Professional Documents

Culture Documents

RMCF / RMCP Series: Stackpole Electronics, Inc

Uploaded by

Naveed AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RMCF / RMCP Series: Stackpole Electronics, Inc

Uploaded by

Naveed AhmedCopyright:

Available Formats

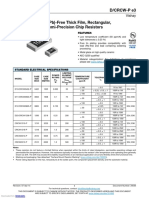

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Features:

• RMCF – standard power ratings

• RMCP – high power ratings

• Nickel barrier terminations standard

• Power derating from 100% at 70ºC to zero at +155ºC

• AEC-Q200 compliant (except RMCP0201)

• RoHS compliant and halogen free

Electrical Specifications - RMCF

Power Rating Max. Max. Max. (2)

Working Ohmic Range (Ω) and Tolerance

Type / Code (W) Overload Jumper Current TCR (ppm/ºC)

(1)

@ 70ºC Voltage (V) Voltage (V) (A) 1% 5%

± 300 10 - 97.6

RMCF01005 0.03 15 30 0.5

± 200 100 - 1 M

± 400 1 - 9.76

RMCF0201 0.05 25 50 0.5

± 200 10 - 10 M

± 200 1 - 9.76 (3)

RMCF0402 0.063 50 100 1 ± 100 10 - 1 M

± 200 1.02 M - 10 M 1.1 M - 20 M

± 500 0.1 - 0.499

± 400 0.5 - 0.976

RMCF0603 0.1 75 150 1 ± 200 1 - 9.76 1 - 20 M

± 100 10 - 1 M -

± 200 1.02 M - 10 M -

± 200 0.1 - 9.76 0.1 - 20 M

RMCF0805 0.125 150 300 2 ± 100 10 - 1 M -

± 200 1.02 M - 10 M -

± 200 0.1 - 9.76 0.1 - 20 M

RMCF1206 0.25 200 400 2 ± 100 10 - 1 M -

± 200 1.02 M - 10 M -

± 200 0.1 - 0.976

RMCF1210 0.5 200 400 3 ± 400 1 - 9.76

± 100 10 - 10 M

± 200 0.1 - 0.976

± 400 1 - 9.76

RMCF2010 0.75 200 400 3

± 200 - 10 - 10 M

± 100 10 - 10 M -

± 200 0.1 - 0.976

± 400 1 - 9.76

RMCF2512 1 200 400 3

± 200 - 10 - 10 M

± 100 10 - 10 M -

Notes: (1) Lesser of √ P*R or maximum working voltage

(2) Contact Stackpole for extended ohmic values

(3) Contact Stackpole for lower ohmic values

Rev Date: 01/19/2021 1 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Electrical Specifications - RMCP

Power Rating Max. Max. Max.

Ohmic Range (Ω) and Tolerance (2)

Type / Code (W) Working Overload Jumper Current TCR (ppm/ºC)

(1)

@ 70ºC Voltage (V) Voltage (V) (A) 1%, 5%

-200 / +400 1 - 9.76

RMCP0201 0.063 25 50 1

± 200 10 - 10 M

± 200 1 - 9.76

RMCP0402 0.125 50 100 1.5

± 100 10 - 10 M

± 200 1 - 9.76

RMCP0603 0.25 75 150 2

± 100 10 - 10 M

± 200 1 - 9.76

RMCP0805 0.33 150 300 2.5

± 100 10 - 10 M

± 400 1 - 9.76

RMCP1206 0.5 200 400 3.5

± 100 10 - 10 M

± 400 1 - 9.76

RMCP1210 0.66 200 400 5

± 100 10 - 10 M

± 200 1 - 9.76

RMCP2010 1 200 400 6

± 100 10 - 10 M

± 200 1 - 9.76

RMCP2512 2 250 500 7

± 100 10 - 10 M

Notes: (1) Lesser of √ P*R or maximum working voltage

(2) Contact Stackpole for extended ohmic values

Electrical Specifications - Jumper

Jumper Rated Current Max Overload Current Jumper Resistance Value

Type / Code

(A) (A)* (Ω)

RMCP0201 0.5 1

RMCP0402 1 3

RMCP0603 1 5

RMCP0805 1 5

0.025 max.

RMCP1206 2 10

RMCP1210 2 12

RMCP2010 2 12

RMCP2512 2 15

* < 1 second and 1 time

Mechanical Specifications

Average Unit L W H a b

Type / Code Unit

Weight (mg) Body Length Body Width Body Height Top Termination Bottom Termination

0.016 ± 0.0008 0.008 ± 0.0008 0.005 ± 0.0008 0.004 ± 0.0012 0.004 ± 0.0012 inches

RMCF01005 0.07

0.40 ± 0.02 0.20 ± 0.02 0.13 ± 0.02 0.10 ± 0.03 0.10 ± 0.03 mm

RMCF0201 0.024 ± 0.0012 0.012 ± 0.0012 0.009 ± 0.0012 0.006 ± 0.002 0.006 ± 0.002 inches

0.16

RMCP0201 0.60 ± 0.03 0.30 ± 0.03 0.23 ± 0.03 0.15 ± 0.05 0.15 ± 0.05 mm

RMCF0402 0.57 0.039 ± 0.004 0.020 ± 0.002 0.012 ± 0.004 0.008 ± 0.004 0.010 ± 0.006 inches

RMCP0402 0.62 1.00 ± 0.10 0.50 ± 0.05 0.30 ± 0.10 0.20 ± 0.10 0.25 ± 0.15 mm

RMCF0603 1.88 0.061 ± 0.006 0.031 ± 0.006 0.018 ± 0.004 0.012 ± 0.008 0.012 ± 0.008 inches

RMCP0603 2.04 1.55 ± 0.15 0.80 ± 0.15 0.45 ± 0.10 0.30 ± 0.20 0.30 ± 0.20 mm

RMCF0805 5.00 0.079 ± 0.008 0.049 ± 0.004 0.020 ± 0.006 0.014 ± 0.010 0.014 ± 0.010 inches

RMCP0805 4.37 2.00 ± 0.20 1.25 ± 0.10 0.50 ± 0.15 0.35 ± 0.25 0.35 ± 0.25 mm

Rev Date: 01/19/2021 2 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Mechanical Specifications (cont.)

Average Unit L W H a b

Type / Code Unit

Weight (mg) Body Length Body Width Body Height Top Termination Bottom Termination

RMCF1206 8.86 0.126 ± 0.010 0.063 ± 0.006 0.022 ± 0.006 0.020 ± 0.012 0.020 ± 0.012 inches

RMCP1206 8.95 3.20 ± 0.25 1.60 ± 0.15 0.55 ± 0.15 0.50 ± 0.30 0.50 ± 0.30 mm

RMCF1210 15.55 0.126 ± 0.010 0.098 ± 0.010 0.022 ± 0.006 0.020 ± 0.012 0.020 ± 0.012 inches

RMCP1210 15.96 3.20 ± 0.25 2.50 ± 0.25 0.55 ± 0.15 0.50 ± 0.30 0.50 ± 0.30 mm

RMCF2010 23.56 0.197 ± 0.008 0.098 ± 0.008 0.022 ± 0.006 0.024 ± 0.012 0.024 ± 0.014 inches

RMCP2010 24.24 5.00 ± 0.20 2.50 ± 0.20 0.55 ± 0.15 0.60 ± 0.30 0.60 ± 0.35 mm

RMCF2512 40.02 0.248 ± 0.008 0.126 ± 0.010 0.022 ± 0.006 0.024 ± 0.012 0.024 ± 0.014 inches

RMCP2512 39.45 6.30 ± 0.20 3.20 ± 0.25 0.55 ± 0.15 0.60 ± 0.30 0.60 ± 0.35 mm

Performance Characteristics

Test Test Specifications Test Conditions (JIS-C 5202)

± (2% + 0.1Ω) 2.5 X rated voltage for 5 seconds

0201 = 1A

Short Time Overload

Jumper: Max 0.05Ω after test 0402 / 0603 / 0805 = 2.5A

1206 / 1210 / 2010 / 2512 = 5A

Dielectric Withstanding Voltage No flashover or breakdown 100 VAC, 1 minute

Resistance to Soldering Heat ± 1% 260ºC ± 5ºC, for 10 seconds ± 0.5 seconds (Solder Bath)

Solderability 95% coverage, minimum 235ºC ± 5ºC, for 2 seconds ± 0.5 seconds (Colophonium flux)

-65ºC: 30 minutes 25ºC: 2 to 3 minutes

± (1% + 0.05Ω)

Temperature Cycle 155ºC: 30 minutes 25ºC: 2 to 3 minutes

Jumper (< 0.05Ω)

(5 Cycles)

1% and below: ± (1% + 0.05Ω)

Load Life 2% and 5%: ± (3% + 0.1Ω) 70 ± 2°C, RCWV or max. working voltage whichever is less

(Endurance) Value < 1Ω: ± (3% + 0.1Ω) for 1000 hours with 1.5 hours "ON" and 0.5 hour "OFF"

Jumper: Max 0.1Ω after test.

1/10 rated voltage for 3 seconds max. then rated voltage for

Voltage Coefficient ± 100 (ppm/V)

3 seconds max.

Robustness of Termination ± (1% + 0.05Ω) Bend of 3 mm for 5 ± 1 seconds

1%: ± (0.5% + 0.05Ω) The tested resistor should be immersed into isopropyl alcohol of

Resistance to Solvent 5%: ± (0.5% + 0.05Ω) 20 ~ 25°C for 60 seconds. Then the resitor is left in the room

Jumper: Max. 0.05Ω after test for 48 hours.

1%: ± (1% + 0.05Ω)

5%: ± (2% + 0.05Ω) 40 ± 2°C, 90 ~ 95% R.H. RCWV or max. working voltage whichever is

Damp Heat with Load

Values < 1Ω: ± (3% + 0.1Ω) less for 1000 hours with 1.5 hours "ON" and 0.5 hours "OFF"

Jumper: Max. 0.1Ω after test

Operating temperature range is -55°C to +155°C for all sizes except for 01005 size

Operating temperature range for 01005 is -55°C to +125°C

Power Derating Curve:

-55ºC 70ºC

100

80

Power Load (%)

60

01005 size

All other sizes

40

20

125ºC 155ºC

0

-60 0 20 40 60 80 100 120 140 160 180

Ambient Temperature (ºC)

Rev Date: 01/19/2021 3 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Repetitive Pulse Information

(This information is for reference only and is not guaranteed performance.)

If repetitive pulses are applied to resistors, pulse wave form must be less than “Pulse limiting voltage”, “Pulse limiting

current” or “Pulse limiting wattage” calculated by the formula below.

Vp = K√P x R x T/t

lp = K√P/R x T/t

Pp = K2 x P x T/t

Where: Vp: Pulse limiting voltage (V)

lp: Pulse limiting current (A)

Pp: Pulse limiting wattage (W)

P: Power rating (W)

R: Nominal resistance (ohm)

T: Repetitive period (sec)

t: Pulse duration (sec)

K: Coefficient by resistors type (refer to below matrix)

[Vr: Rated Voltage (V), Ir: Rated Current (A)]

Note 1: If T > 10 → T = 10 (sec), T / t > 1000 → T / t = 1000

Note 2: If T > 10 and T / t > 1000, “Pulse Limiting power (Single pulse) is applied

Note 3: If Vp < Vr (lp < lr or Pp < P), Vr (lr, P) is Vp (lp, Pp)

Note 4: Pulse limiting voltage (current, wattage) is applied at less than rated ambient temperature. If ambient

temperature is more than the rated temperature (70°C), please decrease power rating according to “Power Derating

Curve”

Note 5: Please assure sufficient margin for use period and conditions for “Pulse limiting voltage”

Note 6: If the pulse waveform is not square wave, please judge after transform the waveform into square wave

according to the “Waveform Transformation to Square Wave”.

RMCF Coefficient (K) Matrix

Resistor Type K

R < 10 Ω 0.50

10 Ω ≤ R < 100 Ω 0.45

100 Ω ≤ R < 1K Ω 0.35

1K Ω ≤ R < 10K Ω 0.25

10K Ω ≤ R 0.20

Rev Date: 01/19/2021 4 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Waveform Transformation to Square Wave

1. Discharge curve wave with time constant “t” → Square wave

2. Damping oscillation wave with time constant of envelope “t” → Square wave

3. Half-wave rectification wave → Square wave

4. Triangular wave → Square wave

5. Special wave → Square wave

Rev Date: 01/19/2021 5 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Recommended Pad Layout

Size A B C Unit

0.008 0.020 0.008 inches

01005

0.20 0.50 0.20 mm

0.012 0.039 0.016 inches

0201

0.30 1.00 0.40 mm

0.020 0.059 0.024 inches

0402

0.50 1.50 0.60 mm

0.031 0.083 0.035 inches

0603

0.80 2.10 0.90 mm

0.047 0.118 0.051 inches

0805

1.20 3.00 1.30 mm

0.087 0.165 0.063 inches

1206

2.20 4.20 1.60 mm

0.087 0.165 0.110 inches

1210

2.20 4.20 2.80 mm

0.138 0.240 0.110 inches

2010

3.50 6.10 2.80 mm

0.193 0.315 0.138 inches

2512

4.90 8.00 3.50 mm

Recommended Solder Profile

This information is intended as a reference for solder profiles for Stackpole resistive components. These profiles should

be compatible with most soldering processes. These are only recommendations. Actual numbers will depend on board

density, geometry, packages used, etc., especially those cells labeled with “*”.

100% Matte Tin / RoHS Compliant Terminations

Soldering iron recommended temperatures: 330°C to 350°C with minimum duration.

Maximum number of reflow cycles: 3.

Wave Soldering

Description Maximum Recommended Minimum

Preheat Time 80 seconds 70 seconds 60 seconds

Temperature Diff. 140°C 120°C 100°C

Solder Temp. 260°C 250°C 240°C

Dwell Time at Max. 10 seconds 5 seconds *

Ramp DN (°C/sec) N/A N/A N/A

Temperature Diff. = Defference between final preheat stage and soldering stage.

Rev Date: 01/19/2021 6 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Convection IR Reflow

Description Maximum Recommended Minimum

Ramp Up (°C/sec) 3°C/sec 2°C/sec *

Dwell Time > 217°C 150 seconds 90 seconds 60 seconds

Solder Temp. 260°C 245°C *

Dwell Time at Max. 30 seconds 15 seconds 10 seconds

Ramp DN (°C/sec) 6°C/sec 3°C/sec *

Recommended Lead Free Resistor Reflow Profile

Packaging (EIA Standard RS-481)

Packaging Specifications

Reel Type Wa M A B C D Unit

7" reel for 0.354 ± 0.020 7.008 ± 0.079 0.079 ± 0.020 0.531 ± 0.020 0.827 ± 0.020 2.362 ± 0.039 inches

8 mm tape 9.00 ± 0.50 178.00 ± 2.00 2.00 ± 0.50 13.50 ± 0.50 21.00 ± 0.50 60.00 ± 1.00 mm

10" reel for 0.394 ± 0.020 10.000 ± 0.079 0.079 ± 0.020 0.531 ± 0.020 0.827 ± 0.020 3.937 ± 0.039 inches

8 mm tape 10.00 ± 0.50 254.00 ± 2.00 2.00 ± 0.50 13.50 ± 0.50 21.00 ± 0.50 100.00 ± 1.00 mm

Rev Date: 01/19/2021 7 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Taping Specifications - 01005, 0201, 0402

7" Reel Typical Full Tape

Size A B W E F Unit

Quantity Reel Weight (g) Width

0.315 0.018 ± 0.001 0.010 ± 0.001 0.315 ± 0.012 0.069 ± 0.004 0.138 ± 0.002 inches

01005 10000 127.3 ± 12.0

8.00 0.45 ± 0.02 0.25 ± 0.02 8.00 ± 0.30 1.75 ± 0.10 3.50 ± 0.05 mm

0.315 0.028 ± 0.006 0.016 ± 0.006 0.315 ± 0.008 0.069 ± 0.004 0.138 ± 0.002 inches

0201 10000 97.2 ± 9.0

8.00 0.70 ± 0.15 0.40 ± 0.15 8.00 ± 0.20 1.75 ± 0.10 3.50 ± 0.05 mm

0.315 0.047 ± 0.006 0.028 ± 0.006 0.315 ± 0.008 0.069 ± 0.004 0.138 ± 0.002 inches

0402 10000 94.5 ± 9.0

8.00 1.20 ± 0.15 0.70 ± 0.15 8.00 ± 0.20 1.75 ± 0.10 3.50 ± 0.05 mm

Size T1 T2 P P0 P1 Unit

0.012 ± 0.001 0.007 ± 0.001 0.079 ± 0.002 0.157 ± 0.002 0.079 ± 0.002 inches

01005

0.31 ± 0.03 0.17 ± 0.03 2.00 ± 0.05 4.00 ± 0.05 2.00 ± 0.05 mm

0.015 ± 0.006 0.011 ± 0.001 0.079 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

0201

0.38 ± 0.15 0.28 ± 0.02 2.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

0.016 ± 0.008 0.016 ± 0.002 0.079 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

0402

0.40 ± 0.20 0.40 ± 0.05 2.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

Taping Specifications - 0603, 0805, 1206, 1210

7" Reel Typical Full Reel

Size Tape Width A B W E Unit

Quantity (1) Weight (g)

0.315 0.071 ± 0.008 0.041 ± 0.008 0.315 ± 0.008 0.069 ± 0.004 inches

0603 5000 118.3 ± 11.0

8.00 1.80 ± 0.20 1.05 ± 0.20 8.00 ± 0.20 1.75 ± 0.10 mm

0.315 0.093 ± 0.010 0.063 ± 0.010 0.315 ± 0.008 0.069 ± 0.004 inches

0805 5000 139.2 ± 13.0

8.00 2.35 ± 0.25 1.60 ± 0.25 8.00 ± 0.20 1.75 ± 0.10 mm

0.315 0.140 ± 0.010 0.077 ± 0.010 0.315 ± 0.008 0.069 ± 0.004 inches

1206 5000 151.4 ± 15.0

8.00 3.55 ± 0.25 1.95 ± 0.25 8.00 ± 0.20 1.75 ± 0.10 mm

0.315 0.138 ± 0.008 0.110 ± 0.010 0.315 ± 0.008 0.069 ± 0.004 inches

1210 4000 175.7 ± 17.0

8.00 3.50 ± 0.20 2.80 ± 0.25 8.00 ± 0.20 1.75 ± 0.10 mm

Rev Date: 01/19/2021 8 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Taping Specifications - 0603, 0805, 1206, 1210 (cont.)

Size F T1 T2 P P0 P1 Unit

0.138 ± 0.002 0.024 ± 0.008 0.024 ± 0.004 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

0603

3.50 ± 0.05 0.60 ± 0.20 0.60 ± 0.10 4.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

0.138 ± 0.002 0.030 ± 0.008 0.030 ± 0.004 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

0805

3.50 ± 0.05 0.75 ± 0.20 0.75 ± 0.10 4.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

0.138 ± 0.002 0.030 ± 0.008 0.030 ± 0.004 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

1206

3.50 ± 0.05 0.75 ± 0.20 0.75 ± 0.10 4.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

0.138 ± 0.002 0.030 ± 0.008 0.030 ± 0.004 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

1210

3.50 ± 0.05 0.75 ± 0.20 0.75 ± 0.10 4.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

Taping Specifications - 2010, 2512

7" Reel Typical Full Reel Tape

Size A B W E F Unit

Quantity Weight (g) Width

0.472 0.217 ± 0.012 0.110 ± 0.008 0.472 ± 0.008 0.069 ± 0.004 0.217 ± 0.002 inches

2010 4000 183.1 ± 18.0

12.00 5.50 ± 0.30 2.80 ± 0.20 12.00 ± 0.20 1.75 ± 0.10 5.50 ± 0.05 mm

0.472 0.264 ± 0.008 0.134 ± 0.008 0.472 ± 0.008 0.069 ± 0.004 0.217 ± 0.002 inches

2512 4000 255.3 ± 25.0

12.00 6.70 ± 0.20 3.40 ± 0.20 12.00 ± 0.20 1.75 ± 0.10 5.50 ± 0.05 mm

Size T1 T2 P P0 P1 Unit

0.041 ± 0.008 0.009 ± 0.006 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

2010

1.05 ± 0.20 0.23 ± 0.15 4.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

0.041 ± 0.008 0.009 ± 0.006 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 inches

2512

1.05 ± 0.20 0.23 ± 0.15 4.00 ± 0.10 4.00 ± 0.10 2.00 ± 0.05 mm

Note: Plastic carrier tape used for 2010 and 2512 sizes.

Rev Date: 01/19/2021 9 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

Single Pulse Power

The data provided are for reference only. They are typical performance for this product but are not guaranteed. The actual pulse

handling of each individual resistor may vary depending on a variety of factors including resistance tolerance and resistance

value. Stackpole Electronics, Inc. assumes no liability for the use of this information. Customers should validate the performance of

these products in their applications. Contact Stackpole marketing to discuss specific pulse application requirements.

Temperature Measurement of Resistor Surface

Description: The resistor surface generated temperature variation after applied rated voltage.

Products and power:

Size 0201 0402 0603 0805 1206 1210 2010 2512

R-V 15K 40.2K 57.6K 180K 182K 100K 100K 75K

Rated Power (W) 1/20 1/16 1/10 1/8 1/4 1/2 3.4 1

Max Rated Voltage (V) 25 50 75 150 200 200 200 200

Test method: Measure component surface temperature directly after the temperature stabilizes.

Test result: As per table below:

Hot Spot Temperature - RMCF

Size 0201 0402 0603 0805 1206 1210 2010 2512

Surface Temp. (°C) 36 37 46.2 50.4 70.6 110.6 141 150.4

Rev Date: 01/19/2021 10 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

The thermal resistance of the RMCP will be similar to the RMCF. For example, the RMCF2512 and the RMCP2512 will have similar

surface temperatures at 1W; the RMCP is designed to withstand higher temperatures associated with high power levels.

Part Marking Specifications

1% Marking 5% Marking

The nominal resistance is marked on The nominal resistance is marked on

the surface of the overcoating with the the surface of the overcoating with the

use of 4 digit markings. use of 3 digit markings.

0201 and 0402 are not marked. 0201 and 0402 are not marked.

For shared E24/E96 values, 1% tolerance product may be marked with three digit marking instead of the standard four digit

marking for all other E96 values. All E24 values available in 1% tolerance are also marked with three digit marking.

Mark Instructions for 0603 1% Chip Resistors (per EIA-J)

A two-digit number is assigned to each standard R-Value (E96) as shown in the chart below.

This is followed by one alpha character which is used as a multiplier. Each letter “Y” – “F” represents a specific

multiplier as follows:

Y = 0.1 X=1 A = 10 B = 100

C = 1000 D(d) = 10000 E = 100000 F = 1000000

EXAMPLE:

Chip Marking Explanation Value

01B 01 means 10.0 and B = 100 10.0 x 100 = 1 K ohm

25C 25 means 17.8 and C = 1,000 17.8 x 1,000 = 17.8 K ohm

93D 93 means 90.9 and D = 10,000 90.9 x 10,000 = 909 K ohm

E96

1% # 1% # 1% # 1% # 1% # 1% #

10.0 01 14.7 17 21.5 33 31.6 49 46.4 65 68.1 81

10.2 02 15.0 18 22.1 34 32.4 50 47.5 66 69.8 82

10.5 03 15.4 19 22.6 35 33.2 51 48.7 67 71.5 83

10.7 04 15.8 20 23.2 36 34.0 52 49.9 68 73.2 84

11.0 05 16.2 21 23.7 37 34.8 53 51.1 69 75.0 85

11.3 06 16.5 22 24.3 38 35.7 54 52.3 70 76.8 86

11.5 07 16.9 23 24.9 39 36.5 55 53.6 71 78.7 87

11.8 08 17.4 24 25.5 40 37.4 56 54.9 72 80.6 88

12.1 09 17.8 25 26.1 41 38.3 57 56.2 73 82.5 89

12.4 10 18.2 26 26.7 42 39.2 58 57.6 74 84.5 90

12.7 11 18.7 27 27.4 43 40.2 59 59.0 75 86.6 91

13.0 12 19.1 28 28.0 44 41.2 60 60.4 76 88.7 92

13.3 13 19.6 29 28.7 45 42.2 61 61.9 77 90.9 93

13.7 14 20.0 30 29.4 46 43.2 62 63.4 78 93.1 94

14.0 15 20.5 31 30.1 47 44.2 63 64.9 79 95.3 95

14.3 16 21.0 32 30.9 48 45.3 64 66.5 80 97.6 96

Rev Date: 01/19/2021 11 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

RoHS Compliance

Stackpole Electronics has joined the worldwide effort to reduce the amount of lead in electronic components and to meet

the various regulatory requirements now prevalent, such as the European Union’s directive regarding “Restrictions on

Hazardous Substances” (RoHS 3). As part of this ongoing program, we periodically update this document with the status

regarding the availability of our compliant components. All our standard part numbers are compliant to EU Directive

2011/65/EU of the European Parliament as amended by Directive (EU) 2015/863/EU as regards the list of restricted

substances.

RoHS Compliance Status

Standard Lead-Free

Standard Package / Lead-Free

Series Lead-Free Termination Effective Date

Product Description Termination Mfg. Effective Date

RoHS Composition Code

Series Type (Std Product Series)

Compliant (YY/WW)

General Purpose Thick Film Jan-04 (Japan) 04/01

RMCF SMD YES(1) 100% Matte Sn over Ni

Surface Mount Chip Resistor Jan-05 (Taiwan, China) 05/01

General Purpose High Power

RMCP SMD YES(1) 100% Matte Sn over Ni Always Always

Thick Film Chip Resistor

Note (1): RoHS Compliant by means of exemption 7c-I.

“Conflict Metals” Commitment

We at Stackpole Electronics, Inc. are joined with our industry in opposing the use of metals mined in the “conflict region”

of the eastern Democratic Republic of the Congo (DRC) in our products. Recognizing that the supply chain for metals

used in the electronics industry is very complex, we work closely with our own suppliers to verify to the extent possible

that the materials and products we supply do not contain metals sourced from this conflict region. As such, we are in

compliance with the requirements of Dodd-Frank Act regarding Conflict Minerals.

Compliance to “REACH”

We certify that all passive components supplied by Stackpole Electronics, Inc. are SVHC (Substances of Very High

Concern) free and compliant with the requirements of EU Directive 1907/2006/EC, “The Registration, Evaluation,

Authorization and Restriction of Chemicals”, otherwise referred to as REACH. Contact us for complete list of REACH

Substance Candidate List.

Environmental Policy

It is the policy of Stackpole Electronics, Inc. (SEI) to protect the environment in all localities in which we operate. We

continually strive to improve our effect on the environment. We observe all applicable laws and regulations regarding the

protection of our environment and all requests related to the environment to which we have agreed. We are committed

to the prevention of all forms of pollution.

Rev Date: 01/19/2021 12 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

RMCF / RMCP Series

General Purpose Thick Film Standard Power Stackpole Electronics, Inc.

and High-Power Chip Resistor Resistive Product Solutions

How to Order - RMCF

1 2 3 4 5 6 7 8 9 10 11 12 13 14

R M C F 0 6 0 3 J T 4 K 7 0

Product Series Size Tolerance Packaging Resistance Value

Code Description Size W Code Tol Value Code Description Size Quantity Four characters with the

Thick Film 01005 0.03 F 1% E96, E24 01005 10000 multiplier used as the

RMCF

Chip 0201 0.05 J 5% E24 7" Reel - Paper 0201, 0402 10000 decimal holder.

0402 0.063 Z Jumper Tape 0603, 0805, 1206 5000 0.1 ohm = R100

T

0603 0.1 1210 4000 4.70 ohm = 4R70

0805 0.125 7" Reel - 10.0 Kohm = 10K0

2010, 2512 4000

1206 0.25 Plastic Tape 1 Mohm = 1M00

1210 0.5 10" Reel - Zero ohm jumper = 0R00

G 0603, 0805, 1206 10000

2010 0.75 Paper Tape

2512 1

How to Order - RMCP

1 2 3 4 5 6 7 8 9 10 11 12 13 14

R M C P 0 6 0 3 J T 4 K 7 0

Product Series Size Tolerance Packaging Resistance Value

Code Description Size W Code Tol Value Code Description Size Quantity Four characters with the

RMCP High Power 0201 0.063 F 1% E96, E24 0201, 0402 10000 multiplier used as the

0402 0.125 J 5% E24 7" Reel 0603, 0805 decimal holder.

T 5000

0603 0.25 Z Jumper Paper Tape 1206, 1210 1 ohm = 1R00

0805 0.33 2010, 2512 4000 10 Kohm = 10K0

1206 0.5 0603, 0805 1 Mohm = 1M00

10" Reel 10000

1210 0.66 G 1206, 1210

Paper Tape

2010 1 2010 8000

2512 2

Rev Date: 01/19/2021 13 www.seielect.com

This specification may be changed at any time without prior notice marketing@seielect.com

Please confirm technical specifications before you order and/or use.

You might also like

- Sei-Rmcf RMCPDocument13 pagesSei-Rmcf RMCPPacermann PacermannNo ratings yet

- Ever Ohms Tech CR2512J8K2E04 - C428971Document12 pagesEver Ohms Tech CR2512J8K2E04 - C428971raveendraNo ratings yet

- Sei SMDocument4 pagesSei SMwijeesf797No ratings yet

- HVC Series: Stackpole Electronics, IncDocument5 pagesHVC Series: Stackpole Electronics, IncDavidNo ratings yet

- Thick Film Chip Resistors Spec SheetDocument10 pagesThick Film Chip Resistors Spec SheetManuel VargasNo ratings yet

- Stackpole Electronics RMCF/RMCP Series Chip ResistorsDocument8 pagesStackpole Electronics RMCF/RMCP Series Chip ResistorsGeorge Romero Tadeu Carvalho NunesNo ratings yet

- Metal Film Precision MELF Resistor AEC-Q200 Qualified for AutomotiveDocument13 pagesMetal Film Precision MELF Resistor AEC-Q200 Qualified for AutomotivecutoNo ratings yet

- CRCW06032431FRT1Document7 pagesCRCW06032431FRT1鄭建銘(小銘)No ratings yet

- ASC - General - Purpose - Capacitor For HallsensorDocument19 pagesASC - General - Purpose - Capacitor For HallsensorLusiNo ratings yet

- Walsin Tech Corp 0402B473K160CT - C338148Document20 pagesWalsin Tech Corp 0402B473K160CT - C338148Fazli WadoodNo ratings yet

- Resistencias SMD WIN-1524917Document4 pagesResistencias SMD WIN-1524917Ignacio Barriga NuñezNo ratings yet

- Capacitor 4700uf 63VDocument13 pagesCapacitor 4700uf 63VEdwar OrtegaNo ratings yet

- 180 - 12000uf, 6.3V - 35VDocument5 pages180 - 12000uf, 6.3V - 35VPadmajan YesodharanNo ratings yet

- 10.1 Data-Sheet-CapacitorDocument10 pages10.1 Data-Sheet-CapacitorMarco OlivaresNo ratings yet

- Acceptance Criteria NDocument2 pagesAcceptance Criteria Nvishal rajputNo ratings yet

- Clamp-On Ground Resistance Tester: Enables Non-Contact Measurements of Ground ConductorsDocument1 pageClamp-On Ground Resistance Tester: Enables Non-Contact Measurements of Ground ConductorsAdam SonenshineNo ratings yet

- RC_Series_dsDocument6 pagesRC_Series_dsAda LakNo ratings yet

- TPS Series: Low EsrDocument13 pagesTPS Series: Low EsrJoão Paulo Lucas BarbosaNo ratings yet

- Current Sense Low Value Resistors: Part Number StructureDocument3 pagesCurrent Sense Low Value Resistors: Part Number StructureraveendraNo ratings yet

- Component Identification ElectronicsDocument23 pagesComponent Identification ElectronicsManjunatha Swamy VNo ratings yet

- Impulse Voltage & Accuracy Test ReportDocument2 pagesImpulse Voltage & Accuracy Test ReportCh ShahzadNo ratings yet

- BKR Cluster A - Gambar Kerja - T30Document10 pagesBKR Cluster A - Gambar Kerja - T30Eky YanuarNo ratings yet

- Panasonic CAP - FMDocument5 pagesPanasonic CAP - FMEvgeniiNo ratings yet

- 22-6800uf, 6.3v-50VDocument4 pages22-6800uf, 6.3v-50VPadmajan YesodharanNo ratings yet

- Carbon Film / Metal Film Resistors: ResistorDocument5 pagesCarbon Film / Metal Film Resistors: ResistorSanjay BoregowdaNo ratings yet

- Ejemplo Calculo KM Tabla EnzimasDocument4 pagesEjemplo Calculo KM Tabla EnzimasValentinaNo ratings yet

- Thick Film Chip Resistors: NEW 01005 Case SizesDocument5 pagesThick Film Chip Resistors: NEW 01005 Case SizesNICCompNo ratings yet

- Sulfur Resistant Chip Resistors for Harsh EnvironmentsDocument7 pagesSulfur Resistant Chip Resistors for Harsh EnvironmentsBelen Dall OglioNo ratings yet

- D/CRCW-P E3: VishayDocument6 pagesD/CRCW-P E3: VishayMohendra PatiNo ratings yet

- Aluminum Electrolytic Capacitors (Radial Lead Type) Series: FC Type: ADocument10 pagesAluminum Electrolytic Capacitors (Radial Lead Type) Series: FC Type: AgaddNo ratings yet

- R2 Vs V: R (MM) Velocidad Terminal Corregida (M/S)Document12 pagesR2 Vs V: R (MM) Velocidad Terminal Corregida (M/S)Nathalia CastilloNo ratings yet

- 7.5 - Rain TestDocument2 pages7.5 - Rain TestCh ShahzadNo ratings yet

- MS Series Bare Metal Resistors - Low Inductance Current SensingDocument1 pageMS Series Bare Metal Resistors - Low Inductance Current SensingUmar MahmudNo ratings yet

- DatasheetDocument1 pageDatasheetStuxnetNo ratings yet

- General Purpose Multilayer Ceramic CapacitorsDocument26 pagesGeneral Purpose Multilayer Ceramic CapacitorsparapNo ratings yet

- 408 Exp 1 GraphsDocument13 pages408 Exp 1 Graphsgoabaone kgopaNo ratings yet

- H (M) Veb (M/S) 0,15 1,7 0,12 1,5 0,09 1,3 0,06 1,1 Incertidumbre: ± 1 〖� 10 〗 ^ (−3) �Document5 pagesH (M) Veb (M/S) 0,15 1,7 0,12 1,5 0,09 1,3 0,06 1,1 Incertidumbre: ± 1 〖� 10 〗 ^ (−3) �Linha LadinoNo ratings yet

- Avxc S A0002375768 1Document12 pagesAvxc S A0002375768 1Belen Dall OglioNo ratings yet

- CJS161000JM DatasheetDocument1 pageCJS161000JM DatasheetElcho AresNo ratings yet

- c70260 Cuni2si0.4 UsDocument2 pagesc70260 Cuni2si0.4 UsBeyzanur TepecikNo ratings yet

- Niccs04353 1Document5 pagesNiccs04353 1Belen Dall OglioNo ratings yet

- TTRB S A0005338368 1-256536601Document3 pagesTTRB S A0005338368 1-256536601charlydigitalNo ratings yet

- ML Series: Low-Ohm Chip Resistors, 0.1W To 3WDocument1 pageML Series: Low-Ohm Chip Resistors, 0.1W To 3WStuxnetNo ratings yet

- Student259: Plot of Concentration (MG/L) Vs Time (Min)Document6 pagesStudent259: Plot of Concentration (MG/L) Vs Time (Min)monarchNo ratings yet

- Abaco de MoodyDocument3 pagesAbaco de MoodyjhordanNo ratings yet

- Eq KuDocument1 pageEq KuSKYhabiaNo ratings yet

- Instructions for Houillon Viscometer TubesDocument2 pagesInstructions for Houillon Viscometer Tubescarlos trilloNo ratings yet

- Ashcroft A Series DatasheetDocument7 pagesAshcroft A Series DatasheetRikiNo ratings yet

- Surface Mount PowerDocument5 pagesSurface Mount PowerM UMAR ABBASINo ratings yet

- Din 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy StandardsDocument1 pageDin 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy Standardsjepri purwantoNo ratings yet

- Lead (Pb)-Bearing Thick Film Chip ResistorsDocument8 pagesLead (Pb)-Bearing Thick Film Chip ResistorsManu MathewNo ratings yet

- SPEC-2450C August 2020Document7 pagesSPEC-2450C August 2020MayoNo ratings yet

- Thalachrome Se 500: High Corrosion ResistanceDocument1 pageThalachrome Se 500: High Corrosion ResistancethyskieNo ratings yet

- 6 Beads Commercial Signal mmz1608 en PDFDocument9 pages6 Beads Commercial Signal mmz1608 en PDFrakeeNo ratings yet

- Din 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy StandardsDocument1 pageDin 862 Caliper Accuracy Standards Jis B7507 Caliper Accuracy StandardsImanuel KurniawanNo ratings yet

- Uas MJ Invest PM 2020 (Kunci)Document2 pagesUas MJ Invest PM 2020 (Kunci)YanjNo ratings yet

- ISO 22768 general tolerances chartDocument1 pageISO 22768 general tolerances chartanil sajjanar100% (1)

- Le Cle I Re Foucault Final BDocument6 pagesLe Cle I Re Foucault Final BdanyNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BiCMOS FabricationDocument7 pagesBiCMOS FabricationMahabub Hossain100% (1)

- Ohs Compliant: S - C02SYANDocument1 pageOhs Compliant: S - C02SYANNaveed AhmedNo ratings yet

- X7R Dielectric, 6.3 - 250 VDC (Commercial Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Document26 pagesX7R Dielectric, 6.3 - 250 VDC (Commercial Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Naveed AhmedNo ratings yet

- Trimmer, 3/8" Square: Trimmer Multiturn Cermet, Top AdjustDocument1 pageTrimmer, 3/8" Square: Trimmer Multiturn Cermet, Top AdjustNaveed AhmedNo ratings yet

- Bicmos TechnologyDocument34 pagesBicmos TechnologyRahil Sharma100% (8)

- A Resistorless Voltage Reference With High-Order Temperature Curvature Compensation in 55 NM CMOS ProcessDocument7 pagesA Resistorless Voltage Reference With High-Order Temperature Curvature Compensation in 55 NM CMOS ProcessNaveed AhmedNo ratings yet

- A Sub-Threshold Based 747 NW Resistor-Less Low-Dropout Regulator For Iot ApplicationDocument7 pagesA Sub-Threshold Based 747 NW Resistor-Less Low-Dropout Regulator For Iot ApplicationNaveed AhmedNo ratings yet

- A Sub-Threshold Based 747 NW Resistor-Less Low-Dropout Regulator For Iot ApplicationDocument7 pagesA Sub-Threshold Based 747 NW Resistor-Less Low-Dropout Regulator For Iot ApplicationNaveed AhmedNo ratings yet

- Jing-Xing DAI, Fu-Hua LI, Jing-Hui AN, Yan ZHOU and Chen-Jian WUDocument5 pagesJing-Xing DAI, Fu-Hua LI, Jing-Hui AN, Yan ZHOU and Chen-Jian WUNaveed AhmedNo ratings yet

- TN65CLDR001 2 3Document674 pagesTN65CLDR001 2 3Naveed Ahmed100% (2)

- TN65CLDR001 2 3Document674 pagesTN65CLDR001 2 3Naveed Ahmed100% (2)

- Microelectronics Journal: ArticleinfoDocument6 pagesMicroelectronics Journal: ArticleinfoNaveed AhmedNo ratings yet

- Action Words for Bloom's TaxonomyDocument1 pageAction Words for Bloom's TaxonomyLycophronNo ratings yet

- Origins of Weak Inversion Circuits ExploredDocument4 pagesOrigins of Weak Inversion Circuits ExploredNaveed AhmedNo ratings yet

- Bicmos TechnologyDocument34 pagesBicmos TechnologyRahil Sharma100% (8)

- Engineer's Kit: EK-0805AS-X: Part No Inductance F Tol Q F SRF DCR ( ) Rated DC CurrentDocument1 pageEngineer's Kit: EK-0805AS-X: Part No Inductance F Tol Q F SRF DCR ( ) Rated DC CurrentNaveed AhmedNo ratings yet

- Peer-E-Kamil (The Perfect Mentor)Document390 pagesPeer-E-Kamil (The Perfect Mentor)Naveed AhmedNo ratings yet

- Bicmos Process FlowchartDocument8 pagesBicmos Process FlowchartNaveed AhmedNo ratings yet

- Atlas Users1Document1,576 pagesAtlas Users1Rituraj SinghNo ratings yet

- 3677 Mini-Circuits POS-300 - 01Document2 pages3677 Mini-Circuits POS-300 - 01Naveed AhmedNo ratings yet

- Hairlikeafox PDFDocument80 pagesHairlikeafox PDFNaveed AhmedNo ratings yet

- Ir 2010Document17 pagesIr 2010Naveed AhmedNo ratings yet

- A Three-Axis Micromachined Accelerometer With A CMOS PositioDocument13 pagesA Three-Axis Micromachined Accelerometer With A CMOS PositioNaveed AhmedNo ratings yet

- USB in A NutShellDocument33 pagesUSB in A NutShellNaveed AhmedNo ratings yet

- Bronchiolitis A Practical Approach For The General RadiologistDocument42 pagesBronchiolitis A Practical Approach For The General RadiologistTara NareswariNo ratings yet

- Common Carrier RulingDocument4 pagesCommon Carrier RulingChic PabalanNo ratings yet

- Pharmacy Preceptors Guild of The Philippines: ObjectiveDocument4 pagesPharmacy Preceptors Guild of The Philippines: ObjectiveCarline ScarletNo ratings yet

- Assignment 12Document7 pagesAssignment 12Anonymous mqIqN5zNo ratings yet

- Tugas Bahasa Inggris-1Document8 pagesTugas Bahasa Inggris-1Nur KomariyahNo ratings yet

- Ex 2013 1 (Recurrent)Document30 pagesEx 2013 1 (Recurrent)alh basharNo ratings yet

- Column FootingDocument57 pagesColumn Footingnuwan01100% (7)

- MSDS 442 BulkDocument2 pagesMSDS 442 BulkEliasNo ratings yet

- Entry-Exit Arrangement With Service RoadDocument1 pageEntry-Exit Arrangement With Service RoadRamBhuvan SonkarNo ratings yet

- GypsumDocument79 pagesGypsumMansi GirotraNo ratings yet

- BMK PDFDocument8 pagesBMK PDFHuỳnh Minh SángNo ratings yet

- Autocad Lab ManualDocument84 pagesAutocad Lab ManualRaghu RamNo ratings yet

- Fetal and Placental Development - FETAL Sac, Umbilical Cord .Abnormalities of PlacentaDocument150 pagesFetal and Placental Development - FETAL Sac, Umbilical Cord .Abnormalities of PlacentaKripa SusanNo ratings yet

- 05.G. Before Takeoff CheckDocument4 pages05.G. Before Takeoff CheckUDAYAPRAKASH RANGASAMYNo ratings yet

- Assignment in English Plus Core 11 Full CircleDocument76 pagesAssignment in English Plus Core 11 Full CircleRitu Maan68% (38)

- Systems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualDocument16 pagesSystems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualBianca LizardoNo ratings yet

- 16 Balance TestDocument15 pages16 Balance Testelga saniNo ratings yet

- XMSDS Sunflower Seed Oil 9925156Document6 pagesXMSDS Sunflower Seed Oil 9925156Lisa RobertsonNo ratings yet

- Capacitores Electroliticos SMDDocument8 pagesCapacitores Electroliticos SMDalvaro marrugoNo ratings yet

- SaponificationDocument2 pagesSaponificationK.SaravananNo ratings yet

- 2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFDocument9 pages2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFfawadintNo ratings yet

- Material ManagementDocument106 pagesMaterial ManagementRomi AfriansyahNo ratings yet

- Concept of StateDocument10 pagesConcept of StateAryansh ShuklaNo ratings yet

- Bs. in P&O India. Syllabus 2010Document58 pagesBs. in P&O India. Syllabus 2010Priscila Arriagada PulgarNo ratings yet

- Bartle Introduction To Real Analysis SolutionsDocument7 pagesBartle Introduction To Real Analysis SolutionsSam Sam65% (20)

- Fitness RX For Women - December 2013Document124 pagesFitness RX For Women - December 2013renrmrm100% (2)

- Worthy - Elevation WorshipDocument1 pageWorthy - Elevation WorshipSabine J.100% (1)

- Ic M802 UDocument79 pagesIc M802 Uharis_fikriNo ratings yet

- LP PG Conversion To Thar CoalDocument3 pagesLP PG Conversion To Thar CoalRaja Zeeshan100% (1)

- Kraby System 2018Document22 pagesKraby System 2018soga010178No ratings yet