Professional Documents

Culture Documents

D9.03XLS Storage Tank Heating Design

D9.03XLS Storage Tank Heating Design

Uploaded by

ezgi ardıçCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D9.03XLS Storage Tank Heating Design

D9.03XLS Storage Tank Heating Design

Uploaded by

ezgi ardıçCopyright:

Available Formats

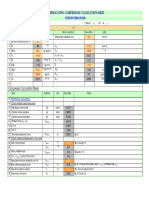

Case D9.

03 Storage Tank Heating System - Heat Tank fro

Coil Inlet Temperature ti degC 15.26 degF

Coil Outlet Temperature to degC 15.05 degF

Vessel Temperature tc degC 12.00 degF

Pipe Outside Diameter 2"x10 SS do mm 60.3 in

Tube hc (Cell M32) W/m2-degK 26.41 ∆t/do

Tube hi (Cell I13) W/m2-degK 3003.076 Manual Result

Tube wall m 0.00277

Thermal Conductivity SS W/m-degK 16

Fouling Ri m2-degK/W 0.000176 Manual Entry

Fouling Ro m2-degK/W 0.000528 Manual Entry

Overall Heat Transfer Coefficient W/m2-degK 25.60 Manual Result

Liquid Volume m3 3842.75

Liquid Level m 16.80

Ambient Temperature degC 12.00 Manual Entry

Heat Loss Heat Transfer Area m2 1442.80 Manual Entry

Heat Loss Heat Transfer Coefficient W/m2-degK 1.13 Manual Entry

Tank T22 Heat Loss duty kW 0.00

Circulation Tank m2 3.5

Heat Loss Heat Transfer Coefficient W/m2-degK 1.2

Heat Loss Duty kW 0.013

Heater Duty kW 0.01

Control Logic

Electric Heater Duty kW 75.00 75.00

Client Heat Loss Calculation Data

T22 & T23 Dimensions

Diameter mm 17068.80

Height mm 18288.00

Heat Loss Estimate ∆T Basis ºC 15.00 Heat Loss kW

Insulated Side U W/m2.ºC 0.50

7.2

Insulated Side Area m2 964.57

Uninsulated Side U W/m2.ºC 22.70

5.5

Uninsulated Side Area m2 16.09

Roof U W/m2.ºC 1.00

3.5

Roof Area m2 233.35

Base U W/m2.ºC 2.37

8.1

Base Area m2 228.82

Mean U W/m2.ºC 1.12

24.3

Total Area m2 1442.83

Total Heat Loss (Check Sum) kW 24.3

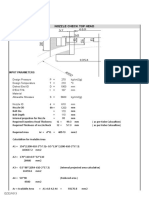

System - Heat Tank from 12 deg C to 15 degC - Ambient at 12 deg C - Heater Duty 75 kW max

59.473 Pipe Inside Diameter 2"x10 SS mm 54.8

59.096 Coil velocity m/s 1.18

53.600 Tubeside Density kg/m3 998.69

Inside Film

2.374 Coefficient hi Re Coil Inlet Dimensionless 55532

2.39 Calculation Cp Btu/lb-F 1.002

Reference Viscosity Bulk lb/ft-h 2.797

Perry 10.16 Thermal Conductivity Btu/h-ft-F 0.342

Seider Tate Viscosity Wall 5 degC lb/ft-h 3.65

Equation Pr Coil Inlet Dimensionless 8.20

Nu 278.03

hi Btu/ft2-h-F 528.90

Static Lift m H2O 2.00

Coil Pressure Drop bar 0.117

Return Pressure Drop bar 0.601

Circulating Heater Pressure Drop bar 0.100

Pump Head Pump to Heater Pressure Drop bar 0.416

Calculation Heater to Tank Pressure Drop bar 0.265

Total head due to pressure drop bar 1.500

Pump head m H2O 17.30

Pump Suction bar -0.166

Methyl Ester Density ρ1 at 41degF kg/m3 884.24

Outside Film Methyl Ester Density ρ2 at 131degF kg/m3 848.87

Coefficient Contents Density ρf kg/m3 877.222

hc Thermal Conductivity kf Btu/h-ft-F 0.059

Calculation Viscosity μf lb/ft-h 18.436

Reference

Cf Btu/lb-F 0.476

D.Q.Kern

Chapter 10 Thermal Expansion β l/F 4.54E-04

Equation Gfc 1.73E-05

10.14 Wall Temperature degC 15.05

Film Coefficient hc Btu/ft2-h-degF 9.30

3 2

Δt ≈ ( t t )/ 2− t ρ −1/ ρ k ρc β

0 .25

Δt

[ ]

1/

i+ o c

β= 2 1

Gfc = f f f

h =116 Gfc

d d (t − t )(1/ ρ ) ' c

do

o o 2 1 av

μ f

File Ref Case 11.06 Storage Tank Heating Design

Cell Colour Key

Data to CHEMCAD

Result from CHEMCAD

Spreadsheet Calculation

y 75 kW max

in 2.15748

ft/s 3.87

lb/ft3 62.32

Dimensionless 55762.57

W/m2-K 3003.08

Manual Entry

m H2O 15.30

lb/ft3 55.17658 t1 degF 41

lb/ft3 52.96949 t2 degF 131

lb/ft3 54.73867

1/ρav 0.018494

μf' units cp 7.619504

kJ/kg-K 2.001

degC 15.04 Uncertainty factor

W/m2-degK 52.83 0.5 26.41345

0 .25

Δt h d = 0. 023Re Pr ( μ/ μ )

[ ]

0. 8 0. 33 0 .14

116 Gfc

i i

w

do k

Vessel temperature control with hot water

temperature override. If vessel temperature

below preset value heater power on full provided

water temperature <85 degC. Heater power is

modulated to hold water temperature below 85

degC.

You might also like

- TankjktDocument57 pagesTankjktAnonymous 20VAru100% (2)

- Calculo Venteo API 2000Document3 pagesCalculo Venteo API 2000Produccion Vegetal100% (1)

- SCR Mean - Metal - Temps For Heat Exchanger TubeDocument2 pagesSCR Mean - Metal - Temps For Heat Exchanger TubescranderiNo ratings yet

- Thermal Design of Water Cooled DuctDocument8 pagesThermal Design of Water Cooled Ductpavan100% (1)

- Internal Coil CalculationDocument19 pagesInternal Coil CalculationMr Incognito100% (3)

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Insulation ThicknessDocument2 pagesInsulation ThicknessShashi Kant KumarNo ratings yet

- Coil HeatDocument4 pagesCoil HeatTarmana Antt50% (2)

- Heating Coil Sizing For Fuel Oil TankDocument2 pagesHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraNo ratings yet

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Document4 pagesDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNo ratings yet

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- NT42 Calculation Heat Transfer of Storage Tank Rail TankDocument2 pagesNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHNo ratings yet

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Venteo API 2000 (Amine)Document8 pagesVenteo API 2000 (Amine)Produccion VegetalNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 pagesSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1No ratings yet

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocument2 pagesAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanNo ratings yet

- Coil Heat CalculationDocument2 pagesCoil Heat CalculationTarmana Antt100% (1)

- Steam Coil SizingDocument21 pagesSteam Coil SizingMildogg100% (1)

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- Crude Oil Storage Tank Heating CoilDocument3 pagesCrude Oil Storage Tank Heating CoilbadelitamariusNo ratings yet

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 pagesWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- Weir Plate or Baffle Plate CalculationDocument2 pagesWeir Plate or Baffle Plate CalculationamaNo ratings yet

- AST Heating Coil Design Calculation Rev 0Document3 pagesAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- Heat Loss /vesselDocument2 pagesHeat Loss /vesselSapariya Hitesh50% (2)

- Heat Loss Tank FarmDocument4 pagesHeat Loss Tank FarmCorrado CannellaNo ratings yet

- Agitator Vessel Design CostingDocument20 pagesAgitator Vessel Design CostingneelNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3Document2 pagesSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Steam Coil DesignDocument2 pagesSteam Coil DesignHendri SinagaNo ratings yet

- Shell Tube Heat Exchanger CalculationDocument20 pagesShell Tube Heat Exchanger CalculationĐoàn TrangNo ratings yet

- Heat Transfer in Jacketed VesselDocument2 pagesHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Mean Metal TempDocument1 pageMean Metal TempsankaranNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- Perhitungan Dan Disain HeaterDocument19 pagesPerhitungan Dan Disain HeatersehonoNo ratings yet

- Nozzle Load T1011 12Document12 pagesNozzle Load T1011 12koyahassanNo ratings yet

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid LambertNo ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Nozzle Check Top Head: Input ParametersDocument2 pagesNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- Half Coil For VersselDocument1 pageHalf Coil For VersselhuangjlNo ratings yet

- Circulating Fluidized Bed Boiler Design and OperationDocument9 pagesCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoNo ratings yet

- Coil in Agitated Vessel SizingDocument8 pagesCoil in Agitated Vessel Sizingankur2061No ratings yet

- Heat Exchanger Calculation Version 2Document2 pagesHeat Exchanger Calculation Version 2huangjlNo ratings yet

- Vent StackDocument6 pagesVent Stackiuiuiooiu0% (1)

- Docslide. Limpet Coil CalculationDocument1 pageDocslide. Limpet Coil CalculationAdrian StoicescuNo ratings yet

- Tank Heat CalculationDocument7 pagesTank Heat CalculationElton Situmeang100% (3)

- Tank Heat LossDocument25 pagesTank Heat Lossdanmaltais100% (3)

- Vent Capacity (API Standard 2000)Document1 pageVent Capacity (API Standard 2000)Vince Bagsit PolicarpioNo ratings yet

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 pagesBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- Limpet Coil CalculationDocument1 pageLimpet Coil Calculationkirandas_mullassery100% (1)

- Pumps Calculation 2Document2 pagesPumps Calculation 2Alchemy EngNo ratings yet

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Heat Loss Insulated PipeDocument14 pagesHeat Loss Insulated PipeJonson CaoNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ParmarNo ratings yet

- Heat Loss Insulated PipeDocument5 pagesHeat Loss Insulated Pipe22238.spoNo ratings yet

- Pipe Insulation CalculationDocument2 pagesPipe Insulation CalculationalvinchuanNo ratings yet

- Tank SizeDocument7 pagesTank SizeSteve WanNo ratings yet

- Large Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalDocument2 pagesLarge Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalBarmar SbahiNo ratings yet

- Monitoring Purchase Orders and Manual EncumbrancesDocument1 pageMonitoring Purchase Orders and Manual EncumbrancesBarmar SbahiNo ratings yet

- August PMDocument1 pageAugust PMBarmar SbahiNo ratings yet

- 44) BC9740Document1 page44) BC9740Barmar SbahiNo ratings yet

- Heating Coil CalculationDocument1 pageHeating Coil Calculationyatin888100% (1)

- Procurement Manual 2017 Roll OutDocument9 pagesProcurement Manual 2017 Roll OutBarmar SbahiNo ratings yet

- Slip Resistance: or orDocument3 pagesSlip Resistance: or orBarmar SbahiNo ratings yet

- Oils, Edible: Palm: Cautionary Response InformationDocument2 pagesOils, Edible: Palm: Cautionary Response InformationBarmar SbahiNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 pagesSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1No ratings yet

- Heat Transfer Tube Coil Sizing: Tfe and MetalDocument2 pagesHeat Transfer Tube Coil Sizing: Tfe and MetalBarmar SbahiNo ratings yet

- Technical Data 6es7315 2af03 0ab0Document6 pagesTechnical Data 6es7315 2af03 0ab0Barmar SbahiNo ratings yet