Professional Documents

Culture Documents

En 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For Remelting

Uploaded by

Bahar ÇolakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En 1706 Aluminum and Aluminum Alloys Castings en 1676 Aluminum Alloyed Ingots For Remelting

Uploaded by

Bahar ÇolakCopyright:

Available Formats

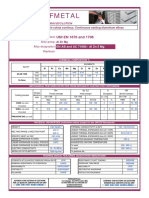

Standard: EN 1706 ALUMINUM AND ALUMINUM ALLOYS CASTINGS

EN 1676 ALUMINUM ALLOYED INGOTS FOR REMELTING

Alloy group: Al Si 9 Mg

Alloy designation: EN AB and AC 46000 - Al Si 9 Cu 3 (Fe)

Replaces:

R l DIN 226 D - GD Al Si 9 Cu 3

CHEMICAL COMPOSITION %

ELEMENTS

ALLOY Individual Global

Si Fe Cu Mn Mg Cr Ni Zn Pb Sn Ti impurities impurities

min 80

8,0 06

0,6 20

2,0 0 15

0,15

EN AB 46000

max 11,0 1,1 4,0 0,55 0,55 0,15 0,55 1,2 0,35 0,15 0,20 0,05 0,25

min 8,0 2,00 0,10 0,10

DIN 226 D

max 11,0 1,0 3,50 0,5 0,50 0,10 0,30 1,20 0,20 0,10 0,15 0,05 0,25

MECHANICAL FEATURES DETECTED FROM SEPARATE CASTING TEST SPECIMENS

Rm Sp 0,2 A HB

Temper Tensile strenght Proof Stress Elongation Brinell hardness

Castingg pprocess

Cast ocess designat

des g at

ions EN 1706 DIN 1725 EN 1706 DIN 1725 EN 1706 DIN 1725 EN 1706 DIN 1725

Mpa N/mm2 Mpa N/mm2 % % HBW HB

SAND (as cast)

Annealed

CHILL (as cast)

Annealed

PRESSURE DIE (as cast) F 240 240 - 310 140 140 - 240 1 0,5 - 3 80 80 - 120

Tel/Phone : +90 212 875 22 22

Merkez Ofis/Head Office : Baksav San.Sit Mustafa Kurdoğlu Cad. no:22/2 Beylikdüzü/ISTANBUL/TURKEY

Fabrika/Factory Faks/Fax : +90 212 875 99 83

: Mimarsinan Mah. Eski Bağlar Cad. No:23 Kapaklı - Çerkezköy / Tekirdağ/TURKEY

E-posta/E-mail : info@mesek.com.tr

You might also like

- Versant English Test Sample Email WritingDocument8 pagesVersant English Test Sample Email Writingrama devi88% (16)

- Ratio Analysis Missing FiguresDocument1 pageRatio Analysis Missing FiguresFahad Batavia0% (1)

- SMChap 011Document59 pagesSMChap 011testbank100% (2)

- Cu Zn 15 alloy properties and applicationsDocument2 pagesCu Zn 15 alloy properties and applicationsPetrus UngureanuNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BS en 00755-9-2016Document25 pagesBS en 00755-9-2016Luis SierraNo ratings yet

- The Efficacy of Talent Management in International Business The Case of European MultinationalsDocument16 pagesThe Efficacy of Talent Management in International Business The Case of European MultinationalstheonlypaulNo ratings yet

- BUS 1101 Principles of Business Management Written Assignment Unit 2Document4 pagesBUS 1101 Principles of Business Management Written Assignment Unit 2Azalia Delgado Vera100% (1)

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- EN47100Document2 pagesEN47100tsonjayaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706satheeskumar VikramasingarajNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- RAFFMETAL: THE ALUMINIUM EVOLUTIONDocument2 pagesRAFFMETAL: THE ALUMINIUM EVOLUTIONAmandeep SinghNo ratings yet

- CuNi18Zn20 M18 CDocument3 pagesCuNi18Zn20 M18 CJORDAN JUNOR ELLANo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document1 pageRaffmetal: UNI EN 1676 and 1706swaroop NalamNo ratings yet

- Raffmetal aluminium alloy guideDocument2 pagesRaffmetal aluminium alloy guideDhamodaran RNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- RAFFMETAL: The Aluminium EvolutionDocument2 pagesRAFFMETAL: The Aluminium EvolutionSachin JawaleNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- The Aluminium Evolution: Continuous Casting Aluminium AlloysDocument2 pagesThe Aluminium Evolution: Continuous Casting Aluminium AlloysHareth MRAIDINo ratings yet

- Is For Heat Resistant Plates in Grade Hi, Hii, 17 Mn4, 15 Mo3, 13crmo44, 10crmo910 and Ast41 Steel GradeDocument2 pagesIs For Heat Resistant Plates in Grade Hi, Hii, 17 Mn4, 15 Mo3, 13crmo44, 10crmo910 and Ast41 Steel GradeAHMED FATHINo ratings yet

- EN71000 From ReinferdenDocument2 pagesEN71000 From ReinferdenJason WuNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- TNI2TIDocument2 pagesTNI2TIKureiNo ratings yet

- Join & Repair High-Carbon Steels with NiCr HLSDocument1 pageJoin & Repair High-Carbon Steels with NiCr HLSwalter091011No ratings yet

- B978 075064284 2 - 50008 9Document5 pagesB978 075064284 2 - 50008 9Tarun ChakrabortyNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

- Free Cutting Mild Steel: Chemical Composition in Volume PercentageDocument1 pageFree Cutting Mild Steel: Chemical Composition in Volume PercentageGANESH KUMARNo ratings yet

- CDA 84400 phosphor bronze alloy propertiesDocument4 pagesCDA 84400 phosphor bronze alloy propertiesShariq KhanNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Din 17200 C60Document2 pagesDin 17200 C60artanNo ratings yet

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document3 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801No ratings yet

- Indura Em12k-H400Document2 pagesIndura Em12k-H400Rodrigo CarizNo ratings yet

- FICHA Técnica Weld 71T-1 PDFDocument2 pagesFICHA Técnica Weld 71T-1 PDFCarlos Padilla67% (3)

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- Medium Strength Extrusion Alloy Data SheetDocument1 pageMedium Strength Extrusion Alloy Data Sheetankur panwarNo ratings yet

- Datasheet For Steel Grades Specialsteel X6Crnimob17-12-2Document3 pagesDatasheet For Steel Grades Specialsteel X6Crnimob17-12-2axis inspection solutionsNo ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardschetanNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- 03112015000000B - Boehler FOX NiCr 70 NB - CeDocument1 page03112015000000B - Boehler FOX NiCr 70 NB - CeFlori MovNo ratings yet

- Product Data Sheet: S 'Submerged Arc Welding'Document1 pageProduct Data Sheet: S 'Submerged Arc Welding'adanmeneses1No ratings yet

- EN 44300 AlSi12 (Fe) (A)Document2 pagesEN 44300 AlSi12 (Fe) (A)wafi2131No ratings yet

- EN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelDocument4 pagesEN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelNaiduNo ratings yet

- Arcaloy 430Nb (Rev.2)Document2 pagesArcaloy 430Nb (Rev.2)RobertoNo ratings yet

- 70cuni TigDocument3 pages70cuni TigGiannhs SeitaridhsNo ratings yet

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocument1 pageCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNo ratings yet

- Product Data Sheet - OK Tigrod 13.09 PDFDocument2 pagesProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNo ratings yet

- Bohler S EMK 6Document1 pageBohler S EMK 6Enaam AtaallahNo ratings yet

- BS 970 070 M46Document2 pagesBS 970 070 M46Dinesh GaikwadNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Regulation 118 Burning Behavior MaterialsDocument30 pagesRegulation 118 Burning Behavior MaterialsBahar ÇolakNo ratings yet

- Din 2768 English VersionDocument1 pageDin 2768 English VersionCesar Augusto Castellar OrtegaNo ratings yet

- BS en 00485-4-1994 (1998)Document19 pagesBS en 00485-4-1994 (1998)Bahar ÇolakNo ratings yet

- BS en 00485-4-1994 (1998)Document19 pagesBS en 00485-4-1994 (1998)Bahar ÇolakNo ratings yet

- ConcreteZero Campaign Overview and Commitment Framework May 2022 (Issue)Document9 pagesConcreteZero Campaign Overview and Commitment Framework May 2022 (Issue)John GiannakopoulosNo ratings yet

- Internet of Things Iot Advantages On E-LDocument7 pagesInternet of Things Iot Advantages On E-LselmiNo ratings yet

- CBLM - School Food Canteen ManagementDocument76 pagesCBLM - School Food Canteen ManagementCeejaay PelinaNo ratings yet

- My3 Pay Monthly Sims: E - Phones, Broadband & Sim Only DealsDocument4 pagesMy3 Pay Monthly Sims: E - Phones, Broadband & Sim Only DealsJames PattersonNo ratings yet

- Famous People: Charles GoodyearDocument4 pagesFamous People: Charles GoodyearFigen ErgürbüzNo ratings yet

- The Informal Sector and Covid-19 Economic Impacts: The Case of Bahia, BrazilDocument14 pagesThe Informal Sector and Covid-19 Economic Impacts: The Case of Bahia, BrazilYago AlvesNo ratings yet

- Joule L0Document12 pagesJoule L0matheusdetoniabapNo ratings yet

- It ResumeDocument4 pagesIt Resumedy9pmkq3100% (1)

- Juan's Electronics Adjusting EntriesDocument1 pageJuan's Electronics Adjusting EntriesCarren Whentrix TolandangNo ratings yet

- Epic Cards DeliveryDocument15 pagesEpic Cards Deliverybdmails rmyNo ratings yet

- Week 2 Tasks and MilestonesDocument52 pagesWeek 2 Tasks and MilestonesManoranjan8720% (5)

- CA FINAL Transfer PricingDocument11 pagesCA FINAL Transfer Pricingjkrapps100% (1)

- ELD-main-report 05 Web 72dpi PDFDocument170 pagesELD-main-report 05 Web 72dpi PDFHarish KumarNo ratings yet

- Public Distribution SystemDocument10 pagesPublic Distribution SystemNitika DhatwaliaNo ratings yet

- Filsyn Corporation Parent Company FS 12.31.2021Document50 pagesFilsyn Corporation Parent Company FS 12.31.2021Elsa MendozaNo ratings yet

- Hils On 2018Document10 pagesHils On 2018gbamhurbainNo ratings yet

- Redefining Home Field Advantage: A Game Plan For Enhancing Fan EngagementDocument20 pagesRedefining Home Field Advantage: A Game Plan For Enhancing Fan EngagementHarsh BhatNo ratings yet

- Asian Women in Top Management-Eight Country CasesDocument23 pagesAsian Women in Top Management-Eight Country CasesSara JordanNo ratings yet

- Assessed Task Two Part A: Analysis and Editing of A Written Professional TextDocument8 pagesAssessed Task Two Part A: Analysis and Editing of A Written Professional TextShehbaz KhanNo ratings yet

- BCM Business Administration Assignment - Strategic ManagementDocument3 pagesBCM Business Administration Assignment - Strategic ManagementAbdullah ShoaibNo ratings yet

- Corporate CultureDocument2 pagesCorporate CultureMae MarinoNo ratings yet

- Team Coaching 2023 - Info PackDocument24 pagesTeam Coaching 2023 - Info PackMohamed Sharaf EldinNo ratings yet

- Py 202303 Cgpay12023p03Document1 pagePy 202303 Cgpay12023p03Dark NationNo ratings yet

- MANAJEMEN PEMASARAN PT. PUNDI KENCANADocument53 pagesMANAJEMEN PEMASARAN PT. PUNDI KENCANAIlham ArdiansyahNo ratings yet

- Theory of Consumer BehaviourDocument81 pagesTheory of Consumer Behavioursupriya dasNo ratings yet