Professional Documents

Culture Documents

Polia Sincronizadora L

Uploaded by

José Luiz NovelinoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polia Sincronizadora L

Uploaded by

José Luiz NovelinoCopyright:

Available Formats

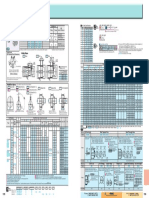

Timing Pulleys L Type

QFor Timing Belts, refer to W P.1177, for Long Timing Belts, refer to W P.1187, for Keyless Timing Pulleys, refer to W P.1139, for Idlers with Teeth, refer to W P.1161

QInch Hole Specifications - ATPA / ATPT / ATP / ATPP

Part Number M Material

No. Nominal Dimension(mm) 6 Express A $8.00/piece D P.88

Belt Width 12.7mm Belt Width 19.1mm Belt Width 25.4mm Belt Width 38.1mm S

A 1/8 3.175 ENon-Returnable P.88 EA flat charge of $21.60 for 3 or more identical pieces

(1/2inch) (3/4inch) (1inch) (1.5inch) Pulley Flange Surface Treatment

B 3/16 4.763

A:14W:19L:31 (39) A:21W:26L:38 (46) A:27W:32L:44 (53) A:40W:45L:57

C 1/4 6.350 - ATPB / ATPK / ATPN

ATPA_ _L050 ATPA_ _L075 ATPA_ _L100 ATPA_ _L150 Clear Anodize

ATPB_ _L050 ATPB_ _L075 ATPB_ _L100 ATPB_ _L150

7075

Aluminum

5052 Black Anodize

D 5/16 7.938 8

Aluminum E 3/8 9.525

ATPK_ _L050 ATPK_ _L075 ATPK_ _L100 ATPK_ _L150 Alloy Hard Clear Anodize* ENon-Returnable P.88

Alloy F 1/2 12.700

ATPN_ _L050 ATPN_ _L075 ATPN_ _L100 ATPN_ _L150 (Extra Super Duralumin) Electroless Nickel Plating

G 5/8 15.875

ATPT_ _L050 ATPT_ _L075 ATPT_ _L100 ATPT_ _L150 - QVolume Discount Rate EThe body price is the unit price in the table multiplied by 1.05 for ATP, 1.1 for ATPB / ATPK, coefficient 1.15 for

1045 Carbon Low Carbon H 3/4 19.050

ATP_ _L050 ATP_ _L075 ATP_ _L100 ATP_ _L150 Black Oxide Quantity 1~4 5~9 10~14 15~ ATPP, 1.2 for ATPN.

Steel Steel J 7/8 22.225

ATPP_ _L050 ATPP_ _L075 ATPP_ _L100 ATPP_ _L150 Electroless Nickel Plating Rate Unit Price 5% 10% 15% EProduct price is the sum of body price and shaft bore machining charge.

K 1 25.400 EFor larger quantity orders "Days to Ship" may differ from published catalog term.D P.87

EFlanges are installed. Set screws are included with P, N & C bore hole specification. *Hard Anodize Treatment: Film Hardness 300HV~ EH, HU bore machining is free of charge.

E L dimensions in ( ) are for 60~72 toothed pulleys. L 1-1/4 31.750

*L M 1-3/8 34.925

*W

•Pulley Shape *L

Tooth Profile *W *W *L N 1-1/2 38.100

(ISO Standard Rack Dimensions) 2.5 *A 2.5

A Shape B Shape *W 2−M*2 2 D Shape *L 2−M*2 2 P 1-5/8 41.275

2.5 *A 2.52 2.5 *A 2.5 7 2−M* *W 2−M*

20° 20° 2−M* W/2 *A 2.5 *W11 Q 1-3/4 44.450

20° 20° W/2 2−M* 2

2.5 7 11

QTapped Hole Dimensions R 1-7/8 47.625

(Shaft Bore: P / N / C) S 2 50.800

86

2.136

R0.53 R0.

dH7 M Accessory

8

R0.

Body Price

2.13

O.D.

Shaft Bore Inner Dia. (Coarse) Set Screw Shaft Bore Machining

P.D.

O.D. R0.53

O.D.

O.D.

DO.D.

P.D.

FP.D.

P.D.

ATPA(x1.0)ATPB / ATPK(x1.1) ATPN(x1.2) ATPT(x1.0) ATP(x1.05) ATPP(x1.15)

P.D.

6.3 6.3 Charge

EdH7

dH7

dH7

6.3

3.10

D

6~12

E

DE

E

EF

EF

M4 M4x3

O.D.

O.D.

O.D.

Teeth

P.D.

P.D.

P.D.

6.3 6.3

dH7

dH7

dH7

6.3 (Body Price +)

3.10

F

L050 L075 L100 L150 L050 L075 L100 L150

13~17 M5 M5x4

AShape BShape AShape BShape AShape BShape AShape BShape AShape B-DShape AShape B-DShape AShape B / DShape AShape BShape P / PU CN // VNU Y

Tooth groove dimensions slightly H H 18~30 M6 M6x5 /F

change according to No. of teeth. H H 31~45 M8 M8x6 10 20.60 24.50 - - - - - - 18.90 22.10 - - - - - - 6.40 10.50 16.90

1

t1.6 1 t1.6 46~65 M10 M10x8 12 21.70 24.90 23.70 28.00 - - - - 19.50 22.10 21.20 24.70 - - - - 6.40 10.50 16.90

(Pitch: 9.525mm) t1.6 t1.6 H Dimension L050= 5 14 22.00 25.60 24.30 29.10 27.80 32.30 37.70 44.00 19.50 22.40 21.20 25.20 24.40 28.00 30.40 35.00 6.90 11.40 18.10

L075=L050=

H Dimension 8 5

*1 t=2.0 for 60 and 72 toothed pulleys (Cut Flange). L075= 8

L100=11 15 22.20 26.00 24.70 29.60 28.30 32.90 38.40 44.80 19.50 22.40 21.30 25.20 24.40 28.00 30.40 35.00 6.90 11.40 18.10

*2 Shaft Bore Specifications H (Round Hole), V,F (Stepped Hole) and Y (Both Sides Stepped Hole), do not have tapped holes. L100=11 16 23.40 27.50 25.70 29.80 31.70 34.60 43.10 47.10 20.70 23.70 22.40 25.40 27.60 29.50 34.50 36.90 6.90 12.00 18.90

17 24.20 28.90 26.80 31.40 33.00 36.40 44.90 49.60 20.70 23.70 22.40 25.40 27.60 29.50 34.50 36.90 6.90 12.00 18.90

18 24.50 28.80 27.60 31.60 33.20 37.70 45.20 51.30 20.90 23.90 23.20 25.90 27.90 31.10 34.90 38.90 9.00 13.10 20.30

•Shaft Bore Specs. EThe shaft bore may not have surface treatment. 19 24.50 28.80 27.60 31.60 33.20 37.70 45.20 51.30 20.90 23.90 23.20 25.90 27.90 31.10 34.90 38.90 9.00 13.10 20.30

H Round Hole P Round Hole+Tap N New JIS Keywayed Bore + Tap 20 25.60 30.60 29.90 34.20 34.70 39.60 47.40 53.90 21.50 24.80 24.70 27.30 28.60 31.90 35.90 39.90 9.20 14.20 21.70

21 25.90 31.10 30.30 34.70 35.30 40.30 48.20 54.90 21.50 24.80 24.70 27.30 28.60 31.90 35.90 39.90 9.20 14.20 21.70

HU Inch Round Hole PU Inch Round Hole+Tap NU Inch New JIS Key Groove Hole + Tap V Stepped Hole F Stepped Hole Y Both Ends Stepped Hole

22 26.90 32.30 31.20 36.70 37.20 42.60 50.60 58.00 22.50 26.00 25.70 29.10 30.40 34.00 38.00 42.50 9.60 14.50 22.10

(counterbored holes on the hub side)

C Old JIS Keywayed Bore + Tap 24 29.30 34.70 33.90 39.80 40.20 45.90 54.80 62.70 24.40 27.60 27.60 31.20 32.60 36.20 40.80 45.40 10.40 15.40 23.30

25 30.20 35.70 34.80 40.80 41.30 47.10 56.30 64.30 24.40 27.60 27.60 31.20 32.60 36.20 40.80 45.40 10.40 15.40 23.30

26 30.20 36.30 35.90 42.50 43.30 49.50 58.90 67.30 25.20 29.10 29.50 34.00 35.70 39.80 44.60 49.70 11.40 17.60 26.20

28 34.10 41.00 39.30 46.70 47.80 55.30 65.00 75.20 27.10 31.00 30.60 35.00 37.30 41.80 46.60 52.20 11.80 18.10 26.80

120

30 34.70 41.90 40.20 47.90 48.80 56.60 66.40 77.00 27.10 31.00 30.60 35.00 37.30 41.80 46.60 52.20 11.80 18.10 26.80

QH7

RH7

ZH7

ZH7

dH7

dH7

°

d

32 40.50 49.00 45.50 53.90 54.60 63.00 74.50 85.90 32.10 36.90 35.00 39.70 42.00 46.60 52.60 58.30 13.40 20.00 29.30

34 41.90 51.10 47.30 56.40 56.80 65.90 77.50 89.80 32.10 36.90 35.00 39.70 42.00 46.60 52.60 58.30 13.40 20.00 29.30

36 46.40 57.20 54.10 65.10 62.50 73.20 85.20 99.60 35.00 40.30 39.50 45.10 45.00 50.50 56.30 63.10 14.30 21.80 31.60

38 47.60 58.10 55.10 66.10 63.50 74.20 86.60 101.10 36.40 41.80 40.90 46.60 46.50 51.90 58.20 64.90 14.30 21.80 31.60

dH7 dH7 dH7 J±0.1 J±0.1 S T

40 52.10 64.20 59.70 71.30 70.30 84.90 95.90 115.70 38.90 44.70 42.70 48.10 50.00 58.30 62.60 72.90 14.80 22.20 32.10

*No tapped holes and set *For A Shape pulley, the set screw hole *For Keyway Dimension Details, XNot available for D Shape. * Applicable to B Shape only. * Applicable to A Shape only.

42 52.10 64.20 59.70 71.30 70.30 84.90 95.90 115.70 38.90 44.70 42.70 47.60 50.00 58.30 62.60 72.90 14.80 22.20 32.10

screws. is set at around 120° to keep away refer to P.1096 *No tapped holes and set * No tapped holes and set * Shaft Bore Dia. D is general tolerance.

from peaks. screws. screws. * No tapped holes and set screws. 44 62.10 73.00 67.10 78.30 81.70 98.90 111.30 134.70 46.60 50.50 47.50 51.70 58.30 68.00 72.90 85.00 17.40 25.80 36.80

46 65.20 77.30 70.70 82.80 85.70 103.70 116.70 141.30 48.10 51.90 49.10 53.20 59.70 69.50 74.60 86.90 17.40 25.80 36.80

48 67.30 79.10 75.80 92.90 86.90 108.70 118.40 148.00 49.80 53.40 53.40 62.10 60.30 73.70 75.40 92.10 17.40 26.60 37.90

Part Number Shaft Bore Spec. (1mm Increment)

50 71.90 84.60 80.80 98.90 92.30 115.30 125.70 157.20 52.70 56.30 56.30 65.00 63.10 76.50 78.90 95.70 19.10 28.30 40.10

H P N/C HU PU NU V/F Y

Type Pulley Shaft Bore 60 - - - - - - - - - 59.70 - 79.40 - 87.40 - - 20.80 30.00 -

J P.D. O.D. D F E

Type Teeth Nominal Shape Specifications dH7 dH7 ZH7 (0.1mm Increment) d QH7 / RH7 S / T 72 - - - - - - - - - 86.60 - 99.30 - 106.90 - - 29.70 38.60 -

Width

AShape B-DShape AShape B-DShape AShape B-DShape AShape B-DShape AShape B-DShape AShape B-DShape AShape BShape AShape BShape AShape-BShape AShape AShape AShape Part Number - Pulley Shape - Shaft Bore Spec. / Inner Dia. - Z - J - Q - R - S - T - (KC90 / QSC / QFC / QTC / KSC / KFC / KTC / BC / NFC / RFC / LFC / FC / TPC / SLH)

10 L050 6~16 6~16 6~14 6~14 8~14 8~14 C~G C~G C~F C~F D~F D~F 6~14 6~14 8~16 8~16 6~14 8~16 30.32 29.56 22 36 24 ATP20L075 - A - H25 - KSC36 - K5

12 L050 / L075 8~22 8~22 8~18 8~18 8~18 8~18 E~H E~H E~G E~G E~G E~G 8~20 8~20 10~23 10~23 8~20 10~22 36.38 35.62 27 45 30

14 8~27 8~26 8~21 8~20 8~21 8~20 E~K E~K E~H E~H E~H E~H 8~25 8~24 10~27 10~26 8~25 10~27 42.45 41.68

30 48 35 Alterations Set Screw Angle Side Tapped Hole Side Through Hole

15 8~27 8~26 8~23 8~20 8~23 8~20 E~K E~K E~J E~H E~J E~H 8~25 8~24 10~27 10~26 8~25 10~27 45.48 44.72

16 10~32 10~28 10~26 10~22 10~23 10~22 F~L F~K F~K F~H F~J F~H 10~30 10~26 12~32 12~28 10~30 12~32 48.51 47.75 32

55 40 Code KC90 QSC / QFC / QTC KSC / KFC / KTC

17 L050 H 10~32 10~30 10~26 10~24 10~26 10~23 F~L F~K F~K F~J F~K F~J 10~30 10~28 12~32 12~30 10~30 12~32 51.54 50.78 34

18 *A :14 10~37 10~32 10~29 10~26 10~29 10~23 F~M F~L F~K F~K F~K F~J 10~35 10~30 12~37 12~32 10~35 12~37 54.57 53.81 36 61 45 Changes an angle of Machines tapped hole on the side surface of hub side. (QSC, QFC, QTC: 1mm Increment) Machines through hole on the side surface of hub side. (KSC, KFC, KTC: 1mm Increment)

*W :19 set screw to 90°. EThickness required: minimum 2mm ESpecify KC90 when selecting QFC for Shaft Bore EThickness required: minimum 2mm ESpecify KC90 when selecting KFC

19 HU 12~42 12~34 12~34 12~28 12~30 12~25 F~P F~L F~L F~K F~K F~J 12~40 12~32 14~42 14~34 12~40 14~42 57.61 56.84 38 67 50 for Shaft Bore Specifications P, N

(7075 Aluminum Alloy) 20 *L :31 EFor A shape pulley, the A Shape: d+M+4≤QSC(QFC / QTC)≤E-(M+4) specifications P, N and C. A Shape: d+K+4≤KSC(KFC / KTC)≤E-(K+4)

12~42 12~36 12~34 12~30 12~30 12~26 F~P F~M F~L F~K F~K F~K 12~40 12~34 14~42 14~36 12~40 14~42 60.64 59.88 40 67 50 set screw hole is set B Shape: d+M+4≤QSC(QFC / QTC)≤D-(M+4) EThe pilot hole for tapping may go through. B Shape: d+K+4≤KSC(KFC / KTC)≤D-(K+4) and C.

ATPA 21 (60, 72 = L: 39) P 12~48 12~38 12~40 12~30 12~32 12~26 F~R F~M F~N F~K F~L F~K 12~46 12~36 14~48 14~38 12~46 14~48 63.67 62.91 42 70 56 at around 90° to keep Ed=Z when the Shaft Bore Specifications is V. XNot applicable to Shaft Bore Ed=Z when the Shaft Bore Specifications is V. XNot applicable to Shaft Bore

ATPB 22 12~52 12~41 12~42 12~33 12~34 12~30 F~S F~N F~P F~L F~L F~K 12~50 12~39 14~52 14~41 12~50 14~52 66.70 65.94 45 80 60 away from peaks. M×2 (6 Places) (4 Places) (3 Places) Specifications F or Y. (6 Places) (4 Places) (3 Places) Specifications F or Y.

L075 KTC XWhen the Shaft Bore Specifications

ATPK 24 A PU 12~59 12~46 12~49 12~38 12~41 12~30 F~S F~Q F~R F~M F~N F~K 12~57 12~44 14~59 14~46 12~57 14~59 72.77 72.00 (6 QSC

Places) (4QFC

Places) (3 QTC

Places)

XWhen the Shaft Bore Specifications (6 KSC

Places) (4 KFC

Places) (3 Places)

ATPN 25

*A :21

12~59 12~46 12~49 12~38 12~41 12~30 F~S F~Q F~R F~M F~N F~K 12~57 12~44 14~59 14~46 (For A Shape) 12~57 14~59 75.80 75.04 87 67 Spec. M×2 are P, N or C, are P, N or C, KSC is not applicable.

*W :26 50 90 QSC QFC QTC QSC is not applicable. KSC KFC KTC K (Through Hole Dia.) Selection

26 N 12~59 12~46 12~49 12~38 12~41 12~30 F~S F~Q F~R F~M F~N F~K 12~57 12~44 14~59 14~46 3.0≤J≤W-3.0 12~57 14~59 3~21 78.83 78.07 °

M Selection M3,M4,M5,M6,M8 K4.0~K13.0

*L :38 90

(1045 Carbon Steel) 28 (60, 72 = L: 46) B 12~67 12~46 12~57 12~38 12~49 12~30 F~S F~Q F~S F~M F~R F~K 12~65 12~44 14~67 14~46 12~65 14~67 S+T≤W-3 84.89 84.13 95 75 ° Ordering Code QFC28-M4 (0.5mm Increment)

NU (For B Shape) Ordering Code

ATPT 30 12~72 12~52 12~62 12~42 12~50 12~34 F~S F~S F~S F~P F~S F~L 12~70 12~50 14~72 14~52 3.0≤J≤L-3.0 12~70 14~72 90.96 90.20

56

99 80 KSC20-K5

ATP 32 L100 C 14~76 14~52 14~65 14~42 14~50 14~34 G~S G~S G~S G~P G~S G~L 14~74 14~50 16~76 16~52 14~74 16~76 97.02 96.26 104 84 6−K Through 4−K Through 3−K Through

*A :27 6−M 4−M 3−M

ATPP 34 *W :32

14~80 14~59 14~65 14~49 14~50 14~41 G~S G~S G~S G~R G~S G~N 14~80 14~57 16~82 16~59 14~75 16~82 103.08 102.32 111 90

6−M 4−M 3−M 6−K Through 4−K Through 3−K Through

36 V 14~80 14~59 14~65 14~49 14~50 14~41 G~S G~S G~S G~R G~S G~N 14~80 14~57 16~94 16~59 14~75 16~94 109.15 108.39 63 123 102

38 *L :44 15~80 15~59 15~65 15~49 15~50 15~41 G~S G~S G~S G~R G~S G~N 15~80 15~57 17~95 17~59 15~75 17~95 115.21 114.45 127 105

40 (60, 72 = L: 53) F 15~80 15~59 15~65 15~49 15~50 15~41 G~S G~S G~S G~R G~S G~N 15~80 15~57 17~95 17~59 15~75 17~95 121.28 120.51 63 131 110 Price Adder Free QSC:7.00 QFC, QTC:5.00 KSC:10.00 KFC, KTC:7.00

42 16~80 16~67 16~65 16~57 16~50 16~49 H~S H~S H~S H~S H~R H~R 16~80 16~65 18~95 18~67 16~75 18~95 127.34 126.58 135 115

44

L150 Y 16~80 16~67 16~65 16~57 16~50 16~49 H~S H~S H~S H~S H~R H~R 16~80 16~65 18~95 18~67 16~75 18~95 133.40 132.64 140 120

Alterations Boss Cut No Flange Single Flange Flange Cut Tapped Hole Dimensions Set Screw Length

*A :40

46 *W :45 16~80 16~67 16~65 16~57 16~50 16~49 H~S H~S H~S H~S H~R H~R 16~80 16~65 18~95 18~67 16~75 18~95 139.47 137.71 71 144 125 Code BC NFC RFC / LFC FC TPC SLH

48 *L :57 16~80 16~67 16~65 16~57 16~50 16~49 H~S H~S H~S H~S H~R H~R 16~80 16~65 18~95 18~67 16~75 18~95 145.53 144.77 152 130 Cuts the hub length in 0.5mm increment. Flange is not installed. Flange installed on the hub Lowers flange by cutting. Changes the tapped hole dimension. Changes the length of the included set screws.

50 16~80 16~67 16~65 16~57 16~50 16~49 H~S H~S H~S H~S H~R H~R 16~80 16~65 18~95 18~67 16~75 18~95 151.60 150.83 160 140 EShaft Bore specification H, V, F: 3≤BC≤L-W (Flange included) side (RFC) or the opposite FC: 0.5mm Increment EApplicable to Shaft Bore specification P, N, C only. EApplicable to Shaft Bore specification P, N, C only.

ATPT 60 A 16~100 16~67 16~65 16~57 16~50 16~49 H~S H~S H~S H~S H~R H~R 16~100 18~125 16~100 18~125 181.91 181.15 170

190 (160) EShaft Bore specification P, N, C: M+3≤BC≤L-W side (LFC) only. ENo surface treatment applied on

ATP - - 71 M TPC Set Screw SLH

ATPP 72 D 16~100 16~67 16~65 16~57 16~50 16~49 H~S H~S H~S H~S H~R H~R 16~100 18~125 16~100 18~125 218.30 217.53 200

225 (197) Ordering Code BC6.5 ESame on A Shape flange circumference. M4 M5 M4x3 5, 8

BC/2 M5 M4, M6

EFor inch hole dimensions detail information refer to next page. E*E dimensions in ( ) are for "D" shape. EClear anodized products may M5x4 6, 10

Spec. not have surface treatment on M6 M5, M8 M6x5 10

EZ-d≥2 for Shaft Bore Specification V. EQ(R)-d≥2 for shaft bore specification Y. XShaft Bore Dia. 8, 9, 11, 13, 14, 17, 21~ 50 are not available for Shaft Bore specification C. the embossed plane. M8 M6, M10

EShaft Bore Dia. 6.35 is selectable for Shaft Bore specifications H, P, V and F.Q (R)-d≥2 for shaft bore specification Y. XNot applicable to A / D Shape.

RFC LFC M8x6 10, 12

M10 M8

FC

F

XShaft Bore Dia. 9 is not available for Shaft Bore specification N. BC EFC≥(O.D.)+2 M10x8 12, 15

ESelect NK10 when New JIS Keywayed Bore + Tap with shaft bore diameter of 10 and keyway width 4.0mm (height 1.8mm) is requested. DP.1096 EFC≤F-2

Ordering Code FC38 Ordering Code TPC5

Ordering Code SLH12

Part Number - Pulley Shape - Shaft Bore Spec. / Inner Dia. - Z - J - Q - R - S - T Price Adder 5.00 Free Free 3.00 Free Free

(Shaft Bore:H / P / N / C) ATP14L075 - A - N10

(Shaft Bore: V / F) ATP36L100 - A - V15 - Z29 - J18.0

1109 (Shaft Bore: Y) ATP50L150 - A - Y25 - Q47 - R47 - S12 - T12

1110

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fence Fittings: Standard Specification ForDocument4 pagesFence Fittings: Standard Specification ForAdán Cogley CantoNo ratings yet

- Ams S 13165Document26 pagesAms S 13165whalenon100% (2)

- Polia Sincronizadora HDocument1 pagePolia Sincronizadora HJosé Luiz NovelinoNo ratings yet

- Mancais Flangeados SKF - AmericanoDocument56 pagesMancais Flangeados SKF - AmericanoJosé Luiz NovelinoNo ratings yet

- Polia Sincronizadora AT5 - AT10Document1 pagePolia Sincronizadora AT5 - AT10José Luiz NovelinoNo ratings yet

- Polia Sincronizadora MXLDocument1 pagePolia Sincronizadora MXLJosé Luiz NovelinoNo ratings yet

- Tech Manual Timing BeltsDocument124 pagesTech Manual Timing BeltsyildyusufNo ratings yet

- Megaflex BeltsDocument50 pagesMegaflex BeltsJosé Luiz NovelinoNo ratings yet

- Elatech Correias SincronizadorasDocument140 pagesElatech Correias SincronizadorasJosé Luiz NovelinoNo ratings yet

- ISO 5296-2-1989 Synchronnues BeltsDocument7 pagesISO 5296-2-1989 Synchronnues BeltsJosé Luiz NovelinoNo ratings yet

- Norma Indiana - Polias SincronizadorasDocument16 pagesNorma Indiana - Polias SincronizadorasJosé Luiz NovelinoNo ratings yet

- Aratron POLIAS SINCRONIZADORASDocument8 pagesAratron POLIAS SINCRONIZADORASJosé Luiz NovelinoNo ratings yet

- Belt 1 PDFDocument31 pagesBelt 1 PDFbennyfergusonNo ratings yet

- ISO 5296-1-1989 Synchronnues BeltsDocument11 pagesISO 5296-1-1989 Synchronnues BeltsJosé Luiz NovelinoNo ratings yet

- L11006 Gripper Chain Brochure Oct 07Document6 pagesL11006 Gripper Chain Brochure Oct 07arhescobarNo ratings yet

- Handbook of Metric Drive Components PDFDocument1,282 pagesHandbook of Metric Drive Components PDFjaisanmecaNo ratings yet

- BRECO ComponentsDocument43 pagesBRECO ComponentsDobrica PetrovicNo ratings yet

- Roda Dentada e Polias Chalenge Catalogue-PT PDFDocument394 pagesRoda Dentada e Polias Chalenge Catalogue-PT PDFJosé Luiz NovelinoNo ratings yet

- Correias Sincronizadoras EspeciaisDocument165 pagesCorreias Sincronizadoras EspeciaisJosé Luiz NovelinoNo ratings yet

- l10902 Industrial Plastic ChainsDocument11 pagesl10902 Industrial Plastic ChainsJosé Luiz NovelinoNo ratings yet

- l14004 Custom Sprocket Design Capabilities BrochureDocument2 pagesl14004 Custom Sprocket Design Capabilities BrochureJosé Luiz NovelinoNo ratings yet

- Ust Ansi Chain Brouchure PDFDocument8 pagesUst Ansi Chain Brouchure PDFRodrigoNo ratings yet

- Polia Sincronizadora XLDocument1 pagePolia Sincronizadora XLJosé Luiz NovelinoNo ratings yet

- Roda Dentada e Polias Chalenge Catalogue-PT PDFDocument394 pagesRoda Dentada e Polias Chalenge Catalogue-PT PDFJosé Luiz NovelinoNo ratings yet

- Sprocket PDF 4275Document88 pagesSprocket PDF 4275Ivan HarijantoNo ratings yet

- l10768 Double Plus Chain and SprocketsDocument25 pagesl10768 Double Plus Chain and SprocketsJosé Luiz NovelinoNo ratings yet

- l0810450 Holyoke Manufacturing Facilities BrochureDocument5 pagesl0810450 Holyoke Manufacturing Facilities BrochureJosé Luiz NovelinoNo ratings yet

- Mil DTL 45204DDocument14 pagesMil DTL 45204DSivaramSubramanianNo ratings yet

- 1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesDocument7 pages1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesAdrian D.RazvanNo ratings yet

- Metals and Nonmetals Work Sheet - 1: Chemistry Worksheets - Class - XDocument6 pagesMetals and Nonmetals Work Sheet - 1: Chemistry Worksheets - Class - Xrita soniNo ratings yet

- Total Quality ManagementDocument36 pagesTotal Quality Managementfonsekapdl100% (1)

- Phosphor Bronze To Bs 1400: Pb2Document1 pagePhosphor Bronze To Bs 1400: Pb2Suresh NairNo ratings yet

- Ferrous Alloys Feah: March Author: R. ADocument22 pagesFerrous Alloys Feah: March Author: R. AsunsirNo ratings yet

- WM055101 GB EWM-Schweisslexikon PDFDocument144 pagesWM055101 GB EWM-Schweisslexikon PDFMilan JavornikNo ratings yet

- Design Guide FOR Cathodic ProtectionDocument27 pagesDesign Guide FOR Cathodic ProtectionA N MadhavanNo ratings yet

- 092 (2006)Document2 pages092 (2006)hrk100No ratings yet

- ENPPI Pressure VesselsDocument47 pagesENPPI Pressure Vesselsisrar khan100% (2)

- Ferrous Polycrystalline Shape-MemoryDocument4 pagesFerrous Polycrystalline Shape-MemoryDavid Santiago Lopez VelezNo ratings yet

- A Critical Revie of Experimental Results and Constitutie Descriptions For Metals and Alloys in Hot WorkingDocument27 pagesA Critical Revie of Experimental Results and Constitutie Descriptions For Metals and Alloys in Hot WorkingS TNo ratings yet

- Highentropy Alloys by Mechanical Alloying A ReviewDocument24 pagesHighentropy Alloys by Mechanical Alloying A ReviewChima UgwuegbuNo ratings yet

- CH 01.07 Galvin SteelDocument5 pagesCH 01.07 Galvin Steelkhairul ardyNo ratings yet

- Welding 2 PDFDocument7 pagesWelding 2 PDFPratyush BhattacharyaNo ratings yet

- CopperDocument26 pagesCopperShirjak ThokarNo ratings yet

- Understanding Magnesium Heat TreatmentDocument2 pagesUnderstanding Magnesium Heat Treatmentmp87_ingNo ratings yet

- Study On Dies For Wood Pellet MachinesDocument10 pagesStudy On Dies For Wood Pellet MachinesAl SaherNo ratings yet

- Mil B 7883BDocument14 pagesMil B 7883BAnonymous 5pURWfNo ratings yet

- Corrosion resistance of aluminum alloy improved by anodizingDocument6 pagesCorrosion resistance of aluminum alloy improved by anodizingMuhammad Zain NawwarNo ratings yet

- 4 AodDocument5 pages4 AodSonu MishraNo ratings yet

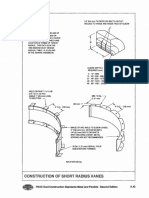

- Short Radius VanesDocument1 pageShort Radius VanesblahblahNo ratings yet

- Distributor, Stainless Steel 316 Weldedpipe Trader, Stainless Steel 316 Seamless Pipe Stockholder, Stainless Steel 316Document3 pagesDistributor, Stainless Steel 316 Weldedpipe Trader, Stainless Steel 316 Seamless Pipe Stockholder, Stainless Steel 316Raaj SteelNo ratings yet

- Manufacturing Lab PDFDocument30 pagesManufacturing Lab PDFShivam VarshneyNo ratings yet

- Carbono EquivalenteDocument81 pagesCarbono EquivalenteRemmy Torres VegaNo ratings yet

- SW 05Document5 pagesSW 05LLNo ratings yet

- Profit-Jigsaw &reciprocating Saw BladeDocument4 pagesProfit-Jigsaw &reciprocating Saw Bladelilymighty8No ratings yet

- Grade Markings For Steel Bolts and ScrewsDocument3 pagesGrade Markings For Steel Bolts and Screwsrexie2canos8964No ratings yet