface dry 10 hour(s) 4 hour(s) 2 hour(s)

Touch dry 24 hour(s) 8 hour(s) 6 hour(s)

*Drying time may vary depending on film thickness,ventilation,humidity,undercoat paint

condition etc.

Overcoating Interval 5 ℃ 20 ℃ 30 ℃

Minimum 48 hour(s) 16 hour(s) 10 hour(s)

Maximum 6 month(s) 6 month(s) 6 month(s)

*The overcoating intervals are based on overcoating with same or same type of paint.

Typical undercoat METALACT H-15

Typical topcoat SD MARINE, NEW ACNON, FERRODOR F

Detail information is given on Material Safety Data Sheet (MSDS). Avoid inhalation of spray mist or

vapour. Avoid skin and eye contact. Paint contacted with skin should be immediately removed with

water and/or suitable cleanser. Eyes should be flushed with water and seek immediate medical

attention. Since this product contains flammable solvents, keep away from sparks and open flames.

Application and handling of this product should be in compliance with relevant national regulations.

Store in dry, cool condition and away from sources of heat and ignition. Containers must be kept

tightly closed. Store conditions shall be in accordance with national regulations.

6 months

- This product is not recommended for continuous water immersion.

- Make sure that paint film shall be dry enough to be overcoated before applying subsequent

coat. Lifting or wrinkling may occur if overcoated on insufficient drying status.

*If any inquiries, please consult Kansai Paint representative for further information.

23/11/2012

You might also like

- ZNT 500Document2 pagesZNT 500Faisal FaizNo ratings yet

- Kansai ZNT - 1000Document2 pagesKansai ZNT - 1000Sugi. masco.proteksiNo ratings yet

- MTH501Document2 pagesMTH501Yogie YogaswaraNo ratings yet

- THMT SCDocument2 pagesTHMT SCZaheer Ahmad RazaNo ratings yet

- Arocoat - Repair Paint Data SheetDocument3 pagesArocoat - Repair Paint Data SheetIsboNo ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- Carboweld 11P PDSDocument4 pagesCarboweld 11P PDS이선엽No ratings yet

- Zinky-14 Inorganic Zinc Primer Technical Data SheetDocument5 pagesZinky-14 Inorganic Zinc Primer Technical Data SheetppglNo ratings yet

- Pilgrim PlasticDocument2 pagesPilgrim Plastichendri sukrisnoNo ratings yet

- DS 428 LuxathaneFDFinishDocument2 pagesDS 428 LuxathaneFDFinishRatish NairNo ratings yet

- Wilkotan BTD: Marine & Protective CoatingsDocument1 pageWilkotan BTD: Marine & Protective CoatingsLHYT NTUANo ratings yet

- Al-Jazeera Afrw Fluorescent Clear EngDocument1 pageAl-Jazeera Afrw Fluorescent Clear EngbsranjhaNo ratings yet

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDocument3 pagesTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Tds Parapex No3Document2 pagesTds Parapex No3Anonymous Nb6t2ezcZ100% (1)

- Camouflage Matt EnamelsDocument3 pagesCamouflage Matt EnamelsIqra AngelsNo ratings yet

- Coaltar EpoxyDocument3 pagesCoaltar EpoxyAkhtar aliNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pages113.007 - Zinc Clad Xi WB BR PDFFernando VittoNo ratings yet

- Zinc Chromate Primer PDFDocument2 pagesZinc Chromate Primer PDFWanda WibisanaNo ratings yet

- Luxaprime1801 Chromate Free Etch PrimerDocument2 pagesLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNo ratings yet

- Product Data Sheet: Transocean Cold Zinc Primer 10.16Document3 pagesProduct Data Sheet: Transocean Cold Zinc Primer 10.16rimshadtpNo ratings yet

- Epilux-78 HB PrimerDocument3 pagesEpilux-78 HB PrimerIqra AngelsNo ratings yet

- Zinc Rich Primer HSDocument3 pagesZinc Rich Primer HSthowchinNo ratings yet

- Zinky-13 Inorganic Zinc Rich Primer Technical Data SheetDocument4 pagesZinky-13 Inorganic Zinc Rich Primer Technical Data SheetppglNo ratings yet

- Technical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionSyedFarhanNo ratings yet

- High Solids Epoxy Primer Formulated for SteelDocument2 pagesHigh Solids Epoxy Primer Formulated for SteelrajeshNo ratings yet

- High Solids Coal Tar Epoxy Product SpecificationsDocument2 pagesHigh Solids Coal Tar Epoxy Product SpecificationsAbuhurairah MunshiNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Product Data Sheet: Transoplate Epoxy Primer 1.57Document2 pagesProduct Data Sheet: Transoplate Epoxy Primer 1.57Sachin NambiarNo ratings yet

- Technical Data Sheet Jazeera Epo-Rich Primer JI-61005: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Epo-Rich Primer JI-61005: DescriptionSyedFarhanNo ratings yet

- Zinc Phosphate PrimerDocument2 pagesZinc Phosphate PrimertrinityallianceconsultancyNo ratings yet

- Carbomastic 15 LT: Selection & Specification DataDocument3 pagesCarbomastic 15 LT: Selection & Specification Datasrinath vNo ratings yet

- Epoxy primer protects steel and concrete surfacesDocument3 pagesEpoxy primer protects steel and concrete surfacesPRERAKNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- b6) Zincanode690 2886Document2 pagesb6) Zincanode690 2886Anonymous XVEucVMsENo ratings yet

- Rust O Cap PDFDocument1 pageRust O Cap PDFTitus PraveenNo ratings yet

- Nippon EA9 Finish HBDocument3 pagesNippon EA9 Finish HBHamza GhaniNo ratings yet

- Sanitile 655: Selection & Specification DataDocument3 pagesSanitile 655: Selection & Specification DataIndraNo ratings yet

- Aluminium Paint HR NipponDocument2 pagesAluminium Paint HR Nipponyarth88No ratings yet

- Indoprotect-490ZCDocument3 pagesIndoprotect-490ZCSwapnil KupaleNo ratings yet

- XYLAN 4090-F2676 CLEAR [P92] [BE]Document3 pagesXYLAN 4090-F2676 CLEAR [P92] [BE]Abdul Rafiq SoudagarNo ratings yet

- Sam Classic FinishDocument2 pagesSam Classic FinishMo MosadNo ratings yet

- Eh6280 (HS)Document2 pagesEh6280 (HS)anminsungNo ratings yet

- KCC - DATASHEET - Cerany IZ1990 (Two-Component) - EngDocument3 pagesKCC - DATASHEET - Cerany IZ1990 (Two-Component) - EngNguyen1987 TrungNo ratings yet

- TDS-JOTACOTE 5-EnglishDocument4 pagesTDS-JOTACOTE 5-EnglishthirdNo ratings yet

- Grand Polycoat PolyurethaneDocument1 pageGrand Polycoat PolyurethaneAniket GaikwadNo ratings yet

- DS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Document2 pagesDS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Ranjan Kumar SahuNo ratings yet

- Bergerthane PU Glossy Finish: Product Data Resistance GuideDocument2 pagesBergerthane PU Glossy Finish: Product Data Resistance Guidesangram keshari pattanaikNo ratings yet

- Nippon HB Epoxy LinerDocument3 pagesNippon HB Epoxy LinerRai Hasnain Ahmad DahaNo ratings yet

- High Build Epoxy Coating for Steel and ConcreteDocument2 pagesHigh Build Epoxy Coating for Steel and ConcreteTejinder KumarNo ratings yet

- Xylan 1070-F2079 Azure Blue (Be)Document3 pagesXylan 1070-F2079 Azure Blue (Be)Mehrad LahutiNo ratings yet

- 112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFDocument2 pages112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFFernando VittoNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- KCC DATASHEET Galvany Shopprimer IZ182 (J) (IMO) (Two-Component) EngDocument3 pagesKCC DATASHEET Galvany Shopprimer IZ182 (J) (IMO) (Two-Component) EngIsabelo AbaoNo ratings yet

- Al-Jazeera Afrw Aman Akis15Document1 pageAl-Jazeera Afrw Aman Akis15bsranjhaNo ratings yet

- Apcosil - PC 2119Document3 pagesApcosil - PC 2119Naren SudarsanNo ratings yet

- High Solids Epoxy Zinc Rich Primer for Corrosion ProtectionDocument2 pagesHigh Solids Epoxy Zinc Rich Primer for Corrosion ProtectionmuthukumarNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- JIS G4304 SUS 890L Stainless Steel Plate: Main ApplicationDocument1 pageJIS G4304 SUS 890L Stainless Steel Plate: Main ApplicationFaisal FaizNo ratings yet

- Resist 86: Technical Data Sheet Application GuideDocument8 pagesResist 86: Technical Data Sheet Application Guidepmendonça_18No ratings yet

- ZNT 1000Document2 pagesZNT 1000Faisal FaizNo ratings yet

- Product Overview: A Division of Marsh BelloframDocument12 pagesProduct Overview: A Division of Marsh BelloframFaisal FaizNo ratings yet

- Pilot QD Primer Safety Data Sheet SummaryDocument12 pagesPilot QD Primer Safety Data Sheet SummaryFaisal FaizNo ratings yet

- Technical Data Sheet for Barrier 80 Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 Zinc Epoxy PrimerBalaji GuruNo ratings yet

- P113 Belgas RegulatorDocument8 pagesP113 Belgas RegulatorFaisal FaizNo ratings yet

- BETE 0320 Metric CatalogDocument140 pagesBETE 0320 Metric CatalogFaisal FaizNo ratings yet

- 976-63033 Zincanode 402 Part B: Safety Data SheetDocument9 pages976-63033 Zincanode 402 Part B: Safety Data SheetFaisal FaizNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. IdentificationFaisal FaizNo ratings yet

- Shell Tellus s2 VX 68Document3 pagesShell Tellus s2 VX 68ironiteNo ratings yet

- P143 Pressure Regulator: ApplicationsDocument3 pagesP143 Pressure Regulator: ApplicationsFaisal FaizNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. IdentificationFaisal FaizNo ratings yet

- Sikadur 31 CF NormalDocument5 pagesSikadur 31 CF NormalBenedick John RubioNo ratings yet

- Nitofi LL UR63: Solvent Free, Two Part Polyurethane Resin For Sealing CracksDocument3 pagesNitofi LL UR63: Solvent Free, Two Part Polyurethane Resin For Sealing CracksFaisal FaizNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. IdentificationFaisal FaizNo ratings yet

- Sikadur®-732: Product Data SheetDocument2 pagesSikadur®-732: Product Data SheetFaisal FaizNo ratings yet

- SigmaCover-300 DataDocument7 pagesSigmaCover-300 DataFaisal FaizNo ratings yet

- 075P80-321 TubacexDocument1 page075P80-321 Tubacexsakshi patilNo ratings yet

- G 21 - 96 R02 - RzixDocument5 pagesG 21 - 96 R02 - RzixjayakumarNo ratings yet

- GW04 20 04 02 1.200ml Automatic Soap DispenserDocument2 pagesGW04 20 04 02 1.200ml Automatic Soap DispenserNwachukwu UmehNo ratings yet

- MESC SPE 77-310 Aug 2011Document10 pagesMESC SPE 77-310 Aug 2011aleeimeran50% (2)

- Safety Helmet Care & Wear GuideDocument2 pagesSafety Helmet Care & Wear GuideRedisme09No ratings yet

- CAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic EtherDocument2 pagesCAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic Ethermohsin shaikh100% (1)

- Asphalt Concrete Report Final VersionDocument11 pagesAsphalt Concrete Report Final VersionLorraine Custodio100% (1)

- Strain Hardening Cement BasedDocument811 pagesStrain Hardening Cement Basedካሳ አለም ፍርዱ100% (1)

- Mci - 2020 / Mci - 2020 V/oDocument4 pagesMci - 2020 / Mci - 2020 V/oOmar Mukthar100% (1)

- Technical Data Reynobond and Reynolux .: Aluminium Composite Panels and SheetsDocument2 pagesTechnical Data Reynobond and Reynolux .: Aluminium Composite Panels and Sheetsfarah rosaNo ratings yet

- Construction cost estimate for washroom renovationDocument2 pagesConstruction cost estimate for washroom renovationAlok chauhanNo ratings yet

- Existing EN AW 5251 H14 Al-Mg2Mn0,3 CompositionDocument8 pagesExisting EN AW 5251 H14 Al-Mg2Mn0,3 Compositionamh.fpdNo ratings yet

- Growth of Passive Films On Valve Metals and Their AlloysDocument9 pagesGrowth of Passive Films On Valve Metals and Their AlloysDjedili AmelNo ratings yet

- Mos Pu Foam CompleteDocument4 pagesMos Pu Foam Completeyusnan yazidNo ratings yet

- Grassroot Refinery Economics PDFDocument45 pagesGrassroot Refinery Economics PDFKokil JainNo ratings yet

- Acids and Bases Identification from ReactionsDocument9 pagesAcids and Bases Identification from ReactionsTARUNKUMARNo ratings yet

- Incorporating Ag RF Core Shell Nanomaterials Into The Thin - 2022 - Science ofDocument12 pagesIncorporating Ag RF Core Shell Nanomaterials Into The Thin - 2022 - Science ofFelipe Leyva HaroNo ratings yet

- Orbitalum Orbital Tube Cutting & Welding Systems CatalogDocument56 pagesOrbitalum Orbital Tube Cutting & Welding Systems CatalogMagaly SaavedraNo ratings yet

- WMS (Method Statement For Formwork, Reinforcement and Concrete Works)Document9 pagesWMS (Method Statement For Formwork, Reinforcement and Concrete Works)PUI CHEE KHIAN100% (1)

- AP Chapter 3 Practice Questions PDFDocument5 pagesAP Chapter 3 Practice Questions PDFtricia ramosNo ratings yet

- Group II Cation Analysis LabDocument3 pagesGroup II Cation Analysis LabNight RaveNo ratings yet

- BARWA Wall CoveringsDocument32 pagesBARWA Wall CoveringsAiswarya RajeevNo ratings yet

- Woodland-Mitts Crochet MittensDocument6 pagesWoodland-Mitts Crochet MittenszenNo ratings yet

- Reolube TF 46SJDocument5 pagesReolube TF 46SJHamsaveni AnemNo ratings yet

- Bride DollDocument32 pagesBride DollApoorva Gowda100% (2)

- ESR - 3572 FisherDocument29 pagesESR - 3572 FisherReinel OrjuelaNo ratings yet

- Hardox On Site CementDocument2 pagesHardox On Site CementFelipe OliveiraNo ratings yet

- AHS 187 - Air Handling Systems Product Selector GuideDocument8 pagesAHS 187 - Air Handling Systems Product Selector GuideKhang NguyenNo ratings yet

- A02 41 (Highlighted)Document1 pageA02 41 (Highlighted)HasmukhNo ratings yet

- Construction Cost EstimateDocument16 pagesConstruction Cost EstimateMark Julius CabasanNo ratings yet

![XYLAN 4090-F2676 CLEAR [P92] [BE]](https://imgv2-2-f.scribdassets.com/img/document/724665913/149x198/5abb118da3/1713536987?v=1)