Professional Documents

Culture Documents

Concrete at Home and On The Farm

Uploaded by

Desmond VlietstraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete at Home and On The Farm

Uploaded by

Desmond VlietstraCopyright:

Available Formats

concrete at home

and on the farm

There are many small concrete projects that the home-owner 4. what mix proportions should I use?

can confidently tackle. The strength of the concrete depends on mix proportions and

should suit the work being done. Mix proportions and quantities

Concrete is made by mixing portland cement, sand, stone and are given in the table overleaf. These proportions are based on

water. The potential strength of concrete depends largely on the the use of grade 32,5 cement. Higher grades will produce higher

proportion of each ingredient in the mix. strengths; lower grades should not be used.

Concrete hardens as a result of the chemical reaction between High-strength concrete should be used for precast items such

the cement and water; if concrete is allowed to dry out too as flagstones, and heavy-duty floors such as workshops.

rapidly it will not develop its full strength. This is why concrete

should be ‘‘cured’’. Medium-strength concrete is suitable for light-duty floors,

paths, patios and steps, driveways and carport floors.

1. what materials do I need? Low-strength concrete is suitable for footings for walls.

Cement should comply with the requirements of SANS 50197-1.

Bags should be clearly marked with the stength grade, cement

type and a Letter of Authority (LOA) number issued by the 5. how should I measure the ingredients?

National Regulator for Compulsory Standards. Use a bucket or tin of convenient size for batching all the

solid ingredients.

The sand and stone must be free of leaves, grass, compost, clay

lumps, etc. Sand should be fairly coarse, with particles ranging Check that the container is clean before you start.

from about 5 mm to dust.

Fill the container accurately each time so that the quality of

Mix proportions are given for stone sizes of 26,5 mm or 19 mm. concrete does not vary from one batch to the next.

These sizes are most commonly available and are the most

economical.

6. how should I mix the concrete?

Any water that is fit to drink is suitable. Concrete can be mixed by hand if quantities are small, or in

a concrete mixer powered by electricity or a petrol engine.

Note that fertilizer, sugar, oil, etc., are harmful to fresh Machine mixing is highly recommended for important work.

concrete.

7. mixing by hand

2. how thick should the concrete be? Very small batches of up to about 25 l of mixed concrete can

Minimum thicknesses are: be mixed in a wheelbarrow.

Paths, patios, floors, driveways – 80 mm.

Bigger batches should be mixed on a concrete slab or steel

Footings for garden walls – 200 mm (width should be 600 mm). plate. Do not mix directly on the ground as water may be drawn

out of the concrete or soil mixed into it.

3. how much concrete do I need? Measure and mix batches of a convenient size (as much as can

Calculate the volume of concrete required. be mixed in about 15 minutes).

For rectangular shapes,

Spread the sand in a layer about 100 mm thick. Spread the

volume = length × width × thickness.

cement on top of this and mix the two thoroughly.

For circular shapes,

volume = diameter × diameter × 0,8 × thickness.

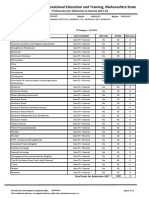

quantities for 1 m3**

of concrete (approx.)

stone mix proportions by volume approx.* cement

sand stone

size yield of 50 kg

mm cement sand stone batch bags m3 m3

High-strength 26,5

1 2 2 3 9,2 0,6 0,6

concrete or 19

Medium-strength 26,5

1 2,5 2,5 4 7,7 0,64 0,64

concrete or 19

Low-strength 26,5

1 3,5 3,5 5,25 5,8 0,67 0,67

concrete or 19

* Batching container units (for example, a 1:2:2 mix batched in a 10 l bucket will yield 30 l of concrete per batch).

** 1 m3 = 1 000 l.

Now make a heap with the mix and make a hollow in the Don’t let the concrete stand so long that it stiffens before it

middle. Add water in small quantities and mix it in. Keep on is placed. Cover concrete with plastic sheets or wet sacking so

adding and mixing in water until the consistence of the mortar that it does not dry out in the sun or wind.

is rather like that of thin porridge.

Next measure the right amount of stone and mix this well 10. placing the concrete

into the mortar until each particle of stone is well coated with Dump the concrete as close to its final position as possible.

mortar. If the mix is too stiff to be placed easily, add a little If concrete is placed on the ground, the soil should be

more water and mix it in thoroughly. thoroughly damp, but without any standing water, when

the concrete is placed.

If too much water is added, the mix will be slushy and the

concrete will be weak. The concrete should be well compacted. Work the concrete right

into the corners and along the edges with a spade or trowel.

If not enough water has been added, the concrete will be To compact concrete slabs, use a wooden beam that spans

difficult to place and compact, which will also reduce its the slab. First use a chopping action and then a sawing action.

strength. Next, wood-float the concrete to obtain an even, but rough

surface. Very smooth, steel-trowelled surfaces on outdoor

paving may be slippery and dangerous.

8. using a concrete mixer

The batch size should suit the mixer – underfilling the mixer

wastes time while overfilling results in spillage and poor mixing. 11. how do I cure the concrete?

By keeping the concrete damp. Once it has stiffened, either

Measured quantities of materials are added in the following cover it with plastic sheeting that is held down firmly along

order: first the stone and about half a measure of water, then its edges, or cover it with hessian or sacking that is kept wet.

the cement, then the sand, and finally more water until the right Curing should continue for 7 days. Good curing also helps to

consistence is reached. limit cracking of the concrete.

When all the materials have been added, continue to mix until

colour and consistence are uniform. Discharge each batch 12. joints and panel sizes

completely. Concrete slabs should be divided into panels to limit random

cracking. The distance between joints should be about 2,5 m in

concrete 80 mm thick, and 3,0 m in concrete 100 mm thick.

9. moving the concrete to the job

The concrete can be moved in buckets or wheelbarrows. If Panels should be more or less square and each panel must be

it is jolted too much the stone will settle at the bottom. If this completed in one operation.

happens, remix the concrete before placing it.

Cement should comply with the requirements of SANS 50197-1.

Bags should be clearly marked with the strength grade, cement

type and a Letter of Authority (LOA) number issued by the

The Concrete Institute, its directors, officers, employees, representatives

National Regulator for Compulsory Standards.

and agents are not liable for any death, harm or injury caused to any

person or any loss, destruction or damage caused to any person’s

property or possessions arising from goods supplied or services

the concrete institute

rendered by The Concrete Institute. po box 168, halfway house, 1685

block d, lone creek, waterfall park, bekker road, midrand

T 011 315 0300 • F 011 315 0315 • E-mail info@theconcreteinstitute.org.za • website www.theconcreteinstitute.org.za

published by the concrete institute, midrand, 2013

© the concrete institute

You might also like

- Building A Pizza Oven: 2.1 CementDocument8 pagesBuilding A Pizza Oven: 2.1 CementGyurmoooNo ratings yet

- Christian Lopez - Mortar BookletDocument9 pagesChristian Lopez - Mortar BookletCHRISTIAN COLLIN LOPEZNo ratings yet

- CE-121 Civil Engineering Materials Lecture 4Document59 pagesCE-121 Civil Engineering Materials Lecture 4Anonymous 0ClbS49QkuNo ratings yet

- Concrete For Precasting Small ItemsDocument4 pagesConcrete For Precasting Small ItemsRm1262No ratings yet

- Paving Paths and Patios 16022010Document2 pagesPaving Paths and Patios 16022010kennedy mulabiNo ratings yet

- Chapter 4.1 MortarDocument20 pagesChapter 4.1 MortarnahomNo ratings yet

- MortarDocument35 pagesMortarNaol AdugnaNo ratings yet

- Chapter 6 MORTAR (Compatibility Mode) PDFDocument14 pagesChapter 6 MORTAR (Compatibility Mode) PDFBerhanu Mengstu AlemayohNo ratings yet

- Building Technology I: 1. Mortars and PlastersDocument11 pagesBuilding Technology I: 1. Mortars and PlastersAN NENo ratings yet

- Concrete Blocks - Sand - Cement Blocks: Previous NextDocument11 pagesConcrete Blocks - Sand - Cement Blocks: Previous NextFeteneNo ratings yet

- General ConcreteDocument48 pagesGeneral ConcreteGemechuNo ratings yet

- Proper Proportioning of Cement Sand GravelDocument4 pagesProper Proportioning of Cement Sand GravelMyrell NaguiatNo ratings yet

- Lecture 4MORTARDocument24 pagesLecture 4MORTARErmiyas AlhegnNo ratings yet

- Cockburn Cement - Concrete FootingsDocument1 pageCockburn Cement - Concrete FootingsSelbyNo ratings yet

- Chapter 7 (MORTARNEW)Document24 pagesChapter 7 (MORTARNEW)Mitiku AregieNo ratings yet

- UNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Document39 pagesUNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Harkamal Singh DevgunNo ratings yet

- Lecture 4MORTARDocument24 pagesLecture 4MORTARErmiyas AlhegnNo ratings yet

- CementmixesDocument2 pagesCementmixesTshepang GaryNo ratings yet

- Construction Technology: Mortars & ConcretesDocument34 pagesConstruction Technology: Mortars & ConcretesDolly MantriNo ratings yet

- Lecture 4MORTARDocument24 pagesLecture 4MORTARSimeon WoyesaNo ratings yet

- Lecture 2 MORTAR (Binding Material)Document22 pagesLecture 2 MORTAR (Binding Material)Jimach Bol WieNo ratings yet

- Untitled 3Document1 pageUntitled 3Kevin John MaximoNo ratings yet

- 9.building MortarsDocument18 pages9.building MortarsB4-63-Harshit RajNo ratings yet

- Good Construction PracticesDocument36 pagesGood Construction PracticesRavi Kiran Nandyala100% (2)

- Reinforced Brickwork: Detailed SpecificationDocument13 pagesReinforced Brickwork: Detailed SpecificationMuskan JainNo ratings yet

- MORTARDocument20 pagesMORTARaduyekirkosu1scribdNo ratings yet

- Material & Construction 2: Credit Hours 3 Session Per Week: 1Document94 pagesMaterial & Construction 2: Credit Hours 3 Session Per Week: 1Abubakar Ashraf AnjumNo ratings yet

- 06-Clay Bricklaying Made Easy PDFDocument2 pages06-Clay Bricklaying Made Easy PDFPietNo ratings yet

- Chapter 3: Aggregates For Mortar, Concrete, ScreedsDocument43 pagesChapter 3: Aggregates For Mortar, Concrete, ScreedsBich Nga BuiNo ratings yet

- Site Plan and Planing of BuildingDocument9 pagesSite Plan and Planing of BuildingSTAR PRINTINGNo ratings yet

- Christian Lopez - Mortar BookletDocument8 pagesChristian Lopez - Mortar BookletCHRISTIAN COLLIN LOPEZNo ratings yet

- Concrete Specifications For Agriculture: Factors Affecting The Quality of ConcreteDocument4 pagesConcrete Specifications For Agriculture: Factors Affecting The Quality of ConcreteRajesh SuraypallyNo ratings yet

- Fig. 1.2 BRICKSDocument53 pagesFig. 1.2 BRICKSDishant ChandraNo ratings yet

- Your Guide To BricklayingDocument6 pagesYour Guide To BricklayingChristopher GeorgeNo ratings yet

- 4.1 MortarDocument21 pages4.1 MortartrfuawlachewNo ratings yet

- MortarDocument56 pagesMortarAlemayehu DargeNo ratings yet

- Durability CharacteristicsDocument4 pagesDurability CharacteristicsSathish KumarNo ratings yet

- Unit - 1 - Bricks PDFDocument105 pagesUnit - 1 - Bricks PDFChandana Chandran100% (1)

- Mix Design BasicsDocument18 pagesMix Design BasicsIremedio, Nicole Allen S.No ratings yet

- Alternate Building BlocksDocument39 pagesAlternate Building BlocksharNo ratings yet

- Mortar and PlaseringDocument6 pagesMortar and Plaseringadnansakib2003No ratings yet

- Concrete BasicsDocument56 pagesConcrete Basicsengcecbepc100% (6)

- Concrete Crafts: Making Modern Accessories for the Home and GardenFrom EverandConcrete Crafts: Making Modern Accessories for the Home and GardenRating: 4 out of 5 stars4/5 (3)

- Making Concrete Pots, Bowls, and Platters: 37 stylish and simple projects for the home and gardenFrom EverandMaking Concrete Pots, Bowls, and Platters: 37 stylish and simple projects for the home and gardenNo ratings yet

- Creating with Concrete and Mosaic: Fun and Decorative Ideas for Your Home and GardenFrom EverandCreating with Concrete and Mosaic: Fun and Decorative Ideas for Your Home and GardenRating: 5 out of 5 stars5/5 (1)

- Garden Mosaics: 19 Beautiful Projects to Make for Your GardenFrom EverandGarden Mosaics: 19 Beautiful Projects to Make for Your GardenRating: 5 out of 5 stars5/5 (2)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- The Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationFrom EverandThe Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationNo ratings yet

- Geometric Patterns from Tiles and Brickwork: And how to draw themFrom EverandGeometric Patterns from Tiles and Brickwork: And how to draw themRating: 4 out of 5 stars4/5 (1)

- Concrete Construction for the Home and the FarmFrom EverandConcrete Construction for the Home and the FarmNo ratings yet

- Process Engineering Toolkit SolutionsDocument71 pagesProcess Engineering Toolkit SolutionsTeymur RegenmaisterNo ratings yet

- Supplement 1Document11 pagesSupplement 1Tabish IslamNo ratings yet

- Sample Problem #22Document8 pagesSample Problem #22Dozdi0% (1)

- UOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSDocument11 pagesUOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSMorteza Sepehran100% (1)

- Offshore - Packaged Air Conditioning UnitDocument7 pagesOffshore - Packaged Air Conditioning UnitLovre PerkovićNo ratings yet

- Clear Burn - E - BrochureDocument21 pagesClear Burn - E - BrochureRamandeep SinghNo ratings yet

- TSP 23 No 1Document44 pagesTSP 23 No 1Primitivo GonzálezNo ratings yet

- Astm f899 PDFDocument6 pagesAstm f899 PDFengineNo ratings yet

- Advanced Polymer Panel TDS PDFDocument2 pagesAdvanced Polymer Panel TDS PDFsaint222No ratings yet

- Yiheng Specifications 2020Document6 pagesYiheng Specifications 2020SAWERA TEXTILES PVT LTDNo ratings yet

- C El 115 PDFDocument23 pagesC El 115 PDFamini_mohiNo ratings yet

- LNG Technology SelectionDocument9 pagesLNG Technology SelectionWayne MonneryNo ratings yet

- L&T Pipeline Ball Valves PDFDocument19 pagesL&T Pipeline Ball Valves PDFSanjeev KachharaNo ratings yet

- Seamless VS Welded TubesDocument1 pageSeamless VS Welded Tubeshirenkumar patelNo ratings yet

- Nitrogen N2 - Data Class 1Document2 pagesNitrogen N2 - Data Class 1neyzaNo ratings yet

- Code 1 WPS Rev 0 PDFDocument18 pagesCode 1 WPS Rev 0 PDFEarl HarbertNo ratings yet

- Long Life Bearing Series: CAT - NO.199EDocument5 pagesLong Life Bearing Series: CAT - NO.199EJhefferson FreitasNo ratings yet

- TeflonDocument1 pageTeflonSanthosh KumarNo ratings yet

- Pour CardDocument2 pagesPour Cardsuchendra singhNo ratings yet

- Basics of Rotary Screw Compressor Lubricants-Tcm67-319606 PDFDocument8 pagesBasics of Rotary Screw Compressor Lubricants-Tcm67-319606 PDFDarmawan Putranto100% (2)

- Rock Cycle Crayon LabDocument4 pagesRock Cycle Crayon Labapi-251355123No ratings yet

- Department of Environment and Natural Resources Environmental Management BureauDocument22 pagesDepartment of Environment and Natural Resources Environmental Management BureauGaisano Capital Tacloban MainNo ratings yet

- MENA Reference MBR Durrat Al BahreinDocument2 pagesMENA Reference MBR Durrat Al BahreinNermeen ElmelegaeNo ratings yet

- Cabin Pressure:: ExampleDocument47 pagesCabin Pressure:: ExamplePrasanth ViratNo ratings yet

- Commscope Trunk & Distribution Cable ProductsDocument51 pagesCommscope Trunk & Distribution Cable ProductsMauro Barragan SanchezNo ratings yet

- UKCS-TI-32 Piping Joints Handbook PDFDocument107 pagesUKCS-TI-32 Piping Joints Handbook PDF임재령No ratings yet

- High Performance LubricantsDocument20 pagesHigh Performance Lubricantsmaicol21n100% (2)

- DVET Amravati Govt ITIDocument32 pagesDVET Amravati Govt ITIVaibhav KaleNo ratings yet

- IDB - DOAS Submittal Rev2Document78 pagesIDB - DOAS Submittal Rev2Jamie CheNo ratings yet

- Adritz Aqua-Guard Self-Washing Continuous Fine ScreenDocument2 pagesAdritz Aqua-Guard Self-Washing Continuous Fine Screentarek555No ratings yet