Professional Documents

Culture Documents

Kia Sportage II 2010 (2.0L) - 12. Steering System

Uploaded by

miguel0 ratings0% found this document useful (0 votes)

25 views43 pagessportage

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsportage

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views43 pagesKia Sportage II 2010 (2.0L) - 12. Steering System

Uploaded by

miguelsportage

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 43

Page 1 of 42

SPORTAGE(KM) > 2010 > G 2.0 DOHC > Steering System

‘Steering System > General Information > Specifications

SPECIFICATIONS

Items Specifications

Rack and pinion

Steering gear type Mos 1 mm (lock to loek : 3.06

Rack stroke ee

Power steering pump type wp

Oil pump displacement 9.6ccltev. MAX. (0.59 in?itev.

2.014)

2.7(V6) MAX)

10.Scc/tev. MAX. (0.64 intev.

MAX)

SERVICE STANDARD

Items Specifications

0~ 30 uum (0 ~ 1.1 in)

Steering wheel free play se790 x yeay"

Steering angle a + 1°30’

Tuner wheel 31,

Outer wheel 29.N (3.0 kg, 6.5 Ibs) or less

Stationary steering effort

Belt deflection {under 98N (10kg, 221b) force]

New belt

Used belt

Oil pump relief pressure

2.0 (Id), 2.7 (V6)

Total pinion preload

Tie rod swing resistance

Ball joint starting torque

88-110mm

12.5~ 143mm

8.6 ~ 9.1 MPa (88 ~ 93 kg/om?, 1251 ~ 1322

psi)

0.6 ~ 1.3 Nm (0.06 ~ 0.13 kgf'm, 5.2 ~ 11.3 Ib-

im)

2~5 Nm (0.2 ~0.5 kef'm, 14 ~ 3.6 lb-ft)

0.5 ~2.5 Nm (0.05 ~ 0.25 kfm, 0.36 ~ 1.78

Ib-f)

TIGHTENING TORQUE

Page 2 of 42

Item Nm kgf-m Ib-tt

Power steering column and shaft

Steering cohimm and shaftmouingbot | 13~18 | 13~18 | 96 45,

Power steering wheel lock nut 4o~50 | 40~50 | OBS

Pinion gear and joint assembly 15~20 15~2 |igg- Ws

Steering column shaft and universal joint | 15~20 | 1.5~2

108~14.8

assembly

Power steering gear box

Gear box mounting bolt 5

" 6o~s0 | 6-8 | 44~59

ere ead Palont audkauekleam | 4569 | 45-6 [325-434

. 1-16 | 1-16 | 74-118

Feed tube to gear box

20-30 | 2-3 | ias~217

Gear box to valve body 30.70 | 327 | 37230

‘Yoke plug lock nut ° ;

Power steering oil pump

Pressure hose to oil pump 39.747

ill pump adjusting bolt 253-37

ill pump mounting bolt

2.0 (ld). 2.7 (V6) 35-50 | 35~5 | 258~37

il pump bracket mounting bolt 35~50 | 35-5 | 258-37

Power steering hose

Power steering reservoir mounting bolt | 17 ~ 26

Power steering hose mounting bolt T~1L

Power steering tube mounting bot T~1L

LUBRICANTS

Item Recommended lubricant, Quantity

ALVANIA #2 OR #3

Bearing of steering shaft (KEUK DONG SHELL. Korea) | A87auzed

SHOWA SUNLIGHT

Ball joint of tie rod end MB-2 OF equivalent 4e

ste 1 ONE-LUBER RP GREASE As ed

teeing gear house (KYODOYUSHI, JAPAN) ASTequr

f° LONG TIME PD2

Inner ball joint of gear box. (OPTIMOL, GERMAN) As required

Contact area of gear box bellows & tie | SILICON GREASE As required

rod (SPEC NO : MSS11-41) Astrea

. 0.8~ 05 liter

Power steering fluid PSF-3 (084-0954)

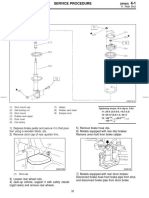

Steering System > General Information > Special Service Tools

SPECIAL TOOLS

Tool (Number and name) Mlustration Use

Page 3 of 42

09222-32100 ‘ustalling the pinion gear bearing

‘Valve stem oil seal installer

09432-21600 = Installing the pinion gear bearing

‘Bearing installer ~~

a “

© “

09434-14200 Iustalling the gear box oil sea

Counter shaft bearing installer LP

<

09561-11002 Removing the steering wheel

Steering wheel puller

09565-11100

Prelo ad socket

Measuring the mainshaft preload.

09555-21000 Removing & installing the oil seal

‘Bar

09568-34000 Separating the tie rod end ball joint.

Ball joint puller

09572-21000

Oil pressure gauge

Measuring the power steering oil pressure

(use with 09572-21200, 09572-22100)

09572-21200

Oil pressure gauge adapter

Measuring the power steering oil pressure

(use with 09572-21000, 09572-22100)

09572-22100

Oil pressure gauge adapter

‘Measuring the power steering oil presste

(use with 09572-21000, 09572-21200)

Page 4 of 42

09573-21000 - Installing the back-up washer and oil seal.

il seal installer gauge (use with 09573-21100, 09573-21200,

09517-11000, 09555-21000)

09573-21100 Installing the back-up washer and oil sea.

il seal installer (use with 09573-21000, 09573-21200,

09555-21000)

09573-21200 1, Removing the gear box oil seal and back

Oil seal guide - washer (use with 09573-21000)

2. Installing the gear box oil seal and back

washer (use with 09555-21000, 09573-

21000)

‘Steering System > General Information > General Information

GENERAL

CHECKING STEERING WHEEL FREE PLAY

1. Start the engine with the steering witeel in the straight ahead position, apply a force of SN (1.1 Ib) tothe steering

‘wheel inthe peripheral direction,

2. Measure the play at the circumference of the steering wheel.

Standard value :

Steering wheel fiee play : 0~ 30 mm (0~ 1.1 in)

Pe

RSS

3. Ifthe play exceeds the standard value, inspect the connection between the steering shaft and tie rod ends,

CHECKING STEERING ANGLE

Page 5 of 42

1. Place the fiout whee! on a tuning radius gauge and measure the steering angle

‘Standard value :

Wheel angle

Inner wheel : 36.77° = 1°30"

‘Outer wheel : 31.8°

2. Ifthe measured value is not within the standard value, adjust the linkage,

CHECKING THE TIE ROD END BALL JOINT STARTING TORQUE

1, Discomnect the tie rod(A) and kuuekle(B) by using the special tool (09568-34000).

2. Shake the ball joint stud several times to check for looseness.

3, Mount the muts on the ball joint, and then measure the ball joint starting torque.

Standard value :

0.5~2.5 Nm (0.05 ~ 0.25 kef-m, 0.36~1.78 Ib-ft)

oA

4. Tf te starting torque exceeds the upper limit ofthe standard value, replace the tie rod end

5. Even ifthe starting torque is below the lower limit of the standard value, check the play of the ball joint and

replace if nece ssary.

Page 6 of 42

CHECKING STATIONARY STEERING EFFORT

1. Place the vehicle on a level surface and place the steering wheel in the straight aead position.

2. Increase the engine speed to 1000 + 100 xpm

‘After checking, reset the engine speed to the standard value (idling

speed).

3. Measure the tuming force with a spring seale(A) by tuning the steering wheel(B) clockwise and

counterclockwise one and a quarter tums.

Standard value :

Stationary steering effort

29N (3.0 kg, 6.5Ibs) of less

QS

Me N

(L——.\

Q 0)

4. Check that there is no sudden change of force while tuming the steering wheel.

5. If te stationary steering effort is excessive, check and adjust the following points.

(1) Damage or cracks on the dust cover of the lower arm ball joint and tie rod end.

(2) Pinion preload of the steering gear box and starting torque of the tie rod end ball joint

(3) Starting torque of the ball joint.

CHECKING STEERING WHEEL RETURN

1. The force required to ttn the steering wheel and the wheel retum should be the same for both left and right in

case of moderate or sharp tums

2. When the steering wheel is tumed 90° and held for a couple of secondls while the vehicle is being driven at

35kph, the steering wheel should return 70° or more.

I the steering wheel is tuned very quickly, steering may be momentarily difficult. Tis is not a malfunction

because the oil pump output will be somewhatcecreased.

Page 7 of 42

CHECKING POWER STEERING BELT TENSION

1. Press the V belt, applying a pressure of 98N (10k, 221b) at the specified point aud measure the deflection to

cconfinu that it is within the standardvalue,

Standard value :

‘New belt : 8.8 ~ 1.0mm

Used belt : 12.5 ~ 14.3 mm

2. Ifthe belt deflection is beyond the standard value, adjust the belt tension as follows.

(1) Loosen the adjusting bolt(A) and the bolt hinged(B).

Ko

“

(2) Put a bar(A) or equivalent, between the bracket(B) and the oil pump(C) and adjust the tension so that the

belt deflection is within the standard value.

(3) Tighten the adjusting bolt(A) and the bolt hinged(B).

Tightening torque :

35 ~ 30 Nm (3.5 ~ 5.0 kgf'm, 25.3 ~ 37 Ib-ft)

Page 8 of 42

(4) Check the belt deflection aud adjust it again if necessary.

Affer tuning the V belt in the no mal rotation direction more than once, recheck the belt deflection.

CHECKING POWER STEERING FLUID LEVEL

1 Position the vehicle on a level surface.

2. Start the engine. With the vehicle kept stationary, tum the steering wheel several times continuously to raise the

fluid temperature to 50 - 60°C(122 to 140°F).

3. With the engine at idle, tum the steering wheel filly clockwise and counterclockwise several times.

4. Make sure there is no foaming or cloudiness in the reservoir fd,

5. Stop the engine to check for any difference in Huid level between a stationary and a running engine.

1. Ifthe fluid level varies 5 mm (0.2 in) or more, bleed the system again.

2. I the fluid level suddenly rises after stopping the engine, further bleeding is required.

3. Incomplete bleeding will produce a chattering sound inthe pump and noise in the flow control valve,

and lead to decreased durability of the pump.

REPLACING POWER STEERING FLUID

1 Jack up the front wheels of the car and support them with jackstands

2. Disconnect the retum hose from the oil reservoir and plug the oil reservoir

3. Connect a hose to the disconnected retum hose, and drain the oil into a container

4, Disconnect the high-tension cables and ignition coils.

While operating the starter motor intermittently, tum the steering wheel al the way to the left and then to the right

several times to drain the fluid.

5. Comnect the return hose and fix it with a el ip,

6. Fill the power steering fluid reservoir with the specified fluid

PSE-3 : 0.8~0.9 lit.

7. Start the engine.

Check for ltd leaks from the hose, then stop the engine

8, Pout the fitid into the bottom of the oil filter in the power steering fhtid reservoir

9. Bleed the air.

AIR BLEEDING

1. Fill the power steering fluid reservoir up to the "MAX" position with specified fluid.

2. Jack up the front wheels,

Page 9 of 42

Disconnect the ignition coil high tension cable, and then, while operating the starter motor inteamittently (for 15 to

20 seconds), tun the steering wheel all the way to the left and then to the right five or six times.

1. When bleeding fluid, replenish with the fluid so that the level does not fall below the bottom of the filter.

2. Perform air bleeding only while cranking to avoid excessive fiuid aeration

4, Connect the high tension cable , and then start the engine (idling),

5, Tum the steering wheel tothe left and then to the right, until there are no air bubbles in the oil reservoir

{NOTE |

Do not hold the steering wheel tumed all the Way to either side for more than ten seconds,

6. Confirm that the uid is not milky and that the level is between "MAX" and "MIN" mau on the reservoir

7. Check that there isa little change in the fluid level when the steering wheel is tuned left and right.

1) If the fluid level varies Suun (0.2 in. or mote, bleed the system again.

2) Ifthe fluid level suddenly rises after stopping the engine, futher bleeding is required.

3) Incomplete bleeding will produce a chattering sound in the pump and noise in the flow control valve,

and lead to decreased durability of the pump.

OIL PUMP PRESSURE TEST

1, Disconnect the pressure hose(B) frou the pump(A). Connect the special tool between the pump and the pressure

hose as illustrated

2. Bleed the air, and then start the engine aud tum the steering wheel several times, measure the fluid temperature by

‘Temperature gauge so that the fluid temperature can rise to approximately 50°C (122°F).

3. Increase the engine speed to 1,000 xp

4. Close the shut-off valve of the special tool and measure the fluid pressure to confirm that it is within the standard

‘vale range

Standard value :

Oil pump pressure

Relief pressure

2.0(14), 2.7(V6)

8.6 ~ 9.1 MPa (88 ~ 93 kg.cm?, 1251 ~ 1322 psi)

Do not keep the shut-off valve on the pressure gange closed for more than ten seconds.

Page 10 of 42,

5. Remove the special tools, and tighten the pressure hose(B) against the oil pump (A) using the specified torque.

Tightening torque :

55 ~ 65 Nm (5.5 ~ 6.5 kef'm, 39.7 ~ 47 lb-ft)

6. Air Dleed the system. (See page ST-10)

‘Steering System > General Information > Troubleshooting

TROUBLESHOOTING

Symptom. Probable cause Remedy

Excessive play in steering | Loose yoke plug Retighten

Loose steering gear mounting bolts Retighten

Loose or worn tie rod end Retighten or replace as necessary)

Steering wheel operation is not | V-belt slippage

smooth (Insufficient power | Damaged V-belt Readjust

assist) Low fluid level Replace

Airinthe uid Replenish,

Twisted or damaged hoses Bleed air

Insufficient oil pump pressure Comrect the routing or replace

Sticky flow control valve Repair or replace the oil pump

Excessive intemal oil pump leakage Replace

Excessive oil leaks from rack and pinion in| Replace the damaged parts

gear box Replace the damaged parts

Distorted or damaged gear box or valve body. | Replace

seals

Steering wheel does not retum | Ex cessive tuning resistance of tierodend | Replace

properly ‘Yoke plug excessively tight Adjust

Tie rod and/or ball joint cannot tum smoothly | Replace

Loose mounting of gear box mounting bracket | Retighten

‘Wom steering shatt joint and/or body grommet | Correct or replace

Distorted rack Replace

Damaged pinion bearing Replace

Twisted or damaged hoses Reposition or replace

Page 11 of 42

Damaged oil pressure coutrol valve Replace

Damaged oil pump input shaft bearing Replace

Noise Hissing Noise in Steering Gear

There is some noise with all power steering systems. Oue of the most common is

a hissing sound when the steering wheel is tumed and the car is not moving. This

noise will be most evident when tuming the wheel while the brakes are being

applied. There is no relationship between this noise and steering performance. Do

not replace the valve unless the "hissing" noise becomes extreme. A replaced

valve will also make a slight noise, and is not always a solution for the condition

Rattling or chucking noise in| Interference with hoses fiom vehicle body | Reposition

the rack and pinion Loose gear box bracket Retighten,

Loose tie rod end and/or ball joint Retighten,

‘Wor tie rod and/or ball joint Replace

‘Noise in the oil pump Low fluid level Replenish

Air in the uid Bleed air

Loose pump mounting bolts Retighten

Steering System > Steering Column & Shaft > Steering Column-Shaft > Components and Components

Location

COMPONENTS

Page 12 of 42

TORQUE : Nm (kgf-m, Ib-ft)

1. steering whoo! 7. Steering column shaft mounting bot

2. Steering column shat assembly 8. Stoorng columa she mounting nut

Universal joint assombly 9. Titlever

4. Steering column shaft mounting bolt 10. Steering column lower shoud

5. Steering column upper shroud 11. Steering coum lower shroud mounting bot

[6 Universal joint mounting bot 12. Mutitunetion atch

Steering System > Steering Column & Shaft > Steering Column-Shaft > Repair procedures

REMOVAL

1, Disconnect the negative (-) tenninal(A) from the battery.

2. Take away the bolts (A) in the illistration, and then remove the driver's airbag module(B)

A

IN

Remove the steering wheel lock mut(A),

Page 13 of 42

4, Afr aligning the marks on the steering shaft and wheel(A), remove the steering wheel using the special tool

(09361-11002).

noe

Do not hammer ou the steering wheel to remove it: it may damage the steering column

Page 14 of 42

5. Remove the steering column upper(A) and lower shrouds(B),

Page 15 of 42

9, Remove the bolts connecting the steering column shaft(A) aud the universal joint(B) as shown in the illustration,

Keep the neutral-range to prevent the damage of the clock spring imer cable when you handlethe steering

wheel.

10. After removing the mounting bolts and nuts on the steering colunn and shaft assembly, remove the steering

column and shaft assembly(A).

A

#

DISASSEMBLY AND REASSEMBLY

KEY LOCK ASSEMBLY

1 Ifit is necessary to remove the key lock assemibly(A), use a punch to make a groove on the head of the special

bolt(B), and then use a screweliverto remove the key lock assembly mounting bracket(C).

Page 16 of 42,

2. Disassemble the key lock assembly(A) fiom the steering colunn and shaft assembly(B).

3, Reassembly is the reverse of disassembly.

UNIVERSAL JOINT ASSEMBLY

1, Remove the bolt(C) connecting the universal joint assembly(A) and the steering column and shaft assembly(B)

3. Reassembly is the reverse of disassembly.

INSPECTION

1. Check the steering column shaft for damage and deformation.

2. Check connections for play, damage and smooth operation,

3. Check: the ball joint bearing for wear and damage.

INSTALLATION

Assembly is the reverse of removal.

When installing the clock spring. refer the RT group to prevent the damage of clock spring inner cable

Page 17 of 42,

Steering System > Hydraulic Power Steering System > Power Steering Gear Box > Components and

‘Components Location

COMPONENTS

1. Tie rod end assembly 4. Feed tubo

12. Tie rod assembly 5. Joint assembly

‘3. Bellows

Page 18 of 42,

2

23

24

1. Feed tube 9. Rack suppor spring 17. Bellows clip

'2. Valve body housing 10, Lock nut 18. Dust cover

‘3. Bolt 111, Power steering gear box mounting clamp 19, Bellows

\4. Yoke plug 12. Rack housing 20, Bellows band

'5. Oli seal 13, Rack 21, Tie rod

\6. Pinion valve assembly 14, Oil seal 22. Circip

'7. Oil seal 15, Tie rod end 23. Oll seal

\B. Rack support yoke 16. Look nut 24. Rack stopper.

Steering System > Hydraulic Power Steering System > Power Steering Gear Box > Repair procedures

REMOVAL

Page 19 of 42

1. Disconnect the cover fixing clip(A) on the universal joint indoor driver inside, loosen the noise covers(B).

ah

nounting bolt and disconnect the universal joint fiom the gear box.

Keep the neutral-range to prevent the damage of the clock spring imer cable when you handlethe steering

wheel.

3. Lift up the vehicle

4, Remove the front tites (RH/LH).

5. Remove the engine under cover.

6. After removing the split pin, disconnect the tie rod() from the knuckle(B) by using the special tool (09568-

34000).

7. Remove the stabilizer link(B) frou the strut assembly(A).

4

9. Remove the propeller shafi(A) and the front muffler assembly(B),

11. Drain power steering oil.

Page 20 of 42,

Page 21 of 42,

12, Remove the couneeting bolt(A) for pressure tubes.

13, Remove two engline mounting bolts(B ©) and six subframe mounting bots in order to remove the subfiame(),

Tightening torque :

engine mounting bolts

50 ~ 65 Nm (5 ~ 6.5 kgf-m, 37 ~ 47.8 lb-ft)

DISASSEMBLY,

Page 22 of 42

1, Remove the tie rod end(A) fiom the tie rod(B).

2, Affer mounting the tie 1od end(A) in a vise, eemove the dust cover(B) fiom the ball joint.

ae

Remove the bellows band(A)

‘a

4. Remove the bellows clip(A).

Page 23 of 42,

5. Pull the bellows out towaud the tie rod.

Check for rust on the rack when the bellows are

replaced.

6, Remove the feed tube from the rack housing.

7. While moving the rack slowly, drain the fuid from the rack housing.

8. Unstake the tab washer(C) which fixes the tie rod(A) and rack(B) with a chisel.

9. Remove the tie rod(B) from the rack(A).

Remove the tie rod(B) fiom the rack), taking eare not to twist the

rack.

10, Remove the yoke plug locking nut(A), and then remove the yoke plug

dp

AL

B

14,

Page 24 of 42,

Remove the lock nut(A), yoke plug(B), rack suppoxt spring(C), rack suppost yoke(D) aud bushing) fiom the

gear box.

FR

SL)

Levy

Remove the valve body housing(B) by loosening the two bolts(A).

A

ft}

Remove the rack bushing and the rack from the rack housing.

Remove the O-ring(A) from the rack bushing(B).

Page 25 of 42,

16, Remove the pinion vlave assembly(C) from the valve body housing(®) with a soft hammer(A).

or <—"\ Bp

he

17. Using the special tool, eemove the oil seal and ball bearing fiom the valve body housing.

18, Remove the oil seal and O-ring fiom the rack housing

Be carefil not to damage the pinion valve cylinder inside of the rack

howing

9, Using the special tool(06573-21200, 09555-21000), remove the oil seal(B) from the rack housing(A),

nn

Be carefull not to damage the rack cylinder inside of the rack housing.

Backup washer

INSPECTION AND ADJUSTMENT BEFORE DISASSEMBLY

Go

‘When mounting the gear box in a vise, ensure the gear box is mounted as shown in the follwing illustration to avoid

damage

Page 26 of 42

TOTAL PINION PRELOAD

1. Rotate the pinion gear for approximately 4 to 6 seconds for one rotation to measure the total pinion preload.

Standard value :

Total pinion preload

6~ 1.3 Nm (0.06 ~ 0.13 kgm, 0.4 ~ 1 Ib-fi)

Measure the pinion preload through the entire stroke of the rack,

FS

dea

2. Ifthe measured value is out of specifications, frst adjust the yoke plug, then recheck the total pinion preload.

3. Ifyou adjust the yoke plug but do not obtain the total pinion preload, check or replace the yoke plug components

TIE ROD SWING RESISTANCE

1. Rotate the tie rod severely ten times,

2. Measure the tie rod(A) swing resistance with a spring scale(B)

Standard valu

Total rod swing resistance :

8~22.N(1.9-4.6 Ib) [2 ~ 5 Nm (0.2 ~ 0.5 kgf'm, 17 ~ 43 Ib-in)]

3. Ifthe measured value exceeds the standard value, replace the tie rod as sembly.

Even if the measured value is below the standard value, the tie rod that swings smoothly without excessive

play may be used. If the measured vahte is below 4.3 N (0.9 1b) [100 Nem (8.7 Ib-in)], replace the tie

rod.

BELLOWS INSPECTION

1 Inspect the bellows for damage or deterioration.

Page 27 of 42,

2. Make sure the bellows are secured in the coueet position.

3. Ifthe bellows are defective, zeplave them with new ones.

REASSEMBLY

1. Apply the specified fluid to the entire surface of the rack oil seal.

Recommended fluid : PSE-3

2. Install the oil seal(A) tothe specified position in the rack housing.

Apply the specified fluid to the entire surface

of the rack bushing oil seal .

Recommended fluid : PSF-3

4, Install the oil seal(B) in the rack bushing(),

5. Apply the specified fluid to the entire surface of the O-ring and install itn the rack bushing

Page 28 of 42

6. Apply the specified grease to the rack teeth,

Recommended grease :

Multipurpose grease SAE 3310, NLGI No.2

Do not plug the vent hole(A) in the rack with grease

7

7. Inset the rack info the rack housing and install the rack bushing and rack stopper.

Install the oil seal and the ball bearing in the valve body

9. After appling the specified fluid and grease to the pinion valve assembly(), install it in the rack housing assembly.

aia

10, After applying the specified fluid tothe oil seal, install it in the rack housing, and fix the valve body assembly(B)

and O-ring in the gear box(A).

Page 29 of 42

11. Install the tab washer and the tie rod and stake the tab washer(A) end at two points over the tie rod

12

B

1. Align the tab washer pavls with the rack grooves.

2. Always use a new tab washer.

O»

sq Ve

x

Tastall the bushing(), rack support yoke(B).

shown in the illustration. Apply semi-drying

installation.

|, rack support spring(C), lock nut(E) and yoke plug(D) in the order

sealantto to the threaded section of the yoke plu g before

With the rack placed in the center position, a

the specified torque.

tach the yoke plug to the rack housing. Tighten the yoke plug to

15 Nun (1.5 kef'm, 11 IDE). Loosen the yoke plug approximately from 30° to60° and tighten the locking nut to

Tightening torque :

50 ~ 70 Nm (5 ~7 kgf'm, 37 ~ 52 Ib-ft)

14, Tighten the feed tube to the specified torque and install the mounting rubber using adhesive.

Page 30 of 42

15. Apply the specified grease to the bellows mounting position (Liting groove) of the tie rod,

Silicone grease

J

WAAAY

16. Install the new attaching band to the bellows.

‘When the bellows are installed, a new band must be

used,

17. Install the bellows in position, taking care not to twist it

18. Fill the dust cover inner side and lip with the specified grease, and fix the dust cover in position with the clip ring

attached in the grooveof the tie rod end.

Recommended greas :

A: POLY LUB GLY 801K or equivalent

B: SHOWA SUNLIGHT MB? or equivalent

Dust cover inner side and lip : THREE BOND

8

A

“|

A &

a and

Page 31 of 42

19. Install the tie rods so that the length of the left and right tie rods equals the standard value.

Standard value :

Tie rod five length : 112.2 mm,

———

20. Check for total pinion preload.

Total pinion preload :

0.6 ~ 1.3 Nun (0.06 ~ 0.13 kefim, 5.2 ~ 11.3 I-ft)

INSTALLATION

1. Insiallation is the reserve of removal.

2. Add power steering fluid.

3. Air bleed the system.

Steering System > Hydraulic Power Steering System > Power Steering Hoses > Components and

‘Components Location

COMPONENTS

Page 32 of 42

1

1. Power steering oil reservoir 6. Retum hose.

'2. Suction hose 7. Pressure tube

‘3. Power steering oil pump assembly 8. Tie rod end

'4, Pressure hose and tube assembly 9. Tie rod end

'5. Feed tube 10. Power steering gear box assembly

Steering System > Hydraulic Power Steering System > Power Steering Hoses > Repair procedures

REMOVAL

1. Drain the power steering oil

Page 33 of 42,

2. Remove both the pressure tube fitting(A) and the retum hose clamp(B) fiom the gearbox. after lifting the vehicle.

#

A

(8

(FA

ee

hose clamp(C).

Remove the pressure tube connecting bolt(A) and the pressure hose mounting bol), then remove the retum

Remove the pressure tube mounting boli(A) and the return tube mounting bol(B).

Tightening torque :

B:7~11 Nm(0.7~ 1.1 kef'm,

A: 90 ~ 100 Nun (9 ~ 10 kef'un, 65 ~ 72 lb-ft)

7.9 lb-ft)

Page 34 of 42,

5. Remove the pressure tube bolt(A) and clamp(B), after lowering the vehicle,

tubeB)

INSTALLATION

1. Installation is the reverse of removal.

2. Add power steering fd.

+ While installing the tube and hose assembly, be sure to align white marks(A) on each fiting,

+ Install the pressure hose and tube so that they are not twisted and they do not come in contact with any

other parts.

+ After installation, air bleed the system.

Page 35 of 42

Steering System > Hydraulic Power Steering System > Power Steering Oil Pump > Components and |

‘Components Location

COMPONENTS

|1. Pulley & driveshaft assembly 9. Var 17. Oil pump side plate

2. Oil seal 40. Rotor 418. O-ring (Outer)

3. Bush 11. Dowel pin 19. Orting (Inner)

l4. Front housing 12. Oil pump cover assembly 20. Connector

'5. O-ting 13, Mounting bolt 21. O-ring

. Suction pipe 14, O-ring 22. Spring

z Mounting bot 15. Soop tog

3. Side plate soring 16. Cam rng

13

Steering System > Hydraulic Power Steering System > Power Steering Oil Pump > Repair procedures

REMOVAL

Page 36 of 42,

1. Loosen the bolt fixing the wiring bracket, and then move the witing sideward

Remove the pressure hose(A) fiom the oll pu

ump(B), and then disconnect the suetion hose(C) fiom the suetion

connector aud dain the fluid into a container. (see page ST-11)

° a

vA Ss

Go

Loosen the tension adjusting bolt(A) on the power steering."

Page 37 of 42

5. Loosen the power steering oil pump mounting bolt and the tension adjusting bolt, and then remove the steering oil

tunp assembly(A).

REASSEMBLY

1. Install the flow control spring, the flow control valve and the connector into the pump body.

3. lusall the pump pulley(A).

es

v

~T

4, Assengle the inner O-ting and the outer O-tin

ng and install the site plate(A),

=

Sy

5. Install the cam ring attending to the groove an

nd the direction of the front housing.

SD

OP 01 purp aver sido

6. stall the rotor

7. Install vanes(A) to the rotor(B).

Be sure to place vanes with a round side

out

Page 38 of 42,

Page 39 of 42,

8, Install the O-ring and the oil pump cover assembly.

9, Install the suetion pipe(A) and O-ring.

INSPECTION

1. Check the fie length of the flow control spring.

Free length of the flow control spring : 36.5mm

2. Check that the flow control valve is not bent

3. Cheek the shaft for wear and damage.

4, Check the V-belt for wear and deterioration.

5. Cheek the grooves of the rotor and vanes for stratified abrasion.

6. Check the contact surface of the cam ring and vanes for stratified abrasion.

7. Check vanes for damage

8. Check that there is no striped wear in the side plate or contacting part between the shaft and the pump cover

surface.

DISASSEMBLY

1, Remove two bolts(A) from the oil pump body, and then remove the suction pipe(B) and O-ring(C),

Page 40 of 42

2. Loosen the four bolts and remove the oil pump cover assemb ly.

3. Remove the cam ting

4, Remove the zotor and vanes.

5. Remove the oil pump side plate.

1a(B).

Remove the snap ring and take out the pulley and the drive shaft assembly(),

8, Remove the oil seal(A) fiom the oil pump body.

Page 41 of 42

9. Remove the connector fiom the oil pump body, and take out the flow control valve and the dow control spring.

emaxeo Of) doe)

INSTALLATION

1. Install the oil pump(A) to the oil pump bracket,

2. Hang the "V" belt on the oil pump and connect the suction hose() and the pressure hose(B)

Install the hose being careful so that it does not twist and come in contact with other

‘components.

Page 42 of 42

3. Insert a bau(C) or similar tod between the bracket(A) aud the oil pump(B) to produce tension and confium that

belt deflection is within the standard value.

4, Add power steering fluid. (see page to ST-10)

5. Air bleed the system. (see page to ST-10)

6. Check the oil pump pressure. (see page to ST-11)

You might also like

- Sportage: Workshop ManualDocument67 pagesSportage: Workshop ManualmiguelNo ratings yet

- Defogger: SectionDocument38 pagesDefogger: SectionmiguelNo ratings yet

- PDF Toyota Manual de Taller Manual de Reparaciones y Mantenimiento Toyota Hi DDDocument109 pagesPDF Toyota Manual de Taller Manual de Reparaciones y Mantenimiento Toyota Hi DDmiguelNo ratings yet

- Replacement of Rear DOJ and BJ Boots: A: RemovalDocument2 pagesReplacement of Rear DOJ and BJ Boots: A: RemovalmiguelNo ratings yet

- Oil Pump: A: RemovalDocument5 pagesOil Pump: A: RemovalmiguelNo ratings yet

- Manual Transaxle System - M6CF3-1 - 1.6LDocument26 pagesManual Transaxle System - M6CF3-1 - 1.6LmiguelNo ratings yet

- Heating, Ventilation & Air ConditioningDocument95 pagesHeating, Ventilation & Air ConditioningmiguelNo ratings yet

- Front Strut: A: RemovalDocument4 pagesFront Strut: A: RemovalmiguelNo ratings yet

- Steering SystemDocument23 pagesSteering SystemmiguelNo ratings yet

- Front Crossmember: B: InspectionDocument2 pagesFront Crossmember: B: InspectionmiguelNo ratings yet

- Rear Differential Mounting SystemDocument1 pageRear Differential Mounting SystemmiguelNo ratings yet

- Rear StabilizerDocument2 pagesRear StabilizermiguelNo ratings yet

- Door and Related PartsDocument1 pageDoor and Related PartsmiguelNo ratings yet

- Front Transverse Link: A: RemovalDocument3 pagesFront Transverse Link: A: RemovalmiguelNo ratings yet

- Tire Rotation: Caution: When Rotating Tires, Replace Unevenly Worn or Damaged Tires With New OnesDocument2 pagesTire Rotation: Caution: When Rotating Tires, Replace Unevenly Worn or Damaged Tires With New OnesmiguelNo ratings yet

- Rear Drive Shaft AssemblyDocument1 pageRear Drive Shaft AssemblymiguelNo ratings yet

- Wheel Balancing: 9. Installation of Wheel Assembly To VehicleDocument1 pageWheel Balancing: 9. Installation of Wheel Assembly To VehiclemiguelNo ratings yet

- Propeller Shaft: A: On-Car ServiceDocument3 pagesPropeller Shaft: A: On-Car ServicemiguelNo ratings yet

- Msa5t0128a34681 PDFDocument2 pagesMsa5t0128a34681 PDFmiguelNo ratings yet

- Application Table 6. Wheel BalanceDocument1 pageApplication Table 6. Wheel BalancemiguelNo ratings yet

- MSA5T0126A27919Document1 pageMSA5T0126A27919miguelNo ratings yet

- Rear Strut: A: RemovalDocument3 pagesRear Strut: A: RemovalmiguelNo ratings yet

- Oil Cooler (AT Vehicles Only) : A: RemovalDocument2 pagesOil Cooler (AT Vehicles Only) : A: RemovalmiguelNo ratings yet

- MSA5T0125A27743Document1 pageMSA5T0125A27743miguelNo ratings yet

- MSA5T0128A34678Document1 pageMSA5T0128A34678miguelNo ratings yet

- Engine Coolant Temperature Sensor: A: Removal and InstallationDocument1 pageEngine Coolant Temperature Sensor: A: Removal and InstallationmiguelNo ratings yet

- Select Monitor Function Mode: 3. Trouble Codes Are DisplayedDocument2 pagesSelect Monitor Function Mode: 3. Trouble Codes Are DisplayedmiguelNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)