Professional Documents

Culture Documents

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM'18) Proceedings

Uploaded by

AMALAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM'18) Proceedings

Uploaded by

AMALACopyright:

Available Formats

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

CONTENTS

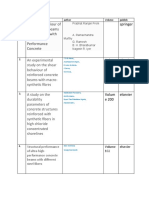

S. Page

Title Author’s Name No.

No.

Analysis of plates using functionally Kari Thangaratnam1, J. Suganya2,

1 1

graded material G. Prabha3

Experimental study on eco bricks by U.Umapathy1, S.Sulfiya Begam 2,

2 incorporating sludge, granite powder and K.Vanaja3 2

fly ash with clay

Flexural behaviour of ferrocement slabs M.Neelamegam1 and S.Santhosh

3 3

with high strength mortar Prabu2

LavanyaPrabha S*,

Study of beam column joint under

4 NayanaSreekumar#, Arthi R#, 4

different reinforcement detailing

Balamurali I#, Pradeep P#,

Structural behaviour of ferrocement M.Nithyalakshmi1, D.Selvapriya2,

5 5

sandwich panel with m-sand M.Visuwesh2,P.Vikash2,S.Saravan2

Reversible shear connectors in composite M.Kavibala1, M.Surendar2

6 6

structures

Experimental study of granite powder Doodi ramesh1 D.Dwarakanath2

7 and iron powder on strength properties of M.Muhesh pandian3 7

concrete B.nandhakumar4

Strength properties ofconcrete partially P.GomathiNagajothi1,

8 8

replaced with wpcb as fine aggregate Dr.T.Felixkala2

Mechanical properties of flyash and ggbs Shanmuga Priya G1,M Sowmiya2 ,V

based geopolymer concrete with partial Sarangy3, M Sudhagar4

9 9

replacement of fine aggregate by copper

slag

Behaviour of basalt fiber reinforced M.Nandhini1, C.Kathampari1,

10 concretefilled stainless steel and mild R.Kaushik1, K. MohanKumar1, 10

steel tube A.Arunraj2

1

J.Jaya Prakash, 1D.K.

Experimental study on basalt fibre

DhanunJayanath, 1K. Manoj and 1A.

11 reinforced foamed concrete 11

Antony AjaiChriston

2

I.AshmiMonisha

Mechanical properties of gsa and rha Priya. B1 rajagopal. T2 . Ashmi

12 blended cement concreteat different monisha. I3 12

temperatures

Flexural behavior of basalt fibre B.Aswini1, M.Keerthana2, B.Krishna3

13 reinforced concrete filled mild steel tube , S.B. Akhilesh Babu4 13

beams

Corrosion prevention on coated rebars Dr. M.Tamil Selvi1, Mrs.S.Gayathri2,

14 14

and fiber in R.C slabs J.Hathari Evangalin3

Study of accessible material for the K.Pushpavalli 1, V.Tamilarasi2

15 15

fabrication of unburnt brick

i Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

Experimental study on strength of V.Thirumurugan.1, S.George vimal

concrete by partial replacement of raj2 , K.Dheenadayalan3

16 cement by cashew nut shell ash (cnsa) & 16

chicken feather fiber (cff) as fiber

reinforcement

Implementation of lean construction in P.SelvaPrasanth 1, S.Ranjitha2,

17 17

residential building projects R.Tharanyalakshmi2

An experimental study on the behavior of R.R.Tharini1, K.Panchavarnam2,

18 18

brick using ball clay, fly ash and jaggery M.Jayalakshmi2

An experimential investigation on partial Dr. M.Tamil Selvi11,

19 replacement of cement by fly ash and Dr.P.B.Sakthivel2, G.Keerthana3 19

coarse aggregate using e-waste

Study on shear connection between steel Gopi Krishnan.P1, Neru Prasad

20 and Concrete in composite structure V.K1, Abirajan.J1, 20

Arjunramasamy.M1, Surendar.M2

Flexural and direct tensile behaviour of G. Anand Raj1, G. Dharmaraju2, V.

21 slurry infiltrated fibre reinforced concrete Palani Mohan3,S. Pon Balakumar4, V. 21

(sifcon) Saravana Karthika5

22 Geogrid reinforced aerated concrete Akshayaa.P1 Hemalattha.S2 22

1

R.Praveena, 2 Prerna Sharma,

Experimental study on concrete with 3

Anmol Basnett,

23 partial replacement of coarse aggregate 23

by waste glass bottles

1

An experimental study on concrete with R. Praveena, 2Trisha subba, 3Sahi

partial replacement of cement by rice chettri,

24 24

husk ash and coarse aggregate by

recycled aggregate

1

Use of iron industrial waste and microbes Nishanth.B, 2Karthikesan.A.K,

25 25

to concrete

Experimental study of musa fibre Lenin Dhal1

26 26

reinforced concrete

Comparitive study of conventional C.Deepika1, G.Swetha2 , A.Hari

27 27

bitumen mix to modified bitumen mix Haran3, V.Murali4, S.Nandhini5

Comparative analysis of using oyster D.Lakshmi Priya1

28 shell ash and powder as cementing 28

material for concrete

Flexural behaviour of ternary blended Saranya 1, Salini 1

29 29

concrete with steel fibres

Application of light expanded clay Ms.A.Pavithra1, M.Shanmuga priyaa

2

30 aggregate as replacement of coarse , S.Shahid Athif 3, G.Vignesh 4, S. 30

aggregate in concrete pavement Vinoth Kumar5.

Comparative study of structural insulated A.SANGEETHA

31 panels system with conventional method 31

of construction

ii Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

Experimental investigation on A.Mohan1, M.Tholkapiyan2,

32 utilization of fly ash and pond ash G.Rushitha sai , G. Yogesh Parri 3.

3

32

with self compacting concrete

Flexural behaviour of rolled steel i beam R.EMILREYAN

33 with different stiffener positions 33

Performance of bacterial concrete using J.Asanammal Saral1 , S.Prashanth2,

34 copper slag M.Rahul3 and M.Yuvaraj4 34

A study on permeable concrete using ground M. Amala, S. Dinesh Kumar

35 granulated blast furnace slag (ggbs) P. Anand Kumar, R. Ajeeth Kumar 35

M. Dinesh

1

Flexural strength performance of thin Madupalli.Akhil , 2 Dr S.J. Mohan

36 36

steel plain and slotted channel sections

Thermal structural analysis of R. Kari Thangaratnam

37 37

functionally graded plates P. Priya, K. Kalingarani

Experimental study on dry-wet cyclic Mr. V. Jayakumar,

38 resistance of air entrained fiber R.Anusuya, 38

reinforced concrete N.Porkodi

Experimental study on strength of Mr. C.S. Maneesh Kumar, A. Aarthi,

concrete by replacement of cement by K. Kavitha

39 39

sugarcane bagasse ash (scba) and fine

aggregate by steel fibre

An Experimental Study on Concrete with Ms. R.Praveena,

Full and Partial Replacement of Fine S.Lavanya, M.Akshaya, G.Venmathi

Aggregate by Quarry Dust and Waste

40 40

Foundry Sand and Partial Replacement

of Coarse Aggregate by Waste Ceramic

Tiles

A review on effect of waste materials, R. Praveena1, K. Vasanthasaena2, M.

41 fibers and temperatures on reactive Jayashree3 41

powder concrete

Mr.G.Srinivas, Dr.S.B.Sankar Rao

Recent trends in structural repairing

42 42

techniques – Evaluation Studies

Ajesh Kumar P.T.1 , Srinivasan

Concrete damaged plasticity based

43 Chandrasekaran* 43

numerical model for shm studies

Fine Aggregate Replacement Using P.M.Rameswaram1,

44 the Eco-Friendly Material - Steel Mill M.MohanaRam2 44

Scale

P.M.Rameshwaram1,

General Review of Glass Fibre

45 M.MohanaRam2 45

Reinforced Concrete

Removal of nickel from industrial Shruthi Meena.R1 ,Sreevelan. M2,

46 46

wastewater using natural adsorbents Saravanan.G3, Wilsha.R.W4

iii Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

Evaluation of adsorption efficiency of

Pamila Ramesa.*, Dr. Vasanthi

renewable adsorbents for the elimination

47 padmanabhanb , Padmaja 47

of heavy metals from wastewater derived

Meghamc,

from waste biomass

Elimination of cadmium from wastewater M.Padmaja1, R.Bhavani2, R.Pamila3

48 48

using natural materials - a review

Aravind.A.R1, Irfan

Environment impact assessment for

49 nadheer.N2,Jephins derek.J.K3, 49

highway

KrishnaraJ.S4, Shree lekhaa.K.R5

A portable spiral shaped farming for R.Chitraa1, C.S.Maneesh

50 50

multiple crops Kumara2,N.Ahilaa3,

1

T.Harish 2T.Kaarunya

Recycling of greywater using low cost 3

51 E.L Lakshadeepa 4K.Monica 5 51

bioadsorbent

C.GHemamalini

Effective treatment of three waste water G.Gnanapragasam1,

52 52

using single reactor D.U.Kowsalya2, M.Poovitha3

Evaluation of anaerobic digester for B. Sasivarman, M. Rajesh Kannan,

53 treating tannery effluent by bottling E. Subash chadrabose, R.sewtha, 53

process V.Sowmiya

L.Chandra Kanthamma1, Rishi P 2,

Water treatment in kallu kuttai lake using

54 Vignesh N2, Vignesh R2, Visaal 54

natural extracts

Ratthen D2

Environmental data analysis through

55 P. Alagambigai 55

visual clustering

iv Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

ANALYSIS OF PLATES USING FUNCTIONALLY GRADED MATERIAL

Kari Thangaratnam1, J. Suganya2, G. Prabha3

1

Director, iDesign Technologies Pvt. Ltd. Chennai

2,3

Department of Civil Engineering, Easwari Engineering College,Chennai – 89

ABSTRACT

A finite element formulation using semiloof shell element is developed to model the

response of displacement and buckling of Functionally Graded Materials (FGM) of square plate

with piezoelectric sensor and actuator layers. The power law distribution model is used to vary the

composition of FGM in thickness direction. The governing equation for buckling analysis is

formed using total potential energy. Buckling analysis is carried out for FGM using different

volume fraction index and voltage. The software that is used in the analysis is FORTRAN. An in-

house package COMSAP that is developed using semiloof shell element for buckling analysis of

plate is extended to FGM.

Key Words - Finite element, Functionally graded Materials, Piezoelectric, Semiloof shell element,

Volume fraction index.

1|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

EXPERIMENTAL STUDY ON ECO BRICKS BY INCORPORATING

SLUDGE, GRANITE POWDER AND FLY ASH WITH CLAY.

U.Umapathy1, S.Sulfiya Begam 2, K.Vanaja3

1

Senior Asst. professor, Department of Civil Engineering, IFET College Of Engineering,

Villupuram.

2, 3

Students, Department of Civil Engineering, IFET College Of Engineering, Villupuram.

ABSTRACT

In general, the ordinary bricks are prepared only by using clay. Due to that preparation, the

clay is exhausting. In order to solve those effect, the waste materials are utilized. The waste

materials such as sludge, granite powder and fly ash are used with clay. In many countries, the

sludge is a serious problem due to its high treatment cost and risks to environment & also to human

health. Granite wastes are obtained from granite sawing and polishing industries, it damages and

pollutes the environment. Fly ash is a useful by-product from thermal power stations using

pulverized coal as a fuel and it has considerable pozzolanic activity. The bricks are the major

concern building materials used for construction purpose. The sludge, granite powder and fly ash

are incorporated with clay in order to control the environmental effect. While the sludge is added

with clay, the water absorption get increased and it reduces the compressive strength. Granite

powder and fly ash are added to get high compressive strength.

Key Words - Clay brick, Waste materials (sludge, granite powder and fly ash), Environmental

effect, Compressive strength.

2|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

FLEXURAL BEHAVIOUR OF FERROCEMENT SLABS WITH HIGH

STRENGTH MORTAR

M.Neelamegam1 and S.Santhosh Prabu2

Professor, Easwari Engineering College, Ramapuram, Chennai.

P.G student, Easwari Engineering College, Ramapuram, Chennai.

ABSTRACT

Ferrocement is one of the structural materials, widely used due to its advantage from its

particular behavior such as mechanical properties and impact strength. This paper deals with the

investigation of ferrocement slabs subjected to flexure test. A total of 4 slabs were cast and tested,

the size of these slabs are of 600m x 300mm x 25mm. These slabs were cast by varying the number

and size of reinforcing mesh layers. Cement mortar matrix mix for ferrocement slabs was finalized

by developing 5 mixes of high strength mortar. A mix of ratio 1:1 mortar with 90% cement, 10%

silica fume and M-sand gives the compressive strength of 80-90MPa, therefore it is adopted as a

best mix for ferrocement slab. Further welded mesh of 2 and 4 layers of 60mm and 30mm openings

were used as reinforcement for these slabs. From the results of this study, it is observed that

flexural strength increases with increase in mesh layers and mesh size.

Key words: ferrocement slabs, welded and wire mesh, high strength mortar, flexural strength etc..

3|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

STUDY OF BEAM COLUMN JOINT UNDER DIFFERENT

REINFORCEMENT DETAILING

LavanyaPrabha S*, NayanaSreekumar#, Arthi R#, Balamurali I#, Pradeep P#,

*

Professor, Department of Civil Engineering, Easwari Engineering College

#

UG Student, Department of Civil Engineering, Easwari Engineering College

#

nayanascivil@gmail.com

ABSTRACT

For any reinforced concrete framed structure, the beam column joint has always been a

vulnerable location. This project aims to develop new mechanism to enhance the performance of

such vulnerable joints in the building. The inspiration for choosing this topic is the evidences

displayed by the failure of these joints in multiple RC structures. Intensive research is being carried

out to strengthen such a vital location in the structure, with modification incorporated in the joint

region. This present study is to understand the effect of different type of detailing at joint region.

Detailing for specimens were carried out considering two new and unique methods. The

experimental investigations have been carried out by subjecting the specimen to cyclic loading and

observations were made on energy dissipation, yield load, ultimate load and cracking load. The

load displacement and moment rotation hysteretic curve were developed for various specimens

and performance comparison was made.

4|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

STRUCTURAL BEHAVIOUR OF FERROCEMENT SANDWICH PANEL

WITH M-SAND

M.Nithyalakshmi1, D.Selvapriya2, M.Visuwesh2,P.Vikash2,S.Saravan2

1

Professor, Civil Engineering, Easwari Engineering College, Chennai.Tamilnadu, India.

2

UG Student, Civil Engineering, Easwari Engineering College, Chennai,Tamilnadu, India.

ABSTRACT

There is a huge growing requirement of building materials in India due to the existing

housing shortage, mainly for the low income groups of people. To fulfill this basic needs, India

requires innovative, energy efficient building materials for strong and durable housing in fast track

method of construction at affordable cost. All these concerns have lead to develop an energy

efficient and economical material. Lightweight prefabricated sandwich slab panel which provides

rapid or faster construction and contributes to environmental protection, can provide a solution to

many of the issues. This project describes the overview of sandwich panel, method of construction

and its properties. In addition, this sandwich construction deals with the problem of delimitation

of face sheets leading to their premature failure. This can avoided by providing binding cover over

the core. The study conducted involved the development of high performance cement based mortar

mix to cast ferro-cement cover. Lightweight sandwich panel is to provides rapid or faster

construction and contributes to environmental protection .The sandwich panel in any structure is

made up of three layers which consists of the thin skin-layer bonded to each side and lightweight

material(polystyrene) as a core. It is used due to reduce the self weight of structure and posses

good thermal characteristics. The eight panels are casted and tested under deflection at mid span

at different load level, compressive and tensile strength at different load level, crack propagation

and crack pattern also identified.

5|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

REVERSIBLE SHEAR CONNECTORS IN COMPOSITE STRUCTURES

M.Kavibala1, M.Surendar2

1

Student, Department of Civil Engineering, Easwari Engineering College, Chennai 89

2

Assistant Professor, Department Of Civil Engineering,

,Easwari EngineeringCollege, Chennai 89

kavibalamks@gmail.com

ABSTRACT

In steel-concrete composite structures the behavior of the shear connections is of a great

importance. A new type of shear connector called the perfobond which was introduced in

recognition of the unsatisfactory behaviour of shear studs resulting from fatigue problems caused

by live loads on composite structures. This connector includes a welded steel plate, with a number

of holes. The flow of concrete through the rib holes formed dowels that provide resistance in both

the vertical and horizontal directions. This shear connector is a viable alternative to the headed

stud connector. It was revealed that passing of transverse reinforcing bars through the perfobond

rib connector holes increased the ultimate capacity of the connection.The test results indicated that

slotted perfobond rib connectors improved the overall ductility of the test specimens. Finally a

comparison between theoritical results of headed stud and existing experimental results of

perfobond shear connectors were concluded with satisfactory results of perfobond connectors.

6|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

EXPERIMENTAL STUDY OF GRANITE POWDER AND IRON POWDER

ON STRENGTH PROPERTIES OF CONCRETE

Doodi ramesh1 D.Dwarakanath2 M.Muhesh pandian3 B.nandhakumar4

1,2,3,4

student, Easwari Engineering College, Ramapuram, Chennai-89.

ABSTRACT

In recent years, the construction industry has been faced with a decline in the availability

of natural sand due to the growth of the industry, exorbitant hike in the price of fine aggregate and

its limited availability. To overcome this type of problems are want to find new consumption

material. Granite and Iron industries produce lot of dust and waste materials. The wastes from the

granite polishing and Iron related units are being disposed to environment which cause health

hazard. This granite powder and Iron powder waste can be utilized for the preparation of concrete

as partial replacement of sand. In order to explore the possibility of utilizing the granite and Iron

powder as partial replacement to sand, an experimental investigation has been carried out. Granite

and Iron fines which are the by-product produced in granite factories and Iron plants while cutting

huge granite rocks to the desired shapes and iron materials respectively. Granite and Iron fines are

used as a filler material in the concrete, replacing the fine aggregate which will help in filling up

the pores in the concrete. Filling up of the pores by granite and iron fines increase the strength of

the concrete and also a material which is abundantly to investigate the strength behaviour of

concrete with use of granite and Iron fines as an additive. Concrete is prepared with granite fines

and Iron fines as a partial replacement of concrete in 4 different propositions making granite

powder as constant as 10% from various literatures and Iron Powder as 10%, 15%, 20% and 25%

and mechanical properties such as compressive strength, split tensile strength and flexural strength

are investigated.

Keywords: Granite Powder, Iron Powder, Environmental Hazards and Mechanical Properties.

7|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

STRENGTH PROPERTIES OFCONCRETE PARTIALLY REPLACED

WITH WPCB AS FINE AGGREGATE

P.GomathiNagajothi1, Dr.T.Felixkala2

1

Research Scholar, St.Peter’s University, Chennai.

2

Professor and Head, Dr.MGR Educational and Research Institute, University, Chennai.

ABSTRACT

Electronic waste is one of the fastest growing waste streams in the world and its generation

is expected to increase by 2-5% annually.Current scenario of its disposal through landfill or

improper recycling techniques canhave negative impacts on theenvironment. On the other hand,

use of conventional materials in concrete making depletes the natural resources constantly unless

they are suitably substituted. Thus, the currentstudy isaimed to use the non-metallic fractions of

waste printed circuit board(WPCB) as a replacement for river sand and fly ash and silica fume as

replacements for cement in concrete making which in turn may directly help in reducing the cost

of concrete manufacturing, reduced landfill cost and energy savings thus protecting the

environment and ecosystem from possible pollutions.Various mix proportions with 0 to 20% of

WPCB is replaced for fine aggregate in M20 grade of concrete. 25% fly ash and 10% silica fume

were used as replacement for cement in all mixes other than control mix. Compressive and split

tensile strength of WPCB replaced concrete and control mix for 7, 21 and 28 days were evaluated

and compared. Results revealed that WPCB can be replaced upto10% for fine aggregate.

Key words: WPCB, concrete, compressive strength and split tensile strength.

8|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

MECHANICAL PROPERTIES OF FLYASH AND GGBS BASED

GEOPOLYMER CONCRETE WITH PARTIAL REPLACEMENT OF FINE

AGGREGATE BY COPPER SLAG

Shanmuga Priya G1,M Sowmiya2 ,V Sarangy3, M Sudhagar4

1,2,3,4

student, Civil Engineering, Easwari Engineering College, Ramapuram, Chennai – 89.

ABSTRACT

Concrete has been one of the major construction materials used since the time of the Roman

Empire. However, the use and manufacturing of concrete has led to serious environmental

concerns. Cement, an ingredient of concrete, is a major contributor to carbon-di-oxide emissions,

which in turn promotes global warming.

Thus Geopolymer Concrete attempts to curb the cement content, by replacement with a

cementitious material like Flyash. Partial replacement of fine aggregate with Copperslag is a type

of waste management strategy, employed to prevent removal of sand from riverbeds. Excessive

removal of the sand can cause destruction of river ecosystems. Hence the aim of this report is to

produce durable and eco-friendly Geopolymer concrete without employing the use of ordinary

Portland Cement.

The component materials of concrete include flyash, GGBS, copperslag, Sand, Gravel,

Sodium hydroxide, Sodium Silicate and water. The molarity of Sodium Hydroxide and Sodium

Silicate solution is taken as 8M. 30 test cubes and 30 cylinders of nominal sizes were cast.The

specimens were tested for compressive and split tensile strength with 0%, 25%, 50%, 75% and

100% replacement by copperslag. Curing of the cubes is done by ambient curing and duration of

the curing process is for 14 days.The results indicate that with increase in copperslag, the

compressive strength of the concrete increases for an optimum percentage of 50%.

Keywords: Geopolymer Concrete, Flyash, Copperslag, GGBFS, Compressive strength.

9|Page Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

BEHAVIOUR OF BASALT FIBER REINFORCED CONCRETEFILLED

STAINLESS STEEL AND MILD STEEL TUBE

M.Nandhini1, C.Kathampari1, R.Kaushik1, K. MohanKumar1, A.Arunraj2

1

U.G Student of SRM Easwari Engineering College, Ramapuram, Chennai-89.

2

Asst. Prof of SRM Easwari Engineering College, Ramapuram, Chennai-89.

ABSTRACT

An experimental study has been carried out to understand the behavior of the basalt fiber

reinforced concrete filled steel tubular column under uniaxial load. A concrete-filled steel tubular

(CFST) column is formed by filling a steel tube with concrete. It was well known that concrete-

filled steel tubular (CFST) columns are being increasingly used in the construction buildings.

Basalt CFST are used to perform better than the normal CFST. The experimental works are carried

by performing various tests such as strength test, flexural test, and compressive test. The results

and graphs are plotted and shown below. A comparative analysis between basalt fiber reinforced

concrete filled mild steel tubular column and basalt fiber reinforced concrete filled stainless steel

tubular column will determine the strength between them.

Keywords: Concrete Filled Steel Columns (CFST), Basalt Fiber Reinforced Concrete (BRFC),

strength, uniaxial load.

10 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

EXPERIMENTAL STUDY ON BASALT FIBRE REINFORCED FOAMED

CONCRETE

1J.Jaya Prakash, 1D.K. DhanunJayanath, 1K. Manoj and 1A. Antony AjaiChriston

2I.AshmiMonisha

1

Final Year Under Graduate students, SRM Easwari Engineering College

2

Assistant Professor, SRM Easwari Engineering College

ABSTRACT

Aerated Concrete utilizes foaming agents or chemical admixtures to entrain air into the

concrete and thereby decreasing the density of the concrete. The process of utilizing foaming

agents produces light weight concrete that can be utilized in many wide applications. But this

Foamed Concrete has the drawback of low strength compared to normal concrete. Hence to

increase the strength of the Foamed concrete while maintaining its advantage of low density

requires that the chemical nature of the Foamed Concrete to not be disturbed. Thus strengthening

of the mechanical aspect by providing Basalt fibre reinforcements is done. The experimental

analysis is carried out with Basalt fibres and from the results the optimum quantity of fibre

reinforcement is found. A Comparative analysis between the mechanical properties such as

Compressive, tensile, flexural and impact strength of normal Foamed Concrete and fibre

reinforced foamed concrete is also done, and the advantages and disadvantages are distinguished.

The economy of utilizing Foamed Concrete as a structural member is also analyzed and a

hypothetical estimation is done.

Keywords - Aerated Concrete, Foamed Concrete, Basalt Fibre, Low Density, Economic

Construction

11 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

MECHANICAL PROPERTIES OF GSA AND RHA BLENDED CEMENT

CONCRETEAT DIFFERENT TEMPERATURES

Priya. B1 rajagopal. T2 . Ashmi monisha. I3

1,2

Students, Eswari engineering college, Ramapuram,Chennai

3

.Asst.prof. Easwari engineering college, Ramapuram, chennai

ABSTRACT

Pozzolanic material have long demonstrated their effectiveness in producing high

performance concrete. Groundnut Shell Ash (GSA) and Rice Husk Ash are also the pozzolanic

material. A pozzolanic material is siliceous or aluminous material which possessing no

cementitious properties but in presence of water, react with chemically with calcium hydroxide at

ordinary temperature to form compounds possessing cementitious properties.

Due to continuous demand and increase in price of cement it is necessary to replace cement

with another pozzolanic compound. Therefore in this project groundnut shell ash (GSA) and Rice

Husk Ash are going to be used as a partial replacement of cement. The main aim of the project is

to check the strength of concrete with the partial replacement of cement with groundnut shell ash

burnt at different temperatures (500ºC, 600ºC, 700ºC).

Rice husk and Groundnut shell are going to be burnt at different temperatures and then it

is used to partially replace cement. Then M30 grade of concrete is prepared and then fresh concrete

tests will be performed. After this casting and curing of concrete is done for 28 days. Hardened

concrete tests will be carried out on the 7, 14 and 28th day. Finally the results will be compared

with the performance of conventional concrete.

12 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

FLEXURAL BEHAVIOR OF BASALT FIBRE REINFORCED CONCRETE

FILLED MILD STEEL TUBE BEAMS

B.Aswini1, M.Keerthana2, B.Krishna3 , S.B. Akhilesh Babu4

1.2.3.4

Under Graduate students, SRM Easwari Engineering College,Chennai - 89

ABSTRACT

Plain Concrete has a major deficiency of low tensile strength. The tensile strength of

concrete is very low because normally concrete contains numerous micro cracks. This deficiency

has lead to considerable research for improving the tensile strength of concrete. This paper

introduces an innovative reinforced concrete filled steel tube beams for improved flexural

behaviour and tensile strength of steel and concrete composite structures. The strength and

ductility of the core concrete are the important factors that influence the bearing capacity of

concrete – filled steel tube structures.

The study is aimed at the effect of basalt fibre on the flexural behaviour of Concrete Filled

Mild Steel Tube Beams. Basalt fibre of 12mm length and 13µm diameter is used for the study.

The fibre is mixed with M30 grade concrete.

Conventional concrete is tested for its compressive strength, and split tensile strength using

9 cubes, and 9 cylinders respectively at the age of 3,14 and 28 days. Basalt Fibre Reinforced

Concrete is also tested for the above properties.

Basalt Fibre Reinforced Concrete in – filled rectangular mild steel tube beams of sizes

2”x4” and 5.5”x4” and conventional size concrete beams with and without fibre reinforced are

tested for the flexural behaviour under four – point load test and the comparative values are

recorded and analyzed.

13 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

CORROSION PREVENTION ON COATED REBARS AND FIBER IN R.C

SLABS

Dr. M.Tamil Selvi1, Mrs.S.Gayathri2, J.Hathari Evangalin3

1

Professor, Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan

Dr.Sakunthala Engineering College

2

Professor, Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala

Engineering College

3

PG Student, Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala

Engineering College

ABSTRACT

Premature failure of reinforcement concrete structures occurs primarily due to early

corrosion of steel reinforcement. The important developments and concrete durability reduces with

the problem of deterioration of reinforced concrete structures. The major cause of deterioration is

the corrosion of the steel reinforcement, that can lead to structural problems. By utilizing our

knowledge on corrosion of steel reinforcement, concrete structures could be made more durable.

The project is aimed at preventing corrosion in RC slabs by coating silicon tombac to the steel

rods. Nylon fiber is induced in concrete to attain strength for the concrete. In this work an attempt

is planned to study the effects of coating material between the conventional and fibers in concrete

was compared with that of uncoated material between the conventional and fiber in concrete

rebar’s. In order to study the corrosion of rebar’s in a short term time the corrosion process is

accelerated by impressing a direct current, the corrosion process is monitored continuously. The

methods used to induce the corrosion is Accelerated corrosion test and Half-cell measurement.

The experimental result of corrosion of RC slabs under coated and uncoated reinforcement with

fiber concrete and the parameters like accelerated corrosion, half-cell potential reading results are

presented.

Key words - Nylon fiber, Silicon tombac coating, Corrosion test.

14 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

STUDY OF ACCESSIBLE MATERIAL FOR THE FABRICATION OF

UNBURNT BRICK

K.Pushpavalli 1, V.Tamilarasi2

1

B.E, Civil engineering, IFET College of engineering, villupuram.

2

B.E, Civil engineering, IFET College of engineering, villupuram.

ABSTRACT

Sun dried or unburnt brick is one of the oldest building materials that has been used for

more than 10000 years to build houses, Mosques, Churches, Palaces and Cities. This process is

very simple with zero maintenance cost, local availability, affordability and has a good thermal

and acoustics insulation. Normally unburnt brick has lower strength and cause cracks during

drying process when compared to conventional bricks .The main aim of this study is to control the

pollution and to increase the strength so, straw and rice husk ash has been used as an additive

material. By usage of straw the shrinkage cracks can be reduced and strength can be achieved by

incorporating rice husk ash. The various proportion involved are 95%,90% and 80% of clay with

5%, 10% and 20% of RHA. Then 98% of clay with 2% of straw. The higher compressive strength

had attained at 98% of clay with 2% of straw with less weight and high durability.

Keywords - Unburnt brick, clay, rice husk ash, straw, compressive strength.

15 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

EXPERIMENTAL STUDY ON STRENGTH OF CONCRETE BY PARTIAL

REPLACEMENT OF CEMENT BY CASHEW NUT SHELL ASH (CNSA) &

CHICKEN FEATHER FIBER (CFF) AS FIBER REINFORCEMENT

V.Thirumurugan.1, S.George vimal raj2 , K.Dheenadayalan3

1

IFET College of Engineering College, Assistant Professor, Department of Civil Engineering,

Email:georgeworld6@gmail.com

2

IFET College of Engineering College, Department of Civil Engineering,

Email:dheena18@gmail.com

3

IFET College of Engineering College, Department of Civil Engineering,

Email:sgeorgevimalraj@gmail.com

ABSTRACT

In this project, to reduce the cement content in the concrete to use the cashew net shell ash

(CNSA). Most ashes have pozzolanic activity, and may be used as a cement replacement material,

resulting in less energy waste and low cost composite. And also increase the strength of concrete

to add the chicken feathers as a fiber. The CFF has presence of more void space in its cross section,

so it has good resilient property. By using the CFF will save cost, eco-friendly environment and

also help the fiber industry sustainable. Combination of CNSA and CFF is cost efficient and

improve strength of concrete block.

Keywords - Cashew nut shell ash, Chicken feather fiber, Pozzolanic, energy waste ,Calcareous ,

argillaceous, Compression, Plain rigid bearing block.

16 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

IMPLEMENTATION OF LEAN CONSTRUCTION IN RESIDENTIAL

BUILDING PROJECTS

P.SelvaPrasanth 1, S.Ranjitha2, R.Tharanyalakshmi2

1

Assistant professor/ Department of Civil Engineering – IFET College of Engineering

2

Final year student- IFET College of Engineering.

ABSTRACT

The construction revolution for the past twenty years had experienced a decline in

productivity when compared to other industrial revolution. To fight against this circumstance, lean

principles have been introduced in the field of construction. Lean construction is a new

construction management philosophy which caused a revolution in the manufacturing planning,

supply and assembly. This method was evolved from lean manufacturing principles to reduce the

production of waste. The goal of our project is to apply the lean techniques in small scale

construction projects such as residential buildings. This project deals with the various lean tools

which includes Last planner system, Increased visualization, Total Quality management, 5S

process and Just in time. These tools helps us to improve the short term scheduling effort and

communication. The essence of lean construction is increased by the elimination of nonvalue

adding activities from the construction.

Keywords - Lean construction, Last planner system, Increased visualization, Total quality

management, 5S process, JIT, Non value adding activities, small scale construction.

17 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

AN EXPERIMENTAL STUDY ON THE BEHAVIOR OF BRICK USING

BALL CLAY, FLY ASH AND JAGGERY

R.R.Tharini1, K.Panchavarnam2, M.Jayalakshmi2

1Assistant professor, Department of civil engineering, IFET College of Engineering.

2,3UG student, Department of civil engineering, IFET College of Engineering.

ABSTRACT

Brick plays a vital role in the field of construction, signifying the need to study the behavior

of brick in different condition and composition. During the manufacturing of bricks CO2 emission

is more and exploitation of clay soil is more. For this reason, we can reduce the clay content and

replaced by waste by product. In this paper we used the ball clay, fly ash and jaggery. We use ball

clay as the replacement of clay and jaggery dissolved water. Jaggery used to increases the

compressive strength of brick and ball clay contain high silica content. It is reduced the water

absorption in brick and increases the workability of the brick. Here we find the fired strength of

the bricks using ball clay, fly ash and jaggery. We use different proportions of materials. The brick

specimen of size 230mm x 110mm x 85mm were cast for different mix percentage of Fly ash (20%

to 50%), Ball clay (10% to 25%), clay (25%to 70%) and Jaggery (60%). Compressive strength

was determined for different proportions. Various test of brick such as compressive strength test,

water absorption test, efflorescence test, shape and size test, hardness test and soundness test.

Keywords - Clay, Ball clay, Fly ash, Jaggery, Waste by-products, Compressive Strength

18 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

AN EXPERIMENTIAL INVESTIGATION ON PARTIAL REPLACEMENT

OF CEMENT BY FLY ASH AND COARSE AGGREGATE USING E-

WASTE

Dr. M.Tamil Selvi11, Dr.P.B.Sakthivel2, G.Keerthana3

1

Professor, Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan

Dr.Sakunthala Engineering College

2

Professor, Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala

Engineering College

3

PG Student, Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan

Dr.Sakunthala Engineering College

ABSTRACT

E- Waste is currently considered as one of the fastest growing waste streams in the world,

with an estimated growth rate of 3- 5% per year. Solid waste management is one of the major

environment concerns in the world. With the scarcity of space for land filling and its ever-

increasing cost, waste utilization has become an attractive alternative for e- waste disposal. In this

paper, an experimental investigation has been done to determine the compressive strength, flexural

strength, load and deflectionof concrete specimens by using E-Waste as a partial replacement for

coarse aggregate. Partial replacement of E-waste has been done at 30%, 35%, and 40% for coarse

aggregate. The concrete cubes of size 150x150x150 and beams of 700x150x150 mm size were

cast and tested at 28 days. Water cement ratio of 0.45 has been used. The compressive strength of

partially replaced E-waste concrete was found to increase by 10% and flexural strength by 18%

when compared to conventional concrete.

Keywords: E-Waste, Compressive Strength, Flexural Strength, Load-Deflection, Concrete

19 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

STUDY ON SHEAR CONNECTION BETWEEN STEEL AND

CONCRETE IN COMPOSITE STRUCTURE

Gopi Krishnan.P1, Neru Prasad V.K1, Abirajan.J1, Arjunramasamy.M1, Surendar.M2

1

UG Students, Department of Civil Engineering, Easwari Engineering College, Chennai.

2

Assistnt Professor, Department of Civil Engineering, Easwari EngineeringCollege,Chennai.

Email: rpgkrish@gmail.com; neruprasath10@gmail.com;Surendar.m@srmeaswari.ac.in

ABSTRACT

For the past few decades, the construction field has been moving towards the usage of steel-

concrete composite structural elements in most of its construction. Various research works are

carried out to increase the structural aspects of such composite construction. Shear connector

between concrete and steel elements in composite construction plays an important role in

developing the composite action by ensuring proper shear transfer between the steel profile and

the concrete element. The connection between the steel and concrete sections are mostly done

using welding, given the durability and strength of welding. For the current study, the shear

connectors, connecting the concrete slabs and steel beam, are welded to the flanges of the beam.

Given the flexible nature of the shear connectors, they can be available in various shapes and sizes.

The performance of each connector was evaluated and compared. The main comparison between

the specimens were carried out by comparing the load slip behaviour of the specimens.

Keywords - Shear connector, Composite action, Channel connector, Welded connection, Load

Slip behaviour.

20 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

FLEXURAL AND DIRECT TENSILE BEHAVIOUR OF SLURRY

INFILTRATED FIBRE REINFORCED CONCRETE (SIFCON)

G. Anand Raj1, G. Dharmaraju2, V. Palani Mohan3,S. Pon Balakumar4, V. Saravana Karthika5

1,2,3,4

UG Students, Easwari Engineering college,Ramapuram,Chennai – 89

5

Assistant Professor, Easwari Engineering College.Ramapuram,Chennai – 89

ABSTRACT

Slurry infiltrated fibre reinforced concrete (SIFCON) is recently developed construction

material. It can be rightly thought as pre placed fibre concrete, analogous to pre placed aggregate

concrete. In fibre reinforced concrete (FRC), the fibres are mixed along with the other ingredients

maximum of two percent volume but the placement of steel fibres in a form or mould is the initial

step in the preparation of SIFCON could be considered as a special type of fibre concrete with

high fibre content up to 20 percent of volume. The matrix consists of cement slurry of flowing

cement mortar. This material has been used for repair of pre-stressed concrete beams, security

vaults, bridge deck rehabilitation, pavement rehabilitation, refractory application, subjected to

blast loading etc. Because of its high strengths, excellent energy absorption, ample stiffness and

many other good properties, pre-cast SIFCON slabs will have a wide range of structural

engineering applications where high energy elements are required. This study's main objective is

to find out the mechanical properties of SIFCON for various types of volume fraction of micro

steel fibres. The aim of present investigation is to study the flexural and direct tensile behaviour

of Slurry Infiltrated Fibre Reinforced Concrete (SIFCON). The matrix in SIFCON has no coarse

aggregates, but a high cementitious content. If percentage of steel fibres in cement matrix could

be increased, one could get a material with very high strength properties which can be called as

SIFCON. The percentage of micro steel fibers by volume used is 4%, 6% and 8%.The fibres are

crimped type of 0.5 mm diameter with an Aspect ratio 25. Proportions of cement and sand used

SIFCON are 1:1 by weight. Water cement ratio taken 0.35. Percentage of silica fume taken 10%

by weight of cement. Percentage of super plasticizers taken 0.8% by weight of cement. An another

type is done by replacing cement by using polymer. The type of polymer used is Poly ester.

Proportions of polymer, fly ash and sand used in SIFCON are 1:1:4.

Key Words - SIFCON, Cement,Polymer, Micro steel fiber, Tensile strength, Flexural strength.

21 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

GEOGRID REINFORCED AERATED CONCRETE

Akshayaa.P1 Hemalattha.S2

1,2

Final year U.G, civil department, Rajalakshmi engineering college.

ABSTRACT

Although the knowledge in structural engineering has advanced enormously in last

decades, structure collapses still occur with significant frequency. The significance of Load

bearing capacity of beam and slab is its high-quality mortar and steel reinforcement. However

when subjected to seismic or any other loading of high intensity will behave as brittle structural

elements. Why steel is used as a reinforcement material in concrete? Just because concrete is weak

in tension, steel is being used as a material of reinforcement. In order to improve their lateral

resistance and ductile behavior, beam and slab are reinforced with steel. But the continuous use of

steel will create scarcity of steel in the next 20 years. Over the years the introduction of sustainable

development to overcome the issues of steel depletion has gained increased attention. The main

objective of this project is to address the potential use of Geogrid as a material for reinforcement

in lightweight concrete for construction of high intensity load resisting beam and slab. Geogrids

are now commonly used to reinforce soil for pavement construction in US and other countries.

Former test results prove that geogrids are considerably strong in tension, hence its replacement

by steel will further account to the improvement in ductile nature of walls which is the main

property required for any civil structure. Thus by reducing the susceptibility of the structure to

these unforeseen events is a key aspect in increasing the safety of buildings.

Key words - Advancement in structures-Geogrid as replacement for steel- Slab-Beam-Improved

load bearing structures-Aerated concrete-Highly economical-Eco-friendly-Increase in safety.

22 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

EXPERIMENTAL STUDY ON CONCRETE WITH PARTIAL

REPLACEMENT OF COARSE AGGREGATE BY WASTE GLASS

BOTTLES

1R.Praveena, 2 Prerna Sharma, 3Anmol Basnett,

1

R.Praveena, Assistant professor,E.S Engineering College, Villupuram

2,3

Student E.S Engineering college, Villupuram

ABSTRACT

Million tons of waste glass (WG) is being generated annually all over the world due to

urbanization and industrialization where most of the waste glass (WG) end up in landfill while

only small fraction can be recycled because of the high cost of cleaning and colour sorting. Once

the glass becomes a waste it is disposed as landfills, which is unsustainable to the environment.

Recent studies have shown that the waste glass (WG) can be effectively used in concrete either as

aggregate or as cement replacement. Glass is principally composed of containing relatively large

quantities of silicon and calcium. This experimental study focusing to partially replacing the coarse

aggregate by the waste glass (WG). Coarse aggregates were replaced by waste glass (WG) in the

ratio of 5%, 10% and 15% in M30 grade of concrete. The compressive strength, splitting tensile

strength, and flexural strength of concrete are determined at the ages of 7days, 14 days and 28

days. The results concluded that using waste glass (WG) as partial replacement of coarse

aggregates up to 10% gives good results as compared to the conventional concrete. Use of waste

glass (WG) as partial replacement of coarse aggregate in concrete could be an important step

toward development of sustainable and economical in construction industries.

Key words - Waste Glass (WG), Recycle, Coarse Aggregate (CA), Compressive strength, Split

tensile strength, Flexural strength.

23 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

AN EXPERIMENTAL STUDY ON CONCRETE WITH PARTIAL

REPLACEMENT OF CEMENT BY RICE HUSK ASH AND COARSE

AGGREGATE BY RECYCLED AGGREGATE

1R. Praveena, 2Trisha subba, 3Sahi chettri,

1

Assistant professor,E.S Engineering College, Villupuram

2, 3

Student E.S Engineering college, Villupuram

ABSTRACT

Increase in the demand of conventional construction materials and the need for providing

a sustainable growth in the construction field has prompted the engineers to opt for 'alternative

materials' feasible for use in construction. As we know that concrete is the main construction

material across the world and mostly used in all types of civil engineering works. Since aggregate

represents about 70-80% of concrete components so it will be beneficial to recycle the aggregate

for construction works and also to solve the environmental problems. When structures made of

concrete are demolished or renovated, concrete recycling is an increasingly common method of

utilizing the coarse aggregate and to minimize construction costs. Similarly, the cement industry

is one of the primary producers of carbon dioxide (greenhouse gas), which affects the environment

badly. Nowadays various research works are being carried out on cement replacement. Rice Husk

Ash (RHA) is an agricultural based pozzolanic material, generated by rice mills in huge quantities.

The rice husk ash (RHA) contains nearly about 85 % to 90 % amorphous silica. With the partial

replacement of Rice Husk Ash (RHA) instead of cement in concrete, we can improve the properties

of concrete. This experimental investigation is to study the strength properties of concrete with

partial replacement of cement by Rice husk ash in the proportion of 20% and partial replacement

of coarse aggregate by Recycled Aggregate (RA) in proportion of 5%, 10% and 15% respectively.

The partial replacement of cement by Rice Husk Ash (RHA) and coarse aggregate by Recycled

Aggregate (RA) gives good strength, which can conserve energy for concrete production and

decrease the emission of green-house gases (CO2) in larger extent, as well it is a solution to the

ever increasing waste disposal problems.

Key words - Recycle Aggregate (RA), Rice Husk Ash (RHA), CO2 Emission, Greenhouse gas,

Solution to waste disposal, Compressive strength, Split tensile strength, Flexural strength.

24 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

USE OF IRON INDUSTRIAL WASTE AND MICROBES TO CONCRETE

1

Nishanth.B, 2Karthikesan.A.K,

1,2

Student, Department of Civil Engineering, Sri muthukumaran institute of

technology,Chennai600122

Email: Nishanthboopathi.civil@gmail.com

ABSTRACT

The environment problems are very common in India due to generation of industrial

by-products. Due to industrialization enormous by-products are produced and to utilize

these by-products is the main challenge faced in India. Iron slag, sponge iron, iron ore fines are

the industrial by-product from the iron and steel making industries. In this paper, the

compressive strength and flexural strength of the various materials obtained from iron

industrial waste was studied. The results confirm that the use of iron slag overcome the pollution

problems in the environment. Some of the major drawbacks are cracking and seepage. Cracks

form an open pathway to the reinforcement and can lead to durability problems like corrosion of

the steel bars. These cracks should be repaired because they can reduce the self-life of the

Structure. The application of synthetic chemicals currently used for concrete repair is a source of

environmental concern, Therefore the use of a biological repair technique is investigated in this

study using microbes. The results shows that the iron slag added to the concrete had greater

strength than the plain concrete.

25 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

EXPERIMENTAL STUDY OF MUSA FIBRE REINFORCED CONCRETE

Lenin Dhal1

1

Assistant Professor, Easwari Engineering College, Ramapuram, Chennai 89.

ABSTRACT

Musa fibres are available worldwide as agricultural waste from Banana cultivation. Musa

fibre are environmental friendly and present important attributes, such as low density, light weight,

low cost, high tensile strength and flexural strength.

For this purpose five mixes, one plain concrete mix and four fibre reinforced mixes

(10%,20%,30%,40%) were prepared and M20 concrete and Ordinary Portland cement of grade 43

was used.

The musa fiber reinforced concrete are tested for compressive strength, splitting tensile

strength, flexural strength at different ages (7,14 &28days).

After the generation of test results musa fiber reinforced concrete is compared with normal

conventional concrete and the differences between their attributes are studied.

26 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

COMPARITIVE STUDY OF CONVENTIONAL BITUMEN MIX TO

MODIFIED BITUMEN MIX

C.Deepika1, G.Swetha2 , A.Hari Haran3, V.Murali4, S.Nandhini5

1.2.3.4

Under Graduate students, SRM Easwari Engineering College,Chennai –89

5Asst.Prof. Easwari Engineering College, Chennai - 89

ABSTRACT

The conventional type of bitumen is widely used in road paving and their viscoelastic

properties are dependent on their chemical composition. At higher temperature bitumen behaves

like a viscoelastic liquid and at low temperature it acts like a brittle viscoelastic material prone to

cracking even at moderate loads. Moreover, at low temperatures bitumen can stay at non-

equilibrium thermodynamic state for extended periods of time. This is the effect of its internal

structure. Such a complex behavior creates problems in engineering applications of asphalt binder

in paving mixes.

Modification of base asphalt is required to improve the material’s performances such as

adhesion, temperature sensitivity, friction properties, oxidation resistance, aging resistance and

durability. The pavement with Polymer Modified Asphalt (PMA) exhibits higher resistance to

rutting and thermal cracking, lower fatigue damage, stripping, aging and temperature

susceptibility. Therefore, asphalt modification with nanotechnology has been attempted to

overcome, or at least delay the above described problems. The Nano powders consist of particles

of a few tens to a few hundreds of nanometers in size. Due to the large surface area to volume

ratio, these materials present new enhanced properties when compared to their bulk properties.

In this study, Nano silica has been used as a modifier with VG 30 bitumen. Nano silica is

a material with a vast surface area, robust adsorption, good dispersion, high chemical purity and

excellent stability. Nano silica is a reputable modifier in inhibiting oxidizing reactions in the

bitumen binder which is having chemical reactions and physical dispersion with the base bitumen.

27 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

COMPARATIVE ANALYSIS OF USING OYSTER SHELL ASH AND

POWDER AS CEMENTING MATERIAL FOR CONCRETE

D.Lakshmi Priya1

1

Asst.Prof. Easwari Engineering College, Ramapuram, Chennai-89

ABSTRACT

The main intension of this study is to examine the application of oyster shell powder and

ash as a cementing material in concrete. As oyster shells are cheaper in cost and is available in

larger quantities, this could be convincingly used as a partial replacement with cement. This project

describes the feasibility of using oyster shell powder and ash which is obtained as waste from the

marine coast. The main aim is to study the strength characteristics of concretes with these

admixtures. The partial replacement of oyster shell powder and ash results in the increase of

compressive strength than the standard mix. Hence a comparative study is made on the

compressive strength, Tensile Strength and Flexural behavior of oyster shell powder and ash in

concrete with the conventional concrete.

Keywords - Oyster shell, cementing material, admixtures, compressive strength.

28 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

FLEXURAL BEHAVIOUR OF TERNARY BLENDED CONCRETE WITH

STEEL FIBRES

Saranya 1, Salini 1

1

Student, civil Engg, Easwari Engineering college, Ramapuram, Chennai - 89

ABSTRACT

Now a day the world is witnessing the construction of very challenging and difficult

structures, concrete being the most important and widely used structural material. The main

ingredient in the conventional concrete is Portland cement. The amount of cement production

emits approximately equal amount of carbon dioxide into the atmosphere. Cement production is

consuming significant amount of natural resources. To overcome the above ill effects, the advent

of newer material and construction techniques and in this drive, admixture has taken newer things

with various ingredients has become a necessity. The addition of cementitious materials with OPC

is the basic concept of ternary blended concrete. Ternary blended concrete marks the inclusion of

two different pozzolanic materials to the concrete with cement acting as the primary binding

material. So the main objective of the project is to produce partial replacement of the cement using

supplementary cementitious materials. This project also aims to provide enhanced strength which

is aided by using basalt fibers. The scope of project is to produce a ternary blended concrete mix

and test it for various mechanical and structural behaviors. Using results obtained from the test

conducted on ternary blended concrete, it is compared with the results obtained from the test

conducted on conventional concrete mix. Also the flexural strength of reinforced beams of ternary

blended and conventional concrete are tested and studied. The methodology of the project involves

collection of the materials like cement, fine aggregate, coarse aggregate, supplementary

cementitious materials (diatomite and waste marble powder). The individual raw materials are

tested. The mix design for M30 grade of concrete is calculated and quantity of materials needed is

estimated. Then the concrete mix is prepared and test on fresh concrete like slump cone, vee bee

consistometer test, flow test etc. are conducted. Then the concrete is cast into cubes, cylinders and

prism and cured for 28 days. After 28 days test on hardened concrete like compression test, split

tensile test and flexural test are conducted. Four design mixes namely conventional concrete,

conventional concrete with fibres, ternary blended concrete and ternary blended concrete with

fibres are prepared and each undergoes test for fresh and hardened concrete. Similarly reinforced

beams for each mix design is casted and is subjected to flexural test and its structural behaviour is

studied. Based on the test results, comparison is done between conventional concrete and sternary

blended concrete based upon the structural and mechanical properties. This result helps us to

understand the behavior of ternary blended concrete and its advantages over conventional concrete.

Keywords - Cementitious materials, basalt fibers, flexural strength, diatomite and marble

powder, test on fresh concrete and hardened concrete, reinforced beams.

29 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

APPLICATION OF LIGHT EXPANDED CLAY AGGREGATE AS

REPLACEMENT OF COARSE AGGREGATE IN CONCRETE

PAVEMENT

Ms.A.Pavithra1, M.Shanmuga priyaa 2, S.Shahid Athif 3, G.Vignesh 4, S. Vinoth Kumar5.

1

Professor, Civil Engineering, Easwari Engineering College , Chennai. Tamilnadu,India.

2

UG student ,Civil Engineering,Easwari Engineering College , Chennai. Tamilnadu,India.

3

UG student, Civil Engineering , Easwari Engineering College, Chennai. Tamilnadu,India.

4

UG student, Civil Engineering , Easwari Engineering College, Chennai. Tamilnadu,India.

5

UG student, Civil Engineering, Easwari Engineering College, Chennai. Tamilnadu,India.

ABSTRACT

The main aim of this project is to develop a concrete pavement by replacing the coarse aggregate

by light weight expanded clay aggregate. The damage caused is less significant and therefore the

maintenance cost is also reduced. In order to understand the effect of light weight aggregate in

concrete, conventional concrete of strength 30Mpa is to be designed. Then the natural coarse

aggregates were replaced by clay aggregates and the mix is redesigned to meet the desired strength

requirement. As the density of the concrete tends to be lowered, the strength of the concrete may

also tend to decrease. Hence suitable chemical and mineral admixture to be incorporated in

addition to significant water reduction to meet the strength requirement.

30 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

COMPARATIVE STUDY OF STRUCTURAL INSULATED PANELS

SYSTEM WITH CONVENTIONAL METHOD OF CONSTRUCTION

A.SANGEETHA

VELTECH RENGARAJAN, DR.SAKUNTHALA R&D INSTITUTE OF SCIENCE AND

TECHNOLOGY

ABSTRACT

Structural insulated panels (SIPs) are a high performance building system for residential and light

commercial construction. The panels consist of an insulating foam core sandwiched between two

structural facings, typically oriented strand board (OSB). These panels usually are manufactured

in various sizes or dimensions with thickness varying between 4 to 8 inches. SIPs are manufactured

under factory controlled conditions and can be fabricated to fit nearly any building design and

some SIP's are manufactured using with no CFC's or HCFC's. The result is a building system that

is extremely strong, energy efficient and cost effective. Buildings with SIPs will save our time,

money and labor.

The main part of the project is to compare the various quantity of the material like sand,

cement, brick, steel, concrete, panels used for the construction using the Structural insulated panels

and the conventional method for constructing of the structure. The cost of the material & labour

has been taken for the Chennai, Tamilnadu zone. The time factor will be calculated using the help

of MS project while the quantity of the various material will be work out using the Microsoft excel.

31 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

EXPERIMENTAL INVESTIGATION ON UTILIZATION OF FLY ASH

AND POND ASH WITH SELF COMPACTING CONCRETE

A.Mohan1, M.Tholkapiyan2, G.Rushitha sai 3, G. Yogesh Parri 3.

1 Assistant professor of civil engineering, Vel tech high tech Dr.Rangarajan Dr.Sakunthala

engineering college,

2 Professor of civil engineering, Vel tech high tech Dr.Rangarajan Dr.Sakunthala engineering

college,

3. Student, Vel tech high tech Dr.Rangarajan Dr.Sakunthala engineering college

ABSTRACT

Self Compacting Concrete (SCC) is a flowing concrete mixture that is able to consolidate

under its own weight, without the need for vibration. The highly fluid nature of SCC makes it ideal

for placing in difficult conditions and in sections with congested reinforcement.

Mixture proportions for SCC differ from those of ordinary concrete, in that the former has

more powder content and less coarse aggregate. Supplementary cementitious materials such as fly

ash, silica fume and blast furnace slag, pond ash are normally used as powders to enhance the

technology of SCC.

In addition, SCC also incorporates chemical admixtures, such as HRWR (High Range

Water Reducer), and VMA (Viscosity Modifying Agent). Large amount of fly ash and pond ash

is being generated in India annually and hence there is a strong need to use this byproduct from

thermal power stations, in large proportions in concrete which is also makes the concrete as cost

effective. A SCC mix was arrived based on available EFNAARC guide lines and using various

mix combinations. An experimental study is made on the properties of SCC incorporating fly ash

and pond ash. Slump flow test, V-funnel test, L-box test were carried out to confirm the self-

compact ability of concrete. Compressive strength test, split tensile test, flexural strength test,

young’s modulus test were carried out on SCC. This experimental investigation studies the

potential of using Pond ash from Thermal Power Plant, as a part replacement with sand in plaster

mortar. Workability of mortar mix is increased due to addition of pond ash, which will result in

the reduced w/c ratio. Change in the volume of hardened mortar is very less due to addition of

pond ash, which results less occurrence of surface cracks.

32 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

FLEXURAL BEHAVIOUR OF ROLLED STEEL I BEAM WITH

DIFFERENT STIFFENER POSITIONS

R.EMILREYAN

EASWARI ENGINEERING COLLEGE,CHENNAI

ABSTRACT

Economy, ease and speed of construction are the main factors for using steel as a building material.

In this paper conventional hot rolled steel I-beam sections are considered as the main flexural

member of industrial buildings. The main goal is to increase the load carrying capacity of the beam

with inverted W shape stiffener condition at centre. The initiative was to identify the maximum

load behaviour and deflection of steel beams with stiffener in the web. The performance of such

beams has been considered only for vertical loads. Hot rolled steel beam of ISMB 100 with

stiffener were tested to failure. The beams were simply supported at the ends and subjected to a 2

equal concentrated load applied at one third of span from both ends. The deflection at centre of

beam and various failure patterns are studied. All the beams were analyzed by the finite element

method by using general finite element analysis software ANSYS and the results were compared

with those obtained experimentally. The finite element results for deformation and ultimate

strength shows good agreement with the corresponding values observed in the experiments. At

last, a comparative study was carried out using finite element method to examine that which type

of beam gives best performance during loading. The numerical results indicate that the use of hot

rolled I section with stiffener is an economical and advantageous choice.

33 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

PERFORMANCE OF BACTERIAL CONCRETE USING COPPER SLAG

J.Asanammal Saral1 , S.Prashanth2, M.Rahul3 and M.Yuvaraj4

Assistant professor1,UG student2,3,4

Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala Engineering College

Avadi, Chennai, Tamil Nadu, India.

ABSTRACT

Concrete is the most commonly used building material, the cracks in concrete affects the

durability of the structure. One such thought has leads to the development of a very special

concrete known as “Bacterial Concrete” where bacteria is induced in the mortars and concrete to

self heal the cracks and faults without taking any remedial measures in the future. This technique

is effective because bacteria is pollution free and natural. Copper slag is one of the waste materials

in the production of copper. The use of Copper Slag in concrete provides environmental as well as

economic benefits for all related industries. Here an attempt was made by using the bacteria

“Bacillus Subtilis” of 105 concentration and copper slag as partial replacement of sand and M30

grade of concrete was designed. The strength characteristics of conventional concrete, bacterial

concrete with and without copper slag such as density, compressive strength and split tensile

strength are determined. The performance of bacteria along with the copper slag has been

performed in this paper. The results of this study would lead to a better understanding of bacillus

subtilis bacteria and copper slag which can be used to optimize a concrete mixture based on design

specifications.

Keywords— Bacillus subtilis, Copper slag, compressive strength, spilt tensile strength,

M30grade.

34 | P a g e Organized by Department of Civil Engineering,

Easwari Engineering College, Ramapuram, Chennai 600 089

National Conference on Structural Health Monitoring and Environmental Management (NCSHMEM’18)

27 & 28 March 2018

A STUDY ON PERMEABLE CONCRETE USING GROUND GRANULATED

BLAST FURNACE SLAG (GGBS)

.𝑨 𝑨 𝑨 . 𝑨 𝑷. 𝑨 𝑨 𝑨 . .𝑨 𝑨

𝐴 𝑖 𝑎 𝑃 , 𝐸𝑎 𝑤𝑎 𝑖 𝐸 𝑖 𝑖 𝐶 , 𝑎 𝑎 𝑎 , 𝐶ℎ 𝑎𝑖, 𝑎 𝑖 𝑁𝑎 ,𝐼 𝑖𝑎

, , ,

𝐺 , 𝐸𝑎 𝑤𝑎 𝑖 𝐸 𝑖 𝑖 𝐶 , 𝑎 𝑎 𝑎 , 𝐶ℎ 𝑎𝑖, 𝑎 𝑖 𝑁𝑎 ,𝐼 𝑖𝑎

ABSTRACT

Permeable Concrete (also called porous concrete, no fines concrete and porous pavement)

is a special type of concrete with a high porosity used for concrete flatwork applications that

allows water from precipitation and other sources to pass directly through, thereby reducing

the runoff from a site and allowing groundwater recharge. Permeable concrete is made using large

aggregates with little to no fine aggregates. The concrete paste then coats the aggregates and allows

water to pass through the concrete slab. Permeable concrete is traditionally used in parking areas,

areas with light traffic, residential streets, pedestrian walkways, and greenhouses. It is an

important application for sustainable construction and is one of many low impact

development techniques used by builders to protect water quality. In this paper, Optimum mix