Professional Documents

Culture Documents

Tensile Structure and Membrane

Uploaded by

MharcianeMaxineMagoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tensile Structure and Membrane

Uploaded by

MharcianeMaxineMagoCopyright:

Available Formats

Rizal Technological University

Boni Ave., Mandaluyong City

College of Engineering and Industrial Technology

Department of Architecture

BUILDING TECHNOLOGY 5

T Y P E S O F

S P E C I F I C A T I O N S

SUMBITTED BY:

Mago, Mharciane Maxine P.

SUMITTED TO:

Arch’t. Joseph A. Rea, UAP

Tensile & Membrane Structure

Tensile structure is the term usually

used to refer to the construction of

roofs using a membrane held in

place on steel cables. Their main

characteristics are the way in which

they work under stress tensile, their

ease of pre-fabrication, their ability to

cover large spans, and their

malleability. This structural system

calls for a small amount of material

thanks to the use of thin canvases,

which when stretched using steel

cable, create surfaces capable of

overcoming the forces imposed upon

them.

A tensile membrane structure is most often used as a roof, as they can economically and attractively

span large distances. Tensile membrane structures may also be used as complete buildings, with a few

common applications being sports facilities, warehousing and storage buildings, and exhibition venues.

Membrane materials

Common materials for doubly curved fabric

structures are PTFE-coated fiber

glass and PVC-coated polyester. These are

woven materials with different strengths in

different directions. The warp fibers (those

fibers which are originally straight

equivalent to the starting fibers on a loom)

can carry greater load than the weft or fill

fibers, which are woven between the warp

fibers.

Common materials for doubly curved fabric structures are PTFE-coated fiber glass and PVC-

coated polyester. These are woven materials with different strengths in different directions.

The warp fibers (those fibers which are originally straight equivalent to the starting fibers on a loom) can

carry greater load than the weft or fill fibers, which are woven between the warp fibers.

Cables

Cables can be of mild steel, high strength steel (drawn carbon steel), stainless

steel, polyester or aramid fibres. Structural cables are made of a series of small strands twisted or

bound together to form a much larger cable. Steel cables are either spiral strand, where circular rods

are twisted together and "glued" using a polymer, or locked coil strand, where individual interlocking

steel strands form the cable (often with a spiral strand core).

Advantages of using Tensile Structures

Examples and Details

Applications

You might also like

- MaterialDocument22 pagesMaterialnagarajNo ratings yet

- TEN 02 Engineered Wood Products and An Introduction To Timber Structural SystemsDocument7 pagesTEN 02 Engineered Wood Products and An Introduction To Timber Structural Systemsdhanya1995No ratings yet

- Membrane StructuresDocument7 pagesMembrane StructuresHyacynth Pedrosa MenesesNo ratings yet

- Experimental Study On Retrofitted RC T-BEAM Using FRPDocument5 pagesExperimental Study On Retrofitted RC T-BEAM Using FRPInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Composite Structures: Hang Zhou, Shengnan Min, Xiaogang ChenDocument12 pagesComposite Structures: Hang Zhou, Shengnan Min, Xiaogang Chenptlimaproject92No ratings yet

- Research Architectural: Tech VDocument6 pagesResearch Architectural: Tech VMark DanielNo ratings yet

- Fiber Reinforced Concrete-FRCDocument93 pagesFiber Reinforced Concrete-FRCAbdul WadoodNo ratings yet

- 1 s2.0 S0020768323003906 MainDocument25 pages1 s2.0 S0020768323003906 MainsobhanNo ratings yet

- 92 Effect of Freezing and Thawing On The Strength Characteristics of Slurry Infiltrated Fibrous Ferrocement Using Steel FibersDocument5 pages92 Effect of Freezing and Thawing On The Strength Characteristics of Slurry Infiltrated Fibrous Ferrocement Using Steel FibersMsheer Hasan AliNo ratings yet

- Tensile Fabric Structure Design Terminology: Art - Architecture - EngineeringDocument4 pagesTensile Fabric Structure Design Terminology: Art - Architecture - EngineeringHitesh ParmarNo ratings yet

- An E-Glass/Polyester FRP, TAUFIQ-Girder: Load-Deflections Relationship and Its Hyperelastic Behaviour Under Flexural LoadsDocument10 pagesAn E-Glass/Polyester FRP, TAUFIQ-Girder: Load-Deflections Relationship and Its Hyperelastic Behaviour Under Flexural LoadstaufiqrochmNo ratings yet

- 004 Bt5 Cable Tensile Fabric StructureDocument23 pages004 Bt5 Cable Tensile Fabric StructureGem de GuzmanNo ratings yet

- WINSEM2019-20 MEE6035 TH VL2019205000607 REFERENCE MATERIAL Manufacturing Mechanics of Composite MaterialsDocument219 pagesWINSEM2019-20 MEE6035 TH VL2019205000607 REFERENCE MATERIAL Manufacturing Mechanics of Composite MaterialsNishar Alam Khan 19MCD0042No ratings yet

- Construction and Building Materials: P.K.V.R. Padalu, Y. Singh, S. DasDocument21 pagesConstruction and Building Materials: P.K.V.R. Padalu, Y. Singh, S. DasMAYANK GANGWARNo ratings yet

- Mechanical Properties of Fibre Reinforced Concrete With Recycled FibresDocument9 pagesMechanical Properties of Fibre Reinforced Concrete With Recycled FibresMilton Massiris Lopez100% (1)

- BT115 - SHOP DRAWINGS 2 - SECTION A-HUSANA, Thessaly Aubrey S.Document15 pagesBT115 - SHOP DRAWINGS 2 - SECTION A-HUSANA, Thessaly Aubrey S.Thessaly HusanaNo ratings yet

- An Experimental Investigation On StructuralDocument5 pagesAn Experimental Investigation On StructuralAtano RoyNo ratings yet

- StructureDocument45 pagesStructureAR Mohd Vaseem SaifiNo ratings yet

- Of Composite Materials: Theodore J. ReinhartDocument13 pagesOf Composite Materials: Theodore J. Reinhartsupriyo1970No ratings yet

- Structural System - I: Lecture # 7Document18 pagesStructural System - I: Lecture # 7KhiZra ShahZadNo ratings yet

- Bamboo MosoDocument13 pagesBamboo MosoYopNo ratings yet

- Notes On Fibre Reinforced ConcreteDocument9 pagesNotes On Fibre Reinforced ConcreteK.ANISH100% (1)

- Tensile Structure PPT FinalDocument25 pagesTensile Structure PPT FinalPawanKumar50% (2)

- Cable Stayed StructureDocument13 pagesCable Stayed StructureSachin MauryaNo ratings yet

- Amorphous FibersDocument10 pagesAmorphous FibersHemant YadavNo ratings yet

- A Ballistic Material Model For Cross-Plied Unidirectional Ultra-High Molecular-Weight Polyethylene Fiber-Reinforced Armor-Grade Composites PDFDocument11 pagesA Ballistic Material Model For Cross-Plied Unidirectional Ultra-High Molecular-Weight Polyethylene Fiber-Reinforced Armor-Grade Composites PDFRamses ChavezNo ratings yet

- Composites Mini ProjectDocument44 pagesComposites Mini ProjectRajaReddyNo ratings yet

- Pneumatic and Kinetic StructuresDocument35 pagesPneumatic and Kinetic StructuresGrace HenryNo ratings yet

- Unit-I TO Composite MaterialsDocument40 pagesUnit-I TO Composite MaterialsSaisurendra VeerlaNo ratings yet

- R.R.Institute of Modern Technology: Tensile StructureDocument25 pagesR.R.Institute of Modern Technology: Tensile StructurePawanKumarNo ratings yet

- A Study ON Behaviour OF Bamboo-Cement AND Ferrocement Slabs With C&D WasteDocument7 pagesA Study ON Behaviour OF Bamboo-Cement AND Ferrocement Slabs With C&D Wastesaurabh shrivastavaNo ratings yet

- Beltrán 2011 Engineering-StructuresDocument12 pagesBeltrán 2011 Engineering-StructuresEskorbutanoNo ratings yet

- The Material Properties in The Design of Tensile Fabric StructuresDocument7 pagesThe Material Properties in The Design of Tensile Fabric StructuresMN ChandrasekaranNo ratings yet

- 7516-Article Text-17840-1-10-20190109Document7 pages7516-Article Text-17840-1-10-20190109Mina EliasNo ratings yet

- Netaji Subhash University of Technology: Home Assignment OnDocument27 pagesNetaji Subhash University of Technology: Home Assignment OnParshant YadavNo ratings yet

- Fabric ArchitectureDocument6 pagesFabric ArchitectureVarun SanthoshNo ratings yet

- CompositesDocument8 pagesCompositesRajnandini PandaNo ratings yet

- A Review On Structural Investigation and Experimental Behavior of Kevlar Fiber IJERTCONV9IS03160Document6 pagesA Review On Structural Investigation and Experimental Behavior of Kevlar Fiber IJERTCONV9IS03160Aneesh A SNo ratings yet

- Composite Materials: 1.2 Characteristics of A Composite MaterialDocument5 pagesComposite Materials: 1.2 Characteristics of A Composite Materialashok pradhanNo ratings yet

- Stab and Cut Resistance of Knitted Structures: A Comparative StudyDocument10 pagesStab and Cut Resistance of Knitted Structures: A Comparative StudyHaider AliNo ratings yet

- Riddhi Patel Margesh Patel Twinkle Rojiwadia Harshil NairDocument20 pagesRiddhi Patel Margesh Patel Twinkle Rojiwadia Harshil NairPola TharwatNo ratings yet

- BT StrucDocument7 pagesBT StrucJayson John CaroNo ratings yet

- BITAR Et Al. 2020Document8 pagesBITAR Et Al. 2020Lidianne FariasNo ratings yet

- Cap 7Document50 pagesCap 7Ricardo Rincon VegaNo ratings yet

- Walnut Shell A ReviewDocument11 pagesWalnut Shell A ReviewGaneshNo ratings yet

- Study of Torsional Behavior of Reinforced Concrete Beams Strengthened With Aramid Fiber StripsDocument10 pagesStudy of Torsional Behavior of Reinforced Concrete Beams Strengthened With Aramid Fiber StripsAkash NitoneNo ratings yet

- Membrane StructuresDocument51 pagesMembrane Structuresimalzeolandicho100% (1)

- Tensile StructuresDocument10 pagesTensile Structuresaditya2053No ratings yet

- Fibre Reinforced ConcreteDocument20 pagesFibre Reinforced ConcreteAll unpluggedNo ratings yet

- AF 5 FibersDocument3 pagesAF 5 Fibersedilberto.penabrsNo ratings yet

- Materials Today Communications: SciencedirectDocument8 pagesMaterials Today Communications: SciencedirectJavier MunozNo ratings yet

- Edited Copy in Ieee .MetDocument4 pagesEdited Copy in Ieee .MetKalai ArasanNo ratings yet

- Composite MaterialsDocument26 pagesComposite MaterialsHussein SaeedNo ratings yet

- Newcastle University E-Prints: Date Deposited: Version of File: Peer Review Status: Citation For ItemDocument32 pagesNewcastle University E-Prints: Date Deposited: Version of File: Peer Review Status: Citation For ItempedrormunozNo ratings yet

- Engineering Structures: Diederik Veenendaal, Philippe BlockDocument12 pagesEngineering Structures: Diederik Veenendaal, Philippe BlockKimNo ratings yet

- Retrofitting Design of Concrete Members Using Carbon Fiber-Reinforced Polymers (CFRP)Document12 pagesRetrofitting Design of Concrete Members Using Carbon Fiber-Reinforced Polymers (CFRP)gcsblue stacksNo ratings yet

- Composites FinalDocument174 pagesComposites FinalAbhishekVerma100% (1)

- An Invent To Improve Bulletproof Vests CapabilitiesDocument7 pagesAn Invent To Improve Bulletproof Vests Capabilitiesniloy mominNo ratings yet

- Composites Mini ProjectDocument44 pagesComposites Mini ProjectVj Aditya100% (1)

- CompositeDocument4 pagesCompositeAshok PradhanNo ratings yet

- Design and Analysis of Composite Drive SDocument8 pagesDesign and Analysis of Composite Drive SfrindgeNo ratings yet

- The Evolution of Philippine Housing Policy and InstitutionsDocument6 pagesThe Evolution of Philippine Housing Policy and InstitutionsMharcianeMaxineMagoNo ratings yet

- Types of SpecificationDocument7 pagesTypes of SpecificationMharcianeMaxineMagoNo ratings yet

- Rizal Technological University: Department of ArchitectureDocument13 pagesRizal Technological University: Department of ArchitectureMharcianeMaxineMagoNo ratings yet

- Rizal Technological University: Department of ArchitectureDocument5 pagesRizal Technological University: Department of ArchitectureMharcianeMaxineMagoNo ratings yet

- "Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 5)Document5 pages"Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 5)JOHN FHILIP ORITNo ratings yet

- CSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityDocument44 pagesCSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityBitch CarrieNo ratings yet

- K - W/ (M.K) Temperature - 25 125 225: Thermal ConductivityDocument16 pagesK - W/ (M.K) Temperature - 25 125 225: Thermal ConductivityJosNo ratings yet

- POROTHERM 100mm Vs Ordinary Brick With Plastering CUTTACKDocument1 pagePOROTHERM 100mm Vs Ordinary Brick With Plastering CUTTACKAkshat Saklani100% (1)

- Spectra and Dyneema: Course: High Performance FibresDocument12 pagesSpectra and Dyneema: Course: High Performance FibresAvik BeraNo ratings yet

- Department of Civil Engineering Lingaya'S UniversityDocument36 pagesDepartment of Civil Engineering Lingaya'S UniversitySudha GopalanNo ratings yet

- Study of Influence of Notch Root RadiusDocument12 pagesStudy of Influence of Notch Root RadiusLuan CaetanoNo ratings yet

- Master GlobalAvailability CL130328Document1 pageMaster GlobalAvailability CL130328rahul srivastavaNo ratings yet

- Prompt SBR: Combined Waterproofer, Adhesive, Plasticiser For Cement Mortars and ConcretesDocument1 pagePrompt SBR: Combined Waterproofer, Adhesive, Plasticiser For Cement Mortars and ConcretesAlex BocicaNo ratings yet

- Polymer Chemistry-1 (Introduction) PDFDocument45 pagesPolymer Chemistry-1 (Introduction) PDFFanny Rahman EkawandiNo ratings yet

- 3c 600-1000v MC-HL (Xhhw-2) Copper Section4-Sheet1Document4 pages3c 600-1000v MC-HL (Xhhw-2) Copper Section4-Sheet1Kiran KarthikNo ratings yet

- Footing Calculation 1.0 Design ParametersDocument1 pageFooting Calculation 1.0 Design ParametersSiva JaseNo ratings yet

- Eires, R., Nunes, J. P., Fangueiro, R., Jalali, S., & Camões, A. (2006) - New Eco-Friendly Hybrid Composite Materials For Civil Construction.Document9 pagesEires, R., Nunes, J. P., Fangueiro, R., Jalali, S., & Camões, A. (2006) - New Eco-Friendly Hybrid Composite Materials For Civil Construction.anitacmontoyaNo ratings yet

- Glass Powder and Flyash Replacing CementDocument3 pagesGlass Powder and Flyash Replacing CementaryanNo ratings yet

- Engineering Failure Analysis: Xiao-Lei Xu, Zhi-Wei YuDocument11 pagesEngineering Failure Analysis: Xiao-Lei Xu, Zhi-Wei YusobhanNo ratings yet

- XENOY™ Resin 1102 - AmericasDocument3 pagesXENOY™ Resin 1102 - AmericasWellington C. de AraujoNo ratings yet

- Standard Tension TestDocument12 pagesStandard Tension TestStephen Mirdo50% (2)

- Tray Cable UL Type TC / TC-ER - 600V THHN Insulation - PVC JacketDocument1 pageTray Cable UL Type TC / TC-ER - 600V THHN Insulation - PVC JacketLuis DGNo ratings yet

- Davco K11 FlexDocument2 pagesDavco K11 Flexjet toledoNo ratings yet

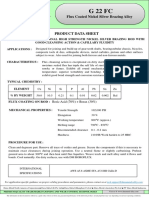

- G 22 FC Product Data Sheet (With Specs)Document1 pageG 22 FC Product Data Sheet (With Specs)candraNo ratings yet

- Lldpe 22501aa22501kjDocument2 pagesLldpe 22501aa22501kj李万福No ratings yet

- CatalogoGenerale GB12 2015 Low 20160107Document291 pagesCatalogoGenerale GB12 2015 Low 20160107Michael WuNo ratings yet

- Inputs Software WUFIDocument2 pagesInputs Software WUFIArthur MusskopfNo ratings yet

- Analysis of Mechanical Properties of Aluminium MetalDocument25 pagesAnalysis of Mechanical Properties of Aluminium MetalShashank SinghNo ratings yet

- Use of Permapol P3.1polymers and Epoxy Resins in The Formulation of Aerospace SealantsDocument6 pagesUse of Permapol P3.1polymers and Epoxy Resins in The Formulation of Aerospace Sealants이형주No ratings yet

- Use of Insulation Coatings For Burn Protection By-Howard MitschkeDocument24 pagesUse of Insulation Coatings For Burn Protection By-Howard MitschkeSeongho ParkNo ratings yet

- Butyl Rubber-IIRDocument26 pagesButyl Rubber-IIRreilyshawnNo ratings yet