Professional Documents

Culture Documents

Sts Qac Sop 001 CR RV Handling Procedure

Uploaded by

mohd as shahiddin jafriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sts Qac Sop 001 CR RV Handling Procedure

Uploaded by

mohd as shahiddin jafriCopyright:

Available Formats

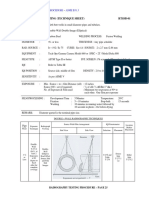

CV/RV HANDLING Doc No: STS/QAC/SOP/01

Rev No: 00

PROCEDURE Date Rev: 17 Dec 2008

Page No: 1 of 3

REVISION HISTORY

Rev Originator Description Of Amendments Date

00 Farid New Document 17.12.2008

Designation Name Signature

Originator Mechanical Eng Mohd Farid Abu Bakar

Reviewed

Approved

Controlled document: No part of this document may be printed or reproduced for external purposes

without the written permission of the management appointee of Science-Tech Solutions Sdn Bhd.

SCIENCE-TECH SOLUTIONS SDN BHD

1. SCOPE

This procedure shall be followed by personal involved in the handling of valves, transportation,

removal and installation of Control Valve and Relief Valves.

2. PROCEDURE

2.1. Dismantling of valves

2.1.1. Carefully dismantle the valve according to manuals and recommendations. Extra

precaution must be taken when breaking the flanges.

2.1.2. Equipment shall be depressurized.

2.1.3. Do not stand in line of fire when breaking the flanges

2.1.4. retighten immediately if line/equipment unable to depressurize completely and inform

supervisor.

2.1.5. Proper and correct facilities should be made available for lifting and transporting

valves from site to workshop.

2.1.6. At the stage of removal activity, all parts shall be visually inspected for evidence of

damage and/or corrosion.

2.1.7. All opened flanges must be blanked off. Use correct tools and gasket rating when

installing the end blind to its position.

2.1.8. For CV, engage Instrument Technician to dismantle instrument connection and re-

installation activities.

2.2. Transportation

2.2.1. All flanged safety valve/ control valve shall be shipped in a secure upright position, to

guard against damaging seats. Flange faces on the valve shall be protected so gasket

faces are not damage.

2.2.2. Take precautions not to drop or strike the valve

2.2.3. If valves is transported by truck, it shall be tied off to prevent from failing over or

striking with other valves. Mattress shall also be used as a support to avoid excessive

shock which could affect the pop pressure.

2.2.4. Do not pick up a valve by its lifting lever.

2.3. Valve Installation

2.3.1. After valve has been services and inspected, it shall be installed back at its original

location and position as per manuals and recommendation. For RV, perform initial pop

test to determine actual/ current set prior to dismantling.

2.3.2. Proper handling should be followed as per item 2.1 above.

2.3.3. Safety shall be followed and implemented during works. Approved JHA shall be

briefed, understand, implemented and visible at site at all times.

2.3.4. Follow JIT procedure for flange management as per MI procedures. (PSM-MI-20433)

3. Standard Operating Procedure.

3.1. Before start work, supervisor to ensure valid permit issued for work activities.

3.2. Workers shall wear proper PPE as per stated in PTW before starting any work.

3.3. House keeping the work area immediately after completion of works.

4. Appendix

4.1. Jab Hazard Analysis

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Piping Replacement Carbon Steel InspectionDocument3 pagesPiping Replacement Carbon Steel Inspectionmohd as shahiddin jafriNo ratings yet

- STS QAC SOP 016 Spring Hanger InspectionDocument6 pagesSTS QAC SOP 016 Spring Hanger Inspectionmohd as shahiddin jafriNo ratings yet

- STS Qac Sop 013 Insulation ProcedureDocument9 pagesSTS Qac Sop 013 Insulation Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 015 PSV ServicingDocument11 pagesSTS QAC SOP 015 PSV Servicingmohd as shahiddin jafri100% (1)

- STS Qac Sop 014 Burner MaintenanceDocument9 pagesSTS Qac Sop 014 Burner Maintenancemohd as shahiddin jafriNo ratings yet

- Inspection Test Plan: Piping (Carbon Steel)Document3 pagesInspection Test Plan: Piping (Carbon Steel)mohd as shahiddin jafriNo ratings yet

- Inspection Test Plan: Grinding, Build Up & ResurfaceDocument3 pagesInspection Test Plan: Grinding, Build Up & Resurfacemohd as shahiddin jafriNo ratings yet

- Inspection Test Plan: 1 QA/QC Document Submission & ApprovalDocument1 pageInspection Test Plan: 1 QA/QC Document Submission & Approvalmohd as shahiddin jafri100% (2)

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument5 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- Tube Plugging and Seal Welding ProcedureDocument7 pagesTube Plugging and Seal Welding Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 007 Repair Procedure For Carbon SteelDocument6 pagesSTS QAC SOP 007 Repair Procedure For Carbon Steelmohd as shahiddin jafriNo ratings yet

- Tube Plugging and Seal Welding ProcedureDocument7 pagesTube Plugging and Seal Welding Proceduremohd as shahiddin jafriNo ratings yet

- Sts Qac Sop 005 Joint Integrity ProcedureDocument32 pagesSts Qac Sop 005 Joint Integrity Proceduremohd as shahiddin jafriNo ratings yet

- HYDROSTATIC TEST PROCEDUREDocument11 pagesHYDROSTATIC TEST PROCEDUREmohd as shahiddin jafriNo ratings yet

- STS Qac Sop 003 Hydrotest ProcedureDocument8 pagesSTS Qac Sop 003 Hydrotest Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 002 Heat Exchanger Retubing ProcedureDocument4 pagesSTS Qac Sop 002 Heat Exchanger Retubing Proceduremohd as shahiddin jafri50% (2)

- Sts Qac Sop 005 Joint Integrity ProcedureDocument32 pagesSts Qac Sop 005 Joint Integrity Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 007 Repair Procedure For Carbon SteelDocument6 pagesSTS QAC SOP 007 Repair Procedure For Carbon Steelmohd as shahiddin jafriNo ratings yet

- STS Qac Sop 004 Inspection Test Plan ProcedureDocument9 pagesSTS Qac Sop 004 Inspection Test Plan Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 009 - 01 Liquid Penetrant Test ProcedureDocument6 pagesSTS QAC SOP 009 - 01 Liquid Penetrant Test Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 004 Inspection Test Plan ProcedureDocument9 pagesSTS Qac Sop 004 Inspection Test Plan Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument5 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- STS Qac Sop 002 Heat Exchanger Retubing ProcedureDocument4 pagesSTS Qac Sop 002 Heat Exchanger Retubing Proceduremohd as shahiddin jafri50% (2)

- STS Qac Sop 001 CR RV Handling ProcedureDocument3 pagesSTS Qac Sop 001 CR RV Handling Proceduremohd as shahiddin jafriNo ratings yet

- 7-Material Handling and Storage - WC007Document7 pages7-Material Handling and Storage - WC007mohd as shahiddin jafriNo ratings yet

- Visual Report (Test Ta2014) - 001-132Document211 pagesVisual Report (Test Ta2014) - 001-132mohd as shahiddin jafriNo ratings yet

- HYDROSTATIC TEST PROCEDUREDocument11 pagesHYDROSTATIC TEST PROCEDUREmohd as shahiddin jafriNo ratings yet

- STS Qac Sop 003 Hydrotest ProcedureDocument8 pagesSTS Qac Sop 003 Hydrotest Proceduremohd as shahiddin jafriNo ratings yet

- ATTACHMENT - ASME V RT TECHNIQUE SHEET - Part 2 (PAGES 25-33)Document9 pagesATTACHMENT - ASME V RT TECHNIQUE SHEET - Part 2 (PAGES 25-33)mohd as shahiddin jafriNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)