Professional Documents

Culture Documents

Klinger Top-Mic Gasket Datasheet

Uploaded by

Joshua HobsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Klinger Top-Mic Gasket Datasheet

Uploaded by

Joshua HobsonCopyright:

Available Formats

KLINGERtop-mic

A combination of specially selected mica,

synthetic fibers and fillers to give a sealing

material with outstanding flexibility and

excellent stability in steam. Wire reinforced.

The Klinger group has been recognized as the General Properties

market leader in gaskets and sealing for over Good resistance to steam

a century. Our research and development Resistant to oils, fuels hydrocarbons etc.

laboratories have investigated over 250 Easy to handle and cut

different fiber forms in the search for 3xA anti-stick finish on both sides

asbestos free alternatives. The search has

resulted in a range of high quality and high Availability

performance asbestos free materials that have Sheeting (m): 2.0 x 1.5*, 3.0 x 2.0, 2.0 x 6.0

been proven in service. Thickness (mm): 1.0, 1.5, 2.0, 3.0

*- Denotes standard sheet size

pT diagram

The Klinger pT diagram provides guidelines for determining the suitability of a particular gasket material for a specific

application based on the operating temperature and pressure only. Always refer to the chemical resistance of the gasket

to the fluid. KLINGERtop-mic is a newly developed material, the pressure and temperature capability is based on a good knowledge

of the fibers and fillers. On site tests are in progress and the results will be published as soon as the tests are completed.

100

Application Guidelines

90

3

80

2 1. Usually satisfactory without reference

70

60

2. Usually satisfactory, but suggest you refer to Klinger

50

40 for advice

30 3. Caution: May be suitable but essential that you refer

20

1 to Klinger for advice

10

p-

bar 2

0 Chemical compatibility must be considered in all cases.

-200 -150 -100 -50 0C 50 100 150 200 250 300 350 400 450 500 550

Temperature ° C

Typical Specifications

Compressibility ASTM F 36 A 10%

Recovery ASTM F 36 A 65%

Stress relaxation DIN 52913 50 Mpa, 16hl 300°C 32MPa

Klinger cold/hot compression (50MPa) Thickness decrease 23°C 10%

decrease at 300° 10%

Gas leakage according to DIN 3535/6 <0.5ml/min

Chlorides (soluble) 0 ppm

Thickness increase after fluid Oil nr.3:5hl 150°C 5%

Immersion ASTM F 146 Fuel B:5hl 23°C 7%

Water: 5hl 110°C 5%

Density 1.7 g/cm³

You might also like

- Klingersil c-4400 PDFDocument2 pagesKlingersil c-4400 PDFUdi PermonoNo ratings yet

- KLINGERSIL C-4430 SPEC SHEETDocument2 pagesKLINGERSIL C-4430 SPEC SHEETDailton SantosNo ratings yet

- Klingersil c-4430 Data PDFDocument2 pagesKlingersil c-4430 Data PDFDhim131267No ratings yet

- Graphite Gasket Material for Chemical ProcessesDocument2 pagesGraphite Gasket Material for Chemical ProcessesJoshua HobsonNo ratings yet

- Klingersil C-4400: Tests and CertificationsDocument2 pagesKlingersil C-4400: Tests and Certificationsmoh ragehNo ratings yet

- Gasket KlingersilDocument2 pagesGasket KlingersilBagusRekaNo ratings yet

- KLINGERsil C-4430 Asbestos-Free Gasket MaterialDocument2 pagesKLINGERsil C-4430 Asbestos-Free Gasket MaterialR.Gaspar BaltaNo ratings yet

- Klingersil C 4324Document2 pagesKlingersil C 4324Cemal NergizNo ratings yet

- DS - Graphite PSM-AS. EngDocument2 pagesDS - Graphite PSM-AS. EngDan PastorNo ratings yet

- Klingersil C 8200Document2 pagesKlingersil C 8200Efraín DaríoNo ratings yet

- Datenblaetter A4 C-4324 eDocument2 pagesDatenblaetter A4 C-4324 eGeneration GrowthNo ratings yet

- SONLOK_3243Document2 pagesSONLOK_3243robinNo ratings yet

- PPC04-PolyGuard™-Anti-Fog-TDS-WEBDocument3 pagesPPC04-PolyGuard™-Anti-Fog-TDS-WEBnox633159No ratings yet

- C 4400Document2 pagesC 4400Efraín DaríoNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- C 4243 Data Sheet PDFDocument3 pagesC 4243 Data Sheet PDFPavlo Fabres SierraltaNo ratings yet

- C-6327 Data SheetDocument2 pagesC-6327 Data Sheetahugandkiss77071No ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- L-TSA Classic Turbine OilDocument3 pagesL-TSA Classic Turbine OilQuy NguyenNo ratings yet

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNo ratings yet

- KLINGERsilC 4509Document2 pagesKLINGERsilC 4509rogerjavier5981No ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Kli - Non Asbestos SheetDocument6 pagesKli - Non Asbestos SheetEast conorNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- L-TSA Turbine OilDocument3 pagesL-TSA Turbine OilQuy NguyenNo ratings yet

- L-TSE Turbine OilDocument3 pagesL-TSE Turbine OilYoong TanNo ratings yet

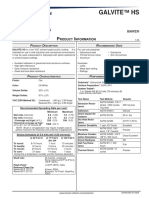

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Top grade wire-reinforced material for extreme serviceDocument2 pagesTop grade wire-reinforced material for extreme serviceindrapatiwNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- BandarImam 0200Document2 pagesBandarImam 0200art72 talNo ratings yet

- PG-GL Data SheetDocument1 pagePG-GL Data Sheetazeem bilalNo ratings yet

- 2-Part Room Temperature Cure Silicone Pottant: Preliminary Data SheetDocument3 pages2-Part Room Temperature Cure Silicone Pottant: Preliminary Data SheetUday TembeNo ratings yet

- Non-Heat Sealable Cellophane Films for PackagingDocument2 pagesNon-Heat Sealable Cellophane Films for PackagingImawan WastNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- hivorex mf5000Document1 pagehivorex mf5000Chu ChuNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Metallographic Clinkers-821-323Document4 pagesMetallographic Clinkers-821-323Arindam PahariNo ratings yet

- KLINGERSIL C-4430plus Data SheetDocument3 pagesKLINGERSIL C-4430plus Data SheetMichael PhamNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- Castrol Tribol Cs 890Document3 pagesCastrol Tribol Cs 890carlos pachecoNo ratings yet

- Technical Data Sheet for 1-Part Silicone Sealant Silcoset 151Document2 pagesTechnical Data Sheet for 1-Part Silicone Sealant Silcoset 151Arun VaideeswaranNo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

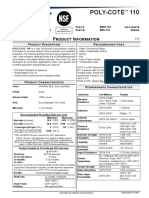

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Shell Corena Oil P: High Performance Lubricant For Reciprocating Air CompressorsDocument2 pagesShell Corena Oil P: High Performance Lubricant For Reciprocating Air CompressorsMahmut GüdülNo ratings yet

- TGSB(M) Turbine OilDocument3 pagesTGSB(M) Turbine OilQuy NguyenNo ratings yet

- Protective DTM Acrylic Primer/Finish Product DescriptionDocument4 pagesProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaNo ratings yet

- Quintolubric 888 BrochureDocument5 pagesQuintolubric 888 BrochurePraveen Kumar MishraNo ratings yet

- KLINGER Graphite PSM-AS Technical Data SheetDocument1 pageKLINGER Graphite PSM-AS Technical Data SheetStart JaguarNo ratings yet

- Carter EpDocument1 pageCarter EpNguyễn Quang HưngNo ratings yet

- Ba SDocument2 pagesBa SFajar SodiqNo ratings yet

- Rockwool Slabs Thickness: 30 MM Density: 50 KG/M: ApplicationsDocument3 pagesRockwool Slabs Thickness: 30 MM Density: 50 KG/M: ApplicationsFirst ChoiceNo ratings yet

- Technical Data - JotunDocument2 pagesTechnical Data - JotunWajid ZiaNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Thermal Transfer Polyester Label Material: Technical Data May 2017Document5 pagesThermal Transfer Polyester Label Material: Technical Data May 2017Sebastian BaenaNo ratings yet

- Klinger Graphite Laminate PSM: Key Features: BenefitsDocument2 pagesKlinger Graphite Laminate PSM: Key Features: BenefitsHammad KhanNo ratings yet

- L-TSELF Long Service Life Extreme Pressure Turbine OilDocument3 pagesL-TSELF Long Service Life Extreme Pressure Turbine OilQuy NguyenNo ratings yet

- Sikagrout 212 DatasheetDocument3 pagesSikagrout 212 DatasheetJoshua HobsonNo ratings yet

- Centurion Diagnostics Made EasyDocument112 pagesCenturion Diagnostics Made EasyJoshua HobsonNo ratings yet

- Brochure Nemtek Dats2Document1 pageBrochure Nemtek Dats2Joshua HobsonNo ratings yet

- Dual detection security for electric fencesDocument1 pageDual detection security for electric fencesJoshua HobsonNo ratings yet

- Mecer Axpert 1000VA-3000VA InverterDocument1 pageMecer Axpert 1000VA-3000VA InverterJoshua HobsonNo ratings yet

- Sikadur 42LE Epoxy Grout DatasheetDocument5 pagesSikadur 42LE Epoxy Grout DatasheetJoshua HobsonNo ratings yet

- Pricelist: 2021 Q2 EX VAT C EuroDocument18 pagesPricelist: 2021 Q2 EX VAT C EuroJoshua HobsonNo ratings yet

- Industrial Sliding Gate Operator: D10 and D10 Turbo Installation ManualDocument72 pagesIndustrial Sliding Gate Operator: D10 and D10 Turbo Installation ManualJoshua HobsonNo ratings yet

- D10 Operation Manual D10 TurboDocument66 pagesD10 Operation Manual D10 TurboJoshua HobsonNo ratings yet

- Abe Hand SanitizerDocument7 pagesAbe Hand SanitizerJoshua HobsonNo ratings yet

- Powder Coating Introduction...Document5 pagesPowder Coating Introduction...Joshua HobsonNo ratings yet

- Sikaswell s-2 DatasheetDocument3 pagesSikaswell s-2 DatasheetJoshua HobsonNo ratings yet

- De-Bottlenecking of The Anglo Platinum Converting Process Utilising AdvancedDocument7 pagesDe-Bottlenecking of The Anglo Platinum Converting Process Utilising AdvancedJoshua HobsonNo ratings yet

- Macsteel VRN Product Catalogue 2021Document48 pagesMacsteel VRN Product Catalogue 2021Joshua Hobson100% (1)

- iTHERM MultiSens Selection Guide (PU01278T-EN-0319)Document2 pagesiTHERM MultiSens Selection Guide (PU01278T-EN-0319)Joshua HobsonNo ratings yet

- COVID-19 Infection Guidelines SummaryDocument16 pagesCOVID-19 Infection Guidelines SummaryJoshua HobsonNo ratings yet

- Durlon Gasket Technical HandbookDocument18 pagesDurlon Gasket Technical HandbookJoshua HobsonNo ratings yet

- KKS Guide BookDocument48 pagesKKS Guide Bookbmw316No ratings yet

- Construction: Price List - Regional ManagersDocument23 pagesConstruction: Price List - Regional ManagersJoshua Hobson100% (1)

- PV Elite Training SupportsDocument52 pagesPV Elite Training SupportsΠάνος Παρδαλάκης100% (5)

- Sikagrout®-212: Product Data SheetDocument3 pagesSikagrout®-212: Product Data SheetMohamed Aadil RahimNo ratings yet

- Some Aspects of Axial Collapse of Cylindrical Thin-Walled TubesDocument16 pagesSome Aspects of Axial Collapse of Cylindrical Thin-Walled TubesJoshua HobsonNo ratings yet

- Zinc CoatingsDocument12 pagesZinc CoatingsvvgdreamNo ratings yet

- Experimental and Numerical Investigation of Static and Dynamic Axial Crushing of Circular Aluminum TubesDocument35 pagesExperimental and Numerical Investigation of Static and Dynamic Axial Crushing of Circular Aluminum TubesJoshua HobsonNo ratings yet

- Trade: Quality Classification of Muscovite Mica Based On Visual PropertiesDocument1 pageTrade: Quality Classification of Muscovite Mica Based On Visual PropertiesJoshua HobsonNo ratings yet

- PROKON User's Guide PDFDocument636 pagesPROKON User's Guide PDFSAMERJARRAR12394% (17)

- A Performance Comparison of Various Protective Coatings Incl PDFDocument17 pagesA Performance Comparison of Various Protective Coatings Incl PDFJoshua HobsonNo ratings yet

- Quasi-Static Axial Compression of Thin-Walled Circular Aluminium TubesDocument21 pagesQuasi-Static Axial Compression of Thin-Walled Circular Aluminium TubesJoshua HobsonNo ratings yet

- Sikagrout®-212: Product Data SheetDocument3 pagesSikagrout®-212: Product Data SheetMohamed Aadil RahimNo ratings yet

- AVEVA LFM - Data Summary v2Document6 pagesAVEVA LFM - Data Summary v2Joshua HobsonNo ratings yet

- Burford-Exam 3 Spring 2018Document6 pagesBurford-Exam 3 Spring 2018api-430812455No ratings yet

- Pip Venix LRDocument2 pagesPip Venix LRThanh VoNo ratings yet

- Kyocera Fs-6900 Parts ManualDocument28 pagesKyocera Fs-6900 Parts ManualNic CowpeNo ratings yet

- Form WorkDocument25 pagesForm Workhina khanNo ratings yet

- STP1236 Eb.1415051 1 PDFDocument208 pagesSTP1236 Eb.1415051 1 PDFpaolaNo ratings yet

- 2GIG KEY2 345 Install GuideDocument2 pages2GIG KEY2 345 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Brief History About Volley BallDocument1 pageBrief History About Volley BallAmbrad, Merlyn H.No ratings yet

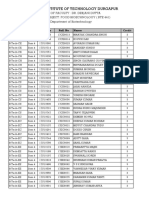

- List of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFDocument26 pagesList of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFArpan JaiswalNo ratings yet

- Electronic V-MAC IV Vehicle Mgmt. and Control With Co-Pilot Display Operator ManualDocument133 pagesElectronic V-MAC IV Vehicle Mgmt. and Control With Co-Pilot Display Operator Manualsanach0412No ratings yet

- Wily Walnut BRAIN SQUEEZERS Vol.1Document116 pagesWily Walnut BRAIN SQUEEZERS Vol.1tarzaman88% (8)

- 5 Variable K-MapDocument15 pages5 Variable K-MapBen SewellNo ratings yet

- 3M CatalogueDocument32 pages3M Cataloguefandi.azs37No ratings yet

- API 510 BasicsDocument40 pagesAPI 510 BasicsBalakumarNo ratings yet

- Experiment# 3 Projectile Motion (Tasks 3 and 4)Document18 pagesExperiment# 3 Projectile Motion (Tasks 3 and 4)Hafiz MuhammadNo ratings yet

- 0610 m16 QP 62Document12 pages0610 m16 QP 62faryal khanNo ratings yet

- The Image of The CityDocument17 pagesThe Image of The CityMay Rose ParagasNo ratings yet

- Jigoku Shoujo Eikyuu No SonzaiDocument166 pagesJigoku Shoujo Eikyuu No Sonzaiapi-224188021No ratings yet

- IGCSE Biology 4325 2H Mark SchemeDocument14 pagesIGCSE Biology 4325 2H Mark SchememuhajireenNo ratings yet

- Resource Guide: Three Phase PowerDocument8 pagesResource Guide: Three Phase PowerddNo ratings yet

- The Nature of Substance - Rudolf Hauschka PDFDocument250 pagesThe Nature of Substance - Rudolf Hauschka PDFBruno Morin100% (5)

- Dsa 5300Document8 pagesDsa 5300Nguyen Van ToanNo ratings yet

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- QRP Yu1lm SDR-RX TXDocument299 pagesQRP Yu1lm SDR-RX TXD BNo ratings yet

- Thyrotronic enDocument4 pagesThyrotronic enVladimirNo ratings yet

- Astm D2467-2013Document8 pagesAstm D2467-2013Renato CorrêaNo ratings yet

- A History of The Jewish People in The Time of Jesus Christ (1891) Index Schürer, Emil, 1844-1910Document132 pagesA History of The Jewish People in The Time of Jesus Christ (1891) Index Schürer, Emil, 1844-1910David Bailey100% (2)

- Manual Hoist ProductsDocument40 pagesManual Hoist Productskavin bhagavathyNo ratings yet

- Genética, Modificaciones y MutacionesDocument12 pagesGenética, Modificaciones y MutacionespokemaniacoplancheNo ratings yet

- Fire and Blast in The Future OffshoreDocument45 pagesFire and Blast in The Future OffshoredrgNo ratings yet

- Lista Arancelaria EUADocument547 pagesLista Arancelaria EUAvilisbeth18No ratings yet