Professional Documents

Culture Documents

CV Safouen BEN CHIKHA Eng 2

Uploaded by

amir0 ratings0% found this document useful (0 votes)

9 views5 pagesOriginal Title

CV Safouen BEN CHIKHA eng 2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views5 pagesCV Safouen BEN CHIKHA Eng 2

Uploaded by

amirCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Safouen BEN CHIKHA

Phone: (+216) 96089833 / 50650232

Email: safouenbenchikha@gmail.com

CIN. N°: 05386349

Address: road of SOKRA Km 4.5, Sfax

Date and place of birth: 29/05/1979 in Sfax

Family status: married

Diplomas and qualifications:

• Superior technician in conception, manufacturing of mold and cutting tools

-2004 – SOUSSE

• ASNT qualification level II in PT

• ASNT qualification level II in MT

• « Electrical habilitation Ht/Bt » certificate, 01 / 2019

• « Fire-fighting » certificate, 06 / 2018

• « First aid » certificate, 06 / 2017

• « Desert Defence Driving » certificate, 03 / 2018

Professional experiences: 2009 – 2021

From 2009 to 2021 -SOCOMENIN:

Surface treatment Responsible (2017-2021):

Definition, implementation and coordination of the production strategy with all

associated services

Arbitration and reallocation of means / resources (human, financial, deadlines,

materials ...) according to results and strategy.

Ensure the application of security measures

Organize, coordinate and ensure operational and technical relations with

subcontracting companies.

Ensure the smooth running of operations (sandblasting, painting, rubber coating, etc.)

following the rules of the art: respect the choice of materials, respect the hygrometric

conditions before any application, take into consideration the manufacturers' technical

sheets, respect the timing, carry out the necessary periodic checks ...

Ensure contractual compliance with the work by applying the relative safety standards.

Reference project:

o 2021: Supervise the rubber lining of 14 sand filters for customer - WABAG

(with Ebonite TIP-TOP).

o 2020: Supervise the rubber lining of 14 sand filters for customer –EPPM (with

Ebonite TIP-TOP).

o 2018: Supervise painting and sandblasting of skids for TDE Client at GTP-Gaz

Treatment Plant-Gabes (with INTERNATIONAL product)

o 2017: Supervise painting and sandblasting of 08 oil storage tanks for customer

- Zawiya Terminal (with INTERNATIONAL product)

Site Responsible 2015, 2017, 2018, 2019:

Management of the site's economic balance

Definition, implementation and coordination of the production strategy with all

associated services.

Organize training and certifications requested by the client (human resource,

equipment, tools, etc.)

Definition and management of the site budget.

Coordination of the various activities and services of the site.

Ensure the application of procedures and standards relating to the work to be

performed: choice of material, qualification of executors, choice of tools and

certifications, periodic verification, ...

Supervise the work to be carried out (welding, assembly, mounting, etc.)

Ensure the application of security measures during the commissioning and hot-

commissioning phase.

Reference project:

o 2019: site responsible / coordinator GTP (Gaz Treatement Plant) -Gabes for

client -ABB / OMV

o 2018: site supervisor / coordinator - GTP (Gaz Treatement Plant) Gabes for

client –TDE / OMV

o 2017: site responsible - Maintenance for 08 tanks at Zawiya oil marketing

company for client -Zawiya Terminal

o 2015: Welding supervisor for customer - GCT-Gafsa (Tunisia chemical Group

)

o 2014: Site supervisor for client - STEG –SOUSSE,

Production responsible (2012/2016):

Guide the planning of daily work

Provide feedback and encouragement to the team to encourage them to do even

better,

Reading of plans (isometric, etc.), manufacturing monitoring, commissioning of the

production process, welding and assembly (piping and structure)

Self-checking (dimensional, material, tools, etc.)

Organize, coordinate and ensure operational and technical relations with

subcontracting companies.

Ensure contractual compliance with the work by applying the relative safety

standards.

Reference project:

o 2016: Responsible for manufacturing 09 LPG gas storage tanks (Gas Bullets /

DRUM INOX) for customer -TDE / OMV

o 2015: Responsible for manufacturing of CS-SS and DUPLEX piping for the

Hannabal gas refinery for client - British Gaz Tunisia

o 2015: Responsible for manufacturing of 12 API650 storage tanks for customer

- PETROFAC Algeria

o 2014: Responsible for manufacturing piping for the Sousse electricity

production station for client - ANSALDO.

o 2013: Responsible for manufacturing piping and guides for the Off-shore

platform according to the requirements of EEMUA 158 Petroleum industry for

client - AQUATERRA.

o 2013: Responsible for manufacturing a batch of API650 storage tanks for the

Tunisian market PETRO-CHEMICAL Industry for client - FURNACE

FABRICA.

o 2012: Responsible for manufacturing piping for the HASDRUBAL gas

refinery for client - British Gaz Tunisia

Quality inspector / Coordinator of non-destructive testing (NDT), (2009/2012):

Coordinate with the customer to ensure the necessary inspections as indicated in the

procedures and (ITP) also the appropriate follow-ups that meet customer

requirements.

Ensure continuous surveillance inspections and record them, example: PT, RT, MT,

UT…

Ensure the necessary staff to carry out the requested controls.

Coordinate with subcontractors and various departments when needed.

Comply with standards and deal with customer complaints and non-conformities,

exp: ASME, EN, ISO, API650,…

Reference project:

o 2012: Inspection of 3 ZECOR stainless steel tanks for customer - ECEC

o 2012: Inspection of wind turbines for customer - GAMESA

o 2011: Inspection of wind turbines for customer - LEITNER

o 2011: Pipe inspection of the Ashtart platform for customer - SEREPT

o 2010: Piping inspection of the dilute and concentrated phosphoric acid

production unit, lot N ° II for customer - MDHILLA

o 2010: Piping inspection of pumping stations for customer - METIS

o 2009: Piping inspection for customer storage tanks - TANKMED

From 2005 to 2009 :

.2008_2009: Forman "AMI": Computer numerically controlled machine tool

programmer.

2007_2008: Quality manager "A G B International": scheduling, following

customer requirements, supervision of quality team.

2006_2007: Team leader MSGI: (manufacturing, follow-up, distribution of the

metallic structure.

2005_2006: Various activities: (training, design...)

Skills:

• Knowledge in inspection and practice of some code and methods in non-

destructive control (UT, PT, MT...)

• Knowledge in construction and maintenance work (steel structure,

mechanical, piping, storage tanks, welding, quality control, Isometric

Reading, ITP, PQR, API 650, API 653, AWS, ASME..)

• Test and verification of different units in gas-in phase, maintenance of

pumps, turbines, compressors…

• Programming and manufacturing on machine to numeric order (Plasma,

center of machining, tower, robo-thread...)

• Management and organization of team.

• HSE: Security measure during the commissioning and gas-in phase

• HSE: Safety measure during electrical work HV/DV

• HSE: Safety measurement during ATEX work

• Knowledge and manipulation of software (Top-Solid, Solid-Works, Peurlid,

Autocad, World, Excel, Lotus, Qualipro...)

Languages :

Spoken Written

French Very Good Very Good

English Good Good

Italien low _

German low low

Some Referance :

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FDR Go (DR-ID800) Operation Guide - M503-E055CDocument32 pagesFDR Go (DR-ID800) Operation Guide - M503-E055CIrvinNo ratings yet

- 2294E2-0000-DA00-SPC-0003 Rev 0 PDFDocument59 pages2294E2-0000-DA00-SPC-0003 Rev 0 PDFamirNo ratings yet

- Horizontal Directional Drilling CalculationDocument60 pagesHorizontal Directional Drilling CalculationMauricio CascellaNo ratings yet

- Standarize Bucekt Repair 390B CATDocument9 pagesStandarize Bucekt Repair 390B CATamirNo ratings yet

- 05 Service Report - TemplateDocument4 pages05 Service Report - TemplateamirNo ratings yet

- Mo 116793Document12 pagesMo 116793amirNo ratings yet

- Pont Roulant 01Document1 pagePont Roulant 01amirNo ratings yet

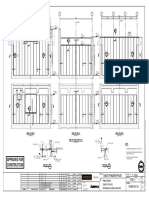

- Approved For Construction: C L CrusherDocument1 pageApproved For Construction: C L CrusheramirNo ratings yet

- 4110 M 111 PDFDocument1 page4110 M 111 PDFamirNo ratings yet

- 4110 C 130 PDFDocument1 page4110 C 130 PDFamirNo ratings yet

- Approved For Construction: D 3 C B A 4 A B C DDocument1 pageApproved For Construction: D 3 C B A 4 A B C DamirNo ratings yet

- 2294E2-0000-DA00-SPC-0002 Rev 0Document14 pages2294E2-0000-DA00-SPC-0002 Rev 0amirNo ratings yet

- Approved For Construction: AusencoDocument1 pageApproved For Construction: AusencoamirNo ratings yet

- Approved For Construction: AusencoDocument1 pageApproved For Construction: AusencoamirNo ratings yet

- Approved For Construction: D A D ADocument1 pageApproved For Construction: D A D AamirNo ratings yet

- Approved For Construction: NotesDocument1 pageApproved For Construction: NotesamirNo ratings yet

- 07-Schedule A - Inspection & Test Plan ITPDocument2 pages07-Schedule A - Inspection & Test Plan ITPamir100% (1)

- Software Project Management - Question BankDocument4 pagesSoftware Project Management - Question BankSanthosh Kumar S50% (4)

- Upgrading Unisab 5655 SB-2827 2008.10 SCRDocument2 pagesUpgrading Unisab 5655 SB-2827 2008.10 SCRandrew.golovanNo ratings yet

- Power SupplyDocument79 pagesPower SupplySharad KumbharanaNo ratings yet

- Latin Square DesignsDocument4 pagesLatin Square Designssabrina saraswatiNo ratings yet

- Pin Diagram of 8086Document11 pagesPin Diagram of 8086VamsiNo ratings yet

- 1306 DNXmid FWupdate enDocument1 page1306 DNXmid FWupdate enxferlaNo ratings yet

- Winning Through InnovationDocument9 pagesWinning Through InnovationAhmet SümerNo ratings yet

- ERS 220 - 2016 Study GuideDocument14 pagesERS 220 - 2016 Study GuideShivaaniNo ratings yet

- Bigfix Mobile: Extending Modern Endpoint Management Capabilities To Ios and Android DevicesDocument3 pagesBigfix Mobile: Extending Modern Endpoint Management Capabilities To Ios and Android Devicessurendra redduNo ratings yet

- Deedy CVDocument2 pagesDeedy CVMohammad HassanNo ratings yet

- Tylr - Smart Robot Vacuum & Mop - TYL-VCB6600 - Giftbox EDITED PDFDocument1 pageTylr - Smart Robot Vacuum & Mop - TYL-VCB6600 - Giftbox EDITED PDFNino Marcos KanapiNo ratings yet

- Chapter 1 Introduction To Emerging TechnologiesDocument39 pagesChapter 1 Introduction To Emerging TechnologiesMiley GirmayNo ratings yet

- Teleprotection Over Packet: Network Migration For UtilitiesDocument25 pagesTeleprotection Over Packet: Network Migration For UtilitiesbaluvelpNo ratings yet

- B760mmortar Wifi MaxwifiDocument438 pagesB760mmortar Wifi Maxwifihwk24031998No ratings yet

- Clevo or Sager Notebook P150SM-A Service ManualDocument132 pagesClevo or Sager Notebook P150SM-A Service Manualdeejjjaaaa100% (1)

- Kristiani Mita Natalia 044657974 Tugas Tutorial 1 Mkwi4201Document4 pagesKristiani Mita Natalia 044657974 Tugas Tutorial 1 Mkwi4201Kristiani Mita NataliaNo ratings yet

- Xlink: Van Lepthien Csci 7818 Fall 2000Document37 pagesXlink: Van Lepthien Csci 7818 Fall 2000Rami MLAYELNo ratings yet

- 1-What Is Integration Using Dynamics 365: Why Integrate With Microsoft Dynamics 365Document3 pages1-What Is Integration Using Dynamics 365: Why Integrate With Microsoft Dynamics 365Uk bhardwajNo ratings yet

- (Ebook PDF) Applied Numerical Methods With Matlab For Engineers and Scientists 4Th EditionDocument42 pages(Ebook PDF) Applied Numerical Methods With Matlab For Engineers and Scientists 4Th Editionjose.exley440100% (45)

- 05 - SkyEdge II - Inbound Data-Link (RCS) - v6.0Document40 pages05 - SkyEdge II - Inbound Data-Link (RCS) - v6.0MarcoNo ratings yet

- Asst Programmer QuestionDocument7 pagesAsst Programmer Questionsajid_391No ratings yet

- Document 15Document17 pagesDocument 15mallapishyamreddyNo ratings yet

- Magelis Easy Gxu Hmigxu5512Document6 pagesMagelis Easy Gxu Hmigxu5512fadlilla noor rahmawatiNo ratings yet

- Data Engineer - Roadmap and FREE Resources - Paper 2021Document7 pagesData Engineer - Roadmap and FREE Resources - Paper 2021svdNo ratings yet

- Experience: A Guide For Marketers and DesignersDocument72 pagesExperience: A Guide For Marketers and DesignersHeinz JanyNo ratings yet

- Identify Microsoft Power Platform Components: 5. Determine The Required Power Apps App TypeDocument61 pagesIdentify Microsoft Power Platform Components: 5. Determine The Required Power Apps App TypeOgochukwu BenyeogorNo ratings yet

- HP 280 Pro G5 - I5Document2 pagesHP 280 Pro G5 - I5kishorsriramNo ratings yet

- 3.6: General Hypothesis TestsDocument6 pages3.6: General Hypothesis Testssound05No ratings yet