Professional Documents

Culture Documents

QOF 150-200 Technical Datasheet August 31 2020

QOF 150-200 Technical Datasheet August 31 2020

Uploaded by

sakura_jCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QOF 150-200 Technical Datasheet August 31 2020

QOF 150-200 Technical Datasheet August 31 2020

Uploaded by

sakura_jCopyright:

Available Formats

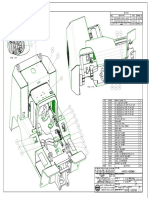

ENGINEERING DATA SHEET

Model QOF150 QOF200

Nominal Power - Main Motor kW 110 145

Nominal Power - Main Motor HP 150 200

Effective working pressure (psi) 100 116 125 100 116 125

Maximum Operating Pressure (2) (psig) 125 125 125 125 125 125

Reference conditions QOF150 QOF200

bar abs 1 1

Relative humidity % 0 0

Ambient temperature °F 68 68

Motor shaft speed rpm 3560 3560

Minimum working pressure psi 65 65

Min/Max ambient temperature °F 32 / 104 32 / 104

Sump Oil Capacity liters 49 49

Performance Data Standard Unit QOF150 QOF200

Effective working pressure (psi) 100 116 125 100 116 125

Capacity FAD (1) cfm 673.2 672.7 672.3 828.9 828.5 828.1

Package Input Power with Fan - Air Cooled (4) kW 126.2 133.6 138.0 160.2 168.5 173.6

Specific Power - Air Cooled (5) kW/100cfm 18.75 19.86 20.53 19.33 20.34 20.96

Power input at no load kW 32.2 39

Power input cooling fan (s) kW 2 x 3.35 2 x 3.35

Motor Shaft Speed rpm 3560 3560

Drive motor efficiency (3) % 95 95.4

Fan motor efficiency %

Noise level (6) dB(A) 79.5 79.5

Design Data QOF150 QOF200

Dimensions ( maximum )

Length inches 118.1 118.1

Width inches 64.1 64.1

Height inches 78.7 78.7

Net Weight - Air Cooled lbs 6365 6786

Air Discharge Inches NPT 3 3

Condensate Drain Inches NPT 1/2 1/2

Aftercooler CTD (°F) 10-12 10-12

Cooling air flow referred to air inlet grating after

cfm 8836 8836

cooler fans

Heat Rejection to Air @116PSI BTU/MIN 7218 9103

Max. allowable pressure drop in ducting before or

in H2O .22/.12 .22/.12

after the compressor (95F/104F)

Electrical Data QOF150 QOF200

Full load current (Amps) (7) (8) 460/3/60 209.8 263.9

Notes:

(1) FAD (Free Air Delivery) is full package performance including all losses. Tested in accordance with Annex C to ISO 1217

(2) Maximum pressure at package discharge, value at which compressor will stop when unit operating at maximum target pressure

(3) IE3 efficiency motor

(4) Measured at rated capacity and rated pressure

(5) Specific power Rated and Certified in accordance with Annex C to ISO 1217

(6) Measured according to ISO 2151: 2004 using ISO 9614/2 (sound intensity method).

(7) 90°C copper cables. Always apply local electrical codes for sizing cables and fusing.

(8) Time delay fuse recommended. Apply local electrical codes for fuse sizing

Design and specifications are subject to change without notice or obligation.

1 8/31/2020

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- City of Miami Planning and Zoning Department Udrb Application FormDocument22 pagesCity of Miami Planning and Zoning Department Udrb Application Formthe next miamiNo ratings yet

- Spears® Technical Information: Injection Molded Dimension ReferencesDocument1 pageSpears® Technical Information: Injection Molded Dimension Referencessakura_jNo ratings yet

- Spears® Technical Information: Fabricated Dimension ReferencesDocument1 pageSpears® Technical Information: Fabricated Dimension Referencessakura_jNo ratings yet

- K1YnzEkeL 9 161 544 019 GFDocument1 pageK1YnzEkeL 9 161 544 019 GFsakura_jNo ratings yet

- 1829 005BLDocument1 page1829 005BLsakura_jNo ratings yet

- Manual DHWDocument12 pagesManual DHWsakura_jNo ratings yet

- Core Identi Fication Guide: Automatic Roll FiltersDocument2 pagesCore Identi Fication Guide: Automatic Roll Filterssakura_jNo ratings yet

- Spears® Technical Information: Injection Molded Dimension ReferencesDocument1 pageSpears® Technical Information: Injection Molded Dimension Referencessakura_jNo ratings yet

- Valve and Controller Manual: Doc #98311000/rev. CDocument76 pagesValve and Controller Manual: Doc #98311000/rev. Csakura_jNo ratings yet

- PTC and PTF Pivotrol Pump ManualDocument10 pagesPTC and PTF Pivotrol Pump Manualsakura_jNo ratings yet

- Valvula Mariposa FlowsealDocument12 pagesValvula Mariposa Flowsealsakura_jNo ratings yet

- B-S5A-5B Valve Status MonitorDocument6 pagesB-S5A-5B Valve Status Monitorsakura_jNo ratings yet

- NGF Series - Element Replacement ProcedureDocument2 pagesNGF Series - Element Replacement Proceduresakura_jNo ratings yet

- SDS - Quin Syn PG - 030715 - Us - enDocument9 pagesSDS - Quin Syn PG - 030715 - Us - ensakura_jNo ratings yet

- Material Safety Data Sheet: Revision Date: 07/11/05 Supercedes: 04/08/05 Activated AluminaDocument4 pagesMaterial Safety Data Sheet: Revision Date: 07/11/05 Supercedes: 04/08/05 Activated Aluminasakura_jNo ratings yet

- Varnish Removal Insert, Vri 27/27: Product SheetDocument1 pageVarnish Removal Insert, Vri 27/27: Product Sheetsakura_jNo ratings yet

- Introduction To Operations ManagementDocument40 pagesIntroduction To Operations ManagementJulia Mae PatsoNo ratings yet

- MRTS StudyDocument36 pagesMRTS StudyRajithacad100% (1)

- Temesgen DolaDocument83 pagesTemesgen DolaBIRUK FEKADUNo ratings yet

- Train PresentationDocument2 pagesTrain Presentationfish manNo ratings yet

- Discontinued Products & MaintenanceDocument3 pagesDiscontinued Products & MaintenanceZafar Yab100% (1)

- Wynyard Walk - Consult Award 2017 - FinalDocument8 pagesWynyard Walk - Consult Award 2017 - FinalUcok DedyNo ratings yet

- Truck LDocument6 pagesTruck LJohnNo ratings yet

- Tren TolucaDocument3 pagesTren TolucaBRYAN CASTILLO HEREDIANo ratings yet

- Network AnalysisDocument23 pagesNetwork Analysisraghav dhanukaNo ratings yet

- The Diligence Required of Common Carriers - Cruz v. Sun Holidays, Inc. (622 SCRA 389)Document1 pageThe Diligence Required of Common Carriers - Cruz v. Sun Holidays, Inc. (622 SCRA 389)Kristiana Montenegro GelingNo ratings yet

- Catan Explorers & Pirates RulebookDocument20 pagesCatan Explorers & Pirates RulebookSd JacobsNo ratings yet

- Costco Final 4-25-20 ComplaintDocument30 pagesCostco Final 4-25-20 ComplaintrkarlinNo ratings yet

- JD-1300E SpecificationDocument14 pagesJD-1300E Specificationedgar cabrera100% (2)

- Parts ManualDocument228 pagesParts ManualandrymartNo ratings yet

- Kam CSM: PER API 8.3, ASTM D5854Document2 pagesKam CSM: PER API 8.3, ASTM D5854SaputraNo ratings yet

- BoardingCard 271752847 FCO OTPDocument1 pageBoardingCard 271752847 FCO OTPMatteo PagliaNo ratings yet

- Fowler BedDocument12 pagesFowler BedChristina WNo ratings yet

- REC122786 KPA Truck Loading and Unloading Operations V3Document9 pagesREC122786 KPA Truck Loading and Unloading Operations V3Ragu RamsinghNo ratings yet

- St. Louis Traffic CitationsDocument6 pagesSt. Louis Traffic CitationsLexi CortesNo ratings yet

- Labour Rate Analaysis and FinalizationDocument39 pagesLabour Rate Analaysis and FinalizationPankaj JagtapNo ratings yet

- Facts and Figures For The EU Toy IndustryDocument25 pagesFacts and Figures For The EU Toy IndustryGutNo ratings yet

- Method Statement (Towercrane)Document17 pagesMethod Statement (Towercrane)Adura OgunnuNo ratings yet

- E0001-S02-Erz-Dg-30036-00 SLDDocument6 pagesE0001-S02-Erz-Dg-30036-00 SLDsenthilNo ratings yet

- EMD Locomotive Specification Book SD40-SPEC8054-31DEC65Document23 pagesEMD Locomotive Specification Book SD40-SPEC8054-31DEC65rodizianoNo ratings yet

- LA-2017.12.28-Land Acquisition Under The National Highways Act, 1956 - Comprehensive Guidelines ThereonDocument31 pagesLA-2017.12.28-Land Acquisition Under The National Highways Act, 1956 - Comprehensive Guidelines ThereonCMU MathuraNo ratings yet

- Indigo - MM PresentationDocument19 pagesIndigo - MM PresentationhemanthsudevNo ratings yet

- I PartialOral Test - Docxana CristinaDocument7 pagesI PartialOral Test - Docxana CristinaLilliana Jirón GutiérrezNo ratings yet

- English For Abecedarian Module 1 - ESDocument27 pagesEnglish For Abecedarian Module 1 - ESAbdulazizAlghamdiNo ratings yet

- Owner'S Manual: BK175 & BK215Document38 pagesOwner'S Manual: BK175 & BK215Brock LynamNo ratings yet