Professional Documents

Culture Documents

Ellis Corporation - Dissolved Air Flotation (DAF)

Uploaded by

AsifOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ellis Corporation - Dissolved Air Flotation (DAF)

Uploaded by

AsifCopyright:

Available Formats

Ellis Corporation | Dissolved Air Flotation (DAF)

About Us Products Services Testimonials Contact Us Search

Ellis >> Products >> Wastewater Treatment Systems >> Dissolved Air Flotation (DAF)

Dissolved Air Flotation (DAF)

Ellis' most versatile and effective wastewater processing equipment.

The Dissolved Air Flotation (DAF) system is perhaps the most

versatile and effective wastewater processing equipment

manufactured by the Ellis Corporation. As a separation device it

generally will effect the highest solids capture and will yield the

highest level of recovered solids under a wide range of flow

conditions. Oil/grease and suspended solids removal rates of greater

than 95% are normal. There are some sites reporting 99.9% O&G

and SS removal. Because of the outstanding performance and

reliability, the DAF is the preferred process for a wide range of industrial treatment problems.

PRECONDITIONING REQUIREMENTS

Most DAF applications require preconditioning of the wastewater using a

coagulant and a flocculating polymer. The more common coagulants are

inorganic salts such as alum, ferric chloride, ferrous sulfate, lime, sodium

hydroxide or organic polymers. The preconditioning requirement is

usually site specific and will impact operating cost, effluent quality, sludge

volume and possibly water reuse.

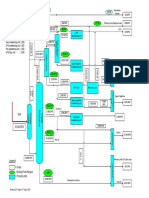

PRESSURIZED WATER

The driving force that allows a DAF to operate is gravity. By attaching small air bubbles to a solid or flocculated

particle the apparent specific gravity of the particle is changed from that of the surrounding water thus causing

the solids to rise or float.

The small air bubbles can be generated several ways. The most common is to spray the wastewater in to a

tank that is under several atmospheres of pressure. The small water droplets from the spray will approach

saturation within the pressurized atmosphere and collect in the bottom of the tank. As this pressurized water is

released to atmosphere, the air will come out of solution forming very small air bubbles.

http://www.elliscorp.com/products/wastewater-treatment-systems/dissolved-air-flotation/[8/1/2012 1:25:51 PM]

Ellis Corporation | Dissolved Air Flotation (DAF)

RECYCLE BLENDING

The pressurized recycle flow is released to atmospheric pressure and blended with the conditioned

wastewater. The mixing of these two streams occur in a chamber designed to enhance mixing without

coalescing of the air bubbles. This mixing chamber is directly connected to the diffusion fixture within the

separation cell. This fixture distributes the blended flow uniformly across the width of the DAF.

SOLIDS CHAMBER AND AUGER

The lower portion of the solids chamber of the DAF has 45° sloped sides to form a V bottom chamber

extending the length of the separation cell. This V bottom chamber is equipped with a slowly rotating ribbon

type screw auger to convey heavy gritty solids to a sludge discharge nozzle.

STAINLESS STEEL CONSTRUCTION

The shell of the DAF is available in 304 SS construction. The environment within the DAF may be highly

corrosive. The presence of chemicals and high levels of dissolved oxygen make frequent inspection and repair

of corrosion resistant coating a necessity. An all stainless steel shell eliminates this requirement.

FLOAT STORAGE CHAMBER

The integral float storage chamber is generously sized with a V-

bottom to permit near complete pumping of accumulated solids.

It is large enough to allow the use of level switches for

automatic solids pumping.

EFFLUENT CHAMBER

The effluent chamber acts as a feed reservoir for the

pressurization system. It is designed to protect the recycle

pump or the multiple stage pressurization pump from damage by running dry. This chamber is an ideal location

to adjust the effluent pH prior to discharge.

PRESSURIZATION SYSTEM

The pressurization system is designed to dissolve air into a portion of the effluent from the DAF. Ellis offers two

different methods of generating this pressurized recycle stream, either a steel constructed pressurized

dissolution tank or air aspirating multiphase pump. Depending on the unique requirements of the customer Ellis

can offer the system most suited to the project.

SKIMMER ASSEMBLY

The pivoted ferris wheel type skimmer is much cleaner and requires

less maintenance than a rigid fixed skimmer. During operation the

leading edge of the pivoted skimmer points downward in both the

skimming and return cycle thus preventing the accumulation of wet

solids on the skimmer blades. The skimmer assembly is driven via a

high torque gear motor connected to the shaft by a chain and

sprocket reduction. Shaft mounted sprockets drive a pair of stainless

steel chains to which are mounted the pivoting skimmer blades.

Ways to pressurize the water: Full Flow, Partial Flow, Recycle Flow, and Pump-Induced Air.

http://www.elliscorp.com/products/wastewater-treatment-systems/dissolved-air-flotation/[8/1/2012 1:25:51 PM]

Ellis Corporation | Dissolved Air Flotation (DAF)

Ellis Oil Water Separator →

Ellis Corporation About Us Products Services Testimonials Contact Us

EllisCorp.com Phone: 1-800-611-6806

© 2012. All rights reserved. E-Mail: info@EllisCorp.com

http://www.elliscorp.com/products/wastewater-treatment-systems/dissolved-air-flotation/[8/1/2012 1:25:51 PM]

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Oil-To-Chemicals: New Approaches: A Review of Developments and Trends in The Expanding Business of Oil-To-ChemicalsDocument4 pagesOil-To-Chemicals: New Approaches: A Review of Developments and Trends in The Expanding Business of Oil-To-ChemicalsAsifNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- FCC Petrochemicals Production at Minimum CapexDocument5 pagesFCC Petrochemicals Production at Minimum CapexAsifNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Crude Switch OptimizationDocument23 pagesCrude Switch OptimizationAsifNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Treatment of Automotive Wastewater by Coagulation-Flocculation Using Poly-Aluminum Chloride (PAC), Ferric Chloride and Aluminum Sulfate (Alum)Document7 pagesTreatment of Automotive Wastewater by Coagulation-Flocculation Using Poly-Aluminum Chloride (PAC), Ferric Chloride and Aluminum Sulfate (Alum)AsifNo ratings yet

- Process Control Fundamentals - ADDDocument115 pagesProcess Control Fundamentals - ADDAsifNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Maximising Yields and Profits From The FCC UnitDocument4 pagesMaximising Yields and Profits From The FCC UnitAsifNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 59a f2015 Lng-Aaa SD SrreportDocument24 pages59a f2015 Lng-Aaa SD SrreportAsifNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Raw Water Flow SchemeDocument1 pageRaw Water Flow SchemeAsifNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Pilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsDocument7 pagesPilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsAsifNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Manit PongchalermpornDocument54 pagesManit PongchalermpornAsifNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Tower Internals FailureDocument22 pagesTower Internals FailureAsifNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Wastewater Treatment-BlanksDocument17 pagesWastewater Treatment-BlanksAsifNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Catalytic Naphtha Reforming: January 2006Document12 pagesCatalytic Naphtha Reforming: January 2006AsifNo ratings yet

- Dissolved Air Flotation and Me PDFDocument30 pagesDissolved Air Flotation and Me PDFtallef001No ratings yet

- Energy Integration of Kero Hydrotreating Unit A Case Study of Nigerian Refinery 2157 7048 1000386Document8 pagesEnergy Integration of Kero Hydrotreating Unit A Case Study of Nigerian Refinery 2157 7048 1000386AsifNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Dissolved-Air Flotation (DAF) Application and DesignDocument3 pagesDissolved-Air Flotation (DAF) Application and DesignAsifNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Refiners Must Optimize FCC Feed Hydrotreating When Producing Low-Sulfur GasolineDocument8 pagesRefiners Must Optimize FCC Feed Hydrotreating When Producing Low-Sulfur GasolineDaniel VillanuevaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Modelling and Optimisation of A Crude Oil Hydrotreating Process Using Neural NetworksDocument6 pagesModelling and Optimisation of A Crude Oil Hydrotreating Process Using Neural NetworkshamodiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Corrosion of Boiler Tubes Some Case Studies.... 15Document27 pagesCorrosion of Boiler Tubes Some Case Studies.... 15Leonardo Della MeaNo ratings yet

- 1000444Document5 pages1000444Semih ÖzsağıroğluNo ratings yet

- Ripi - Light Naphtha IsomerizationDocument4 pagesRipi - Light Naphtha IsomerizationAsifNo ratings yet

- Benzene Reduction PDFDocument11 pagesBenzene Reduction PDFAsifNo ratings yet

- Investigation of Economizer Tube Failure in Shuqaiq Plant Boiler No. 1Document16 pagesInvestigation of Economizer Tube Failure in Shuqaiq Plant Boiler No. 1Mohammad Sazid AlamNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- PPD ClariantDocument9 pagesPPD ClariantAsifNo ratings yet

- 13 Heat Integration in A Crude Distillation Unit Using Pinch Analysis ConceptsDocument29 pages13 Heat Integration in A Crude Distillation Unit Using Pinch Analysis ConceptsxinghustNo ratings yet

- NHT PDFDocument1 pageNHT PDFAsifNo ratings yet

- Benzene Reduction PDFDocument11 pagesBenzene Reduction PDFAsifNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Wed Sep 30 17:24:56 2020 Case: NHT and GRU - HSC Flowsheet: Case (Main)Document1 pageWed Sep 30 17:24:56 2020 Case: NHT and GRU - HSC Flowsheet: Case (Main)AsifNo ratings yet

- Visio ORC 1@35000BPD New HRA PDFDocument1 pageVisio ORC 1@35000BPD New HRA PDFAsifNo ratings yet

- Soy Candle ModuleDocument17 pagesSoy Candle ModuleCla Rence0% (2)

- Solutions Manual For Introduction To Management Accounting 16Th Edition Horngren Sundem Schatzberg Burgstahler 0133058786 9780133058789 Full Chapter PDFDocument36 pagesSolutions Manual For Introduction To Management Accounting 16Th Edition Horngren Sundem Schatzberg Burgstahler 0133058786 9780133058789 Full Chapter PDFdavid.rex111100% (10)

- Nano-technology for Post-Harvest Management of Fruits and VegetablesDocument3 pagesNano-technology for Post-Harvest Management of Fruits and VegetablesArin RujinNo ratings yet

- Channelling Done: Channel DetailsDocument2 pagesChannelling Done: Channel DetailsKaushala SamarawickramaNo ratings yet

- Integral Abutment Bridge Design (Modjeski and Masters) PDFDocument56 pagesIntegral Abutment Bridge Design (Modjeski and Masters) PDFAnderson UrreaNo ratings yet

- Sand Patch TestDocument5 pagesSand Patch TestgreatpicNo ratings yet

- University of The Cordilleras Process CostingDocument5 pagesUniversity of The Cordilleras Process CostingJane PadillaNo ratings yet

- Sterotex SheetDocument2 pagesSterotex SheetHemant DangarNo ratings yet

- Motion in A Straight Line: Initial PositionDocument7 pagesMotion in A Straight Line: Initial PositionEngelbert Bicoy AntodNo ratings yet

- Guidelines For The Design and Construction of Suspension FootbridgesDocument141 pagesGuidelines For The Design and Construction of Suspension Footbridgesjavali2100% (2)

- Blockchain For IBMers - Eng Model v2.01Document25 pagesBlockchain For IBMers - Eng Model v2.01ayanmukherjee1No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cortes Constitutional Foundations of Privacy in Emerging Trends in LawDocument3 pagesCortes Constitutional Foundations of Privacy in Emerging Trends in LawAce Reblora IINo ratings yet

- Channel CapDocument9 pagesChannel CapDeepika RastogiNo ratings yet

- Passive Fire Protection PDFDocument7 pagesPassive Fire Protection PDFVictor SampaNo ratings yet

- Understanding Data GovernanceDocument28 pagesUnderstanding Data GovernanceJoe leninja100% (1)

- Job - Details - Grant Acquisition Management (GAM) Manager - 5219Document4 pagesJob - Details - Grant Acquisition Management (GAM) Manager - 5219Salman DigaleNo ratings yet

- Ethernet Networking EssentialsDocument5 pagesEthernet Networking Essentialsjmiguel000No ratings yet

- RTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealDocument5 pagesRTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealAmmie AsturiasNo ratings yet

- Green Economy in The Transport SectorDocument138 pagesGreen Economy in The Transport Sectorclayton MaramwidzeNo ratings yet

- PATHFit 4 Volleyball BSEDDocument7 pagesPATHFit 4 Volleyball BSEDJULIUS JIM CREDONo ratings yet

- Week 05 Simulation Using GPSS (1) NEWDocument59 pagesWeek 05 Simulation Using GPSS (1) NEWPutriska RazaniNo ratings yet

- Dual Rectifier Solo HeadDocument11 pagesDual Rectifier Solo HeadВиктор АлимовNo ratings yet

- Manual For The Implementation of International Development Cooperation Projects of SloveniaDocument7 pagesManual For The Implementation of International Development Cooperation Projects of SloveniarefikrosicNo ratings yet

- Lay Up ProcedureDocument21 pagesLay Up ProcedureAmir100% (1)

- Licence Acoknowledgement SlipDocument1 pageLicence Acoknowledgement SlipBicky ChoudhuryNo ratings yet

- Viewing Partition of India as an Imperfect SolutionDocument36 pagesViewing Partition of India as an Imperfect Solutionsingh1910511753No ratings yet

- Introduction, Concepts, Scope of Community Health NursingDocument32 pagesIntroduction, Concepts, Scope of Community Health Nursingmuthukumar82% (28)

- 638341140 (1)Document7 pages638341140 (1)Nishit BhanushaliNo ratings yet

- Plan Test Strategy for Flight Search WebsiteDocument13 pagesPlan Test Strategy for Flight Search WebsiteНаталья ПримаNo ratings yet

- Comparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626Document128 pagesComparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626phuongnhsfc100% (1)