Professional Documents

Culture Documents

Section 5: TUBULAR Completion Equipment

Uploaded by

Ahmed ChahineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 5: TUBULAR Completion Equipment

Uploaded by

Ahmed ChahineCopyright:

Available Formats

Section 5: TUBULAR Completion Equipment

Completion Equipment . . . . . . . . . . . . .243

Manufacturing of Tubular Perforating Gun Hardware

Holing and Slotting of Casing

Manufacturing of Screens

Holing and Slotting of Casing

Introduction. . . . . . . . . . . . . . . . . . . . . . 247-248

Slotted Casing . . . . . . . . . . . . . . . . . . . . . 249

Slotted Design and Calculation . . . . . . . . . . . . . . . 250

Percentage of Open Area Per Square Foot . . . . . . . . . . 251

Holed Casing . . . . . . . . . . . . . . . . . . . . . . 252

Holed Casing Calculation . . . . . . . . . . . . . . . . . 253

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

TUBULAR Completion Equipment

NOV ASEP Elmar manufacture tubular completion equipment to client’s own drawings and specifications. All tubular manufacture is

subject to agreed and documented quality assurance processes, and relevant certification and documentation is provided. Our three

tubular product lines are Perforating Guns, Slotted and Holed Casing, and Screen products. For further information contact your local sales

representative or visit www.nov.com/ASEPElmar

Manufacturing of Tubular

Perforating Gun Hardware

ASEP Elmar have been manufacturing

perforating gun hardware and accessories

since 1989 and currently have a total

capacity of approximately 55,000 feet of

production per month between the Dubai

and Aberdeen plants. Sizes from 1 9/16”

to 10” can be produced along with all

Section 5 - TUBULAR Completion Equipment

required loading tubes, adapters and other

accessories. Where applicable the guns

meet requirements including API, NACE

NPD and EEUMA and are certified by a

Third Party certifying authority.

Perforating Guns

243

Holing and Slotting of Manufacturing of Screens

Casing

ASEP Elmar have been producing wire

ASEP Elmar slotted and holed liners wrapped screens under license since

are manufactured on specially designed 1995 and have a capacity of 150 joints per

multi spindled machines that assure a week, with a range of base pipe sizes from

high level of machining accuracy whilst 4” to 9 5/8.

maintaining metallurgical properties

through the continuous application of At the Westhill facility we have

coolant during the cutting process. We the capability to complete the

are able to deburr pipes from 2 3/8” to 12” whole screen assembly

OD and 50’ length with a purpose built from machining of the

deburring machine capable of removing base pipe, welding

swarf, rust and grease. After deburring of components;

the pipes are given a protective coating wrapping of wire

to prevent further rust. Slot widths of through to complete

0.012” to 0.25” in a variety of patterns inspection and assembly.

can be accommodated with a range of

slot lengths to suit the requirement. Holed Documents are maintained for customer

casing can be produced with a variety of assurance of full traceability of materials

hole patterns and pitches, with diameters and control of procedures.

from 9.5mm to 25mm.

Holed and Slotted Casing

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

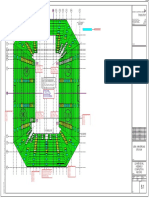

TUBULAR Holing and Slotting Of Casing

Introduction . . . . . . . . . . . . . . . . . . 247-248

Slotting machines

Hydraulic Handling System

Holing Machines

Deburring

Pipe coating

Banding

QA Certification

Slotted Casing . . . . . . . . . . . . . . . . . 249

Slot sizes

Straight or keystone slots

Slot width and length guide

Slot patterns

Casing sizes

Slotted Design & Calculation . . . . . . . . 250

Straight slot

Keystone slot

Determining slots per foot

Calculation of required slots/foot

Percentage of Open Area

Per Square Foot . . . . . . . . . . . . . . . . 251

3.5” slotted liner

4.5” slotted liner

5.5” slotted liner

7” slotted liner

Holed Casing . . . . . . . . . . . . . . . . . . 252

Perforated casing

Hole sizes

Casing sizes

Holing patterns

Holed Casing Calculation . . . . . . . . . . 253

Determining holes per foot

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

Holing and Slotting of Casing

NOV ASEP Elmar has the capability at its Aberdeen facility for precision machining and quick delivery of Slotted,

Holed or Plugged Casing.

Section 5 - TUBULAR Completion Equipment

Slotting Machine

247

CASING MACHINES

Slotting Machines Hydraulic Handling System

• Specially designed multi-spindle milling • With health and safety a priority this roller

machines are used to manufacture NOV ASEP system has been designed to feed both slotting

Elmar slotted liners. and drilling machines resulting in increased

• Circular milling saws cut the slots with efficiency while greatly reducing potential

continuous application of coolant to maintain safety risks.

the pipe’s metallurgical integrity.

Multi-spindle milling

Hydraulic handling system

Multi-purpose CNC turning lathe

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

Holing and Slotting of Casing

Section 5 - TUBULAR Completion Equipment

Holing Machine

248

HOLING MACHINES

Holing Machines Deburring Pipe Coating

• ASEP Elmar holed liners are manufactured • A deburring service is offered for both slotted • A pipe coating service is available with the

on specially-designed multi-spindle drilling and holed casing. ability to coat pipe up to 50ft long internally and

machines. externally with a capacity of 100 pipes per day.

• Our facility has capacity to de-burr pipes

• The holes are drilled using high quality drill from 2 3/8” O.D. to 12” O.D. The O.D. and

bits and the CNC control allows high positional I.D. are washed with 3,000 psi jets of water,

accuracy. Coolant is continuously applied to a degreaser is used if required. Hard sand

maintain the pipe’s metallurgical integrity. stones remove rust and burrs from the inside

of pipes up to 50ft long. Box and pin caps are

cleaned with 3,000 psi jets of water on the I.D

and O.D.

Pipe coating process

Banding

• Pipe is supplied in bundles, banded or with

slings as required.

Multi-spindle drilling

QA Certification

CNC Control

• Lloyd’s accredited to BS EN ISO 9001: 2008

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

Slotted Casing

Slot Sizes

• ASEP Elmar provides a range

of slot sizes to suit the majority of

customer’s requirements.

Straight Slots

or Keystone Slots

• Minimum Slot Width = 0.012”

• Maximum Slot Width = 0.250”

Casing Sizes

• Casing up to a maximum diameter of 14” can

be slotted.

Slot Width and Length

As a guide the following are the standard slot widths and lengths commonly used:

Section 5 - TUBULAR Completion Equipment

STANDARD SLOT WIDTH AND LENGTH GUIDE

1.5” Long 2.0” to 2.5” Long 2.5” Long

0.012” wide 0.024” wide 0.078” wide

0.015” wide 0.025” wide 0.125” wide

0.016” wide 0.038” wide 0.250” wide

0.018” wide 0.048” wide

0.058” wide

Slotting Patterns

249

Staggered pattern (ASEP Elmar preferred option) Straight or parallel pattern

Slotted Casing

Hi density pattern

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

Slotting Design & Calculation

Straight Slot

• This is the most common type of slot

manufactured. It has straight sides, equal width

through the wall of the casing and is normally

used in consolidated formations or when slots

of 0.030” or wider are specified.

Straight Form 0.048”

• Straight slots are very resistant to wear and

are more economic than keystone.

Section 5 - TUBULAR Completion Equipment

Keystone Slot

• The slot is narrow at the liner surface and of

increasing width with depth into the casing

material.

• The narrow slot width at the suface of the

liner allows sand grains to bridge across the

Keystone Form 0.025”

opening. Sand grains that do enter the slot will

pass completely through without clogging.

6°

250

Determining Slots Per Foot For example, if an open area of 3% is required with

4.5” diameter liner and a slot width of 0.020” wide x

• To achieve a required percentage of open area 1.5” long has been selected to control the formation,

on the pipe surface, the preferred slot size should then the number of slots to be cut in the liner is:

be selected from the formulation evaluation.

The number of slots per foot of pipe can then be

calculated using the following formula and tables. (12 x 3.14 x 4.5 x 3)

N = = 169.646

(100 x 0.020 x 1.5)

Calculation of Required

Slots/Foot

This figure is then rounded to either the nearest

• After selecting the open area, the slot size and multiple of 4 or the nearest multiple of 8 depending

the diameter of the liner, the number of slots on the slotting pattern being cut.

per foot can be determined from the following

Slot Length

formula: Because the slots are cut by a circular blade, the

slot is always longer at the O.D. than it is at the

I.D. When specifying the slot length the value used

(12 x 3.14 x D x C) always applies to the length at the I.D.

N =

(100 x W x L)

where

N = Required slots/foot

D = Outside diameter of the liner (inches)

C = Required open area (percent of surface area)

W = Selected slot width (inches)

L = Length of slot (inches)

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

Percentage of Open Area Per Square Foot

3.5” Slotted Liner 4.5” Slotted Liner

3.5" Slotted Liner 4.5" Slotted Liner

180 180

0.1 1.5

170 170

1.5

5

1.5

0.1 x 1.

1.5

1 .5

6x

8x

160 160

2x

6

2x

0.1

8x

0.1

0.1

150 150

0.1

x 1 .5

1

140 140

.5

0. 25 x

130 130

0.

28

120 120

1.5 2.0

SLOTS PER FOOT

SLOTS PER FOOT

.5

110 5x x1 110

5 x 2.0

100 0.2 .28 100 . 2

0 8x

0

0.2

90 2.0 90

5x

Section 5 - TUBULAR Completion Equipment

80 0.2 80

2.0

70 2.0 70 8x

8x 0.3

60 0.2 0 60

x 2.

0.38

50 50 x 2.0

40 2.0 40 0.58

0.58 x

30 30 2.0

0.125 x

20 0.125 x 2.0 20

10 10

0.5 1.0 1.5 20 2.5 3.0 3.5 0.5 1.0 1.5 20 2.5 3.0 3.5

REQUIRED PERCENTAGE OF OPEN AREA REQUIRED PERCENTAGE OF OPEN AREA

251

5.5” Slotted Liner 7” Slotted Liner

5.5" Slotted Liner 7.0" Slotted Liner

180 180

5

170

1.5

170

x 1.

0.1 1.5

1.5

1.5

0.2 1.5

1.5

0.18 5

2.0

0.2 1.5

1.5

x 1.

6x

8x

2x

5x

8x

160 160

8x

5x

5x

x

0.1

0.2

0.16

0.1

0.2

0.12

0.2

150 150

.0

x2

140 . 0 140

x2

28

5

0.

130 2 0 130

0. x 2.

120 2 8 120

0. 2.0

SLOTS PER FOOT

SLOTS PER FOOT

110 110 x

0.38

100 100

90 2 .0 90

8x

80 0.3 80

2.0

70 70 8x

0.5

0

60 x 2. 60

50 0.58 50

40 40

x 2.0

x 2.0 0.125

30 0.125 30

20 20

10 10

0.5 1.0 1.5 20 2.5 3.0 3.5 0.5 1.0 1.5 20 2.5 3.0 3.5

REQUIRED PERCENTAGE OF OPEN AREA REQUIRED PERCENTAGE OF OPEN AREA

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

Holed Casing

Perforated

Casing

• ASEP Elmar provides casing

with a range of hole sizes and hole

patterns to suit the majority of customers

requirements.

Hole Sizes

• Our standard hole diameter sizes; 9.5mm,

13mm, 14mm, 16mm ,19mm and 25mm.

Other hole sizes can be achieved. Please

contact your completions team for details.

Holing Patterns

ASEP Elmar preferred patterns. Casing Sizes

• Casing up to a maximum diameter of 9 5/8”

can be holed.

Section 5 - TUBULAR Completion Equipment

Figure 1: 6” Pitch Pattern Figure 4: 4” Pitch Pattern

252

Figure 2: 3” Pitch Pattern Figure 5: Rows Pattern

Pitches can be 1”, 2”, 3”, 4”, 6” or 12” apart (where

2”, 3” and 6” are the preferred).

The number of holes in each spiral then determines

the total amount of holes per foot.

Alternative patterns which do not have spirals can be

arranged (see figure 5).

Please contact sales for details.

Normally the pitch of the spirals and the number of

holes in each spiral are selected to give an even

spread of holes on the pipe surface.

Figure 3: 2” Pitch Pattern

The ASEP Elmar preferred patterns have the holes

arranged in spirals around the pipe. The spacing

between the start and the end of one full spiral is

defined as the pitch (see above diagrams).

Holed Casing

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

Holed Casing Calculation

Determining Holes For example, if an open area of 3.0% is required with For spirals on a 2” pitch, round this to the nearest

Per Foot 4.5” diameter liner and a hole diameter of 0.5” then number divisible by 6 (6 Spirals per foot). In this

the number of holes to be drilled in the liner is: example = 24 or 30 HPF

• To achieve a required percentage of open

area on the pipe surface, the preferred hole For spirals on a 4” pitch, round this to the nearest

Section 5 - TUBULAR Completion Equipment

diameter should be selected. The number of number divisible by 3 (3 Spirals per foot). In this

holes per foot of pipe can then be calculated (12 x 4.5 x 3)

example = 24 or 27 HPF

N = = 25.92

using the following formula: (25 x 0.5 2)

Having determined the amount of holes per foot

required, it is necessary to choose a preferred

(12 x D x C) For spirals on a 6” pitch, round this to the nearest pattern. Ideally this would be one that would provide

N = number divisible by 2 (2 Spirals per foot). In this

(25 x d 2) evenly spaced holes.

example = 26 HPF

where

N = Required holes/foot For spirals on a 3” pitch, round this to the nearest

number divisible by 4 (4 Spirals per foot). In this

D = Outside diameter of the liner (inches) example = 24 or 28 HPF

C = Required open area (percent of surface area)

d = Diameter of hole (inches) 253

© 2010 National Oilwell Varco www.nov.com/ASEPElmar

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- KF FlangeDocument76 pagesKF Flangehisaj4uNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Data Sheet: Elcometer 124 Thickness GaugeDocument3 pagesData Sheet: Elcometer 124 Thickness GaugeMohamed NouzerNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Elcometer 124 Thickness Gauge Product Data SheetDocument2 pagesElcometer 124 Thickness Gauge Product Data SheetMohamedNo ratings yet

- Pfeifer Wire Ropes Technical Information Brochure enDocument20 pagesPfeifer Wire Ropes Technical Information Brochure eneddie2166No ratings yet

- Liquidtight Fittings: Cooper Crouse-HindsDocument8 pagesLiquidtight Fittings: Cooper Crouse-HindsAlex RamirezNo ratings yet

- KAESER MOBILAIR General CatalogueDocument7 pagesKAESER MOBILAIR General CatalogueVietnam UMacNo ratings yet

- Your Partner For Innovative & Reliable EquipmentDocument8 pagesYour Partner For Innovative & Reliable EquipmentHamid BenNo ratings yet

- Data AL Series Threaded Insert DataDocument3 pagesData AL Series Threaded Insert DataJuan RamirezNo ratings yet

- 12 Nor CalProductsChambersandWeldmentsCatalog2018Document17 pages12 Nor CalProductsChambersandWeldmentsCatalog2018Jose SantosNo ratings yet

- Bul 4835 e Z Form HoseDocument8 pagesBul 4835 e Z Form HoseyensebastianNo ratings yet

- GasketDocument12 pagesGasketAbraham BongòNo ratings yet

- Rotary Actuators, NAMUR Interface VDI - VDE 3845 & ISO 5211 (ATEX Certified) Series ARPDocument8 pagesRotary Actuators, NAMUR Interface VDI - VDE 3845 & ISO 5211 (ATEX Certified) Series ARPJhonata CavalcanteNo ratings yet

- SFT Company ProfileDocument8 pagesSFT Company ProfileAndy BayuNo ratings yet

- The Oilfield's Most Reliable Source of Information To Accurately Machine, Inspect, andDocument3 pagesThe Oilfield's Most Reliable Source of Information To Accurately Machine, Inspect, andLevi BriceñoNo ratings yet

- Product Data: 39T Central Station Air-Handling UnitsDocument100 pagesProduct Data: 39T Central Station Air-Handling UnitsJesus CantuNo ratings yet

- Scraper Traps: Traditionally DependableDocument6 pagesScraper Traps: Traditionally DependableMurli ramchandranNo ratings yet

- S C C P U: Elf-Ontained Ooling Ackage NitsDocument60 pagesS C C P U: Elf-Ontained Ooling Ackage Nitsdavid villaNo ratings yet

- Literature ReviewDocument11 pagesLiterature ReviewFendyNo ratings yet

- Flumes - Water Engineering PDFDocument24 pagesFlumes - Water Engineering PDFMogie TalampasNo ratings yet

- Zulzer Ohh E00581 PDFDocument8 pagesZulzer Ohh E00581 PDFJorge OportoNo ratings yet

- 6744-00-16-46-SP-09 RaDocument4 pages6744-00-16-46-SP-09 Ravijay bariNo ratings yet

- Manual Tacho ConvencionalDocument6 pagesManual Tacho ConvencionalcvergaraesNo ratings yet

- Securemount CatalogDocument8 pagesSecuremount CatalogJohn Alexander Bonilla AngelNo ratings yet

- EHP Series Piston Accumulators: 0.1 To 1000 Litres, Up To 350 BarDocument32 pagesEHP Series Piston Accumulators: 0.1 To 1000 Litres, Up To 350 BarMichael Akhramovich100% (1)

- Manual2019 EN Grid50 PDFDocument12 pagesManual2019 EN Grid50 PDFFOUEDNo ratings yet

- DeZURIK BAW AWWA BUTTERFLY VALVESDocument32 pagesDeZURIK BAW AWWA BUTTERFLY VALVESLuis Daniel ContrerasNo ratings yet

- Technical Specifications Preparation Gui Del LinesDocument7 pagesTechnical Specifications Preparation Gui Del Linesrakeshkumar1971No ratings yet

- Industrial Wire Screens CatalogueDocument15 pagesIndustrial Wire Screens Catalogueos ozNo ratings yet

- CME Mill Liner FlyerDocument2 pagesCME Mill Liner FlyerDiegoAlvarezHuguezNo ratings yet

- 49 - Spinning - AmslerDocument1 page49 - Spinning - AmslerWajih HashmiNo ratings yet

- Robofil 240 SLP 440 SLPDocument11 pagesRobofil 240 SLP 440 SLPJakus JankaNo ratings yet

- Omsco Drillpipe CatalogueDocument24 pagesOmsco Drillpipe Cataloguerwinmill100% (3)

- PIX32-V5 Connect 100pin (Panasonic-AXK5S-6S) Data SheetDocument10 pagesPIX32-V5 Connect 100pin (Panasonic-AXK5S-6S) Data SheetashleyNo ratings yet

- Flue Duct Dampers: A World of SolutionsDocument3 pagesFlue Duct Dampers: A World of SolutionsmohdfirdausNo ratings yet

- EN - Allround Technical BrochureDocument48 pagesEN - Allround Technical BrochuresivanaNo ratings yet

- Complete Guide To Pressure and Vacuum Sealing AssembliesDocument22 pagesComplete Guide To Pressure and Vacuum Sealing Assembliesrahulkraj123No ratings yet

- 241 Plug FansDocument28 pages241 Plug FansHORNOS SAMO THERMALNo ratings yet

- Esab - Covered Electrodes - Brochure - CEP-10009Document6 pagesEsab - Covered Electrodes - Brochure - CEP-10009YgcdwhNjdshNo ratings yet

- Anechoic ChambersDocument15 pagesAnechoic Chambersbadmike71No ratings yet

- SFT Company Profile USDocument8 pagesSFT Company Profile USSALES HOANG HANo ratings yet

- ASST Datasheet v4.2Document2 pagesASST Datasheet v4.2gusyahri001No ratings yet

- Ancra Aircraft-Catalog403Document28 pagesAncra Aircraft-Catalog403Robert FlorezNo ratings yet

- Multi WingDocument3 pagesMulti WinghariharanNo ratings yet

- Mesin Bor Explorac R50Document12 pagesMesin Bor Explorac R50julianusginting00No ratings yet

- AHI - AVI - Sales Guide - PUBL-5509Document6 pagesAHI - AVI - Sales Guide - PUBL-5509Michael FutolNo ratings yet

- Steelway StandardsDocument20 pagesSteelway StandardscanettijNo ratings yet

- AccessorDocument6 pagesAccessorapi-3864578No ratings yet

- Dezurik Awwa Butterfly Valves Baw Baw Awwa Butterfly Valves 43 - 00 - 1Document32 pagesDezurik Awwa Butterfly Valves Baw Baw Awwa Butterfly Valves 43 - 00 - 1jacquesstrappe06No ratings yet

- Hard Rock Drilling Solutions at Your FingertipsDocument4 pagesHard Rock Drilling Solutions at Your Fingertipsعلی محمودیNo ratings yet

- Acople Ameriflex DiaphragmDocument24 pagesAcople Ameriflex Diaphragmmarcelo castilloNo ratings yet

- Valve Solutions For Drilling BRDocument8 pagesValve Solutions For Drilling BRshamekhalmaamariNo ratings yet

- Group AssignmentDocument5 pagesGroup Assignmentkhairulaqib.baha01No ratings yet

- Testex Tape Product Data Sheet 122Document2 pagesTestex Tape Product Data Sheet 122Bash MatNo ratings yet

- RoofCurbs CatalogDocument8 pagesRoofCurbs CatalogstronginternacionalhondurasNo ratings yet

- Espey-Burgmann - EB - E1 - Compressor Seal WKA250ND - 1100HPDocument8 pagesEspey-Burgmann - EB - E1 - Compressor Seal WKA250ND - 1100HPmunhNo ratings yet

- Tube Upsetting Machines BrochureDocument10 pagesTube Upsetting Machines BrochuredemirilkNo ratings yet

- The Cameron FLEXPACKER Ram: Comprehensive Advancement in Multiple-Bore Pressure Control TechnologyDocument3 pagesThe Cameron FLEXPACKER Ram: Comprehensive Advancement in Multiple-Bore Pressure Control TechnologyTerry SmithNo ratings yet

- PETE 625 Well Control: Lesson 9 Fracture GradientsDocument55 pagesPETE 625 Well Control: Lesson 9 Fracture GradientsAhmed ChahineNo ratings yet

- 12.1 CoringDocument40 pages12.1 CoringAhmed ChahineNo ratings yet

- Service Fluides Et Ciment Janvier, Fevrier, Mars Mi Swaco SQM Trimèstre 1Document5 pagesService Fluides Et Ciment Janvier, Fevrier, Mars Mi Swaco SQM Trimèstre 1Ahmed ChahineNo ratings yet

- Onqor: Product BulletinDocument2 pagesOnqor: Product BulletinAhmed ChahineNo ratings yet

- Gisement Et Production Serie 2Document3 pagesGisement Et Production Serie 2Ahmed ChahineNo ratings yet

- Section 1 K-WINCHDocument80 pagesSection 1 K-WINCHAhmed Chahine100% (2)

- The Peoples Democratic Republic of AlgeriaDocument8 pagesThe Peoples Democratic Republic of AlgeriaAhmed ChahineNo ratings yet

- The Palestinian Centipede Illustrated ExcerptsDocument58 pagesThe Palestinian Centipede Illustrated ExcerptsWael HaidarNo ratings yet

- PDFDocument3 pagesPDFAhmedraza123 NagdaNo ratings yet

- SDSSSSDDocument1 pageSDSSSSDmirfanjpcgmailcomNo ratings yet

- Perdarahan Uterus AbnormalDocument15 pagesPerdarahan Uterus Abnormalarfiah100% (1)

- China Training WCDMA 06-06Document128 pagesChina Training WCDMA 06-06ryanz2009No ratings yet

- Instant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdDocument17 pagesInstant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdLance CorreaNo ratings yet

- Alfa Week 1Document13 pagesAlfa Week 1Cikgu kannaNo ratings yet

- Iguard® LM SeriesDocument82 pagesIguard® LM SeriesImran ShahidNo ratings yet

- UNIT 5-8 PrintingDocument17 pagesUNIT 5-8 PrintingNOODNo ratings yet

- Ch-10 Human Eye Notes FinalDocument27 pagesCh-10 Human Eye Notes Finalkilemas494No ratings yet

- PDFDocument27 pagesPDFER Saurabh KatariyaNo ratings yet

- Dating Apps MDocument2 pagesDating Apps Mtuanhmt040604No ratings yet

- Yale Revision WorksheetDocument3 pagesYale Revision WorksheetYASHI AGRAWALNo ratings yet

- Fuzzy Gain Scheduled Pi Controller For ADocument5 pagesFuzzy Gain Scheduled Pi Controller For AOumayNo ratings yet

- Toolbox TalkDocument14 pagesToolbox Talkcall_mustafas2361No ratings yet

- Carnegie Mellon Thesis RepositoryDocument4 pagesCarnegie Mellon Thesis Repositoryalisonreedphoenix100% (2)

- 9400 Series - Catalogue - AccessoriesDocument86 pages9400 Series - Catalogue - AccessoriesSaulo Leonardo Fabelo FontesNo ratings yet

- 4th Sept - Marathon Series Lecture 8 - General AwarenessDocument208 pages4th Sept - Marathon Series Lecture 8 - General AwarenessManbir ArinNo ratings yet

- View All Callouts: Function Isolation ToolsDocument29 pagesView All Callouts: Function Isolation Toolsمهدي شقرونNo ratings yet

- Engleza Referat-Pantilimonescu IonutDocument13 pagesEngleza Referat-Pantilimonescu IonutAilenei RazvanNo ratings yet

- Data MiningDocument28 pagesData MiningGURUPADA PATINo ratings yet

- Lacey Robertson Resume 3-6-20Document1 pageLacey Robertson Resume 3-6-20api-410771996No ratings yet

- LP32HS User Manual v1Document52 pagesLP32HS User Manual v1tonizx7rrNo ratings yet

- APA Vs Harvard Referencing - PDFDocument4 pagesAPA Vs Harvard Referencing - PDFTalo Contajazz Chileshe50% (2)

- Pediatrics: The Journal ofDocument11 pagesPediatrics: The Journal ofRohini TondaNo ratings yet

- De Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020Document11 pagesDe Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020HiềnNo ratings yet

- Caring For Women Experiencing Breast Engorgement A Case ReportDocument6 pagesCaring For Women Experiencing Breast Engorgement A Case ReportHENINo ratings yet

- Test 2-Module 1 12-10-2017: VocabularyDocument2 pagesTest 2-Module 1 12-10-2017: VocabularySzabolcs Kelemen100% (1)

- Existentialism in CinemaDocument25 pagesExistentialism in CinemanormatthewNo ratings yet

- SubaruDocument7 pagesSubaruclaude terizlaNo ratings yet