Professional Documents

Culture Documents

Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion Protection

Uploaded by

Hendra Awan0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

PDS_NA_WB

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion Protection

Uploaded by

Hendra AwanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

WrapidBond®

A visco-elastic adhesive based system

for pipeline corrosion protection

WrapidBond® is a wraparound corrosion protective coating

consisting of a modified and reinforced visco-elastic adhesive

applied onto a polyethylene carrier film. Supplied in roll form,

WrapidBond® provides effective corrosion protection by providing a

barrier to water and oxygen. WrapidBond® is for use on aboveground

and underground pipelines, and steel structures.

Adhesion & Creep Resistance

Applications

• Specially formulated adhesive bonds to even the most difficult

substrates and provides good elevated temperature creep

resistance and resistance to soil stresses. Oil & Gas

• Improved soil stress resistance is achieved with the installation of

WrapidCoat® PVC or PE outer wrap.

Repair & Rehab

Wide Range of Applications

• Diverse range of applications including: coating repair on new

pipeline construction; transition areas from above to below ground Corrosion Coating

pipelines; special sections such as bends, tees, flanges, etc.; reha-

bilitation of existing pipelines; tanks chimes, etc.

Full System Approach Girth-Weld Joints

• Includes ultra flexible products, filler materials, weld bead and

seam tapes, and WrapidCoat® PVC or PE mechanical

protection. Refer to the WrapidCoat® PVC or PE product data Fittings & Bends

sheet for more information.

Field Friendly

Water Pipelines

• Long shelf-life, with various widths available with convenient roll

lengths for ease of inventory

• Fast installation with excellent adhesion to steel and other

er base

surfaces without applying primer

• No drying or hardening time

• Plastic-elastic properties allow self healing ability if damaged

aged

PRODUCT DATA SHEET canusacps.com

The product information

® shown here is intended as a guide

WrapidBond for standard products.

Consult your Canusa

A visco-elastic adhesive based system for pipeline representative for specific

projects or unique applications.

corrosion protection

Sleeve Operating Characteristics Test Method Typical Value

Maximum Pipeline Operating Temp. Up to 80°C (175°F)

Resistance to Circumferential Forces Very Good

Resistance to Soil Stress Very Good

Resistance to Axial Pipe Movement Very Good

Main Line Coating Compatibility PE, PP, FBE, PU, Coal tar, Bitumen

Typical Product Properties

Thickness Measured > 1.8 mm

Density ASTM D792 1.1 - 1.3 g/cm3 Canusa-CPS

A division of Shawcor Ltd.

Impact Resistance* EN 12068 15 J

Head Office

Indentation Resistance* EN 12068 0.60 mm remaining (pass) 25 Bethridge Road

Toronto, ON, Canada M9W 1M7

Peel Strength* EN 12068 > 0.5 N/mm Cohesive failure Tel: +1 416 743 7111

Fax: +1 416 743 5927

Lap Shear Strength EN 12068 0.02 N/mm² Canada

Dome Tower St. 2200, 333-7th Avenue SW

Glass Transition Temp. ASTM D3418 < -20°C Calgary, AB, Canada T2P 2Z1

Tel: +1 403 218 8207

Cathodic Disbondment Resistance* ASTM G8/EN 12068 2 mm @ 23°C Fax: +1 403 264 3649

Cathodic Disbondment Resistance* ASTM G42/ EN 12068 1 mm @ 60°C Americas

5875 N. Sam Houston Pkwy W., Suite 200

Electrical Resistance* EN 12068 > 1015 ohm/cm Houston, TX, USA 77086

Tel: +1 281 886 2350

Unwinding Test @ -30°C EN 12068 No separation, tears or cracks Fax: +1 281 886 2353

Middle East

Low Temp. Flexibility @ -30°C EN 12068 No separation, tears or cracks ADPC - Mussafah Port, P.O. Box 2621

Abu Dhabi, UAE

Water Absorption ASTM D570 < 0.05% Tel: +971 2 496 3500

Fax: +971 2 496 3501

Drip Resistance EN 12068 Pass at 90°C

Europe, Africa & Russia

* When used with WrapidCoat® PVC or PE. Refer to the WrapidCoat® PVC or PE data sheet for more information. Dellaertweg 9-E, Gebouw “Le Carrefour”

2316 WZ Leiden, The Netherlands (NL)

Tel: +31 71 80 802 70

Fax: +31 71 80 802 71

Asia-Pacific

101 Thomson Road, #11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Fax: +65 6749 8919

Quality Management system

registered to ISO 9001

Canusa warrants that the product conforms to its

chemical and physical description and is appropriate

for the use stated on the product data sheet when

used in compliance with Canusa’s written instructions.

Since many installation factors are beyond our control,

the user shall determine the suitability of the products

for the intended use and assume all risks and liabilities

in connection therewith. Canusa’s liability is stated

in the standard terms and conditions of sale. Canusa

makes no other warranty either expressed or implied.

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings All information contained in this data sheet is to be

used as a guide and is subject to change without

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high notice. This data sheet supersedes all previous data

sheets on this product. E&OE

performance products are manufactured to the highest quality standards and are available in a number

of configurations to accommodate many specific project applications. PDS_Wrapid Bond_rev024

You might also like

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 pagesWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanNo ratings yet

- Canusa GTS 80Document2 pagesCanusa GTS 80ZainudinNo ratings yet

- Wrapidtape: Primerless Crosslinked Protective TapeDocument2 pagesWrapidtape: Primerless Crosslinked Protective TapeHendra AwanNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectioncocoaNo ratings yet

- CANUSA Wrapid TapeDocument2 pagesCANUSA Wrapid TapeHalimNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionsenthilkumarNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanNo ratings yet

- Pds Na Gts65Document2 pagesPds Na Gts65Yan FerizalNo ratings yet

- Wrapidbond™ FST: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 pagesWrapidbond™ FST: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDinesh PillaiNo ratings yet

- Parche CRP 65 - Ficha Técnica - en InglesDocument2 pagesParche CRP 65 - Ficha Técnica - en IngleserwinvillarNo ratings yet

- PDS - NA - PRP Repair Data SheetDocument2 pagesPDS - NA - PRP Repair Data SheetHendra AwanNo ratings yet

- PDS - Na - Klon-KlnnDocument2 pagesPDS - Na - Klon-Klnndemi bajakanNo ratings yet

- Manta Canusa - GTS65 - en InglesDocument2 pagesManta Canusa - GTS65 - en IngleserwinvillarNo ratings yet

- Superseal: Heat Shrinkable Sleeve For Protection of Pre-Insulated Pipe JointsDocument2 pagesSuperseal: Heat Shrinkable Sleeve For Protection of Pre-Insulated Pipe JointsPer Bagus HandokoNo ratings yet

- Scar Guard EnglishDocument2 pagesScar Guard EnglishVismael SantosNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetAgustina De Winne100% (1)

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- GRE 5N10-B Pipe-Fitting-Spec PN10 RTRP12ED - Liner 0.5-R1mmDocument8 pagesGRE 5N10-B Pipe-Fitting-Spec PN10 RTRP12ED - Liner 0.5-R1mmPoom PPWNo ratings yet

- Wrapid BondDocument2 pagesWrapid BondgrtunaNo ratings yet

- CCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0Document4 pagesCCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0amanraza.canNo ratings yet

- Mariseal 400 Aqua Version18Document2 pagesMariseal 400 Aqua Version18Chetal BholeNo ratings yet

- Wrapid Tape™: Product DescriptionDocument2 pagesWrapid Tape™: Product DescriptionCristobal Leal Aranda100% (1)

- Densolen - System AS39P / R20HT: Product InformationDocument2 pagesDensolen - System AS39P / R20HT: Product InformationCarlos PazNo ratings yet

- DS 40 Full SubmittalDocument50 pagesDS 40 Full Submittalahmed100% (1)

- Sikaproof 808Document4 pagesSikaproof 808happyNo ratings yet

- Canusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSDocument2 pagesCanusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSozcanNo ratings yet

- FR Gboard Tds21Document1 pageFR Gboard Tds21rangarajan1989100% (1)

- Waterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetDocument3 pagesWaterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetCC Cost AdvisoryNo ratings yet

- PipeWrap CTDocument2 pagesPipeWrap CTVineet KhanduriNo ratings yet

- Coating Joint - Canusa Wrapid TapDocument2 pagesCoating Joint - Canusa Wrapid TapDani HartantoNo ratings yet

- Pds Tial m80Document2 pagesPds Tial m80Yan FerizalNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- Pds Covalence Htlp80 v3 Dec16 Aarps 0199Document2 pagesPds Covalence Htlp80 v3 Dec16 Aarps 0199Benaknaik S GajannavarNo ratings yet

- Laticrete Hydroban Tds NFDocument6 pagesLaticrete Hydroban Tds NFAbdul Raheem SyedNo ratings yet

- Ficha Tecnica Cinta de Juntas 930 35 50 PDFDocument3 pagesFicha Tecnica Cinta de Juntas 930 35 50 PDFfernando100% (1)

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazNo ratings yet

- Thumb 20180521C775Document2 pagesThumb 20180521C775Alle LunagNo ratings yet

- HSS Canusa PDFDocument2 pagesHSS Canusa PDFresp-ectNo ratings yet

- Torch SealDocument2 pagesTorch Sealmk779900mkNo ratings yet

- CSDS Stopaq FAST GRE V3Document2 pagesCSDS Stopaq FAST GRE V3AndyNo ratings yet

- TDS FlexiClad 70Document2 pagesTDS FlexiClad 70DuongNo ratings yet

- TDS 104 Spanish RedGardDocument6 pagesTDS 104 Spanish RedGardgrisselNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- Yellow Jacket ProtectionDocument2 pagesYellow Jacket ProtectionMarcio NegraoNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- Sika® Carbodur® S: Product Data SheetDocument4 pagesSika® Carbodur® S: Product Data SheetMohammed FarhanNo ratings yet

- Densoplast - Tape: Product InformationDocument2 pagesDensoplast - Tape: Product InformationAnant RubadeNo ratings yet

- Fosroc Nitoproof WB PrimerDocument3 pagesFosroc Nitoproof WB PrimermailingreenlifeNo ratings yet

- Poly FlameDocument2 pagesPoly Flamemk779900mkNo ratings yet

- PDS Polyken 980 955 V3 Jan19 Aarps 0285Document2 pagesPDS Polyken 980 955 V3 Jan19 Aarps 0285Irawan FajarNo ratings yet

- Raychem MWTM Medium Wall PDFDocument4 pagesRaychem MWTM Medium Wall PDFLeo TopacioNo ratings yet

- Imperseal 7000Xl: Salient FeaturesDocument2 pagesImperseal 7000Xl: Salient FeaturesJeff GajeNo ratings yet

- MetazealDocument3 pagesMetazealhernie vergel de diosNo ratings yet

- Custom Fiberglass Products - Pas-Gon - Israel ExporterDocument2 pagesCustom Fiberglass Products - Pas-Gon - Israel ExporterIsrael ExporterNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- GRI-GM30: Weld Easier. Install Faster. Contain BetterDocument2 pagesGRI-GM30: Weld Easier. Install Faster. Contain BetterAndreas Erdian WijayaNo ratings yet

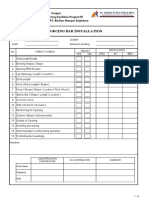

- Bar InstallationDocument1 pageBar InstallationHendra AwanNo ratings yet

- Preheat and PWHT Procedure: GlobalDocument12 pagesPreheat and PWHT Procedure: GlobalHendra AwanNo ratings yet

- Fine-Scale Precipitation and Mechanical Properties of Thin Slab Processed Titanium-Niobium Bearing High Strength SteelsDocument9 pagesFine-Scale Precipitation and Mechanical Properties of Thin Slab Processed Titanium-Niobium Bearing High Strength SteelsHendra AwanNo ratings yet

- Timor-1 CFSPP Project Supporting DokumenDocument2 pagesTimor-1 CFSPP Project Supporting DokumenHendra AwanNo ratings yet

- Traksi: Pengaruh Post Weld Heat Treatment (PWHT) Terhadap Struktur Mikro Dan Kekerasan Sambungan Las Stainless SteelDocument9 pagesTraksi: Pengaruh Post Weld Heat Treatment (PWHT) Terhadap Struktur Mikro Dan Kekerasan Sambungan Las Stainless SteelHendra AwanNo ratings yet

- Post Weld Heat Treatment Procedure PWHTDocument12 pagesPost Weld Heat Treatment Procedure PWHTchiragNo ratings yet

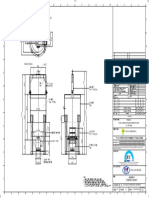

- Coal Fired Steam Power Plant Timor-1 (2 X 50 MW) : Reference DrawingDocument1 pageCoal Fired Steam Power Plant Timor-1 (2 X 50 MW) : Reference DrawingHendra AwanNo ratings yet

- Interprime 198: AlkydDocument4 pagesInterprime 198: AlkydHendra AwanNo ratings yet

- General Remark:: Concrete BucketDocument1 pageGeneral Remark:: Concrete BucketHendra AwanNo ratings yet

- Timor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Document2 pagesTimor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Hendra AwanNo ratings yet

- Material Receiving Report: 1 Inch X 6M 60mm X 500Document3 pagesMaterial Receiving Report: 1 Inch X 6M 60mm X 500Hendra AwanNo ratings yet

- Timor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Document2 pagesTimor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Hendra AwanNo ratings yet

- Timor-1 CFSPP Project Supporting Dokumen: Doc No.: 004.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Document2 pagesTimor-1 CFSPP Project Supporting Dokumen: Doc No.: 004.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Hendra AwanNo ratings yet

- Interterm 715 GreenDocument13 pagesInterterm 715 GreenHendra AwanNo ratings yet

- Covalence Dirax PP: Product Data SheetDocument2 pagesCovalence Dirax PP: Product Data SheetHendra AwanNo ratings yet

- PolykenDocument7 pagesPolykenJanllo83No ratings yet

- PDS - NA - PRP Repair Data SheetDocument2 pagesPDS - NA - PRP Repair Data SheetHendra AwanNo ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- Polyken 955Document2 pagesPolyken 955raditia2205No ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- Polyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerDocument2 pagesPolyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerHendra AwanNo ratings yet

- PolykenDocument7 pagesPolykenJanllo83No ratings yet

- Polyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerDocument2 pagesPolyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerHendra AwanNo ratings yet

- Polyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerDocument2 pagesPolyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerHendra AwanNo ratings yet

- Wrapidcoat Pe: Superior Mechanical ProtectionDocument2 pagesWrapidcoat Pe: Superior Mechanical ProtectionHendra AwanNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanNo ratings yet

- RAL Color ShadesDocument5 pagesRAL Color ShadesMahesh2101No ratings yet

- West Tower Condominium vs. FPICDocument24 pagesWest Tower Condominium vs. FPICDennis VelasquezNo ratings yet

- SIMOPSDocument11 pagesSIMOPSmanoj_sitec100% (1)

- Reading - Towill & Christopher Developing Market Specific Supply Chain StrategiesDocument29 pagesReading - Towill & Christopher Developing Market Specific Supply Chain StrategiesSasha KingNo ratings yet

- CHM - 10 Tankcleaning CowDocument9 pagesCHM - 10 Tankcleaning Cowsushant shelarNo ratings yet

- 12 Procedure For Coating Wrapping Rev 01Document6 pages12 Procedure For Coating Wrapping Rev 01dnbinh100% (2)

- Ammonia Plant Cryogenic TanksDocument18 pagesAmmonia Plant Cryogenic TankslilianurNo ratings yet

- Crude Sampling Device IOM-135Document15 pagesCrude Sampling Device IOM-135Stephen MalobaNo ratings yet

- GRE Pipe Testing MethodDocument3 pagesGRE Pipe Testing MethodVanaa MohanNo ratings yet

- Water InjectionDocument11 pagesWater Injectionrogelio legorretaNo ratings yet

- FLOWTITE Case Studies - Water Applications - enDocument36 pagesFLOWTITE Case Studies - Water Applications - enMigain RayanNo ratings yet

- Mi-101en Id147Document48 pagesMi-101en Id147Christian MendozaNo ratings yet

- Tonisco Service Eng 2015 MailDocument12 pagesTonisco Service Eng 2015 MailbederinadmlNo ratings yet

- The Cervic Corrosion in Storage TankDocument7 pagesThe Cervic Corrosion in Storage TankAmer KhanNo ratings yet

- 220802DBRQME208-Fabrication and Installation Procedure For Piping and Structure Rev - 02Document25 pages220802DBRQME208-Fabrication and Installation Procedure For Piping and Structure Rev - 02nimrod napituNo ratings yet

- Latihan Inisiasi 8 B.ingDocument2 pagesLatihan Inisiasi 8 B.ingMeisye NovitasariNo ratings yet

- Terminal Operator Job Description: Essential Duties and ResponsibilitiesDocument3 pagesTerminal Operator Job Description: Essential Duties and ResponsibilitiesseguntaiwoNo ratings yet

- Bondstrand®, Centron®, Dualoy® and Bondstrand® SSLDocument312 pagesBondstrand®, Centron®, Dualoy® and Bondstrand® SSLallouche_abdNo ratings yet

- Company Profile-ILF-NGR.Document65 pagesCompany Profile-ILF-NGR.Ayodele JamesNo ratings yet

- The Main Installations: 1. Degassing StationsDocument4 pagesThe Main Installations: 1. Degassing Stationsعمار ياسرNo ratings yet

- 402-91-EL-LIS-00003 Rev B - SignedDocument14 pages402-91-EL-LIS-00003 Rev B - SignedKrishnan KrishNo ratings yet

- Pipeline Valve Spacing - Comparison of CodesDocument10 pagesPipeline Valve Spacing - Comparison of CodesspottedkelpieNo ratings yet

- Safety Instrumentation Oisd STD 152Document55 pagesSafety Instrumentation Oisd STD 152Deny Arief Rusamsi100% (2)

- Air TestDocument2 pagesAir TestAli HaiderNo ratings yet

- Tenaris OverviewDocument19 pagesTenaris OverviewAnonymous evKjt4OeENo ratings yet

- Abbas - Bilgrami CNG Transportation Trans CanadaDocument48 pagesAbbas - Bilgrami CNG Transportation Trans CanadaMustafa100% (1)

- Corrosion Brochure 2022Document12 pagesCorrosion Brochure 2022Shiraz AlamNo ratings yet

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFDocument612 pagesGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahNo ratings yet

- KM Service ManualDocument15 pagesKM Service ManuallucaemigranteNo ratings yet

- WorldPipelines August 2015Document182 pagesWorldPipelines August 2015Integridad de Equipos y Gestión de Activos Nelcam100% (3)

- Product Specifications: Section 2Document6 pagesProduct Specifications: Section 2sebas guzNo ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet