Professional Documents

Culture Documents

Blow Down Calculation For Boiler

Blow Down Calculation For Boiler

Uploaded by

parvezblogOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blow Down Calculation For Boiler

Blow Down Calculation For Boiler

Uploaded by

parvezblogCopyright:

Available Formats

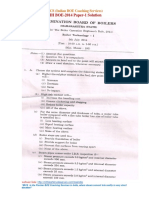

BLOWDOWN CALCULATION FOR BOILER

This term is the most important term in boiler operation and monitoring. The

parameters of the blow down are to be maintained for particular boiler. This

is due to the fact that water inside the boiler gets continuously evaporated

due to steam generation. Concentration of dissolve solid, inside the drum

increases and reach beyond the limit, so carryover of solids along with

steam can occur. To prevent boiler tube chocking and overheating of the

boiler tubes the blow down is necessary.

The blow down is the water removed from boiler to maintain the solids level

in the boiler drum. This can be calculated as follows:

E = Evaporation or steam generation rate.

S = Amount of solids (ppm)

B = Blow down (m3 / hr)

C = Maximum permissible concentration of solid inside the boiler drum

B = E x S (m3 / hr.)

C–S

%B= S

C–S

This formula has been equally applied to control individual constituents in

boiler.

Blow down means, “lost heat”. This is because any water, which is getting

drained from the boiler drum, will be at the saturation temperature of steam

and this has been heated starting from water of ambient temperature.

Hence any reduction in this quantity of water would mean corresponding

saving of fuel which can be qualified.

The chart attached showing volume of boiler Water Blow Liter/minute at

various pressure and valve size in most common use:

• 1 kg / cm2 = 14.2 PSIG

Garware-Wai Case Study:

Boiler capacity = 2.5 TPH

Steam Pressure = 9.5 kg/cm2

Blowdown valve diameter = 1 inch

Holdup volume = 5 m3

Feed water TDS = 300 ppm (max.)

Existing Boiler water TDS = 6000 ppm

As per formula:

Blowdown = 300 x 100

6000 – 300

= 5.263

For 2.5 TPH capacity boiler

= 2.5 x 5.263

100

= 0.131

= 131 litres / hrs

= 3157 litres / day

Now as per chart 9.5 kg/cm2

At 9.50 kg/cm2 by having 1 inch blowdown valve diameter, we can remove

480 lit / minute.

To remove 3157 liter/day, we need = 3157

480

= 6.58 minutes of total blow down.

Our current blow down confirms the above calculation. Based on above

calculation, one can easily calculate the blow down needed to maintain the

TDS at any level.

For above case, to maintain TDS at 3500

The water to be removed from the system is 5625 lit/day & the total

required blow down time is 11.71 minutes.

B.O. Valve 1" Pipe 1.5" Pipe 2" Pipe 2.5" Pipe 3" Pipe

Press. Temp. Litre / Kg Litre / Kg Litre / Kg Litre / Kg Litre / Kg

Kg/cm2 °C Minute Coal Minute Coal Minute Coal Minute Coal Minute Coal

7.04 167.22 435.84 14.98 1089.60 37.68 1852.32 64.47 2655.90 92.16 4767.00 165.71

8.80 178.33 463.08 16.80 1198.56 43.58 2015.76 73.55 2941.92 107.60 5039.40 184.32

10.56 185.56 503.94 19.07 1307.52 49.94 2233.68 85.35 3214.32 123.03 5448.00 208.39

12.32 191.67 544.80 21.34 1416.48 55.84 2451.60 97.16 3541.20 140.29 5856.60 231.99

14.08 197.78 599.28 24.52 1525.44 62.65 2669.52 109.41 3813.60 156.18 6265.20 256.96

15.85 202.78 653.76 27.69 1634.40 69.01 2860.20 120.31 4086.00 172.07 6673.80 281.03

17.61 207.78 708.24 29.96 1743.36 75.36 3105.36 134.38 4358.40 188.41 7082.40 306.45

21.13 216.11 789.96 35.41 1906.80 85.81 3386.84 152.09 4712.52 212.02 7845.12 353.21

24.65 223.89 817.20 39.50 2070.24 97.16 3650.16 171.16 5066.64 237.44 8607.84 404.51

28.17 231.11 926.16 44.95 2233.68 108.05 3940.72 191.13 5420.76 262.87 9397.80 455.82

31.69 237.22 1007.88 49.94 2397.12 119.40 4194.96 208.84 5774.88 287.84 10187.76 507.57

You might also like

- Boiler Blow Down: Workshop On Efficient Operation & Maintenance of BoilersDocument3 pagesBoiler Blow Down: Workshop On Efficient Operation & Maintenance of Boilerskcp1986No ratings yet

- 660 MW Sipat BoilerDocument88 pages660 MW Sipat BoilerKrishnan Santhanaraj100% (3)

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- Properties of Steam Numericals v2Document32 pagesProperties of Steam Numericals v2Saurabh R Shah100% (4)

- Failure of Boiler Tubes Due To EROSIONDocument9 pagesFailure of Boiler Tubes Due To EROSIONShiVa20155244No ratings yet

- Efficiency of Waste Heat Boiler, HRSGDocument13 pagesEfficiency of Waste Heat Boiler, HRSGHasan Ahmed100% (1)

- Explosion Occurance in CFBC Boiler and Necessary OperationsDocument6 pagesExplosion Occurance in CFBC Boiler and Necessary OperationsAnudeep ChittluriNo ratings yet

- The Indian Boilers Act 1923Document16 pagesThe Indian Boilers Act 1923Anand Swami100% (1)

- h (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8Document9 pagesh (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8RajashekarBheemaNo ratings yet

- SCHROEDAHL Automatic Recirculation ValveDocument12 pagesSCHROEDAHL Automatic Recirculation ValveJaebeom YiNo ratings yet

- CBD IbdDocument2 pagesCBD Ibdpremk20100% (5)

- Dryness Fraction PDFDocument3 pagesDryness Fraction PDFPranay NayanNo ratings yet

- 2011 GJ Boe P-1Document10 pages2011 GJ Boe P-1Alok DoshiNo ratings yet

- 34 - 244Document208 pages34 - 244rohithunni100% (1)

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDocument7 pagesIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNo ratings yet

- MH BOE 2016 Paper 2 SolutionDocument9 pagesMH BOE 2016 Paper 2 SolutionKamleshNo ratings yet

- Boiler NotesDocument34 pagesBoiler NotesRakesh Singh BhadoriyaNo ratings yet

- KKP Boiler Training Material - Vol 1Document92 pagesKKP Boiler Training Material - Vol 1parthi20065768No ratings yet

- MH BOE 2014 Paper 1 SolutionDocument15 pagesMH BOE 2014 Paper 1 SolutionPratima MondalNo ratings yet

- Surging & Blow Out of Loop Seals in A CFBC BoilerDocument9 pagesSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragNo ratings yet

- Boiler Emergencies - 2017Document10 pagesBoiler Emergencies - 2017RAJKUMAR100% (1)

- MH BOE 2016 Paper 1 SolutionDocument12 pagesMH BOE 2016 Paper 1 SolutionPratima MondalNo ratings yet

- Pump Manual - Single Plunger AmbicaDocument24 pagesPump Manual - Single Plunger AmbicaHimTex /JaswinderNo ratings yet

- Bed Tube Failure Diagnosis - Final Report by Venus 19 Dec 2013Document65 pagesBed Tube Failure Diagnosis - Final Report by Venus 19 Dec 2013parthi20065768No ratings yet

- "Boiler Tube Failures": Project ReportDocument30 pages"Boiler Tube Failures": Project ReportmdjanNo ratings yet

- Boiler Operation EngineerDocument10 pagesBoiler Operation EngineerSarah Frazier100% (2)

- Effciency of Boilers & TurbinesDocument32 pagesEffciency of Boilers & TurbinesMuthu Kumar100% (1)

- Recommended Procedure For Alkali Boil OutDocument3 pagesRecommended Procedure For Alkali Boil OutretrogradesNo ratings yet

- IR CFBC Cold Start Up ProcedureDocument15 pagesIR CFBC Cold Start Up ProcedureJose Angie CabreraNo ratings yet

- Boiler Q ADocument26 pagesBoiler Q AGnanaSekar100% (1)

- Boiler Light UpDocument19 pagesBoiler Light Upabbutalibb5407100% (1)

- Smart Soot Blower SystemDocument8 pagesSmart Soot Blower SystemidigitiNo ratings yet

- Boiler Boil OutDocument1 pageBoiler Boil Outgshori2000No ratings yet

- Boiler Inspector TRAINING - 2021Document8 pagesBoiler Inspector TRAINING - 2021SUNIL BABURAO GAVADENo ratings yet

- Boiler Water TreatmentDocument1 pageBoiler Water TreatmentRommel Cena NepalarNo ratings yet

- Boiler Blowdown Types and Boiler Blowdown CalculationDocument3 pagesBoiler Blowdown Types and Boiler Blowdown CalculationMark StrifeNo ratings yet

- A Diagnostic Study in A Husk Fired Boiler For A Power PlantDocument44 pagesA Diagnostic Study in A Husk Fired Boiler For A Power Plantparthi20065768No ratings yet

- Boiler Efficient, Safe & Emergency OperationDocument51 pagesBoiler Efficient, Safe & Emergency OperationShambhu MehtaNo ratings yet

- AP BOE-2013 Paper-1 SolutionDocument9 pagesAP BOE-2013 Paper-1 SolutionAlok Doshi50% (2)

- CFBC Boiler Start Up ProblemsDocument40 pagesCFBC Boiler Start Up ProblemsarvindshuklaNo ratings yet

- Bed Ash Cooler's in Ir-Cfbc Boilers PDFDocument12 pagesBed Ash Cooler's in Ir-Cfbc Boilers PDFpradeep1987coolNo ratings yet

- Chandrapur CTPS 15 Days Training ReportDocument21 pagesChandrapur CTPS 15 Days Training ReportUday Wankar0% (1)

- Boiler Start-Up & Shut-DownDocument42 pagesBoiler Start-Up & Shut-DownBurhan Khan100% (1)

- NPTI Publications PDFDocument3 pagesNPTI Publications PDFBalraj SinghNo ratings yet

- Vizag Steel Plant WHRB RussiaDocument47 pagesVizag Steel Plant WHRB RussiakaustavNo ratings yet

- Successful Commissioning of An AFBC BoilerDocument72 pagesSuccessful Commissioning of An AFBC Boilerparthi20065768No ratings yet

- Kerala BOE-2014 Paper-1 SolutionDocument10 pagesKerala BOE-2014 Paper-1 SolutionAlok DoshiNo ratings yet

- Boiler Bed Height Formula - NirmaDocument1 pageBoiler Bed Height Formula - NirmaRaj Kumar100% (1)

- Requirements of Bed Material, Charcoal & Diesel. Bed MaterialDocument4 pagesRequirements of Bed Material, Charcoal & Diesel. Bed MaterialpurvgargNo ratings yet

- BOE IntroductionDocument18 pagesBOE IntroductionAnsuman Sen SharmaNo ratings yet

- Boiler EmergenciesDocument5 pagesBoiler Emergenciesshantanu_scribdNo ratings yet

- Determination of Steam and Makeup Water Requirements of A Deaerator by EMEMERURAI ODocument45 pagesDetermination of Steam and Makeup Water Requirements of A Deaerator by EMEMERURAI OMohammad Ali ZamanNo ratings yet

- Tds Contro Heat RecoverylDocument31 pagesTds Contro Heat RecoverylHélder PascoalNo ratings yet

- Steam PlantsDocument228 pagesSteam PlantsMark Allen San Antonio100% (1)

- Difference Between - Hogging - Sagging, Pipe - Tubes, IBR - Non IBR Boiler, Cold End - Hot End Corrosion - ASKPOWERPLANTDocument16 pagesDifference Between - Hogging - Sagging, Pipe - Tubes, IBR - Non IBR Boiler, Cold End - Hot End Corrosion - ASKPOWERPLANTRaju MaityNo ratings yet

- Slop Fired Boiler: Development of An EfficientDocument36 pagesSlop Fired Boiler: Development of An EfficientSantosh Kumar JaiswalNo ratings yet

- Blow Down BoilerDocument41 pagesBlow Down Boilergiannis2No ratings yet

- Block 15 DesuperheatingDocument42 pagesBlock 15 DesuperheatingBabu Aravind100% (1)

- To Calculate The Boiler Blowdown RateDocument6 pagesTo Calculate The Boiler Blowdown Rateedos izedonmwenNo ratings yet

- Boiler BlowdownDocument3 pagesBoiler BlowdownSwaroop Kumar100% (1)