Professional Documents

Culture Documents

Vanceva - Colored Polyvinyl Butyral Interlayer: Product Technical Data

Uploaded by

Larry CastañedaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vanceva - Colored Polyvinyl Butyral Interlayer: Product Technical Data

Uploaded by

Larry CastañedaCopyright:

Available Formats

www.vanceva.

com

PRODUCT TECHNICAL DATA

Vanceva® - Colored Polyvinyl Butyral Interlayer

Vanceva® interlayers are premium colored plasticized polyvinyl butyral (PVB) sheets produced by Eastman

Chemical Company and its affiliates. These interlayers are permanently bonded through a heat and pressure

process to two or more pieces of glazing to produce laminates with impact and glass containment properties.

Laminated glass with the properly selected type of Saflex interlayer are capable of being classified as safety glass

in accordance with, but not limited to, various regulations such as ANSI Z26.1, ANSI Z97.1, AS/NZS 2208; CNS

1183, CPSC 16 CFR 1201, EN 12600 and ISO 29584.

Product Overview:

Vanceva interlayers, including Vanceva Colors, Vanceva Earth Tones and Vanceva Illusion White, are Saflex R

formulation products. Vanceva Colors and Vanceva Earth Tones have premium colorants uniformly distributed

throughout the sheeting. Vanceva Illusion White has a white gradient band of 30 cm with a gentle fade to clear in

the width of a single roll. All Vanceva products have demonstrably met or exceeded many regulations for

laminated safety glazing (including those listed above) when properly selected, laminated, and installed.

Vanceva interlayers are specifically formulated to provide exceptional durability when exposed to natural

weathering, especially when laminate edges are left unprotected from the elements. Vanceva interlayers have

been shown to be compatible and durable when laminated in intimate contact with most infrared reflective,

metal coated, ceramic frit, and printed glasses. Compatibility should always be verified through the coating, frit or

ink manufacturer.

Color Designations:

Vanceva Colors are typically an assembly of interlayer layers, up to 4 layers, between two pieces of glass and

are designated by the abbreviation “VCV” followed by a four-digit color code (e.g. #0234) so the designation for

the above example would be VCV #0234. Vanceva Illusion White is designated in the Vanceva Colors system

as layer code “J”.

Vanceva Earth Tones are designed to match traditional colored float glass. They are typically a single layer of

colored interlayer and are designated with the abbreviation “VCV” followed by a five-digit code which always

starts with an “S” (indicating a single layer). The “S” is followed by the color code (e.g.: #2165). This example

would be specified as VCV #S-2165. The use of the “S” is critically important when specifying by the color code.

Figure 1 shows the dramatic difference between products with the same numeric code with and without the “S”

present.

Figure 1: Vanceva Color (left) versus Vanceva Earth Tone (Right, requires “S”) nomenclature for code 2165.

Vanceva Colors and Vanceva Earth Tones, when used as a single layer are also given a descriptive name as

outlined in the table below. The table shows only the product nomenclature. A more detailed listing of Vanceva

Colors and other formulations as well as solar and optical properties for most transparent layered combinations

can be found at www.vanceva.com or by contacting your local Eastman representatives.

Applications Technical Documentation (ATD)

730 Worcester Street | Springfield, MA 01151

glazing@eastman.com | www.saflex.com | www.vanceva.com

product technical sheet - vanceva_033020.docx

Page 1 of 7

www.vanceva.com

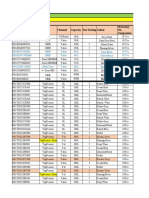

Table 1: Vanceva Color and Vanceva Earth Tones – Codes and Descriptive Names

Formulation

Vanceva Code Code Product Code Vanceva Name Color

Vanceva Colors

1 RB17 807800 Coral Rose Red

2 RB17 827800 Aquamarine Blue

3 RB17 837800 Smoke Grey Black

4 RB17 817800 Sahara Sun Yellow

5 RB17 805000 Ruby Red Red

6 RB17 825000 Sapphire Blue

7 RB17 835000 Evening Shadow Black

8 RB17 818600 Golden Light Yellow

9 RB17 216500 Arctic Snow White

A RB17 218000 Cool White White

C RB17 851500 Deep Red Red

D RB17 841400 True Blue Blue

E RB17 864100 Tangerine Orange

F RB17 220700 Polar White White

G RB17 830000 Absolute Black Black

H RB17 876100 Ocean Grey Grey

J RB45 216500 Illusion White Gradient White

Vanceva Earth Tones

S-0828 RB17 082800 Graphite Grey

S-3609 RB17 360900 Truffle Brown

S-3628 RB17 362800 Mocha Brown

S-3655 RB17 365500 Dusk Brown

S-3773 RB17 377300 Marine Blue-Green

S-3773 RB47 377300 Marine Blue-Green

S-5538 RB47 553800 Limestone 38 Bronze (0.76 mm only)

S-5558 RB17 555800 Limestone Bronze

S-6376 RB17 637600 Glacier Blue

S-6428 RB17 642800 Gobi Bronze

S-6452 RB17 645200 Dolomite Bronze

S-6452 RB47 645200 Dolomite Bronze

S-6544 RB17 654400 Shale Grey

S-6544 RB47 654400 Shale Grey

S-7558 RB17 755800 Sky Blue

Available Forms:

All Vanceva interlayers are supplied in roll form on 15.2 cm (6 inch) diameter cores.

Vanceva interlayers are supplied in a variety of roll lengths and widths. Most common standard roll length is 100

meters (328 feet). The most common thickness is 0.38 mm (0.015 inch), although some colors are available in

0.76 mm (0.030 inch) thickness.

Vanceva interlayers are produced in one adhesion level. Vanceva colored PVB interlayer is supplied in rolls as

refrigerated or interleaved with polyethylene that do not require refrigeration (additional charge applies).

Interleaving is not available for all products.

Please contact your Saflex Sales Manager, Technical Service Representative, Customer Service

Representative or visit www.saflex.com for further information.

Applications Technical Documentation (ATD)

730 Worcester Street | Springfield, MA 01151

glazing@eastman.com | www.saflex.com | www.vanceva.com

product technical sheet - vanceva_033020.docx

Page 2 of 7

www.vanceva.com

Storage Conditions:

Vanceva interlayers should be stored inside the moisture barrier bag that the roll is shipped in and maintained

within the temperatures recommended in the Saflex Laminating Guide. It is recommended that the interlayer be

used within a two-year period from purchase to minimize this roll blocking.

Laminating Conditions:

Eastman makes available to our fabricating customers a Saflex® Laminating Guide which details nominal methods

for storage, handling, and lamination of both Saflex and Vanceva PVB interlayer products. This technical guide is

available only from a Saflex Technical Service (TS) Representative or Saflex Sales Manager. To find the name

of the Saflex representative for your organization, call 1-800-636-8670.

Vanceva® colored PVB interlayer - Select properties1:

Vanceva®

Test Property Test Method Units Conditions

interlayer

Extent of Burning ASTM D635 mm - 7.9

Heat of ASTM E1354

MJ/kg - 31

Combustion ISO 1716

Flammability1 mm/min

Rate of Burning ASTM D 635 - <25

ºC

Self-Ignition ASTM D1929 ºC - 404

Smoke Density ASTM D2843 % - 5

50 mm/min

ISO 527-3 % 270

Elongation at 23ºC|50% RH

Failure 20 mm/min

JIS K6771 % 265

23ºC|50% RH

Poisson's Ratio ASTM D638 - 23ºC|50% RH 0.5

Shear Modulus; See Table

EN 16613 MPa Relaxation

G(t) Below

Mechanical ASTM D624 N/mm 23ºC|50% RH -

Tear Resistance

ASTM D1004 N/cm 23ºC|50% RH 112

50 mm/min

ISO 527-3 MPa 23

23ºC|50% RH

Tensile strength

20 mm/min

JIS K6771 MPa 20

23ºC|50% RH

Young's Modulus; See Table

EN 16613 MPa Relaxation

E(t) Below

Clear 3 mm

Haze ASTM D1003 % n/a

Glass

Optical Refractive Index ASTM D542 - 23ºC 1.479

Clear 3 mm

Yellowness Index ASTM E313 YI n/a

Glass

Applications Technical Documentation (ATD)

730 Worcester Street | Springfield, MA 01151

glazing@eastman.com | www.saflex.com | www.vanceva.com

product technical sheet - vanceva_033020.docx

Page 3 of 7

www.vanceva.com

Vanceva®

Test Property Test Method Units Conditions

interlayer

Frequency 1

Glass Transition

- ºC Hz Heating 25ºC±1

Temperature

Rate 3º C/min

cut/stacked to

Hardness ASTM D2240 Shore A 77

12.5 mm

Moisture EMN % - Target ± 0.05

Plasticizer EMN PHR - Target ± 2

ordered

Roll Length EMN m -

minimum

Physical

Specific

ASTM D792 g/cm3 23ºC 1.07

Gravity/Density

Specific Heat ASTM E1269 J/Kg -ºK 50ºC 1980

Thickness EMN mm 0.76 ±0.025 mm

Ordered

Width EMN cm -

minimum

ANSI Z26.1;

2.2 kg (5 lb) Ball ASTM F3006, - 0.76 mm Comply

ECE R43

EN 12600;

Twin Tyre 1B1 0.76 mm Comply

ISO 29584

Safety Class B

Glazing ANSI Z97.1;

45 kg (100 lb) Cat I;

Impact CPSC 16 CFR 0.38 mm Comply

Shot Bag 667 N

1201

(150 ftlb)

Class A;

ANSI Z97.1;

45 kg (100 lb) Cat II;

CPSC 16 CFR 0.76 mm Comply

Shot Bag 1779 N

1201

(400 ftlb)

Applications Technical Documentation (ATD)

730 Worcester Street | Springfield, MA 01151

glazing@eastman.com | www.saflex.com | www.vanceva.com

product technical sheet - vanceva_033020.docx

Page 4 of 7

www.vanceva.com

Test Property Test Method Units Vanceva® interlayer

Solar Transmittance % varies

Solar Reflectance % varies

LBNL WINDOW 7.0

Solar Absorptance NFRC 100 % varies

Visible Transmittance % varies

Visible Reflectance % varies

Solar Heat Gain

NFRC 300 SHGC | g value varies

Coefficient

Solar2 Sun Protection Factor Calculated SPF3 50+

Light to Solar Gain Calculated LSG varies

U Factor NFRC 100 W/m2-K varies

Damage Weighted

300 - 500 nm 0.33

(Tdw-K)

UV Factors

Damage Weighted

(maximum) 300 - 600 nm 0.65

(Tdw-ISO)

Transmitted UV 300 - 380 nm <1%

Vanceva®

Test Property Test Method Units Conditions

interlayer

Coefficient of Thermal 30ºC to

ASTM E831 ppm/°C 155

Expansion 100ºC

Thermal

Thermal Conductivity ASTM D5930 W/m*K 65ºC 0.2

Emissivity ASTM C1371 - 19.5ºC 0.94

1 - Data based on NOA for Saflex formulation

2 - Solar Data – Due to the colorants in Vanceva products, the solar, thermal, optical and color data will vary. Visit www.vanceva.com

for this data in thousands of combinations in 3 mm clear glass. Eastman also supplies calculated data upon request for most transparent

configurations. Calculations are performed using OPTIC and WINDOW 7.0 by Lawrence Berkeley National Laboratory.

3 - SPF is a calculated value based on the spectral data from a clear laminate and not a result of direct testing.

Applications Technical Documentation (ATD)

730 Worcester Street | Springfield, MA 01151

glazing@eastman.com | www.saflex.com | www.vanceva.com

product technical sheet - vanceva_033020.docx

Page 5 of 7

www.vanceva.com

The relaxation modulus and calculated Young’s modulus for Vanceva (colored PVB interlayer) based on

relaxation modulus values for a given duration at temperature is provided for use in calculating structural

capacity of laminated glass containing this product.

Vanceva® shear relaxation modulus G(t) (MPa)

Load duration Temperature (°C)

10 15 20 25 30 35 40 45 50 55 60

3 sec 52 29 11 4.2 1.7 0.82 0.56 0.46 0.40 0.36 0.31

10 sec 36 16 6.1 2.1 0.94 0.61 0.47 0.40 0.36 0.31 0.25

30 sec 25 8.6 2.9 1.2 0.69 0.49 0.42 0.37 0.32 0.26 0.16

1 min 18 6.2 2.1 0.90 0.58 0.46 0.39 0.35 0.29 0.21 0.10

5 min 7.3 2.3 1.0 0.59 0.46 0.39 0.34 0.28 0.19 0.07

10 min 5.0 1.7 0.77 0.51 0.42 0.37 0.32 0.24 0.13 0.02

30 min 2.4 1.0 0.59 0.45 0.39 0.33 0.27 0.16 0.03

1 hour 1.8 0.78 0.51 0.42 0.37 0.31 0.22 0.10

6 hours 0.81 0.51 0.42 0.36 0.30 0.20 0.06

12 hours 0.68 0.47 0.39 0.34 0.26 0.15 0.02

1 day 0.57 0.44 0.37 0.31 0.22 0.08

5 days 0.46 0.38 0.32 0.22 0.08

1 week 0.44 0.37 0.31 0.20 0.05

3 weeks 0.39 0.33 0.25 0.10

1 month 0.38 0.32 0.22 0.07

1 year* 0.30 0.17 0.02

10 years* 0.14

15 years* 0.10

50 years* 0.02

*values not validated

Applications Technical Documentation (ATD)

730 Worcester Street | Springfield, MA 01151

glazing@eastman.com | www.saflex.com | www.vanceva.com

product technical sheet - vanceva_033020.docx

Page 6 of 7

www.vanceva.com

Vanceva® Young's relaxation modulus E(t) (MPa)

Load

duration Temperature (°C)

10 15 20 25 30 35 40 45 50 55 60

3 sec 156 86 33 13 5.2 2.5 1.7 1.37 1.19 1.07 0.93

10 sec 109 48 18 6.3 2.8 1.8 1.4 1.21 1.08 0.94 0.74

30 sec 75 26 8.7 3.7 2.1 1.5 1.3 1.11 0.97 0.77 0.49

1 min 53 19 6.2 2.7 1.7 1.4 1.2 1.04 0.88 0.64 0.29

5 min 22 6.8 2.9 1.8 1.4 1.2 1.0 0.85 0.58 0.21

10 min 15 5.1 2.3 1.5 1.3 1.1 1.0 0.73 0.40 0.06

30 min 7.3 2.9 1.8 1.4 1.2 1.0 0.80 0.48 0.10

1 hour 5.4 2.3 1.5 1.3 1.1 0.93 0.67 0.29

6 hours 2.4 1.5 1.3 1.1 0.90 0.61 0.19

12 hours 2.1 1.4 1.2 1.0 0.79 0.44 0.06

1 day 1.7 1.3 1.1 0.94 0.66 0.24

5 days 1.4 1.1 1.0 0.67 0.23

1 week 1.3 1.1 0.92 0.60 0.15

3 weeks 1.2 1.00 0.74 0.31

1 month 1.2 0.96 0.67 0.20

1 year* 0.89 0.52 0.06

10 years* 0.42

15 years* 0.30

50 years* 0.05

*values not validated

Values calculated using E = 3G as per EN 16613 par 5.1; for exact values of the Young's modulus available actual Poisson's ratio can

be used

Notice: Although the information and/or recommendations as may be set forth herein (hereafter “Information”) are presented in good faith and believed to be correct at the

date hereof, Eastman Chemical Company and its subsidiaries and affiliates including Eastman Inc. (hereinafter "Eastman") make no representations or warranties as to the

completeness or accuracy thereof. Information is supplied upon the condition that the persons receiving same will make their own determination as to its suitability for their

purposes prior to use. In no event, will Eastman be responsible for damages of any nature whatsoever resulting from the use of or reliance upon Information or the product

to which Information refers. Nothing contained herein is to be construed as a recommendation to use any product, process, equipment or formulation in conflict with any

patent, and Eastman makes no representation or warranty, express or implied, that the use thereof will not infringe any patent. NO REPRESENTATIONS OR WARRANTIES,

EITHER EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER NATURE ARE MADE HEREUNDER WITH

RESPECT TO INFORMATION OR THE PRODUCT TO WHICH INFORMATION REFERS.

The data presented is derived from samples tested. Results are not guaranteed for all samples or for conditions other than those tested. Data and its respective measured,

calculated or estimated single number ratings is for glass panels only – glazing installed in frames may differ significantly in performance.

© 2020 Eastman Chemical Company. Eastman brands referenced herein are trademarks of Eastman or one of its subsidiaries or are being

used under license. The ® symbol denotes registered trademark status in the U.S.; marks may also be registered internationally. Non-

Eastman brands referenced herein are trademarks of their respective owners.

Applications Technical Documentation (ATD)

730 Worcester Street | Springfield, MA 01151

glazing@eastman.com | www.saflex.com | www.vanceva.com

product technical sheet - vanceva_033020.docx

Page 7 of 7

You might also like

- Service Bulletin: NUMBER: 13-101-18 Date: APPLICABILITY: All 2019MY Vehicles SUBJECT: 2019 MY Paint Coding InformationDocument3 pagesService Bulletin: NUMBER: 13-101-18 Date: APPLICABILITY: All 2019MY Vehicles SUBJECT: 2019 MY Paint Coding Informations.navarro.skcNo ratings yet

- SIBU Katalog PDFDocument120 pagesSIBU Katalog PDFMikeProkopenkoNo ratings yet

- WM PanasonicsDocument4 pagesWM PanasonicsKhalid RahmanNo ratings yet

- Culori Tabla LindabDocument12 pagesCulori Tabla LindabRadu MihaiNo ratings yet

- Carta Colores SW900Document4 pagesCarta Colores SW900Javier GonzalezNo ratings yet

- Yamaha Revstar ManualDocument23 pagesYamaha Revstar ManualusemabxNo ratings yet

- Neoxy Price List April 2019Document5 pagesNeoxy Price List April 2019Haru VaghelaNo ratings yet

- Scheda Colori A4 Baxi Design OkDocument2 pagesScheda Colori A4 Baxi Design OkRed AP A PerezNo ratings yet

- DespatchDocument2 pagesDespatchgsp_chemmmNo ratings yet

- Roca Pricelist Leaflet - 22 - Final-CompressedDocument12 pagesRoca Pricelist Leaflet - 22 - Final-CompressedSibi VarmanNo ratings yet

- E-Catalogue BambiDocument57 pagesE-Catalogue BambiDenny IrawanNo ratings yet

- TeckWrap Catalog 2019Document54 pagesTeckWrap Catalog 2019Len TanNo ratings yet

- Argelith Lieferprogramm GBDocument24 pagesArgelith Lieferprogramm GBmutyokaNo ratings yet

- IU Catalogue 2017Document176 pagesIU Catalogue 2017Julius IguguNo ratings yet

- Avery Dennison Supreme Wrapping Film: High Performance and Easy Application... in Your Choice of ColorsDocument2 pagesAvery Dennison Supreme Wrapping Film: High Performance and Easy Application... in Your Choice of ColorsCristian LibrepensadorNo ratings yet

- Big Size Helmets (XXL) : Merk Type Price (IDR)Document9 pagesBig Size Helmets (XXL) : Merk Type Price (IDR)junaidi abdillahNo ratings yet

- Price List SKU Bambi Eyewear (SYSTEM)Document4 pagesPrice List SKU Bambi Eyewear (SYSTEM)logistikmandirisoetaNo ratings yet

- List Ink Dan MixingDocument2 pagesList Ink Dan MixingFeby Kemala sariNo ratings yet

- Servierwagen-Verkleidung PBL enEXDocument2 pagesServierwagen-Verkleidung PBL enEXKeshor KiittuNo ratings yet

- SWF 2021 AdDocument3 pagesSWF 2021 AdJose LariosNo ratings yet

- Dulux Powder Colour Selector Web 2018Document8 pagesDulux Powder Colour Selector Web 2018dhani prayogoNo ratings yet

- E-Catalog 2021 January EditDocument84 pagesE-Catalog 2021 January EditMartin SantoyoNo ratings yet

- Marco Galaxy MX7 Recessed Downlighting Catalog 1982Document4 pagesMarco Galaxy MX7 Recessed Downlighting Catalog 1982Alan MastersNo ratings yet

- Viennaplusanthracite SUP018MDocument15 pagesViennaplusanthracite SUP018MCosmin RoboNo ratings yet

- Kingspan External Colour & Coating Brochure 082017 UK EN PDFDocument12 pagesKingspan External Colour & Coating Brochure 082017 UK EN PDFSuresh BabuNo ratings yet

- Kingspan External Colour & Coating Brochure 082017 UK EN PDFDocument12 pagesKingspan External Colour & Coating Brochure 082017 UK EN PDFSuresh BabuNo ratings yet

- LSI Masters Series Spec Sheet 1981Document2 pagesLSI Masters Series Spec Sheet 1981Alan MastersNo ratings yet

- Nixon Spring 2018 ECatDocument20 pagesNixon Spring 2018 ECatTim OttNo ratings yet

- Renolux v4nr04Document12 pagesRenolux v4nr04Simon KennyNo ratings yet

- AKNEWSOCT2017ENDDocument6 pagesAKNEWSOCT2017ENDOTTONo ratings yet

- PVC Ceiling Wall Panels Best Low Price India SupplierDocument12 pagesPVC Ceiling Wall Panels Best Low Price India SupplierOnesmas TwinomugishaNo ratings yet

- Cadweld PluscuDocument2 pagesCadweld PluscuAmine DabbabiNo ratings yet

- Carta ModelAir Rev03Document2 pagesCarta ModelAir Rev03ogrosx0% (1)

- LCDoane MIL F 16377 10 Luminaire 300BP Series - Revised - 122121Document1 pageLCDoane MIL F 16377 10 Luminaire 300BP Series - Revised - 122121Dhiraj KapoorNo ratings yet

- FLAVIKERDocument4 pagesFLAVIKERahmedNo ratings yet

- Product CatalogueDocument10 pagesProduct CatalogueBhagwati Pd GuptaNo ratings yet

- GX1000 Service ManualDocument32 pagesGX1000 Service ManualJadi PurwonoNo ratings yet

- Three-Dimensional Effect With Fundermax Individualdekor: For People Who CreateDocument8 pagesThree-Dimensional Effect With Fundermax Individualdekor: For People Who Createdilian bikovNo ratings yet

- Valve Data Sheet 01Document1 pageValve Data Sheet 01kapsarcNo ratings yet

- Tapered SeamDocument2 pagesTapered SeamCathy PrikhodkoNo ratings yet

- Zotano LadrilloDocument6 pagesZotano LadrilloEdwin TapiaNo ratings yet

- Max - Ford Colour Codes - 2005 2015Document25 pagesMax - Ford Colour Codes - 2005 2015Nugie Dwika RiyantoNo ratings yet

- DC Combine Master CatalogDocument68 pagesDC Combine Master CatalogSai Teja ChandupatlaNo ratings yet

- Dyes ListDocument2 pagesDyes ListMs.SaziaNo ratings yet

- ISSFDocument1 pageISSFspibluNo ratings yet

- Duro Dyne Stick PinDocument12 pagesDuro Dyne Stick PinEmad ArafaNo ratings yet

- No Nama Kode Stock HD HADocument5 pagesNo Nama Kode Stock HD HADjie GuerrNo ratings yet

- Red Spot BS Industrial Fuse Holders: BussmannDocument13 pagesRed Spot BS Industrial Fuse Holders: BussmannNarendra SachdevNo ratings yet

- Axalta PaintDocument8 pagesAxalta PaintElliza IshakNo ratings yet

- L07 5211 SPSHTDocument2 pagesL07 5211 SPSHTKEMP REVOLUTIONS SACNo ratings yet

- Abrasive-A ReviewDocument43 pagesAbrasive-A ReviewA.YusoffNo ratings yet

- FloDocument28 pagesFloZoran DanilovNo ratings yet

- Xelsis SS E74144 Rev 00 PDFDocument11 pagesXelsis SS E74144 Rev 00 PDFDenis Fernando MariucioNo ratings yet

- Chemical Injection System Reduced PDFDocument14 pagesChemical Injection System Reduced PDFCHE.ENG1734No ratings yet

- Convert L A B Values To The Nearest Standard Colour: Celebrating Our Centenary YearDocument5 pagesConvert L A B Values To The Nearest Standard Colour: Celebrating Our Centenary YearGabriel BroascaNo ratings yet

- Coating Equivalent List KCCDocument3 pagesCoating Equivalent List KCCchrismas_g100% (2)

- Hard-Wearing Surfaces For Kitchens, Furniture and InteriorsDocument2 pagesHard-Wearing Surfaces For Kitchens, Furniture and Interiors4uengineerNo ratings yet

- SLRSOEBP SubmittalsDocument4 pagesSLRSOEBP SubmittalsQuality AssuranceNo ratings yet

- MM NTSDocument1 pageMM NTSEnrique Sanchez (KicKeWoW)No ratings yet

- P 05 305Document1 pageP 05 305Larry CastañedaNo ratings yet

- Sentryglas: Sentryglas Elastic Properties (Sg5000)Document2 pagesSentryglas: Sentryglas Elastic Properties (Sg5000)Larry CastañedaNo ratings yet

- Multilayer Laminated Glass - EET Method PDFDocument36 pagesMultilayer Laminated Glass - EET Method PDFLarry CastañedaNo ratings yet

- Multilayer Laminated Glass - EET Method PDFDocument36 pagesMultilayer Laminated Glass - EET Method PDFLarry CastañedaNo ratings yet

- Unit 1-Chapter 1. Introduction To Engg. MaterialsDocument76 pagesUnit 1-Chapter 1. Introduction To Engg. Materialssainath reddy kesam reddyNo ratings yet

- Marble and Granite FinishesDocument34 pagesMarble and Granite FinishesAnonymous UjtDiabwuNo ratings yet

- 1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionDocument3 pages1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionroxanaNo ratings yet

- Materials Science and EngineeringDocument15 pagesMaterials Science and EngineeringCharlenne CosejoNo ratings yet

- Normazione: Aluminium - and Zinc-Lamellar Base Anti-Corrosion Coating For Ferrous Material PartsDocument15 pagesNormazione: Aluminium - and Zinc-Lamellar Base Anti-Corrosion Coating For Ferrous Material Partserkin gulerNo ratings yet

- Mec 132 - Assignment 1Document17 pagesMec 132 - Assignment 1diana tahaNo ratings yet

- HES D2021 enDocument6 pagesHES D2021 enEdgar LoeraNo ratings yet

- Civil Engineering Materials ConstructionDocument36 pagesCivil Engineering Materials ConstructionJerry Mors0% (1)

- Pages From 70TMSS04R0 Warning Tapes For HV and Telecom (HV)Document2 pagesPages From 70TMSS04R0 Warning Tapes For HV and Telecom (HV)maherNo ratings yet

- BLK 49-Unit24Document6 pagesBLK 49-Unit24Mary Eunice GarciaNo ratings yet

- Selection of Grinding WheelsDocument3 pagesSelection of Grinding WheelsAbhishek PrajapatiNo ratings yet

- FKM 95 Compound 514162Document1 pageFKM 95 Compound 514162heningputriNo ratings yet

- Blended Hydraulic Cements: Standard Specification ForDocument8 pagesBlended Hydraulic Cements: Standard Specification ForMartha Carolina Gomez Martinez100% (1)

- Interior Column According To Aci 318-02 (Nonprestressed Slabs) c81Document2 pagesInterior Column According To Aci 318-02 (Nonprestressed Slabs) c81Love SemsemNo ratings yet

- Role of Polyisocyanate in PU Coatings: How To Make A PU SystemDocument5 pagesRole of Polyisocyanate in PU Coatings: How To Make A PU SystemAditya NarainNo ratings yet

- Role of Oxygen Inhibited Layer On Shear Bond Strength of CompositesDocument4 pagesRole of Oxygen Inhibited Layer On Shear Bond Strength of CompositesAli QawasNo ratings yet

- Aluminium AssignmentDocument12 pagesAluminium AssignmentAnonymous hVkq1jQvNo ratings yet

- Cini Handbook 1.3.10Document1 pageCini Handbook 1.3.10123spamnstuffNo ratings yet

- This Study Resource Was: 1. What Ingredients Are Used For The Production of Portland Cement?Document7 pagesThis Study Resource Was: 1. What Ingredients Are Used For The Production of Portland Cement?Stephanie Love T. BaringNo ratings yet

- Question Bank For UTU Students First Mid Term ExamDocument1 pageQuestion Bank For UTU Students First Mid Term ExamAbhinav BhatnagarNo ratings yet

- The Electrical Conductivity of The Copper-Aluminum Alloys.Document21 pagesThe Electrical Conductivity of The Copper-Aluminum Alloys.Bruna GomesNo ratings yet

- SeminarDocument31 pagesSeminarMahaManthra100% (2)

- CHG 308LDocument1 pageCHG 308LImmalatulhusnaNo ratings yet

- Failure Analysis of A Helical Gear in A Gearbox Used in A Steel Rolling MillDocument7 pagesFailure Analysis of A Helical Gear in A Gearbox Used in A Steel Rolling MillymsyaseenNo ratings yet

- Ferrocement HandbookDocument158 pagesFerrocement HandbookAditya Gosavi100% (2)

- Slim FloorDocument36 pagesSlim Floorpate84No ratings yet

- Thermo-WrapInspectable PS July2019Document2 pagesThermo-WrapInspectable PS July2019Williams Smailliw100% (1)

- 2nd Progress Billing Warehouse FaustinoDocument2 pages2nd Progress Billing Warehouse FaustinoHenry TuganoNo ratings yet

- Prestressed ConcreteDocument123 pagesPrestressed ConcreteThien Mai100% (3)