Professional Documents

Culture Documents

Prompt SBR: Combined Waterproofer, Adhesive, Plasticiser For Cement Mortars and Concretes

Uploaded by

Alex BocicaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prompt SBR: Combined Waterproofer, Adhesive, Plasticiser For Cement Mortars and Concretes

Uploaded by

Alex BocicaCopyright:

Available Formats

Prompt SBR

Combined waterproofer, adhesive, plasticiser for cement mortars and concretes

Description Mix Design 1

Prompt SBR has been formulated to enhance the physical and chemical Floor Screeding and Screed Repair (min. 6mm)

properties of cement mortars and concretes. It is compatible with most forms by weight by volume

of cement, sands and aggregates. Together with the cement, it forms a 50kg cement 1 pbv

powerful adhesive to bond the aggregates together, producing a tougher, 150kg medium sand 2.5 pbv

waterproof and more impact and abrasion resistant floor, repair mix, render 10 litres Prompt SBR {1:1 Prompt SBR:water

or bonding primer. 9 litres water* {add to consistency

3

Yield approx 0.1m

Uses

Prompt SBR modified mortars are used for screeds, floor repairs, waterproof Mix Design 2

renders, waterproof fine concretes and bonding. Heavy Duty Floor Toppings (min. 12mm)

by weight by volume

Properties 50kg cement 1 pbv

The properties of the cured mix will vary depending on the type of cement, 75kg medium sand 1.25 pbv

sand and aggregates used. 75kg 6-3mm grano chips 1.25 pbv

10 litres Prompt SBR {1:1 Prompt SBR:water

Compression 9 litres water* {add to consistency

Age N/mm2 Yield approx 0.11m 3

1 day 14-18

28 days 40-50 Mix Design 3

(strength dependent on mix design) Waterproof Renders (min. 6mm)

by weight by volume

Preparation 50kg cement 1 pbv

Surfaces to which Prompt SBR mixes are to be applied must be clean, strong, 125kg medium sand 2 pbv

free from oil, grease, and with a rough profile. Best preparation is with a 10 litres Prompt SBR {1:1 Prompt SBR:water

scabbler or power washer. If metal surfaces are to be covered they must be 9 litres water* {add to consistency

rust free and wire brushed or grit blasted. Cement based substrates must be Yield approx 0.1m3

damped with clean water and excess water removed. A primer coat of 1:1

Prompt SBR/cement is brush applied to the prepared surface. Refer to Mix Design 4

relevant standards and codes of practice. Water Resistant Concrete (min. 25mm)

by weight by volume

Mixing and application 50kg cement 1 pbv cement

Hand mix or use a forced action mixer. The components of the selected mix 100kg medium sand 1.5 pbv

are measured by weight or volume and dry mixed. The Prompt SBR and water 100kg 10-5mm pea shingle 1.5 pbv

is added to give the desired consistency. In an efficient mechanical mixer, 5 litres Prompt SBR {1:3 Prompt SBR:water

mixing should continue for 2-3 minutes. When hand mixing mix the cement, 13 litres water* {add to consistency

aggregate and sand dry then add sufficient of the Prompt SBR / water until a Yield approx 0.14m3

homogeneous consistency is achieved.

Mix Design 5

The mixed mortar is applied to the prepared and primed surface whilst the Bonding Screeds, Plaster, New Concrete to Old

primer is still wet/tacky, using conventional screeding, rendering and by weight by volume

concreting techniques. Apply as required on to wet or tacky primer, compact 1kg cement 1 pbv cement

well and finish. If the primer dries, cross hatch scratch and reapply. If 1litre Prompt SBR 1 pbv Prompt SBR

necessary apply mortar in multiple layers to achieve total thickness, priming Yield approx. 3-4m2 per litre

between layers with Prompt SBR : cement primer. Cure surface when finished

to prevent rapid drying, with Ronacrete Monocure Curing Membrane, tight Mix Design 6

fitting polythene, or similar. Floating screed (min. 38mm)

by weight by volume

Storage 50kg cement 1 pbv

Prompt SBR must be stored unopened in dry warehouse conditions between 150kg medium sand 2.5 pbv

+5°C and 25°C and out of direct heat and sunlight. In these conditions 5 litres SBR {1:3 Prompt SBR:water

Prompt SBR should have a shelf life of approximately 12 months. 13 litres water* {add to consistency

Yield approx 0.1m3

Packaging

Prompt SBR is available in 5, 25 and 205 litre containers. Mix Design 7

Floor Screeding and Screed Repair (min. 26mm)

Health and Safety by weight by volume

There are no emissions of noxious or offensive fumes. Prompt SBR is alkaline 50kg cement 1 pbv

when mixed with cement and sand; do not allow prolonged contact with skin. 150kg medium sand 2.5 pbv

COSHH information available. 5 litres SBR {1:3 Prompt SBR:water

13 litres water* {add to consistency

Site Attendance Yield approx 0.1m3

When on site Ronacrete representatives are able, if asked, to give a general

indication of the correct method of installing a Ronacrete product. It is 1. * =add to working consistency

important to bear in mind that Ronacrete Ltd is a manufacturer and not an 2. All sands must be medium grade sharp.

application contractor and it is therefore the responsibility of the contractor 3. Aggregates must be clean, well graded and not

and his employer to ensure he is aware of and implements the correct “to dust”.

practices and procedures to ensure the correct installation of the product and

that liability for its correct installation lies with the contractor and not with

Ronacrete Ltd.

Ronacrete Ltd

Ronac House, Flex Meadow, Merring Way

RONL 072 Issue 4 1st January 2005 Harlow, Essex CM19 5TD

The information detailed in this leaflet is liable to modification from time to time in the light of experience Tel: 01279 638700 Fax: 01279 638701

and of normal product application, and before using, customers are advised to check with Ronacrete Ltd,

quoting the reference number, that they possess the latest issue. Any person or company using the product

without first making further enquiries as to the suitability of the product for the intended use does so at his

own risk, and Ronacrete Ltd can accept no responsibility for the performance of the product, or for any loss

Email: tech@ronacrete.co.uk

or damage arising out of such use. Web: www.ronacrete.co.uk

You might also like

- 18 Composition Rules For Photos That ShineDocument20 pages18 Composition Rules For Photos That Shinemahfuzkhan100% (1)

- QAQC Requirement-Tile Works - 副本 12345Document4 pagesQAQC Requirement-Tile Works - 副本 12345Mile StoneNo ratings yet

- Computer System Validation - Definition and Requirements - MustRead PDFDocument3 pagesComputer System Validation - Definition and Requirements - MustRead PDFtraining validNo ratings yet

- Module 6 Metal Properties and Destructive TestingDocument46 pagesModule 6 Metal Properties and Destructive TestingMiki Jaksic100% (6)

- MasterEmaco SBR 2v1Document3 pagesMasterEmaco SBR 2v1Zulfikar A. SheriNo ratings yet

- S BR CombinedDocument6 pagesS BR CombinedsajjaduetNo ratings yet

- MasterEmaco SBR ECO v1Document3 pagesMasterEmaco SBR ECO v1mcsomashekaraNo ratings yet

- MasterEmaco SBR 2Document3 pagesMasterEmaco SBR 2Radja NurNo ratings yet

- Myk Arment Rearm Coat ZPDocument4 pagesMyk Arment Rearm Coat ZPpraveenpatel.pp7143No ratings yet

- MasterEmaco SBR 3 PDFDocument3 pagesMasterEmaco SBR 3 PDFMd. Shahadat HossainNo ratings yet

- 6 2 3 6 1 Polybond SBR PDFDocument2 pages6 2 3 6 1 Polybond SBR PDFHtun ZarniNo ratings yet

- Fullproof Damp FreeDocument1 pageFullproof Damp Freesinghanishant8No ratings yet

- Expanbond SBRDocument5 pagesExpanbond SBRAmar WadoodNo ratings yet

- Sika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairDocument3 pagesSika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairJoeNo ratings yet

- Cempol SBR: Bonding AdmixtureDocument2 pagesCempol SBR: Bonding AdmixtureJagdishNo ratings yet

- PACTOBond SBR-DatasheetDocument2 pagesPACTOBond SBR-DatasheethidiNo ratings yet

- BMC ConcreteDocument3 pagesBMC ConcreteRachelNo ratings yet

- Mastercast 141 TdsDocument5 pagesMastercast 141 TdsJORGE ALICE ALEENo ratings yet

- Latex Power PDFDocument3 pagesLatex Power PDFSubhadeep GhoshNo ratings yet

- Nitobond SBR TDSDocument3 pagesNitobond SBR TDSstephanus AndiNo ratings yet

- Faircrete SBR Mortar and Screed Modifier Cum Bonding AgentDocument2 pagesFaircrete SBR Mortar and Screed Modifier Cum Bonding Agentkk777kk77777No ratings yet

- Screed For Polishing Method StatementDocument2 pagesScreed For Polishing Method StatementhemantrulzNo ratings yet

- Nitobond SBR TDS PDFDocument3 pagesNitobond SBR TDS PDFravi0% (1)

- Chapter VDocument22 pagesChapter VAbhishek JoshiNo ratings yet

- Sikalatex® SBR: Product Data SheetDocument4 pagesSikalatex® SBR: Product Data SheetSandeep JangraNo ratings yet

- 301 Dr. Fixit Pidicrete URPDocument4 pages301 Dr. Fixit Pidicrete URPAlpesh ShahNo ratings yet

- CEMFOAMDocument2 pagesCEMFOAMOsama Abu ShalthamNo ratings yet

- Drill-Thin Thinner: Application Material NeededDocument1 pageDrill-Thin Thinner: Application Material NeededNayive LancherosNo ratings yet

- Masonry Conversions - MortarDocument6 pagesMasonry Conversions - MortarJose Ramon MarcanoNo ratings yet

- Sika 1®Document4 pagesSika 1®JKR BuildersNo ratings yet

- Cemfair SmoothDocument2 pagesCemfair Smoothosama mohNo ratings yet

- PPC Ebrochure Bricks & Blocks 2011 1Document2 pagesPPC Ebrochure Bricks & Blocks 2011 1Ryan MalyonNo ratings yet

- A. Admixtures 1. Air Entraining AgentsDocument26 pagesA. Admixtures 1. Air Entraining AgentsShady RainNo ratings yet

- Kem Latex KRPN 47Document2 pagesKem Latex KRPN 47BinodNo ratings yet

- Rheomac 707 PDFDocument3 pagesRheomac 707 PDFMohamed KhanNo ratings yet

- X-Roc Multibond LX: Multi-Purpose Primer and Mortar AdditiveDocument2 pagesX-Roc Multibond LX: Multi-Purpose Primer and Mortar AdditiveAmr RagabNo ratings yet

- Emulsion 93 - NZ - PDSDocument3 pagesEmulsion 93 - NZ - PDSPraneet KumarNo ratings yet

- Nitobond - SBR FosrocDocument6 pagesNitobond - SBR FosrocVedachalam ManiNo ratings yet

- Sikalatex IqDocument3 pagesSikalatex Iqاحمد الشاويNo ratings yet

- GFRC Admix Mix DesignDocument5 pagesGFRC Admix Mix Designdepi_rachmanNo ratings yet

- Nitobond SBRDocument4 pagesNitobond SBRzishan khanNo ratings yet

- Nitobond SBR TDSDocument3 pagesNitobond SBR TDSHariom GuptaNo ratings yet

- CerachemDocument2 pagesCerachemKapilNo ratings yet

- A. Admixtures 1. Air Entraining AgentsDocument27 pagesA. Admixtures 1. Air Entraining AgentsShady RainNo ratings yet

- W Job-Report WR-Series 0116 GBDocument20 pagesW Job-Report WR-Series 0116 GBBahrudin MadihinNo ratings yet

- X-Roc Latex S: Product DescriptionDocument2 pagesX-Roc Latex S: Product DescriptionAmr RagabNo ratings yet

- Nitobond SBRDocument4 pagesNitobond SBRAzhar ShaikhNo ratings yet

- Cempatch SBR Method Statement (Liquid Polymer Bonding Agent For Cement Containing Mixes)Document3 pagesCempatch SBR Method Statement (Liquid Polymer Bonding Agent For Cement Containing Mixes)Enry GunadiNo ratings yet

- 701 Planicrete Latex GBDocument4 pages701 Planicrete Latex GBaygunbayramNo ratings yet

- Conplast RP264Document4 pagesConplast RP264Jitendra BridgemohanNo ratings yet

- Sika PDS - E - SikaLatexDocument3 pagesSika PDS - E - SikaLatexKhin Sandi KoNo ratings yet

- M M Ma Aasssttte Eerrrs S Se Eea Aal 5 551 111 11: (Formerly Known As Rheomix 115)Document2 pagesM M Ma Aasssttte Eerrrs S Se Eea Aal 5 551 111 11: (Formerly Known As Rheomix 115)gangwarNo ratings yet

- TDS Nitobond SBR Latex India4Document3 pagesTDS Nitobond SBR Latex India4rakeshNo ratings yet

- Concrete at Home and On The FarmDocument2 pagesConcrete at Home and On The FarmDesmond VlietstraNo ratings yet

- Acrybond 1116Document1 pageAcrybond 1116Sājä Al MallakNo ratings yet

- Masteremaco 2525: Solvent Free Epoxy Binder, Structural Adhesive and General Purpose PrimerDocument2 pagesMasteremaco 2525: Solvent Free Epoxy Binder, Structural Adhesive and General Purpose PrimerSetyo poernomoNo ratings yet

- MasterCast 141MDocument5 pagesMasterCast 141Mrobin rezkNo ratings yet

- CF Desco Deflocculant PDFDocument1 pageCF Desco Deflocculant PDFMaria IndiraNo ratings yet

- MortarDocument12 pagesMortarshahidul islamNo ratings yet

- RESDEV Specialist Designer Flooring BrochureDocument20 pagesRESDEV Specialist Designer Flooring BrochureAlex BocicaNo ratings yet

- Subfloor Preparation GuideDocument8 pagesSubfloor Preparation GuideAlex BocicaNo ratings yet

- Waterproofing Systems GuideDocument28 pagesWaterproofing Systems GuideAlex Bocica100% (1)

- Resdev Colour ChartDocument2 pagesResdev Colour ChartAlex BocicaNo ratings yet

- Screedmaster: Rapid Repair MortarDocument2 pagesScreedmaster: Rapid Repair MortarAlex BocicaNo ratings yet

- Resuline 2013 07Document2 pagesResuline 2013 07Alex BocicaNo ratings yet

- Husqvarna PG 450: Highly Versatile Easy To Transport and Set-Up Easy To Use Efficient Dust ManagementDocument2 pagesHusqvarna PG 450: Highly Versatile Easy To Transport and Set-Up Easy To Use Efficient Dust ManagementAlex BocicaNo ratings yet

- Deutsche Bauchemie Conductive FlooringsDocument22 pagesDeutsche Bauchemie Conductive FlooringsAlex BocicaNo ratings yet

- KDR White Cement (Filler Part C) SDS (En) Revision 2Document6 pagesKDR White Cement (Filler Part C) SDS (En) Revision 2Alex BocicaNo ratings yet

- Floor Cleaning and Maintenance DocumentDocument1 pageFloor Cleaning and Maintenance DocumentAlex BocicaNo ratings yet

- Slip Resistant Coating (R12) : Ferfa Type 2 SystemDocument2 pagesSlip Resistant Coating (R12) : Ferfa Type 2 SystemAlex BocicaNo ratings yet

- HSE Anti Slip GuideDocument6 pagesHSE Anti Slip GuideAlex BocicaNo ratings yet

- Register of Licensed Premises Under The Licensing Act 2003Document175 pagesRegister of Licensed Premises Under The Licensing Act 2003Alex BocicaNo ratings yet

- Isi Rumen SBG Subtitusi HijauanDocument3 pagesIsi Rumen SBG Subtitusi HijauanBagas ImamsyahNo ratings yet

- Application of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionDocument17 pagesApplication of The Strain Energy To Estimate The Rock Load in Non-Squeezing Ground ConditionAmit Kumar GautamNo ratings yet

- Applying For A Job: Pre-ReadingDocument5 pagesApplying For A Job: Pre-ReadingDianitta MaciasNo ratings yet

- Alaba Adeyemi AdediwuraDocument12 pagesAlaba Adeyemi AdediwuraSchahyda ArleyNo ratings yet

- Iguard® LM SeriesDocument82 pagesIguard® LM SeriesImran ShahidNo ratings yet

- DirectionDocument1 pageDirectionJessica BacaniNo ratings yet

- De Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020Document11 pagesDe Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020HiềnNo ratings yet

- Derivational and Inflectional Morpheme in English LanguageDocument11 pagesDerivational and Inflectional Morpheme in English LanguageEdificator BroNo ratings yet

- SG110CX: Multi-MPPT String Inverter For SystemDocument2 pagesSG110CX: Multi-MPPT String Inverter For SystemKatherine SmithNo ratings yet

- ..Product CatalogueDocument56 pages..Product Catalogue950 911No ratings yet

- UNIT 5-8 PrintingDocument17 pagesUNIT 5-8 PrintingNOODNo ratings yet

- Mcdaniel Tanilla Civilian Resume Complete v1Document3 pagesMcdaniel Tanilla Civilian Resume Complete v1api-246751844No ratings yet

- The Linguistic Colonialism of EnglishDocument4 pagesThe Linguistic Colonialism of EnglishAdriana MirandaNo ratings yet

- SP-Chapter 14 PresentationDocument83 pagesSP-Chapter 14 PresentationLoiDa FloresNo ratings yet

- Research FinalDocument55 pagesResearch Finalkieferdem071908No ratings yet

- Toolbox TalkDocument14 pagesToolbox Talkcall_mustafas2361No ratings yet

- ISA InTech Journal - April 2021Document50 pagesISA InTech Journal - April 2021Ike EdmondNo ratings yet

- Central University of Karnataka: Entrance Examinations Results 2016Document4 pagesCentral University of Karnataka: Entrance Examinations Results 2016Saurabh ShubhamNo ratings yet

- 9400 Series - Catalogue - AccessoriesDocument86 pages9400 Series - Catalogue - AccessoriesSaulo Leonardo Fabelo FontesNo ratings yet

- USER MANUAL ABRITES Commander For Nissan PDFDocument20 pagesUSER MANUAL ABRITES Commander For Nissan PDFBosi GashiNo ratings yet

- Caring For Women Experiencing Breast Engorgement A Case ReportDocument6 pagesCaring For Women Experiencing Breast Engorgement A Case ReportHENINo ratings yet

- China Training WCDMA 06-06Document128 pagesChina Training WCDMA 06-06ryanz2009No ratings yet

- Test Bank For Psychology 6th Edition Don HockenburyDocument18 pagesTest Bank For Psychology 6th Edition Don HockenburyKaitlynMorganarwp100% (42)

- SCERT Kerala State Syllabus 9th Standard English Textbooks Part 1-1Document104 pagesSCERT Kerala State Syllabus 9th Standard English Textbooks Part 1-1Athulya ThondangattilNo ratings yet

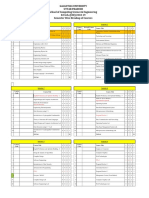

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDocument2 pagesGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiNo ratings yet

- IR2153 Parte6Document1 pageIR2153 Parte6FRANK NIELE DE OLIVEIRANo ratings yet

- Lesson 1 3 Transes in Reading in Philippine HistoryDocument17 pagesLesson 1 3 Transes in Reading in Philippine HistoryNAPHTALI WILLIAMS GONo ratings yet