Professional Documents

Culture Documents

Klingersil c-4400 PDF

Uploaded by

Udi PermonoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Klingersil c-4400 PDF

Uploaded by

Udi PermonoCopyright:

Available Formats

KLINGERsil C-4400

High quality non-asbestos grade based on

aramid fibre with nitrile rubber binder. A

general purpose material for many industrial-

sealing applications.

The Klinger group has been General Properties

recognised as the market Good resistance to oils, fuels, hydrocarbons

leader in gaskets and Good creep resistance

sealing for over a century. Low leakage

Very successful in internal combustion engine applications

Our research and

3xA anti-stick finish on both sides

development laboratories

have investigated over 250 Tests and Certifications

different fibre forms in the BS 7531 Grade Y

search for asbestos free BS F 130 Type A

alternatives. The search has Firesafe HTB 90.0223.39.0

resulted in a range of high DIN-DVGW

0

quality and high BAM U W28 for use with oxygen 100 C / 80 Bar

performance asbestos free KTW A 528/88/G

SVGW 89-053-7

materials that have been Germanischer Lloyd 98 952 – 97 HH

proven in service TA-Luft (Clean Air) certificate acc. VDI 2440

Availability

Sheeting (m): 2.0 x 1.5*, 4.0 x 1.5, 1.5 x 1.0

Thickness (mm): 0.25, 0.4, 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 3.0

* - Denotes standard sheet size

Also available with re-inforcements:

KLINGERsil C-4408, mild steel mesh

KLINGERsil C-4409, expanded mild steel

KLINGERsil C-4400

Application

Guidelines

1. Usually satisfactory without reference.

2. Usually satisfactory, but suggest you

refer to Klinger for advice

3. Caution: May be suitable but essential

that you refer to Klinger for advice.

Chemical compatibility must be considered

in all cases.

Typical Specifications

Compressibility ASTM F 36 A 11%

Recovery ASTM F 36 A 55%

Stress relaxation DIN 52913 50MPa, 16h/175°C 32MPa

50MPa, 16h/300°C 25MPa

Stress relaxation BS 7531 23MPa

Klinger cold/hot compression, 50MPa Thickness decrease 23°C 10%

Thickness decrease at 300°C 20%

Gas leakage according to DIN 3535/6 0.02ml/min

Thickness increase after fluid Oil no.3:5h/150°C 3%

immersion ASTM F 146 Fuel B:5h/23°C 5%

Chlorides (soluble) 150ppm

3

Density 1.6g/cm

Average surface resistance ROA 1.4x10E12

Average specific volume resistance D 1.2x10E12 cm

Average dielectric strength 21.6 kV/mm

Average power factor 1kHz,ca. 2mm thick 0.075 tan

Average dielectric constant 1kHz,ca.2mm thick 7.7 r

Thermal conductivity 0.4-0.42W/mK

Head Office Klinger Ltd. Grangemouth Klinger Ltd. Runcorn

KLINGER Ltd Tel: 01324 472 231 Tel: 01928 577 030

Wharfedale Road Fax: 01324 482 111 Fax: 01928 575 223

Euroway Trading Estate

Bradford BD4 6SG Klinger Ltd. Aberdeen Klinger Ltd. Middlesbrough

Tel: 01224 772 962 Tel: 01642 220 289

Tel: 01274 688 222 Fax: 01224 772 953 Fax: 01642 220 290

Fax: 01274 688 549

enquiries@klingeruk.co.uk Klinger Ltd. Southampton

www.klingeruk.co.uk Tel: 023 8061 1855

Fax: 023 8061 0360

All information and recommendations contained in this specification sheet are to the best of our knowledge correct. Since

conditions of use are beyond our control, users must satisfy themselves that the products are suitable for the intended

processes and uses. No warranty is given or implied in respect of information or recommendations or that any use of

products will not infringe rights belonging to other parties. In any event or occurrence our liability is limited to our invoice value

of the goods delivered by us to you. We reserve the right to change product design and properties without notice

You might also like

- Shoulder Hypertrophy Specialization ProgramDocument3 pagesShoulder Hypertrophy Specialization ProgramEli Harris100% (1)

- C95500 ASTM - Nickel Aluminum BronzeDocument2 pagesC95500 ASTM - Nickel Aluminum BronzethuykvNo ratings yet

- Toshiba E-Studio 306SE Trouble Error Codes List 12pageDocument11 pagesToshiba E-Studio 306SE Trouble Error Codes List 12pagenafees50% (2)

- ABPK2203 Perception and Emotion Module PDFDocument147 pagesABPK2203 Perception and Emotion Module PDFPhoebeilsie RaimiNo ratings yet

- Introduction CavitationDocument19 pagesIntroduction CavitationArturoNo ratings yet

- MUNICIPAL ORDINANCE NOpawikanDocument6 pagesMUNICIPAL ORDINANCE NOpawikanjacquelyn samson100% (2)

- Klingersil c-4430 Data PDFDocument2 pagesKlingersil c-4430 Data PDFDhim131267No ratings yet

- Info Tecnica C-4430Document2 pagesInfo Tecnica C-4430R.Gaspar BaltaNo ratings yet

- Gasket KlingersilDocument2 pagesGasket KlingersilBagusRekaNo ratings yet

- Klingersil C 8200Document2 pagesKlingersil C 8200Efraín DaríoNo ratings yet

- KLINGERsilC 4509Document2 pagesKLINGERsilC 4509rogerjavier5981No ratings yet

- Klinger PSM Gasket Data SheetDocument2 pagesKlinger PSM Gasket Data SheetJoshua HobsonNo ratings yet

- Klingersil C 4324Document2 pagesKlingersil C 4324Cemal NergizNo ratings yet

- DS - Graphite PSM-AS. EngDocument2 pagesDS - Graphite PSM-AS. EngDan PastorNo ratings yet

- Klingersil C-4430: General PropertiesDocument2 pagesKlingersil C-4430: General PropertiesDailton SantosNo ratings yet

- Klingerit 1000 PDFDocument2 pagesKlingerit 1000 PDFindrapatiwNo ratings yet

- Klinger Top-Mic Gasket DatasheetDocument1 pageKlinger Top-Mic Gasket DatasheetJoshua HobsonNo ratings yet

- Klingersil C-4400: Tests and CertificationsDocument2 pagesKlingersil C-4400: Tests and Certificationsmoh ragehNo ratings yet

- Kli - Non Asbestos SheetDocument6 pagesKli - Non Asbestos SheetEast conorNo ratings yet

- C 4400Document2 pagesC 4400Efraín DaríoNo ratings yet

- C 4243 Data Sheet PDFDocument3 pagesC 4243 Data Sheet PDFPavlo Fabres SierraltaNo ratings yet

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- C-6327 Data SheetDocument2 pagesC-6327 Data Sheetahugandkiss77071No ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

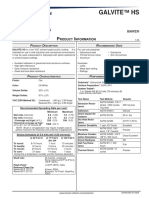

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Hivorex mf5000Document1 pageHivorex mf5000Chu ChuNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Klingersil C 4400Document2 pagesKlingersil C 4400Peter JordanNo ratings yet

- polarlite-UK 4mmDocument4 pagespolarlite-UK 4mmoportunidade.engenharia.slzNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Grilamid® L 25 ANZDocument4 pagesGrilamid® L 25 ANZTUNCAY GUMUSNo ratings yet

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntNo ratings yet

- Advefoam 32Document2 pagesAdvefoam 32melsabaeNo ratings yet

- Klinger C4401 PDFDocument2 pagesKlinger C4401 PDFArtur MkrtchyanNo ratings yet

- PPC04 PolyGuard™ Anti Fog TDS WEBDocument3 pagesPPC04 PolyGuard™ Anti Fog TDS WEBnox633159No ratings yet

- Greenkashi Bio Energy Private Limited: Property Unit Typical Value MethodDocument1 pageGreenkashi Bio Energy Private Limited: Property Unit Typical Value MethodGbeNo ratings yet

- Klingersil C 4300Document2 pagesKlingersil C 4300Feri KaruanaNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- ArmaGelDT - TDS - EN-Dual TempDocument4 pagesArmaGelDT - TDS - EN-Dual TempLee Kok RoyNo ratings yet

- BinanizincspecsDocument6 pagesBinanizincspecsJimmy ThomasNo ratings yet

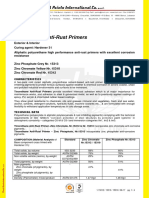

- Tinorethane Anti-Rust PrimersDocument4 pagesTinorethane Anti-Rust PrimersAbed samadsureyft7vewyrNo ratings yet

- Klingersil C-4430: Key Features: BenefitsDocument2 pagesKlingersil C-4430: Key Features: Benefitsdawn moonNo ratings yet

- KLINGERsilC-4500 Gasket MaterialDocument2 pagesKLINGERsilC-4500 Gasket MaterialHardik AcharyaNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- 313P Stecind ENGDocument2 pages313P Stecind ENGSophia RoseNo ratings yet

- KLINGER Top-Chem 2003: PAR Group LTD Technical Data SheetDocument1 pageKLINGER Top-Chem 2003: PAR Group LTD Technical Data SheetJOELNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 pageP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- KLINGERSIL C-4430plus Data SheetDocument3 pagesKLINGERSIL C-4430plus Data SheetMichael PhamNo ratings yet

- Cellophane P: Features - Non Heat-Sealable Permeable FilmsDocument2 pagesCellophane P: Features - Non Heat-Sealable Permeable FilmsImawan WastNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- Denso TapeDocument1 pageDenso TapeBogdanBNo ratings yet

- Engen Premium EP SeriesDocument2 pagesEngen Premium EP SeriesNunoNo ratings yet

- Temasil NG: CSF Sheet JointingDocument3 pagesTemasil NG: CSF Sheet JointingTài TrầnNo ratings yet

- Fasit OmniaDocument1 pageFasit OmnianightmanirNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Environmental CrisisDocument2 pagesEnvironmental CrisisBenÜt BalleraNo ratings yet

- CHAPTER 7 Project Management and Network AnalysisDocument31 pagesCHAPTER 7 Project Management and Network AnalysisNitinNo ratings yet

- Applications of NanotechnologyDocument24 pagesApplications of NanotechnologyVijay KumarNo ratings yet

- J. Electrochem. Soc. 1954 Belle 339 42Document4 pagesJ. Electrochem. Soc. 1954 Belle 339 42Sutanwi LahiriNo ratings yet

- Linear Programming AssignementDocument5 pagesLinear Programming AssignementHuzaifaNo ratings yet

- MSDS Gum Copal Magica AgroDocument6 pagesMSDS Gum Copal Magica AgroIrawan KhanNo ratings yet

- Xdeed3qtt - 1 - Concepts in The Care of at Risk and Sick Adult ClientsDocument14 pagesXdeed3qtt - 1 - Concepts in The Care of at Risk and Sick Adult ClientsCamille GuintoNo ratings yet

- Project Documentation Part 2Document42 pagesProject Documentation Part 2Lorena LanchoNo ratings yet

- ValdorDocument1 pageValdorprojectkmoNo ratings yet

- 7 Improper Integrals, Exp, Log, Arcsin, and The Integral Test For SeriesDocument24 pages7 Improper Integrals, Exp, Log, Arcsin, and The Integral Test For SeriesDani IbrahimNo ratings yet

- PSLVDocument14 pagesPSLVVinod SrinivasanNo ratings yet

- PSRIG LiftingDocument12 pagesPSRIG LiftingCristinaHernándezNo ratings yet

- 3 Module in Arts Week 3 4Document8 pages3 Module in Arts Week 3 4ARVEE DAVE GIPANo ratings yet

- DEBUT ScriptDocument9 pagesDEBUT ScriptKen NethNo ratings yet

- Direct Vs Indirect Fire SupportDocument1 pageDirect Vs Indirect Fire Support水傲南100% (1)

- Increase and Decrease WBC CountDocument2 pagesIncrease and Decrease WBC CountLecture NotesNo ratings yet

- Lect 6.3 PDFDocument8 pagesLect 6.3 PDFHorlar YeankahNo ratings yet

- Smart Cities - A Case Study in Waste Monitoring and ManagementDocument10 pagesSmart Cities - A Case Study in Waste Monitoring and Managementfaris100% (1)

- Yvl2 7eDocument9 pagesYvl2 7ekazmi81No ratings yet

- Head and Neck LL Spotters - Q and ADocument26 pagesHead and Neck LL Spotters - Q and A76 S.SHRAVAN KUMARNo ratings yet

- Safety Data Sheet: NEOPOR 2200Document11 pagesSafety Data Sheet: NEOPOR 2200Şerbuţă AlexandruNo ratings yet

- Essential Medical Supplies and EquipmentsDocument41 pagesEssential Medical Supplies and EquipmentsKashif BashirNo ratings yet

- Multi Parking System Fional Project ReportDocument54 pagesMulti Parking System Fional Project ReportVinay MuleyNo ratings yet

- More Serious Health ProblemsDocument3 pagesMore Serious Health ProblemsYassin KhanNo ratings yet

- Tolerance Charting PDFDocument7 pagesTolerance Charting PDFSudeep Kumar SinghNo ratings yet