Professional Documents

Culture Documents

SGS Academy Syllabus LSS Green Belt VIRTUAL - SGS Academy Special Price

Uploaded by

ASTRI yulia0 ratings0% found this document useful (0 votes)

103 views2 pagesOriginal Title

SGS Academy Syllabus LSS Green Belt VIRTUAL _SGS Academy Special Price

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

103 views2 pagesSGS Academy Syllabus LSS Green Belt VIRTUAL - SGS Academy Special Price

Uploaded by

ASTRI yuliaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

COURSE OUTLINES

LE AN SIX SIGMA GREEN BELT

CERTIFICATION PROGRAM BY SGS ACADEMY

DURATION (DAYS) 5 D A Y S ( T R A I N I N G + E X A M)

TRAINING OPTIONS Public (Virtual)

ACCREDITATION SGS INDONESIA

COURSEWARE

BAHASA INDONESIA

LANGUAGE

INVESTMENT

RP. 8.250.000,- (EXC PPN 10%)

(Special Price)

COURSE DESCRIPTION

The full-range learning and practice application of Lean Management and Six Sigma

methodology with process improvement business case study.Participant will learn the

concepts and practice the technical knowledge required to be able to improve the “No one can whistle a

business processes. symphony. It takes a

AUDIENCE PROFILE whole orchestra.”

This workshop is recommended for managers at all levels, from supervisors and

middle management. Team Leader or Supervisor who participate substantially in HE Luccock

process improvement are also encourage to attend.

PRE & POST COURSE REQUIREMENTS

As prerequisite, participant should have business case as a subject of process “Lean is about the total

improvement prior joining the course. Course will include 100 items of knowledge and elimination of waste

technical Aptitude Test. As part of the Certification, after joining the course participant

should follow up and provide Lean Six Sigma Project Report for qualification. and showing respect

for people.”

LEARNING OUTCOMES

Mark Grabban

By the end of the course participant will be able to:

Understand the mixture of Lean & Six Sigma concepts for process improvement.

Use various approach and tools in analysis and decision making for improvements.

Conduct a process improvement project implementation.

COURSE TOPICS

General Overview

Analyze

o Introduction to Lean

o Value and Waste Analysis

Management

o Graphical Analysis

o Introduction to Six Sigma

o Data Statistical Analysis

o Walkthrough Concept of

o Root Cause Analysis

Lean Six Sigma

o Understanding The Risk in

Define

Analyze Phase

o The Roadmap

Improvement

o Tree Diagram – thinking to

o Idea Generation

break the spots

o Cost & Benefits Analysis

o Chartering the Project

o Assessing Risk in

o Planning for Project Team

Improvement Phase

o Stakeholder Management

o Improvement Thinking

o Change Management

o Solution Selection

o Project Communication

o Decision Making

o VOC & CTQ

Control

o SIPOC

o Control Plan

Measure

o Visual Control

o Process Mapping

o Project Handover

o Cost of Poor Quality (COPQ)

o Post Implementation Review

o Data Collection and Sampling

(PIR)

o Measurement System

Knowledge & Technical Aptitude Test

o Normal Distribution

o 90 Question items – multiple

o Statistical Process Control

choice

o Process Stability

o 10 Question items – essay

o Process Capability

SGS Indonesia The Garden Centre 2nd - Cilandak Commercial Estate –

Jl. Raya Cilandak KKO

Phone ( 021) 29780600 Fax (021) 29780678

Jakarta, Indonesia www.sgs.com

SGS Indonesia The Garden Centre 2nd - Cilandak Commercial Estate –

Jl. Raya Cilandak KKO

Phone ( 021) 29780600 Fax (021) 29780678

Jakarta, Indonesia www.sgs.com

You might also like

- The Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsFrom EverandThe Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsRating: 3.5 out of 5 stars3.5/5 (5)

- Six Sigma Green BeltDocument4 pagesSix Sigma Green BeltJJ AsonyerNo ratings yet

- Six Sigma Green Belt Certification Project: Identification, Implementation and EvaluationFrom EverandSix Sigma Green Belt Certification Project: Identification, Implementation and EvaluationNo ratings yet

- Chapter 1introduction To Six SigmaDocument39 pagesChapter 1introduction To Six SigmaKaranShindeNo ratings yet

- Lean Six Sigma Green Belt PDFDocument4 pagesLean Six Sigma Green Belt PDFBùi Hoàng LongNo ratings yet

- Fundamentos de Seis Sigma (Nivel Yellow Belt) : CursoDocument237 pagesFundamentos de Seis Sigma (Nivel Yellow Belt) : CursoSergio Alejandro Aguilera RojoNo ratings yet

- ASQ Course Outline Lean Six Sigma Green Belt - ASQ - LSSGB01MSDocument4 pagesASQ Course Outline Lean Six Sigma Green Belt - ASQ - LSSGB01MSElitaZesfNo ratings yet

- Lean Six Sigma Green Belt TrainingDocument4 pagesLean Six Sigma Green Belt TrainingThắng TrángNo ratings yet

- Lean Six Sigma: Green Belt (Csse-Gb)Document10 pagesLean Six Sigma: Green Belt (Csse-Gb)pankaj100% (1)

- Syllabus - Lean SixsigmaDocument2 pagesSyllabus - Lean SixsigmajvanandhNo ratings yet

- Certified Lean Six Sigma Yellow Belt TrainingDocument2 pagesCertified Lean Six Sigma Yellow Belt TrainingChuckie GarciaNo ratings yet

- Six Sigma Awareness TrainingDocument4 pagesSix Sigma Awareness TrainingDerrickNo ratings yet

- Sixsigma OnlineDocument4 pagesSixsigma OnlineNeelakandan SiavathanuNo ratings yet

- ASQ - Course Outline Lean Six SIgma Black Belt Minitab - ASQ - LSSBBM01MS PDFDocument5 pagesASQ - Course Outline Lean Six SIgma Black Belt Minitab - ASQ - LSSBBM01MS PDFSalas J AlbertoNo ratings yet

- Industrial Management 2: Six Sigma OverviewDocument17 pagesIndustrial Management 2: Six Sigma OverviewYagnik prajapatiNo ratings yet

- Six Sigma Yellow BeltDocument59 pagesSix Sigma Yellow Beltahmed adelNo ratings yet

- Six Sigma: Process Improvement MethodologyDocument40 pagesSix Sigma: Process Improvement Methodologybabudukku100% (6)

- Six SigmaDocument58 pagesSix Sigmafarid agungNo ratings yet

- LSSGB Program BrochureDocument6 pagesLSSGB Program Brochurefatin wahabNo ratings yet

- 1 2 Introduction To Lean Six SigmaDocument32 pages1 2 Introduction To Lean Six SigmaTony AshrafNo ratings yet

- Lean Six Sigma Training and Certification IndexDocument18 pagesLean Six Sigma Training and Certification IndexadnaneNo ratings yet

- Lecture CombinedDocument1,291 pagesLecture CombinedgeorgeNo ratings yet

- The Software Development Life Cycle SDLCDocument23 pagesThe Software Development Life Cycle SDLCsapsdeccNo ratings yet

- Six Sigma Black Belt: Indian Statistical Institute SQC & or Unit HyderabadDocument5 pagesSix Sigma Black Belt: Indian Statistical Institute SQC & or Unit HyderabadPapaiNo ratings yet

- Six Sigma GreenBelt DetailsDocument4 pagesSix Sigma GreenBelt DetailsSheena MaiNo ratings yet

- Six Sigma Recap: BITS PilaniDocument32 pagesSix Sigma Recap: BITS PilaniFUNTV5No ratings yet

- Boutique Product Development CompanyDocument42 pagesBoutique Product Development CompanySaumya RayalNo ratings yet

- Six Sigma Green Belt CoursewareDocument144 pagesSix Sigma Green Belt CoursewareAdela M Bud100% (1)

- LSSI Lean Six Sigma International CertificationDocument12 pagesLSSI Lean Six Sigma International CertificationOrlando Arie Machuca GarciaNo ratings yet

- Lean Six SigmaDocument2 pagesLean Six SigmaNikhitaNo ratings yet

- CH 2 - Six Sigma & DmaicDocument97 pagesCH 2 - Six Sigma & DmaicMohd Amirul Bin YunosNo ratings yet

- Session 1 SS and LT CourseDocument12 pagesSession 1 SS and LT CourseUmesh VyasNo ratings yet

- GB - 5 - Define - Wrap Up and Action Items PDFDocument18 pagesGB - 5 - Define - Wrap Up and Action Items PDFEtienne VeronNo ratings yet

- Innovation & RND Management: Value Analysis/Value Engineering & New Product DevelopmentDocument24 pagesInnovation & RND Management: Value Analysis/Value Engineering & New Product Developmenthikam anggaNo ratings yet

- 6 SigmaDocument37 pages6 SigmaonelovejigarNo ratings yet

- 2 LSS DefineDocument22 pages2 LSS DefineAbdelaziz EldeebNo ratings yet

- Timesaver: Essential Presentation TemplatesDocument93 pagesTimesaver: Essential Presentation Templateslittlebuddy039275No ratings yet

- LSSGB (Simplilearn, 2014) - Lesson - 1. Overview of Lean Six SigmaDocument66 pagesLSSGB (Simplilearn, 2014) - Lesson - 1. Overview of Lean Six Sigmataghavi1347No ratings yet

- Six Sigma Green Belt Certification: Organized byDocument4 pagesSix Sigma Green Belt Certification: Organized byNeelakandan SiavathanuNo ratings yet

- An Introductionto Six SigmaDocument18 pagesAn Introductionto Six SigmaAmrNo ratings yet

- Six Sigma Black Belt CourseDocument4 pagesSix Sigma Black Belt CourseKhalńaayak JiNo ratings yet

- Program Outline - TÜV SÜD South Asia Certified Lean Six Sigma Green Belt (CLSSGB) PDFDocument4 pagesProgram Outline - TÜV SÜD South Asia Certified Lean Six Sigma Green Belt (CLSSGB) PDFShuvo036No ratings yet

- Go-Getters Guide To Dmaic: An Easy To Use, Comprehensive Reference For Completing Successful Lean Six Sigma ProjectsDocument8 pagesGo-Getters Guide To Dmaic: An Easy To Use, Comprehensive Reference For Completing Successful Lean Six Sigma ProjectsMony ES100% (1)

- Six Sigma at Ford: Achieving World Class Performance through Reduced VariabilityDocument31 pagesSix Sigma at Ford: Achieving World Class Performance through Reduced Variabilitydaredevil19901No ratings yet

- Module - 7 - Control PhaseDocument231 pagesModule - 7 - Control Phasemohmedkelioy1No ratings yet

- A Strategy For Achieving World Class Perfor-Mance A Strategy For Achieving World Class Perfor - ManceDocument19 pagesA Strategy For Achieving World Class Perfor-Mance A Strategy For Achieving World Class Perfor - ManceMOHD.ARISHNo ratings yet

- A Fictitious Six Sigma Green Belt Part IDocument19 pagesA Fictitious Six Sigma Green Belt Part IhalilpashaNo ratings yet

- MRII Lean 6 Sigma WorkshopDocument191 pagesMRII Lean 6 Sigma WorkshopDonna CincoNo ratings yet

- Productivity Improvement Through Six Sigma & KaizenDocument28 pagesProductivity Improvement Through Six Sigma & KaizenSanjay JajundaNo ratings yet

- Six Sigma Green Belt-1Document24 pagesSix Sigma Green Belt-1SunilNo ratings yet

- 2 How Is Six Sigma Implemented in The Laboratory Update 23 SeptemberDocument59 pages2 How Is Six Sigma Implemented in The Laboratory Update 23 SeptemberRendy widayat parlaunganNo ratings yet

- Research PaperDocument22 pagesResearch PaperRajamahanti Surya KiranNo ratings yet

- Day 1 - Yellow BeltDocument88 pagesDay 1 - Yellow BeltMister ItoldyaNo ratings yet

- Six Sigma: Not To Be Confused WithDocument11 pagesSix Sigma: Not To Be Confused WithJibin K JamesNo ratings yet

- An Introduction To Six Sigma QualityDocument18 pagesAn Introduction To Six Sigma Qualitygunjan tiwariNo ratings yet

- Green Belt Certification - Dec 2021Document3 pagesGreen Belt Certification - Dec 2021taufikNo ratings yet

- Lean Six SigmaDocument14 pagesLean Six Sigmababudukku100% (10)

- Introduction To Six SigmaDocument140 pagesIntroduction To Six SigmaAERON CASAONo ratings yet

- Isms Iso 27001 Idocia - FCDocument1 pageIsms Iso 27001 Idocia - FCASTRI yuliaNo ratings yet

- Online Public Training - LSS Green Belt (Feb-21)Document2 pagesOnline Public Training - LSS Green Belt (Feb-21)ASTRI yuliaNo ratings yet

- Proposal Penawaran Training PUB - Lead Implementer ISO 27001 HalodocDocument4 pagesProposal Penawaran Training PUB - Lead Implementer ISO 27001 HalodocASTRI yuliaNo ratings yet

- IT Risk ManagementDocument2 pagesIT Risk ManagementASTRI yuliaNo ratings yet

- Isms Iso 27001 Idocia - FCDocument1 pageIsms Iso 27001 Idocia - FCASTRI yuliaNo ratings yet

- Registration Form SGS AcademyDocument1 pageRegistration Form SGS AcademyASTRI yuliaNo ratings yet

- Online Public Training - LSS Green Belt (Feb-21)Document2 pagesOnline Public Training - LSS Green Belt (Feb-21)ASTRI yuliaNo ratings yet

- PT. Media Dokter Investama Proposal Public Training Six Sigma Green Belt Q527585Document16 pagesPT. Media Dokter Investama Proposal Public Training Six Sigma Green Belt Q527585ASTRI yuliaNo ratings yet

- Isms Iso 27001 Idocia - FCDocument1 pageIsms Iso 27001 Idocia - FCASTRI yuliaNo ratings yet

- SubtitleDocument1 pageSubtitlebradyNo ratings yet

- Quotation in House Training ISO 27001 - 2013Document2 pagesQuotation in House Training ISO 27001 - 2013ASTRI yuliaNo ratings yet

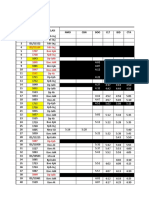

- Jadwal Web Update 16 April 2020Document114 pagesJadwal Web Update 16 April 2020yanuar buanaNo ratings yet

- Penghitungan Indeks Formula Eritrosit Pada Uji Saring Thalasemia MinorDocument7 pagesPenghitungan Indeks Formula Eritrosit Pada Uji Saring Thalasemia Minordiahnisa7No ratings yet

- An Introduction To Lean Six SigmaDocument4 pagesAn Introduction To Lean Six SigmaRosana SilvaNo ratings yet

- 2020.10 - Compiled Slides - LSSBB 1Document680 pages2020.10 - Compiled Slides - LSSBB 1DebashishDolonNo ratings yet

- Lean Six Sigma Green Belt Certification Training - BrochureDocument8 pagesLean Six Sigma Green Belt Certification Training - BrochureSean AkirangaNo ratings yet

- Day 1 - Yellow BeltDocument88 pagesDay 1 - Yellow BeltMister ItoldyaNo ratings yet

- Six Sigma Action PlanDocument16 pagesSix Sigma Action PlanJachson MedinaNo ratings yet

- Lean Six Sigma: A Literature Review: A Journal of Composition Theory ISSN: 0731-6755Document24 pagesLean Six Sigma: A Literature Review: A Journal of Composition Theory ISSN: 0731-6755alanNo ratings yet

- Full Course List 31 SFW and ConstructionFINAL2Document154 pagesFull Course List 31 SFW and ConstructionFINAL2NicholasFCheongNo ratings yet

- Tools of Lean Six Sigma PDFDocument6 pagesTools of Lean Six Sigma PDFAbhishek YadavNo ratings yet

- Six Sigma in BankingDocument39 pagesSix Sigma in BankingmainjailNo ratings yet

- Chapter 19 - Continual Improvement Methods With Six Sigma and LeanDocument8 pagesChapter 19 - Continual Improvement Methods With Six Sigma and LeanAhmad Ipul SyaifuddinNo ratings yet

- Introduction To Lean Six SigmaDocument19 pagesIntroduction To Lean Six SigmaSanketNo ratings yet

- QXC9EKAD Lean Six-Sigma CS Assignment #2ADocument16 pagesQXC9EKAD Lean Six-Sigma CS Assignment #2ARakib KhanNo ratings yet

- Cancer Center Improves Lab Specimen Labeling with Lean Six SigmaDocument6 pagesCancer Center Improves Lab Specimen Labeling with Lean Six SigmadrustagiNo ratings yet

- Six Sigma Banking SectorDocument26 pagesSix Sigma Banking SectorCharvi Ahuja100% (2)

- Six Sigma HealthcareDocument8 pagesSix Sigma HealthcareCasey MedinaNo ratings yet

- Greenbelt CurriculumDocument7 pagesGreenbelt Curriculumsan130781No ratings yet

- Lean Six Sigma - WikipediaDocument4 pagesLean Six Sigma - Wikipediakirthi83No ratings yet

- Porter's Generic Strategies (Business Level/ Competitive) :: I. Differentiation StrategyDocument16 pagesPorter's Generic Strategies (Business Level/ Competitive) :: I. Differentiation StrategyAhsan HabibNo ratings yet

- Unit 2 Lesson Guide in Tourism Hospitality MarketingDocument20 pagesUnit 2 Lesson Guide in Tourism Hospitality MarketingSalvacion CalimpayNo ratings yet

- Six Sigma Information PDFDocument17 pagesSix Sigma Information PDFFidel AragonNo ratings yet

- Kaizen A Tool For Continuous Quality Improvement IDocument8 pagesKaizen A Tool For Continuous Quality Improvement IAwadhut MaliNo ratings yet

- Lean Six SigmaDocument9 pagesLean Six SigmaSudah LupaNo ratings yet

- Lean Six Sigma EbookDocument68 pagesLean Six Sigma EbookBilal KaraNo ratings yet

- Overview of Lean Six Sigma: Presented by The University of Texas-School of Public HealthDocument22 pagesOverview of Lean Six Sigma: Presented by The University of Texas-School of Public Healthsobczak9marysiaNo ratings yet

- Improving Small Business Operations with Lean Six SigmaDocument15 pagesImproving Small Business Operations with Lean Six SigmaMayur NarsaleNo ratings yet

- PDFDocument322 pagesPDFvarun sehgalNo ratings yet

- IASSC LeanSixSigma BoK YellowBelt PDFDocument7 pagesIASSC LeanSixSigma BoK YellowBelt PDFFranco Raos0% (1)

- Review Yellow BeltDocument11 pagesReview Yellow BeltRyan Martinez100% (1)

- Lean Six Sigma Approach Autor Ait Business SolutionsDocument30 pagesLean Six Sigma Approach Autor Ait Business SolutionsGoran SpasićNo ratings yet

- Lean Six Sigma DMAIC ApproachDocument8 pagesLean Six Sigma DMAIC ApproachSteven Bonacorsi100% (4)

- The First Minute: How to start conversations that get resultsFrom EverandThe First Minute: How to start conversations that get resultsRating: 4.5 out of 5 stars4.5/5 (55)

- Spark: How to Lead Yourself and Others to Greater SuccessFrom EverandSpark: How to Lead Yourself and Others to Greater SuccessRating: 4.5 out of 5 stars4.5/5 (130)

- The Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverFrom EverandThe Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverRating: 4.5 out of 5 stars4.5/5 (186)

- How to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersFrom EverandHow to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersRating: 4.5 out of 5 stars4.5/5 (95)

- The 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsFrom EverandThe 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsRating: 4.5 out of 5 stars4.5/5 (411)

- Scaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0From EverandScaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0Rating: 5 out of 5 stars5/5 (1)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Leadership Skills that Inspire Incredible ResultsFrom EverandLeadership Skills that Inspire Incredible ResultsRating: 4.5 out of 5 stars4.5/5 (11)

- The 7 Habits of Highly Effective PeopleFrom EverandThe 7 Habits of Highly Effective PeopleRating: 4 out of 5 stars4/5 (2564)

- How to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobFrom EverandHow to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobRating: 4.5 out of 5 stars4.5/5 (36)

- Radical Candor by Kim Scott - Book Summary: Be A Kickass Boss Without Losing Your HumanityFrom EverandRadical Candor by Kim Scott - Book Summary: Be A Kickass Boss Without Losing Your HumanityRating: 4.5 out of 5 stars4.5/5 (40)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Work the System: The Simple Mechanics of Making More and Working Less (4th Edition)From EverandWork the System: The Simple Mechanics of Making More and Working Less (4th Edition)Rating: 4.5 out of 5 stars4.5/5 (22)

- Unlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsFrom EverandUnlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsRating: 4.5 out of 5 stars4.5/5 (27)

- Billion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsFrom EverandBillion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsRating: 4.5 out of 5 stars4.5/5 (52)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andFrom EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andRating: 4.5 out of 5 stars4.5/5 (709)

- How the World Sees You: Discover Your Highest Value Through the Science of FascinationFrom EverandHow the World Sees You: Discover Your Highest Value Through the Science of FascinationRating: 4 out of 5 stars4/5 (7)

- Work Stronger: Habits for More Energy, Less Stress, and Higher Performance at WorkFrom EverandWork Stronger: Habits for More Energy, Less Stress, and Higher Performance at WorkRating: 4.5 out of 5 stars4.5/5 (12)

- 7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthFrom Everand7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthRating: 5 out of 5 stars5/5 (51)

- The 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsFrom EverandThe 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsRating: 4.5 out of 5 stars4.5/5 (48)

- The 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsFrom EverandThe 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsRating: 4.5 out of 5 stars4.5/5 (90)

- Agile: The Insights You Need from Harvard Business ReviewFrom EverandAgile: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (34)

- The Other Kind of Smart: Simple Ways to Boost Your Emotional Intelligence for Greater Personal Effectiveness and SuccessFrom EverandThe Other Kind of Smart: Simple Ways to Boost Your Emotional Intelligence for Greater Personal Effectiveness and SuccessRating: 4.5 out of 5 stars4.5/5 (13)

- Good to Great by Jim Collins - Book Summary: Why Some Companies Make the Leap...And Others Don'tFrom EverandGood to Great by Jim Collins - Book Summary: Why Some Companies Make the Leap...And Others Don'tRating: 4.5 out of 5 stars4.5/5 (63)

- The Introverted Leader: Building on Your Quiet StrengthFrom EverandThe Introverted Leader: Building on Your Quiet StrengthRating: 4.5 out of 5 stars4.5/5 (35)

- Summary: Choose Your Enemies Wisely: Business Planning for the Audacious Few: Key Takeaways, Summary and AnalysisFrom EverandSummary: Choose Your Enemies Wisely: Business Planning for the Audacious Few: Key Takeaways, Summary and AnalysisRating: 4.5 out of 5 stars4.5/5 (3)

- Sustainability Management: Global Perspectives on Concepts, Instruments, and StakeholdersFrom EverandSustainability Management: Global Perspectives on Concepts, Instruments, and StakeholdersRating: 5 out of 5 stars5/5 (1)