Professional Documents

Culture Documents

Ferrites and Accessories: E 19/8/5 Core

Uploaded by

Yani SetiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ferrites and Accessories: E 19/8/5 Core

Uploaded by

Yani SetiaCopyright:

Available Formats

Ferrites and accessories

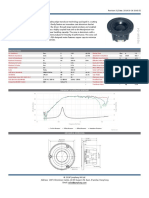

E 19/8/5

Core

Series/Type: B66379

Date: May 2017

EPCOS AG 2017. Reproduction, publication and dissemination of this publication, enclosures hereto and the

information contained therein without EPCOS’ prior express consent is prohibited.

EPCOS AG is a TDK Group Company.

E 19/8/5

Core B66379

■ Size based on US lam. size E cores

US designation E 187

■ E cores with high permeability

for common-mode chokes and

broadband applications

■ Delivery mode: single units

Magnetic characteristics (per set)

Σl/A = 1.76 mm–1

le = 39.6 mm

Ae = 22.5 mm2

Amin = 22.1 mm2

Ve = 891 mm3

Approx. weight 4.4 g/set

Ungapped

Material AL value μe PV Ordering code

nH W/set

N30 1700 +30/–20% 2380 B66379G0000X130

T46 5800 ±30% 8120 B66379F0000X146

N27 1050 +30/–20% 1470 < 0.18 (200 mT, 25 kHz, 100 °C) B66379G0000X127

N87 1150 +30/–20% 1610 < 0.50 (200 mT, 100 kHz, 100 °C) B66379G0000X187

Other AL values/air gaps and materials available on request ─ see Processing remarks on page 3.

Calculation factors (for formulas, see “E cores: general information”)

Material Relationship between Calculation of saturation current

air gap – AL value

K1 (25 °C) K2 (25 °C) K3 (25 °C) K4 (25 °C) K3 (100 °C) K4 (100 °C)

N27 46.4 –0.697 63.3 –0.847 57.9 –0.865

N87 46.4 –0.697 64.1 –0.796 56.1 –0.873

Validity range: K1, K2: 0.10 mm < s < 2.00 mm

K3, K4: 40 nH < AL < 350 nH

Please read Cautions and warnings and

Important notes at the end of this document. 2 5/17

Ferrites and accessories

Cautions and warnings

Cautions and warnings

Mechanical stress and mounting

Ferrite cores have to meet mechanical requirements during assembling and for a growing number

of applications. Since ferrites are ceramic materials one has to be aware of the special behavior

under mechanical load.

As valid for any ceramic material, ferrite cores are brittle and sensitive to any shock, fast tempera-

ture changing or tensile load. Especially high cooling rates under ultrasonic cleaning and high static

or cyclic loads can cause cracks or failure of the ferrite cores.

For detailed information see data book, chapter “General - Definitions, 8.1”.

Effects of core combination on AL value

Stresses in the core affect not only the mechanical but also the magnetic properties. It is apparent

that the initial permeability is dependent on the stress state of the core. The higher the stresses are

in the core, the lower is the value for the initial permeability. Thus the embedding medium should

have the greatest possible elasticity.

For detailed information see data book, chapter “General - Definitions, 8.1”.

Heating up

Ferrites can run hot during operation at higher flux densities and higher frequencies.

NiZn-materials

The magnetic properties of NiZn-materials can change irreversible in high magnetic fields.

Ferrite Accessories

EPCOS ferrite accessories have been designed and evaluated only in combination with EPCOS

ferrite cores. EPCOS explicitly points out that EPCOS ferrite accessories or EPCOS ferrite cores

may not be compatible with those of other manufacturers. Any such combination requires prior te-

sting by the customer and will be at the customer‘s own risk.

EPCOS assumes no warranty or reliability for the combination of EPCOS ferrite accessories with

cores and other accessories from any other manufacturer.

Processing remarks

The start of the winding process should be soft. Else the flanges may be destroyed.

– Too strong winding forces may blast the flanges or squeeze the tube that the cores can not be

mounted any more.

– Too long soldering time at high temperature (>300 °C) may effect coplanarity or pin arrange-

ment.

– Not following the processing notes for soldering of the J-leg terminals may cause solderability

problems at the transformer because of pollution with Sn oxyde of the tin bath or burned insula-

tion of the wire. For detailed information see chapter “Processing notes”, section 2.2.

– The dimensions of the hole arrangement have fixed values and should be understood as

a recommendation for drilling the printed circuit board. For dimensioning the pins, the group

of holes can only be seen under certain conditions, as they fit into the given hole arrangement.

To avoid problems when mounting the transformer, the manufacturing tolerances for positioning

the customers’ drilling process must be considered by increasing the hole diameter.

Please read Cautions and warnings and

Important notes at the end of this document. 3 5/17

Ferrites and accessories

Cautions and warnings

Display of ordering codes for EPCOS products

The ordering code for one and the same product can be represented differently in data sheets,

data books, other publications and the website of EPCOS, or in order-related documents such as

shipping notes, order confirmations and product labels. The varying representations of the

ordering codes are due to different processes employed and do not affect the

specifications of the respective products. Detailed information can be found on the Internet

under www.epcos.com/orderingcodes.

Please read Cautions and warnings and

Important notes at the end of this document. 4 5/17

Ferrites and accessories

Symbols and terms

Symbols and terms

Symbol Meaning Unit

A Cross section of coil mm2

Ae Effective magnetic cross section mm2

AL Inductance factor; AL = L/N2 nH

AL1 Minimum inductance at defined high saturation ( μa) nH

Amin Minimum core cross section mm2

AN Winding cross section mm2

AR Resistance factor; AR = RCu /N2 μΩ = 10–6 Ω

B RMS value of magnetic flux density Vs/m2, mT

ΔB Flux density deviation Vs/m2, mT

B̂ Peak value of magnetic flux density Vs/m2, mT

ΔB̂ Peak value of flux density deviation Vs/m2, mT

BDC DC magnetic flux density Vs/m2, mT

BR Remanent flux density Vs/m2, mT

BS Saturation magnetization Vs/m2, mT

C0 Winding capacitance F = As/ V

CDF Core distortion factor mm–4.5

DF Relative disaccommodation coefficient DF = d/μi

d Disaccommodation coefficient

Ea Activation energy J

f Frequency s–1, Hz

fcutoff Cut-off frequency s–1, Hz

fmax Upper frequency limit s–1, Hz

fmin Lower frequency limit s–1, Hz

fr Resonance frequency s–1, Hz

fCu Copper filling factor

g Air gap mm

H RMS value of magnetic field strength A/m

Ĥ Peak value of magnetic field strength A/m

HDC DC field strength A/m

Hc Coercive field strength A/m

h Hysteresis coefficient of material 10–6 cm/A

h/μi 2 Relative hysteresis coefficient 10–6 cm/A

I RMS value of current A

IDC Direct current A

Î Peak value of current A

J Polarization Vs/m2

k Boltzmann constant J/K

k3 Third harmonic distortion

k3c Circuit third harmonic distortion

L Inductance H = Vs/A

Please read Cautions and warnings and

Important notes at the end of this document. 5 5/17

Ferrites and accessories

Symbols and terms

Symbol Meaning Unit

ΔL/L Relative inductance change H

L0 Inductance of coil without core H

LH Main inductance H

Lp Parallel inductance H

Lrev Reversible inductance H

Ls Series inductance H

le Effective magnetic path length mm

lN Average length of turn mm

N Number of turns

PCu Copper (winding) losses W

Ptrans Transferrable power W

PV Relative core losses mW/g

PF Performance factor

Q Quality factor (Q = ωL/Rs = 1/tan δL)

R Resistance Ω

RCu Copper (winding) resistance (f = 0) Ω

Rh Hysteresis loss resistance of a core Ω

ΔRh Rh change Ω

Ri Internal resistance Ω

Rp Parallel loss resistance of a core Ω

Rs Series loss resistance of a core Ω

Rth Thermal resistance K/W

RV Effective loss resistance of a core Ω

s Total air gap mm

T Temperature °C

ΔT Temperature difference K

TC Curie temperature °C

t Time s

tv Pulse duty factor

tan δ Loss factor

tan δL Loss factor of coil

tan δr (Residual) loss factor at H → 0

tan δe Relative loss factor

tan δh Hysteresis loss factor

tan δ/μi Relative loss factor of material at H → 0

U RMS value of voltage V

Û Peak value of voltage V

Ve Effective magnetic volume mm3

Z Complex impedance Ω

Zn Normalized impedance |Z|n = |Z| /N 2 × ε (le /Ae) Ω/mm

Please read Cautions and warnings and

Important notes at the end of this document. 6 5/17

Ferrites and accessories

Symbols and terms

Symbol Meaning Unit

α Temperature coefficient (TK) 1/K

αF Relative temperature coefficient of material 1/K

αe Temperature coefficient of effective permeability 1/K

εr Relative permittivity

Φ Magnetic flux Vs

η Efficiency of a transformer

ηB Hysteresis material constant mT-1

ηi Hysteresis core constant A–1H–1/2

λs Magnetostriction at saturation magnetization

μ Relative complex permeability

μ0 Magnetic field constant Vs/Am

μa Relative amplitude permeability

μapp Relative apparent permeability

μe Relative effective permeability

μi Relative initial permeability

μ p' Relative real (inductive) component of μ (for parallel components)

μ p" Relative imaginary (loss) component of μ (for parallel components)

μr Relative permeability

μrev Relative reversible permeability

μs' Relative real (inductive) component of μ (for series components)

μs" Relative imaginary (loss) component of μ (for series components)

μtot Relative total permeability

derived from the static magnetization curve

ρ Resistivity Ωm–1

Σl/A Magnetic form factor mm–1

τCu DC time constant τCu = L/RCu = AL/AR s

ω Angular frequency; ω = 2 Πf s–1

All dimensions are given in mm.

Surface-mount device

Please read Cautions and warnings and

Important notes at the end of this document. 7 5/17

Important notes

The following applies to all products named in this publication:

1. Some parts of this publication contain statements about the suitability of our products for certain areas

of application. These statements are based on our knowledge of typical requirements that are often placed

on our products in the areas of application concerned. We nevertheless expressly point out that such

statements cannot be regarded as binding statements about the suitability of our products for a

particular customer application. As a rule we are either unfamiliar with individual customer applications or

less familiar with them than the customers themselves. For these reasons, it is always ultimately incumbent

on the customer to check and decide whether a product with the properties described in the product

specification is suitable for use in a particular customer application.

2. We also point out that in individual cases, a malfunction of electronic components or failure before

the end of their usual service life cannot be completely ruled out in the current state of the art, even

if they are operated as specified. In customer applications requiring a very high level of operational safety

and especially in customer applications in which the malfunction or failure of an electronic component could

endanger human life or health (e.g. in accident prevention or life-saving systems), it must therefore be

ensured by means of suitable design of the customer application or other action taken by the customer (e.g.

installation of protective circuitry or redundancy) that no injury or damage is sustained by third parties in the

event of malfunction or failure of an electronic component.

3. The warnings, cautions and product-specific notes must be observed.

4. In order to satisfy certain technical requirements, some of the products described in this publication

may contain substances subject to restrictions in certain jurisdictions (e.g. because they are

classed as hazardous). Useful information on this will be found in our Material Data Sheets on the Internet

(www.tdk-electronics.tdk.com/material). Should you have any more detailed questions, please contact our

sales offices.

5. We constantly strive to improve our products. Consequently, the products described in this publication

may change from time to time. The same is true of the corresponding product specifications. Please

check therefore to what extent product descriptions and specifications contained in this publication are still

applicable before or when you place an order.

We also reserve the right to discontinue production and delivery of products. Consequently, we

cannot guarantee that all products named in this publication will always be available. The aforementioned

does not apply in the case of individual agreements deviating from the foregoing for customer-specific

products.

6. Unless otherwise agreed in individual contracts, all orders are subject to our General Terms and

Conditions of Supply.

7. Our manufacturing sites serving the automotive business apply the IATF 16949 standard. The IATF

certifications confirm our compliance with requirements regarding the quality management system in the

automotive industry. Referring to customer requirements and customer specific requirements (“CSR”) TDK

always has and will continue to have the policy of respecting individual agreements. Even if IATF 16949

may appear to support the acceptance of unilateral requirements, we hereby like to emphasize that only

requirements mutually agreed upon can and will be implemented in our Quality Management

System. For clarification purposes we like to point out that obligations from IATF 16949 shall only become

legally binding if individually agreed upon.

8. The trade names EPCOS, CeraCharge, CeraDiode, CeraLink, CeraPad, CeraPlas, CSMP, CTVS,

DeltaCap, DigiSiMic, ExoCore, FilterCap, FormFit, LeaXield, MiniBlue, MiniCell, MKD, MKK, MotorCap,

PCC, PhaseCap, PhaseCube, PhaseMod, PhiCap, PowerHap, PQSine, PQvar, SIFERRIT, SIFI, SIKOREL,

SilverCap, SIMDAD, SiMic, SIMID, SineFormer, SIOV, ThermoFuse, WindCap are trademarks registered

or pending in Europe and in other countries. Further information will be found on the Internet at www.tdk-

electronics.tdk.com/trademarks.

Release 2018-10

Please read Cautions and warnings and

Important notes at the end of this document. 8 5/17

You might also like

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- Ferrites and Accessories: E 40/16/12 CoreDocument8 pagesFerrites and Accessories: E 40/16/12 CoreDenemeNo ratings yet

- Ferrites and Accessories: E 34/14/9 CoreDocument9 pagesFerrites and Accessories: E 34/14/9 Corerajareddy235No ratings yet

- PQ - 50 - 50 DatasheetDocument9 pagesPQ - 50 - 50 DatasheetwootaudioNo ratings yet

- Inverter CoreDocument8 pagesInverter CoreAdityaJayakarNo ratings yet

- Ferrite Cores Magnetic and Physical PropertiesDocument9 pagesFerrite Cores Magnetic and Physical PropertiesBigHead Rider100% (1)

- Ferrites and Accessories: Toroids (Ring Cores) R 36.0 23.0 15.0Document9 pagesFerrites and Accessories: Toroids (Ring Cores) R 36.0 23.0 15.0CarlosNo ratings yet

- Datasheet - Anello Di FerriteDocument7 pagesDatasheet - Anello Di FerriteStefano Di GennaroNo ratings yet

- Ferrites and Accessories: Data Sheet Data SheetDocument7 pagesFerrites and Accessories: Data Sheet Data SheetstanculescuamNo ratings yet

- Ferrites and Accessories: Data Sheet Data SheetDocument7 pagesFerrites and Accessories: Data Sheet Data Sheetалексей ЛфNo ratings yet

- Ferrites and Accessories: Data Sheet Data SheetDocument7 pagesFerrites and Accessories: Data Sheet Data SheetManuel GuiracochaNo ratings yet

- Toroide Ferrita N87Document7 pagesToroide Ferrita N87Duna OlivesNo ratings yet

- TDK N87Document11 pagesTDK N87dword2addNo ratings yet

- Symbols and TermsDocument5 pagesSymbols and Termsسليم درباشيNo ratings yet

- Ferrites and AccessoriesDocument10 pagesFerrites and AccessoriesfacastrofNo ratings yet

- Epcos ETD59Document9 pagesEpcos ETD59Ka LaciNo ratings yet

- Etd 59 31 22 PDFDocument10 pagesEtd 59 31 22 PDFJosé GonzálezNo ratings yet

- Epcos China (TDK) ER - 35!20!11Document7 pagesEpcos China (TDK) ER - 35!20!11leoNo ratings yet

- 75.eddy Current Loss CalculationDocument9 pages75.eddy Current Loss CalculationVenkateswaran venkateswaranNo ratings yet

- Magnetic Hysteresis and Ferromagnetic MaterialsDocument67 pagesMagnetic Hysteresis and Ferromagnetic MaterialsafwdNo ratings yet

- Useful Design Parameters (Simplified)Document2 pagesUseful Design Parameters (Simplified)Pay RentNo ratings yet

- High Efficiency Solid State Amplifiers - 1Document44 pagesHigh Efficiency Solid State Amplifiers - 1wingchaoNo ratings yet

- Fire Cable 2X18 C/P LSZHDocument1 pageFire Cable 2X18 C/P LSZHClaudio PalominosNo ratings yet

- Ferrites and AccessoriesDocument11 pagesFerrites and AccessoriesMaulik ShahNo ratings yet

- Principle of Electrostatic Chuck PDFDocument7 pagesPrinciple of Electrostatic Chuck PDFkamaveriyan100% (1)

- PDFDocument5 pagesPDFAhmedNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- Cable Incendio 2X18 Awg S/P: UL1424FPLRDocument1 pageCable Incendio 2X18 Awg S/P: UL1424FPLR04143510504gallucciNo ratings yet

- PCB Material Selection For RF Microwave and Millimeter Wave Designs 1Document61 pagesPCB Material Selection For RF Microwave and Millimeter Wave Designs 1Umair IllahiNo ratings yet

- 2C + e Cu-Xlpe-PvcDocument3 pages2C + e Cu-Xlpe-Pvcraviroj SOMVADEENo ratings yet

- Line Parameters - Series ResistanceDocument10 pagesLine Parameters - Series ResistanceRONALD LUIS D. BOQUIRENNo ratings yet

- Ferrites and Accesories - E 25-13-7 (EF25) PDFDocument10 pagesFerrites and Accesories - E 25-13-7 (EF25) PDFcarlosD2884No ratings yet

- Ferrites and Accessories: Data Sheet Data SheetDocument10 pagesFerrites and Accessories: Data Sheet Data SheetThanhha NguyenNo ratings yet

- Effect of Saturation On Iron Loss in PMSM: Xiaofeng Ding, Hong Guo, Min Du, Binbin Li, Guanliang Liu, Linlin ZhaoDocument5 pagesEffect of Saturation On Iron Loss in PMSM: Xiaofeng Ding, Hong Guo, Min Du, Binbin Li, Guanliang Liu, Linlin ZhaoJayesh KothavadeNo ratings yet

- A User Guide To Soft Magnetic Materials: by Wulf Günther and Paul WinklerDocument19 pagesA User Guide To Soft Magnetic Materials: by Wulf Günther and Paul WinklerRohan RaoNo ratings yet

- FDP20N50 184794Document11 pagesFDP20N50 184794Paulo NogueiraNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- Driver Specification Sheet: Product DescriptionDocument1 pageDriver Specification Sheet: Product DescriptionBart FrisNo ratings yet

- Formula Input FagrafjellDocument16 pagesFormula Input FagrafjellSiddarthan AnnamalaiNo ratings yet

- Jumper Cable Spec 14-16 PDFDocument3 pagesJumper Cable Spec 14-16 PDFRAMESH KUMARNo ratings yet

- Ee2325 - P1 - L2 - Resistance of TLDocument21 pagesEe2325 - P1 - L2 - Resistance of TLHendrick Brian QuezaNo ratings yet

- Peerless SLS P830667Document1 pagePeerless SLS P830667Alexander ShivaNo ratings yet

- Predicting Temperature Rise of Ferrite Cored TransformersDocument5 pagesPredicting Temperature Rise of Ferrite Cored TransformersPhạm Văn TưởngNo ratings yet

- Magnetic Equivalent Circuit of MF Transformers: Modeling and Parameter UncertaintiesDocument15 pagesMagnetic Equivalent Circuit of MF Transformers: Modeling and Parameter Uncertaintiesjeos20132013No ratings yet

- GTP HavellsDocument24 pagesGTP HavellsPradeep GoelNo ratings yet

- Cathodic Calculation RuleDocument8 pagesCathodic Calculation RulegtomehNo ratings yet

- Ferrites and AccessoriesDocument11 pagesFerrites and AccessoriesAdel DechirNo ratings yet

- Gas-Filled Contactor For High-Voltage DC SwitchingDocument11 pagesGas-Filled Contactor For High-Voltage DC Switchingilayaraja2k20No ratings yet

- 264 1118 Peerless 830669 SpecificationsDocument1 page264 1118 Peerless 830669 Specificationsbk1313No ratings yet

- Cathodic Protection CalculationDocument5 pagesCathodic Protection Calculationjohnnie okoromaNo ratings yet

- Full Range: SpecificationsDocument1 pageFull Range: SpecificationsPablo DpNo ratings yet

- MV Power CablesDocument2 pagesMV Power CablesQC ĐNNo ratings yet

- Driver Specification Sheet: Product DescriptionDocument1 pageDriver Specification Sheet: Product DescriptionPablo DpNo ratings yet

- T4S4-90A-R2 Product SpecificationsDocument6 pagesT4S4-90A-R2 Product Specifications'Theodora GeorgianaNo ratings yet

- Edc Lab ManualDocument96 pagesEdc Lab ManualUday DesirajNo ratings yet

- RF DC Bias TeeDocument15 pagesRF DC Bias TeechrisjennNo ratings yet

- DatasheetDocument8 pagesDatasheetRegisk8 OliveiraNo ratings yet

- 12-MOSFET - Structure and DC Characteristics-22!02!2024Document20 pages12-MOSFET - Structure and DC Characteristics-22!02!2024ashbinny1No ratings yet

- 15 ThreePhase Common Mode PDFDocument12 pages15 ThreePhase Common Mode PDFVito LNo ratings yet

- UNIT VI Solid State Devices: Two Common Schematic SymbolsDocument69 pagesUNIT VI Solid State Devices: Two Common Schematic SymbolsMonte CarloNo ratings yet

- 21 Design of Leaf SpringsDocument10 pages21 Design of Leaf SpringsPRASAD326100% (1)

- Galerkin MethodDocument12 pagesGalerkin Methodahmed namaNo ratings yet

- AVL HandoutDocument3 pagesAVL HandoutAkash ByjuNo ratings yet

- Experiment 4: Frictional ForceDocument4 pagesExperiment 4: Frictional Forcekyle gerome BayotNo ratings yet

- Counter Rotating Propeller StudyDocument6 pagesCounter Rotating Propeller StudyWoodyNo ratings yet

- Flow VisualizationDocument6 pagesFlow VisualizationMuralikrishnan GMNo ratings yet

- 2022 Jan Unit 1 New - PhysicsDocument28 pages2022 Jan Unit 1 New - PhysicsABDULLAH SHAHZADNo ratings yet

- 7182 C007 PDFDocument18 pages7182 C007 PDFankitsarvaiyaNo ratings yet

- f2 Physics Simplified Notes SPDocument30 pagesf2 Physics Simplified Notes SPmicah isaboke100% (1)

- Tutorial 3Document15 pagesTutorial 3carleston thurgoodNo ratings yet

- LyapunovDocument25 pagesLyapunovDipanjan DasNo ratings yet

- Course - Outline - PHY 163 - IPE L1T2Document4 pagesCourse - Outline - PHY 163 - IPE L1T2Atika AlamNo ratings yet

- Creep Analysis With SolidworksDocument3 pagesCreep Analysis With Solidworksanjal22No ratings yet

- Exp 4Document4 pagesExp 4Rakesh KumarNo ratings yet

- Vectors Summary Sheet122211Document2 pagesVectors Summary Sheet122211pfredaacNo ratings yet

- Pile Capacity - BR.-649Document20 pagesPile Capacity - BR.-649Sangramkeshari BejaNo ratings yet

- The HY6801M Electric Leakage Relay Using Introduction: Edition v1.0Document10 pagesThe HY6801M Electric Leakage Relay Using Introduction: Edition v1.0Jon Chen0% (2)

- Chapter 1 - Brief Overview of Fluid PowerDocument13 pagesChapter 1 - Brief Overview of Fluid PowerLuis JácomeNo ratings yet

- As Level Chemistry BookDocument121 pagesAs Level Chemistry Book11560100% (1)

- Ultrav RaysDocument10 pagesUltrav Raysharry smithNo ratings yet

- Power Systems Protection Course: Al-Balqa Applied UniversityDocument31 pagesPower Systems Protection Course: Al-Balqa Applied UniversityDiego Del CastilloNo ratings yet

- An Analysis of Michelson's 1913 Experiment With Rotating MirrorsDocument4 pagesAn Analysis of Michelson's 1913 Experiment With Rotating MirrorsConexão Terra PlanaNo ratings yet

- Analysis of Simply-Supported Orthotropic Plates Subject To Static and Dynamic LoadsDocument16 pagesAnalysis of Simply-Supported Orthotropic Plates Subject To Static and Dynamic LoadsKevin LeeNo ratings yet

- Ch. 18 Fundamentals of Spectrophotometry: What Is Spectroscopy?Document4 pagesCh. 18 Fundamentals of Spectrophotometry: What Is Spectroscopy?JaiNo ratings yet

- Chapter 1 Introduction To Transport PhenomenaDocument38 pagesChapter 1 Introduction To Transport PhenomenaAnas IqmalNo ratings yet

- The Heat Transfer Across A 5" Wall of Firebrick Is...Document3 pagesThe Heat Transfer Across A 5" Wall of Firebrick Is...MelindaNo ratings yet

- S.S.Dav Public School, Khunti Sub:-Physics Second Mock Test Fm:-70Document4 pagesS.S.Dav Public School, Khunti Sub:-Physics Second Mock Test Fm:-70sharique alamNo ratings yet

- Statics - Assignment 8: MCE 111 MechanicsDocument4 pagesStatics - Assignment 8: MCE 111 MechanicsOmar NabilNo ratings yet

- BEAD PULL TEST BENCH For RFQDocument3 pagesBEAD PULL TEST BENCH For RFQVikas RajputNo ratings yet