Professional Documents

Culture Documents

Torqued S

Uploaded by

AndyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torqued S

Uploaded by

AndyCopyright:

Available Formats

The Importance of Tightening Torque

The Problem

Most Engineers already know the importance of a high

A survey of car service managers preload in maintaining joint integrity. For torque

completed in the United States, controlled tightening, achieving the right preload is

indicated that 23% of all service dependent upon the correct tightening torque being

problems were traceable to loose specified. Without the proper analytical tools and

fasteners. Such problems are information, specifying the correct torque can be

common across many industries. A problematical. Whether you are a Service or a Design

major cause of fastener loosening Engineer, you frequently need to know what is the

is inadequate tightening. A single correct tightening torque. For many types of threaded

bolt, inaccurately or incorrectly fasteners, this information is either not available, or not

tightened, can lead to the failure of readily available.

the complete product. The TORQUE program can help by providing

you with a state of the art tool that will assist you in

Program Overview establishing what is the correct torque for a given set of

conditions and what the preload value will be.

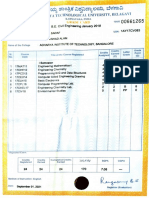

TORQUE is designed for use under the Microsoft Presented at below is the data entry screen

Windows operating system and will determine the (when metric units have been selected) from the

tightening torque and preload for a threaded fastener. TORQUE program showing the ease at which data can

The program is designed to assist the Engineer in the be entered. Once the thread diameter has been entered,

solution of problems related to the torque tightening of default values (that can be edited) are filled in

threaded fasteners. The program determines both automatically by the program.

tensile stress due to the elongation of the fastener, and

the torsional stress due to the applied torque. It

accounts for the frictional effects in the thread and

between the nut face and clamped surface. Account

can also be made for the effects of a reduced shank

diameter (smaller than the thread size) and a prevailing

torque. The prevailing torque is the torque required to

run a nut down a thread before engagement with the

joint surface. This resistance can be provided by a

nylon insert, a distorted thread profile or the use of a

thread adhesive. A prevailing torque can significantly

affect the amount of preload provided by the fastener

for a given tightening torque.

Torque Controlled Tightening

Help

The most prevalent controlled method of tightening

threaded fasteners is by tightening so that a specified Help is available which can furnish information

torque is achieved. This method is generally known as relating to both the program and to threaded

torque control. The major problem related to this fasteners in general.

method is that the fastener clamp force (referred to as An in-built database is provided containing

preload) generated as the result of an applied torque information appertaining to thread pitch, root,

depends upon the fastener design and the prevailing effective and nut bearing diameters for standard

frictional conditions. Despite the problems of potentially fasteners. The default metric coarse thread data used

large preload variations occurring at the same torque by the program can be changed to metric fine,

level, torque control is still the most popular way of Unified Coarse or Unified Fine by selecting the

ensuring that an assembled bolt complies with an appropriate menu option. The program can also use

engineering specification. This is due to its simplicity metric or imperial units.

and its widespread understanding by all engineers.

Analysis of Bolted Joints Example Problem

A great deal of sophistication can nowadays be applied Presented below is the analysis output by the

to the analysis of structures. Frequently however, the TORQUE program for a M12 fastener.

assumptions made in the analysis regarding the value

TORQUE TIGHTENING ANALYSIS RESULTS

of a bolt’s preload is often simplistic considering the

effort frequently placed on establishing the correctness FASTENER THREAD DETAILS

of data. Frequently, this can be a fatal flaw in the Thread Details: M12 x 1.75 Coarse Thread

structural analysis. Fluctuation in a bolt’s preload is Fastener Diameter = 12.000 mm

Thread Pitch = 1.750 mm

mainly caused by variations in the frictional conditions

Fastener Shank Diameter = 12.000 mm

and the method of tightening being used. If this Basic Thread Pitch Diameter = 10.863 mm

fluctuation is outside the assumed value, product Basic Thread Root Diameter = 9.853 mm

reliability problems can result. Such reliability problems

ADDITIONAL THREAD/FASTENER DETAILS

can manifest themselves as fluid leakage past a

Fastener Clearance Hole Diameter = 13.00 mm

gasket, fatigue failure of the bolt itself or of the whole Fastener Inner Bearing Diameter = 13.00 mm

joint. Being able to predict what will be the fastener Diameter related to the Thread Stress Area = 10.358 mm

preload can be crucial to the reliability of a product. Thread Stress Area = 84.267 mm²

Thread Root Area = 76.247 mm²

Fastener Shank Cross Sectional Area = 113.097 mm²

Friction Diameter of Bolt Head/Nut = 14.800 mm

Bearing Area under Nut/Bolt Head = 83.692 mm²

Fastener Head Outer Bearing Diameter = 16.600 mm

FASTENER PROPERTY DETAILS

Standard for Fastener Material: ISO 898-1 Mechanical properties of

fasteners made of carbon steel and alloy steel.

Property Class or Fastener Grade = 8.8

Fastener Yield Strength = 640.00 N/mm²

JOINT ASSEMBLY DETAILS

Thread Frictional Conditions: Zinc Flake Coating

Thread Friction Value = 0.120

Underhead Frictional Conditions: Zinc Flake Coating

Nut/Bolt Head Friction Value = 0.120

FASTENER TIGHTENING ANALYSIS

Yield Point Tightening Factor specified = 0.90

Total Tightening Torque = 82.737 Nm

Versatile Analysis Options Torque needed to extend the fastener = 12.007 Nm

Torque needed to overcome thread friction = 32.447 Nm

The program will work either in metric or imperial Torque needed to overcome nutface friction = 38.283 Nm

units, the analysis options include the determination Prevailing Torque Value Specified = 0.000 Nm

Fastener Preload = 43111.24 N

of : Direct Force that would Yield the Fastener = 53930.57 N

a) The tightening torque and preload so that a given

stress level is achieved in the fastener. STRESSES INDUCED INTO THE FASTENER

b) The tightening torque having specified the Percentage of the yield strength utilised = 90.00 %

Von-Mises Equivalent Stress = 576.00 N/mm²

preload required. Tensile Stress due to Preload = 511.61 N/mm²

c) The preload having specified the tightening Surface Pressure under the Fastener Face = 515.12 N/mm²

torque.

Bolt Science Limited

Victoria House, 16 Rotherwick Ave., Chorley

Lancashire, PR7 2PY England

Tel: +44 (0)1257 411503

Fax: +44 (0)1257 411650

URL: www.boltscience.com

Email: info@boltscience.com

TORQUE is produced and marketed by Bolt Science Limited. A

demonstration program is available from our website which also

provides additional information related to bolted joint technology.

Bolt Science reserves the right to improve this product without

notice. This data sheet is the property of Bolt Science Limited and is

protected by copyright. Copyright © 2018 Bolt Science Limited. All

rights reserved.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- OceanofPDF - Com Alkaline Diet and Herbal Medical by DR Se - Henry BeatDocument112 pagesOceanofPDF - Com Alkaline Diet and Herbal Medical by DR Se - Henry BeatKristine GerbolingoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Van Halen Rising by Greg Renoff PDFDocument372 pagesVan Halen Rising by Greg Renoff PDFAdrian ReynosoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2015 Nissan Service Maintenance GuideDocument70 pages2015 Nissan Service Maintenance GuideAhmed Almaghrby100% (2)

- L2 AND L3 Switch DifferenceDocument6 pagesL2 AND L3 Switch DifferenceVivek GhateNo ratings yet

- Module 5 Developing Mission, Vision, and ValuesDocument25 pagesModule 5 Developing Mission, Vision, and ValuesMatthew ScarellaNo ratings yet

- PM Speed Adjusting Motor For PSGDocument2 pagesPM Speed Adjusting Motor For PSGFathima Regin100% (2)

- QradarDocument112 pagesQradarOleg PadurariNo ratings yet

- ASE2000 Version 2 User Guide DNP3 Serial and LAN/WAN ProtocolsDocument30 pagesASE2000 Version 2 User Guide DNP3 Serial and LAN/WAN Protocolsjacastillo68No ratings yet

- A5E43455517 6 76 - MANUAL - SITOP Manager - en USDocument252 pagesA5E43455517 6 76 - MANUAL - SITOP Manager - en USdasdNo ratings yet

- Li Fi TechnologyDocument15 pagesLi Fi TechnologyParmeshprasad Rout100% (1)

- COT 1 - (Science 7) - Cell To Biosphere 4as Semi-Detailed LPDocument10 pagesCOT 1 - (Science 7) - Cell To Biosphere 4as Semi-Detailed LPARLENE AGUNOD100% (1)

- ISO 542 (Sampling OIlseeds)Document12 pagesISO 542 (Sampling OIlseeds)FIDEL CANELOS100% (2)

- (EIE529) Assignment 2Document3 pages(EIE529) Assignment 2JefferyMak100% (1)

- BSC MSC PHD Scholarships by DR Oluseun Ajayi 1673218909 PDFDocument3 pagesBSC MSC PHD Scholarships by DR Oluseun Ajayi 1673218909 PDFInnocent MataazNo ratings yet

- PRP ConsentDocument4 pagesPRP ConsentEking InNo ratings yet

- Measure and IntegralDocument5 pagesMeasure and Integralkbains7No ratings yet

- JLG Skytrak Telehandler 6042 Operation Service Parts ManualsDocument22 pagesJLG Skytrak Telehandler 6042 Operation Service Parts Manualschristyross211089ntz100% (133)

- Air Quality Report - SWDocument43 pagesAir Quality Report - SWromesh 96No ratings yet

- Polycab Pricelist 21-01-2019Document5 pagesPolycab Pricelist 21-01-2019KULDEEP TRIPATHINo ratings yet

- Technology,: OF Credits EarnedDocument8 pagesTechnology,: OF Credits EarnedAATISH KUMARNo ratings yet

- William Blomquist: Education SUNY Plattsburgh Work Experience Costco WholesaleDocument1 pageWilliam Blomquist: Education SUNY Plattsburgh Work Experience Costco WholesaleWilliam BlomquistNo ratings yet

- Academic and Occupational English Needs of Tourism and Hotel Management Students Oral Communication Skills in FocusDocument136 pagesAcademic and Occupational English Needs of Tourism and Hotel Management Students Oral Communication Skills in FocusYeneneh WubetuNo ratings yet

- Unit Plan Lesson 1 - 3Document16 pagesUnit Plan Lesson 1 - 3api-547362187No ratings yet

- Nandana Varusha PanchangamDocument49 pagesNandana Varusha Panchangamsangeethac11No ratings yet

- How To Utilize Different Keyboards in Java MEDocument7 pagesHow To Utilize Different Keyboards in Java MEKalvin Kae TacdoroNo ratings yet

- Ch16 Cost Allocation Joint Products and ByproductsDocument11 pagesCh16 Cost Allocation Joint Products and ByproductsChaituNo ratings yet

- A Literary Voyage Into The Unconscious: A Philosophical Approach To The Psychological Novel in Woolf's Mrs. Dalloway (1925)Document10 pagesA Literary Voyage Into The Unconscious: A Philosophical Approach To The Psychological Novel in Woolf's Mrs. Dalloway (1925)Muhammad IbrahimNo ratings yet

- Sergey Kojoian Graph Theory NotesDocument11 pagesSergey Kojoian Graph Theory NotesSergey KojoianNo ratings yet

- Impact of COVID-19 On Student LifeDocument10 pagesImpact of COVID-19 On Student LifeZunii MalikNo ratings yet

- IPC Lab 9Document12 pagesIPC Lab 9abdullah1996No ratings yet