Professional Documents

Culture Documents

ATTACHMENT - ASME V RT TECHNIQUE SHEET - Part 2 (PAGES 25-33)

Uploaded by

mohd as shahiddin jafriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATTACHMENT - ASME V RT TECHNIQUE SHEET - Part 2 (PAGES 25-33)

Uploaded by

mohd as shahiddin jafriCopyright:

Available Formats

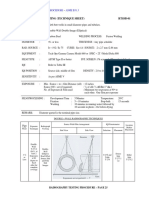

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.

3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-01

COMPONENT: Girth butt welds in small diameter pipes and tubulars.

TECHNIQUE : Double-Wall-Double-Image (Elliptical)

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : 3½ or less THICKNESS : Any pipe schedule

RAD. SOURCE : Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Source side, middle of film DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : 12 inches

Source Off – set (if required) : 1/5 of sfd (1/3 sfd for 1” dia.)

No. of Exposure & Film used : Minimum two exposures at 90o to

each other. One film per exposure

FILM PROCESSING : Development Time : 5 Minutes Temperature: 20oC

Fixation : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK: Diameter quoted is the nominal pipe size.

DOUBLE – WALL RADIOGRAPHIC TECHNIQUES

Source-Weld-Film Arrangement IQI Penetrameter Location

Pipe Exposure Radiograph

Marker

O.D. Technique Viewing

Placement

End View Side View Selection Placement

Double-

Wall:

T-271.2 Double-

(b)(1) at Wall

least 2 (Ellipse): Source

3½ Exposures T-276 and Either

Read Offset Side

or at 90 Table Side

Source Side T-277.1

Less degree to T-276 T-275.2

and Film (a)

Each Side

other for Images

complete

coverage

RADIOGRAPHY TESTING PROCEDURE – PAGE 25

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-02

COMPONENT: Girth butt welds in small diameter pipes and tubulars.

TECHNIQUE : Double-Wall-Double-Image (Super-imposed)

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : 3½” or less THICKNESS : Schedule 160

RAD. SOURCE : Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Source side, middle of film DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : 12 inches

Source Off – set (if required) : Not required

No. of Exposure & Film used : 4 exposures.

One film per exposure

FILM PROCESSING : Development Time : 5 Minutes Temperature: 20oC

Fixating : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK: Diameter quoted is the nominal pipe size.

DOUBLE – WALL RADIOGRAPHIC TECHNIQUES (CONT’D)

Source-Weld-Film Arrangement IQI Penetrameter Location

Pipe Exposure Radiograph

Marker

O.D. Technique Viewing

Placement

End View Side View Selection Placement

Double-

Wall:

T-271.2 Double-

(b)(2) at Wall: Read

least 3 Super-

Exposures imposed

3½ at 60 Source Side T-276 and Source Either

or degree or and Film Table Side T- Side

Less 120 Side T-276 277.1(a) T-275.2

degree to Images

Each

other for

complete

coverage

RADIOGRAPHY TESTING PROCEDURE – PAGE 26

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-03

COMPONENT: Girth butt welds in small diameter pipes and tubulars.

TECHNIQUE : Double-Wall-Double-Image (contact)

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : Any THICKNESS : Any schedule

RAD. SOURCE: Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Film side, middle of film DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : Pipe outside diameter

Source Off – set (if required) : Not required

No. of Exposure & Film used : 4 exposures 90o to each other.

One film per exposure

FILM PROCESSING : Development Time : 5 Minutes Temperature: 20oC

Fixating : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK: Diameter quoted is the nominal pipe size.

DOUBLE - WALL RADIOGRAPH TECHNIQUES

Source-Weld-Film Arrangement IQI Penetrameter Location

Pipe Exposure Radiograph

Marker

O.D. Technique Viewing

Placement

End View Side View Selection Placement

Double-

Wall: Source

T-271.2 Side

(a) at T-277.1

least 3 (a)

Exposures

120

degree to T-276 and Film Side

Each Single –

Any Table T-275.1

other for Wall

T-276 (b) (1)

complete

coverage Film Side

T-277.1

(b)

RADIOGRAPHY TESTING PROCEDURE – PAGE 27

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-04

COMPONENT: Girth and longitudinal butt welds in pipe and tubulars

TECHNIQUE : Single-Wall-Single-Image (Film Outside, Source Inside)

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : Any THICKNESS : Any pipe schedule

RAD. SOURCE : Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Film or source side, middle of film DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : Pipe diameter

Source Off – set (if required) : Not required

No. of Exposure & Film used : 6” and below – 4 exposure

Above 6” – 3 exposure (15”x 4”)

FILM PROCESSING : Development Time : 5 Minutes Temperature: 20oC

Fixation : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK: Diameter quoted is the nominal pipe size.

SINGLE - WALL RADIOGRAPH TECHNIQUES

Source-Weld-Film Arrangement IQI Penetrameter Location

Pipe Exposure Radiograph

Marker

O.D. Technique Viewing

Placement

End View Side View Selection Placement

Single –

Wall Source

T – 271.1 Side

T – 277.1

(a)

T-276 and Film Side

Single –

Any Table T-275.1

Wall

T-276 (a) (3)

Film Side

T-277.1

(b)

RADIOGRAPHY TESTING PROCEDURE – PAGE 28

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-05

COMPONENT: Girth butt welds in pipes and tubulars.

TECHNIQUE : Single-Wall-Single-Image (Panoramic)

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : Any THICKNESS : Any pipe schedule

RAD. SOURCE : Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Film or source side DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : Radio of pipes

Source Off – set (if required) : Not required

No. of Exposure & Film used : Single exposure

No. of films to be used depends on the pipe size

FILM PROCESSING : Development Time : 5 Minutes Temperature: 20oC

Fixation : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK: Diameter quoted is the nominal pipe size.

4 IQI at 90o to each other is acceptable if roll pack film

is used. Other wise at least 1 IQI per film.

SINGLE - WALL RADIOGRAPH TECHNIQUES

Source-Weld-Film Arrangement IQI Penetrameter Location

Pipe Exposure Radiograph

Marker

O.D. Technique Viewing

Placement

End View Side View Selection Placement

Source

Side

T-277.1

(a)

Single –

Wall

T-276 and Film Side

T-271.1 Single –

Any Table T-275.1

Wall

T-276 Film Side (b) (1)

T-277.1

(b)

RADIOGRAPHY TESTING PROCEDURE – PAGE 29

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-06

COMPONENT: Girth and longitudinal butt welds in pipes and tubulars.

TECHNIQUE : Double-Wall-Single-Image (contact)

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : Any THICKNESS : Any pipe schedule

RAD. SOURCE: Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T/ Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & 0.254mm back

IQI : Refer to Table III

IQI POSITION : Film or source side DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : Pipe diameter

Source Off – set (if required) : Not required

No. of Exposure & Film used : Minimum 3 exposures at 120o to

each other. 4 exposures for 8” pipe

schedule 160 or xxs. One film per

exposure.

FILM PROCESSING : Development Time: 5 Minutes Temperature: 20oC

Fixation : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK: Pipe diameter quoted is the nominal pipe size.

DOUBLE - WALL RADIOGRAPH TECHNIQUE

Source-Weld-Film Arrangement IQI Penetrameter Location

Pipe Exposure Radiograph

Marker

O.D. Technique Viewing

Placement

End View Side View Selection Placement

Double-

Wall: Source

T-271.2 Side

(a) at T-277.1

least 3 (a)

Exposures

120 T-276 and Film Side

Single –

Any degree to Table T-275.1

Wall

Each T-276 (b) (1)

other for

complete Film Side

coverage T-277.1

(b)

RADIOGRAPHY TESTING PROCEDURE – PAGE 30

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-07

COMPONENT : Girth and longitudinal butt welds in pipes and tubulars.

TECHNIQUE : Single-Wall-Single-Image (Film Inside, Source Outside)

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : Any THICKNESS : Any pipe schedule

RAD. SOURCE: Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Source side DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : 12 inches

Source Off – set (if required) : Not required

No. of Exposure & Film used : Minimum 4 exposures at 90o to each

other for girth buttwelds. One film

per exposure.

FILM PROCESSING : Development Time : 5 Minutes Temperature: 20oC

Fixation : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK: Pipe diameter quoted is the nominal pipe size.

SINGLE - WALL RADIOGRAPH TECHNIQUES

Source-Weld-Film Arrangement IQI Penetrameter Location

Pipe Exposure Radiograph

Marker

O.D. Technique Viewing

Placement

End View Side View Selection Placement

Source

Side

T-277.1

(a)

Single –

Wall Source

T-276 and

T-271.1 Single – Side

Any Table

Wall T-275.1

T-276

(a) (3)

Film Side

T-277.1

(b)

RADIOGRAPHY TESTING PROCEDURE – PAGE 31

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-08

COMPONENT : Butt welds in flat position – example butt welds in plates and web of wide flange beams.

TECHNIQUE : Single-Wall-Single-Image

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : N. A. THICKNESS : 6mm and above

RAD. SOURCE: Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Source side DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : 12 inches

Source Off – set (if required) : Not required

No. of Exposure & Film used : One or more films per exposure

FILM PROCESSING : Development Time: 5 Minutes Temperature: 20oC

Fixation : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK:

SKETCH

i. Butt in Beam ii. Butt weld in plate

IQI

flange IQI

source

x Film

web

IQI

X – Sectional view

Side View x

Film

X Location Marker

RADIOGRAPHY TESTING PROCEDURE – PAGE 32

SHAMIRA SDN BHD RT PROCEDURE – ASME B31.3

2016 REV.0

RADIOGRAPHIC TESTING (TECHNIQUE SHEET) RTSSB-09

COMPONENT : Butt welds in flange of wide flange beam.

TECHNIQUE : Single-Wall-Single-Image

MATERIAL : Carbon Steel WELDING PROCESS: Fusion Welding

DIAMETER : N. A. THICKNESS : 4mm and above

RAD. SOURCE : Ir – 192 / Se 75 CURIE: See 4.4 SOURCE: 2 x 2.7 mm /2.86 mm

EQUIPMENT : Tech-Ops Gamma Camera Model 660 or SPEC – 2T / Model Delta 880

FILM TYPE : ASTM Type II or better INT. SCREEN : Pb screen-0.125mm front & back

IQI : Refer to Table III

IQI POSITION : Source side DENSITY : 2.0 to 4.0 H & D

SENSITIVITY : As per ASME V

EXPOSURE : Min. Source – to – film Distance (sfd) : 12 inches or depth of beam

whichever is less.

Source Off – set (if required) : Not required

No. of Exposure & Film used : At least two separate exposures. One or more films

per exposure depending on sfd and effective film

length.

FILM PROCESSING : Development Time : 5 Minutes Temperature: 20oC

Fixation : 5 – 10 minutes Stop-bath : 15 seconds

Washing : 10 minutes in running water followed by

10 seconds in photo – flo before drying

REMARK:

SKETCH

Film Film

x x

IQI IQI

Weld

Source

Side View X – sectional view

RADIOGRAPHY TESTING PROCEDURE – PAGE 33

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Inspection Test Plan: Piping (Carbon Steel)Document3 pagesInspection Test Plan: Piping (Carbon Steel)mohd as shahiddin jafriNo ratings yet

- Inspection Test Plan: Grinding, Build Up & ResurfaceDocument3 pagesInspection Test Plan: Grinding, Build Up & Resurfacemohd as shahiddin jafriNo ratings yet

- Piping Replacement Carbon Steel InspectionDocument3 pagesPiping Replacement Carbon Steel Inspectionmohd as shahiddin jafriNo ratings yet

- STS QAC SOP 007 Repair Procedure For Carbon SteelDocument6 pagesSTS QAC SOP 007 Repair Procedure For Carbon Steelmohd as shahiddin jafriNo ratings yet

- STS QAC SOP 016 Spring Hanger InspectionDocument6 pagesSTS QAC SOP 016 Spring Hanger Inspectionmohd as shahiddin jafriNo ratings yet

- Sts Qac Sop 005 Joint Integrity ProcedureDocument32 pagesSts Qac Sop 005 Joint Integrity Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 013 Insulation ProcedureDocument9 pagesSTS Qac Sop 013 Insulation Proceduremohd as shahiddin jafriNo ratings yet

- Inspection Test Plan: 1 QA/QC Document Submission & ApprovalDocument1 pageInspection Test Plan: 1 QA/QC Document Submission & Approvalmohd as shahiddin jafri100% (2)

- Tube Plugging and Seal Welding ProcedureDocument7 pagesTube Plugging and Seal Welding Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 015 PSV ServicingDocument11 pagesSTS QAC SOP 015 PSV Servicingmohd as shahiddin jafri100% (1)

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument5 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- STS QAC SOP 007 Repair Procedure For Carbon SteelDocument6 pagesSTS QAC SOP 007 Repair Procedure For Carbon Steelmohd as shahiddin jafriNo ratings yet

- STS Qac Sop 003 Hydrotest ProcedureDocument8 pagesSTS Qac Sop 003 Hydrotest Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 014 Burner MaintenanceDocument9 pagesSTS Qac Sop 014 Burner Maintenancemohd as shahiddin jafriNo ratings yet

- Sts Qac Sop 001 CR RV Handling ProcedureDocument3 pagesSts Qac Sop 001 CR RV Handling Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 002 Heat Exchanger Retubing ProcedureDocument4 pagesSTS Qac Sop 002 Heat Exchanger Retubing Proceduremohd as shahiddin jafri50% (2)

- HYDROSTATIC TEST PROCEDUREDocument11 pagesHYDROSTATIC TEST PROCEDUREmohd as shahiddin jafriNo ratings yet

- Sts Qac Sop 005 Joint Integrity ProcedureDocument32 pagesSts Qac Sop 005 Joint Integrity Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 009 - 01 Liquid Penetrant Test ProcedureDocument6 pagesSTS QAC SOP 009 - 01 Liquid Penetrant Test Proceduremohd as shahiddin jafriNo ratings yet

- Tube Plugging and Seal Welding ProcedureDocument7 pagesTube Plugging and Seal Welding Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 001 CR RV Handling ProcedureDocument3 pagesSTS Qac Sop 001 CR RV Handling Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 003 Hydrotest ProcedureDocument8 pagesSTS Qac Sop 003 Hydrotest Proceduremohd as shahiddin jafriNo ratings yet

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument5 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- STS Qac Sop 004 Inspection Test Plan ProcedureDocument9 pagesSTS Qac Sop 004 Inspection Test Plan Proceduremohd as shahiddin jafriNo ratings yet

- STS Qac Sop 002 Heat Exchanger Retubing ProcedureDocument4 pagesSTS Qac Sop 002 Heat Exchanger Retubing Proceduremohd as shahiddin jafri50% (2)

- STS Qac Sop 004 Inspection Test Plan ProcedureDocument9 pagesSTS Qac Sop 004 Inspection Test Plan Proceduremohd as shahiddin jafriNo ratings yet

- ATTACHMENT - ASME V RT TECHNIQUE SHEET - Part 2 (PAGES 25-33)Document9 pagesATTACHMENT - ASME V RT TECHNIQUE SHEET - Part 2 (PAGES 25-33)mohd as shahiddin jafriNo ratings yet

- 7-Material Handling and Storage - WC007Document7 pages7-Material Handling and Storage - WC007mohd as shahiddin jafriNo ratings yet

- HYDROSTATIC TEST PROCEDUREDocument11 pagesHYDROSTATIC TEST PROCEDUREmohd as shahiddin jafriNo ratings yet

- Visual Report (Test Ta2014) - 001-132Document211 pagesVisual Report (Test Ta2014) - 001-132mohd as shahiddin jafriNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- General Duty In-Line Mixer: Technical Data SheetDocument1 pageGeneral Duty In-Line Mixer: Technical Data Sheetالسماني احمدNo ratings yet

- Pipe Stress Analysis Design BasisDocument25 pagesPipe Stress Analysis Design Basischandru683100% (3)

- 50Hz Water Solutions N Series Data BookletDocument67 pages50Hz Water Solutions N Series Data BookletKhang TrầnNo ratings yet

- Return Line Filter RF: Up To 15000 L/min, Up To 25 BarDocument10 pagesReturn Line Filter RF: Up To 15000 L/min, Up To 25 BarnidishNo ratings yet

- Plumbing Safety Tips for Any JobDocument46 pagesPlumbing Safety Tips for Any JobJulius KipropNo ratings yet

- WSHR enDocument8 pagesWSHR enkaoblekstenaNo ratings yet

- Teknopoli: North American ConnectionsDocument39 pagesTeknopoli: North American ConnectionsKishor JadhavNo ratings yet

- Alabama power cooling water pipe scheduleDocument5 pagesAlabama power cooling water pipe scheduleMegan BrewerNo ratings yet

- Slip StreamDocument1 pageSlip StreamvietsdsNo ratings yet

- HPCO2 TechnicianDocument104 pagesHPCO2 TechnicianAbdelrahim OdehNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Bill of Material: Angle PN Material Standard ND Description Unit QuantityDocument3 pagesBill of Material: Angle PN Material Standard ND Description Unit QuantityMuhammad NuhNo ratings yet

- Gestión de proyectos de infraestructura - Especificaciones de válvulasDocument1 pageGestión de proyectos de infraestructura - Especificaciones de válvulasJOHNNY ROMERONo ratings yet

- Mcnichols Gratings Catalog PDFDocument28 pagesMcnichols Gratings Catalog PDFyugandhar singhNo ratings yet

- Flutec High Pressure Ball ValveDocument2 pagesFlutec High Pressure Ball ValvefahazumeeNo ratings yet

- Sistema de Lubricacion Pump HorizontalesDocument16 pagesSistema de Lubricacion Pump HorizontalesRodríguez EdwardNo ratings yet

- Sizing Charts For Pipe Fittings Flanges and AccessoriesDocument61 pagesSizing Charts For Pipe Fittings Flanges and AccessoriesahmedNo ratings yet

- Sanitary Specifications - RDDocument13 pagesSanitary Specifications - RDRaymundo DelfinNo ratings yet

- Shan-Rod Fabricated Butterfly Valves 4300 Series: Bulletin 4300Document4 pagesShan-Rod Fabricated Butterfly Valves 4300 Series: Bulletin 4300drNo ratings yet

- Schedule of Rates For Watermain Construction in Sarawak 2020Document35 pagesSchedule of Rates For Watermain Construction in Sarawak 2020Ryan LaiNo ratings yet

- Building Brochure - Sadef - 2020 - EN - WEBDocument55 pagesBuilding Brochure - Sadef - 2020 - EN - WEBGetahun AmareNo ratings yet

- Air Compressor Attachment PartsDocument5 pagesAir Compressor Attachment PartsKarthii AjuNo ratings yet

- 东风康明斯发动机备件目录Document27 pages东风康明斯发动机备件目录Handri AksaNo ratings yet

- Piping Stress Handbook - by Vi 1Document121 pagesPiping Stress Handbook - by Vi 1Med RjebNo ratings yet

- BSI-British Standard ValvesDocument3 pagesBSI-British Standard ValvesVincent RajNo ratings yet

- Enerpac LPHT312: Operation & Maintenance ManualDocument26 pagesEnerpac LPHT312: Operation & Maintenance ManualMohammed Al-BayatiNo ratings yet

- Vane Gaz Honeywell PDFDocument16 pagesVane Gaz Honeywell PDFCezaryCezasNo ratings yet

- Pub020 014 00 0620Document90 pagesPub020 014 00 0620Aman MeidanlooNo ratings yet

- Spraying Systems Tank WashDocument52 pagesSpraying Systems Tank Washavi07me4uNo ratings yet

- Bends - Route SelectionDocument6 pagesBends - Route SelectionanishsrNo ratings yet