Professional Documents

Culture Documents

Durastrength ® 4000 - TDS

Uploaded by

fredCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Durastrength ® 4000 - TDS

Uploaded by

fredCopyright:

Available Formats

Durastrength ® 4000

Multifunctional Acrylic Impact Modifier

PRODUCT DESCRIPTION 2. Faster fusion than alternative non-acrylic impact modifiers without the

need for additional processing aids.

Durastrength® 4000 acrylic impact modifier represents the newest, low

cost technology that imparts excellent impact properties to rigid PVC

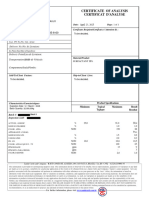

Torque Rheometer Fusion (175°C, 75rpm and 100 cc sample size)

products and provides outstanding processability. Durastrength® 4000

impact modifier can be used in place of alternative non-acrylic impact Torque RheometerFusion: 175C,°75 RPM and 100 cc sample size

modifiers while maintaining the processing advantages of traditional 3500

acrylic impact modifiers. Alternative Impact Modifier 1

Alternative Impact Modifier 2

3000 Durastrength ® 4000

Durastrength ® 200

2500

TYPICAL PHYSICAL PROPERTIES Torque (mg)

2000

Physical Form White Powder

Specific Gravity 1.47 1500

Bulk Density 0.50 g/cc

1000

Particle Size 15% Max on 50 Mesh 0 1 2 3 4 5 6 7

Percent Volatiles 1.2% Max Time (min)

3. Substrate applications utilizing Durastrength® 4000 impact modifier

maintain important mechanical properties for final PVC product

PRODUCT BENEFITS

performance.

1. Excellent impact resistance that is equivalent to or better than

alternative non-acrylic impact modifiers. Mechanical Property Performance (Tensile and HDT Evaluation)

Impact Resistance [Izod Impact Performance (Siding Substrate

Young’s Tensile Heat

Formulation @ 4.5phr Modifier)] Impact Modifier Modulus Stress @ Deflection

(psi)* Yield (psi)* Temp. (!C )**

Izod Impact Performance (Siding Substrate Formulation @ 4.5phr Modifier)

Alternative Impact Modifier 1 431893 6388 65

5.0

Alterative Impact Modifier 2 445543 6488 66

4.5 Durastrength® 4000 471580 6397 65

Durastrength® 200 445731 6336 66

- lb/in)

4.0

Impact Strength (ft

* Evaluation followed ASTM D-638

3.5 ** Evaluation followed ASTM D-648

Impact modifiers tested at 4.5 phr

3.0

2.5

4. Durastrength® 4000 impact modifier has traditional acrylic

2.0

characteristics such as a low melt viscosity which when employed in a

Alternative Impact Alternative Impact Durastrength ® 4000 Durastrength ® 200

Modifier 1 Modifier 2 vinyl formulation results in good stability, smooth processing, and high

output rates.

ENVIRONMENTAL AND Durastrength® Impact FOR MORE INFORMATION

SAFETY INFORMATION Modifiers CONTACT

BEFORE HANDLING THIS MATERIAL, Durastrength® acrylic impact modifiers Please contact your local account

READ AND UNDERSTAND THE MSDS deliver outstanding impact characteristics manager or our headquarters:

(MATERIAL SAFETY DATA SHEET) / for outdoor durable applications in PVC

SDS (SAFETY DATA SHEET) FOR and Engineering Resins. In Europe:

ADDITIONAL INFORMATION ON ARKEMA

SAFETY, HEALTH AND Plastistrength® Process Aids Arkema Coating Resins

ENVIRONMENTAL INFORMATION. 420 Rue d’Estienne d’Orves

Plastistrength® process aids offer

DURASTRENGTH 4000/4686E/09.2019/pdf - PlastAdd - Photos : Getty images - Design : www.ideephare.com

The MSDS/SDS are available on our 92705 COLOMBES Cedex, France

Arkema France - Société Anonyme immatriculée au R.C.S. de Nanterre (France) sous le numéro 319 632 790

producers a complete line of melt

Website www.arkema.com or upon Tel: +33 (0) 149 008 080

strengtheners and metal release

request at our Customer Service www.arkema.com/en/products/contact

agents for PVC and Engineering Resins.

Department. Arkema believes strongly

Plastistrength® process aids can improve

in Responsible Care® as a public In US:

fusion, surging, and aesthetics.

commitment. Arkema Inc.

Coating Resins

Clearstrength® Impact

MORE TECHNICAL 410 Gregson Dr

Modifiers

INFORMATION Cary, NC 27511

AVAILABLE Clearstrength® MBS impact modifiers Tel: +1 (877) 331-6696

are designed for extreme impact or www.arkema.com/en/products/contact

Ask your Arkema account manager for

impact/clarity combination in PVC

further information on high quality

and Engineering Resins. In Asia:

Arkema additives for use in PVC, PC,

Arkema Pte Ltd.

PBT, ABS, PLA and other polymer

Biostrength® Additives 10, Science Park Road, #01-01A,

systems. Arkema produces a full line of

Biostrength® product line of impact The Alpha Singapore Science Park II,

impact modifiers, processing aids and

Singapore 117684 Tel: +65 6419 9199

epoxidized vegetable oils. In addition, modifiers, melt strengtheners and metal

www.arkema.com/en/products/contact

Arkema’s Technical Service staff is release agents are designed to improve

also available to assist compounders properties and enhance processability

VISIT US AT OUR WEBSITE

and processors with formulation and of polylactic acid (PLA) and other

www.additives-arkema.com

processing advice. biopolymers compounds.

www.arkema.com

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of the pro-

duct and of the information referred to PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED, IS MADE CONCERNING

THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN. The information provided herein relates only to the specific product designated and may not be applicable

when such product is used in combination with other materials or in any process. The user should thoroughly test any application before commercialization. Nothing contained

herein constitutes a license to practice under any patent and it should not be construed as an inducement to infringe any patent and the user is advised to take appropriate steps to

be sure that any proposed use of the product will not result in patent infringement. See SDS for Health & Safety Considerations. Arkema has implemented a Medical Device Policy

regarding the use of Arkema products in medical device applications that are in contact with the body or circulating bodily fluids: (http://www.arkema.com/en/social-responsibi-

lity/ responsible-product-management/medical-device-policy/index.html). Arkema has designated Medical grades to be used for such medical device applications. Products that

have not been designated as medical grades are not authorized by Arkema for use in medical device applications that are in contact with the body or circulating bodily fluids.

In addition, Arkema strictly prohibits the use of any Arkema products in Medical Device applications that are implanted in the body or in contact with bodily fluids or tissues for

greater than 30 days.

The Arkema trademarks and the Arkema name shall not be used in conjunction with customers’ medical devices, including without limitation, permanent or temporary implantable

devices, and customers shall not represent to anyone else, that Arkema allows, endorses or permits the use of Arkema products in such medical devices. It is the sole responsibility of

the manufacturer of the medical device to determine the suitability (including biocompatibility) of all raw materials, products and components, including any medical grade Arkema

products, in order to ensure that the final end-use product is safe for its end use; performs or functions as intended; and complies with all applicable legal and regulatory require-

ments (FDA or other national drug agencies) It is the sole responsibility of the manufacturer of the medical device to conduct all necessary tests and inspections and to evaluate the

medical device under actual end-use requirements and to adequately advise and warn purchasers, users, and/or learned intermediaries (such as physicians) of pertinent risks and

fulfill any postmarket surveillance obligations. Any decision regarding the appropriateness of a particular Arkema material in a particular medical device should be based on the

judgment of the manufacturer, seller, the competent authority, and the treating physician.

Clearstrength® and Plastistrength® are registered trademarks of Arkema.

Biostrength® and Durastrength® are registered trademarks of Arkema Inc.

Responsible Care® is a registered trademark of the American Chemistry Council Inc.

2019 Arkema Inc. All rights reserved.

Headquarters: Arkema France

420, rue d’Estienne d’Orves

92705 Colombes Cedex – France

Tél. : 33 (0)1 49 00 80 80

Fax : 33 (0)1 49 00 83 96

arkema.com arkema.com

You might also like

- Stockosorb 660 - PTDocument2 pagesStockosorb 660 - PTfredNo ratings yet

- Coa - Surfact 30 - ZaniniDocument1 pageCoa - Surfact 30 - ZaninifredNo ratings yet

- Zanini, Curtis & Company - August 2022Document27 pagesZanini, Curtis & Company - August 2022fredNo ratings yet

- MSDS - Sulfochem (TM) TD-3 PHP SurfactantDocument11 pagesMSDS - Sulfochem (TM) TD-3 PHP SurfactantfredNo ratings yet

- Zanini, Curtis & Company - August 2022Document27 pagesZanini, Curtis & Company - August 2022fredNo ratings yet

- Zanini, Curtis & Company - August 2022Document27 pagesZanini, Curtis & Company - August 2022fredNo ratings yet

- Plastistrength® 562 - SDSDocument14 pagesPlastistrength® 562 - SDSfredNo ratings yet

- Plastistrength® 551 - TDSDocument2 pagesPlastistrength® 551 - TDSfredNo ratings yet

- Plastistrength® 550 - SDSDocument14 pagesPlastistrength® 550 - SDSfredNo ratings yet

- Plastistrength® 550 - TDSDocument2 pagesPlastistrength® 550 - TDSfredNo ratings yet

- Plastistrength® 551 - SDSDocument14 pagesPlastistrength® 551 - SDSfredNo ratings yet

- Durastrength® 200 - TDSDocument3 pagesDurastrength® 200 - TDSfredNo ratings yet

- Durastrength ® 4000 - SDSDocument14 pagesDurastrength ® 4000 - SDSfredNo ratings yet

- PD - 1136 (1159) ® - SDSDocument14 pagesPD - 1136 (1159) ® - SDSfredNo ratings yet

- Durastrength ® 4000 - SDSDocument14 pagesDurastrength ® 4000 - SDSfredNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Naukri AngelinPrincy (6y 0m)Document2 pagesNaukri AngelinPrincy (6y 0m)TEMS ServicesNo ratings yet

- Manuf Sterility Testing GuidelinesDocument36 pagesManuf Sterility Testing GuidelinesAlief AnggaNo ratings yet

- CRCST 136Document5 pagesCRCST 136jerimiah_manzonNo ratings yet

- CAPA in Medical Devices ManufacturingDocument7 pagesCAPA in Medical Devices ManufacturingShantha Kumar ParameswaranNo ratings yet

- SRM Valliammai Engineering College: (An Autonomous Institution)Document13 pagesSRM Valliammai Engineering College: (An Autonomous Institution)vijayalakshmiNo ratings yet

- Gowns Risk IdentificationDocument16 pagesGowns Risk IdentificationIca LarissaNo ratings yet

- HTM 2010 P2 Des 1995Document96 pagesHTM 2010 P2 Des 1995Cinzio SinebroNo ratings yet

- 2016 Gap Analysis TemplateDocument14 pages2016 Gap Analysis Templateamit545100% (1)

- Technical Data Sheet: BD Microlance™ 3 Hypodermic Needle Sterile, Single Use, Latex FreeDocument9 pagesTechnical Data Sheet: BD Microlance™ 3 Hypodermic Needle Sterile, Single Use, Latex FreeKranti yadavNo ratings yet

- Guidance For Industry and FDA Staff in Vitro Diagnostic (IVD) Device Studies Frequently Asked QuestionsDocument53 pagesGuidance For Industry and FDA Staff in Vitro Diagnostic (IVD) Device Studies Frequently Asked QuestionsDummy Tester JrNo ratings yet

- A Review of The Changes in ISO 13485Document4 pagesA Review of The Changes in ISO 13485Ola Gf OlamitNo ratings yet

- ASG Memo - Medical Equip & Cons Strategy - Strategic Goods and ServicesDocument5 pagesASG Memo - Medical Equip & Cons Strategy - Strategic Goods and ServicesPoli ClibeNo ratings yet

- DBEABE614Document6 pagesDBEABE614bariNo ratings yet

- Document ChecklistDocument2 pagesDocument Checklistbilijoabucejo.acmhNo ratings yet

- ICMED Standard Book Final PDFDocument147 pagesICMED Standard Book Final PDFShekharNo ratings yet

- Ha17324a LM324Document10 pagesHa17324a LM324ApriadiNo ratings yet

- NeerajPathak (7 0) Ringing No Response 20july2021Document6 pagesNeerajPathak (7 0) Ringing No Response 20july2021CE CERTIFICATENo ratings yet

- 05 Industrial Pharmacy II Unit VDocument15 pages05 Industrial Pharmacy II Unit VRahul VermaNo ratings yet

- Technical Tip: Sterility Assurance Levels (Sals) : IrradiationDocument3 pagesTechnical Tip: Sterility Assurance Levels (Sals) : IrradiationRakeshNo ratings yet

- Kiran Medical Systems-Corporate-eBrochureDocument26 pagesKiran Medical Systems-Corporate-eBrochureSaifuddin HaswareNo ratings yet

- Economic Development Quarterly 2012 Kimelberg 34 49Document17 pagesEconomic Development Quarterly 2012 Kimelberg 34 49Hamayoun MurtazaNo ratings yet

- AGFA CR30 X Service Manual PDFDocument429 pagesAGFA CR30 X Service Manual PDFWellington Trajano100% (2)

- Checklist of Mandatory Documentation Required by ISO 13485:2016Document17 pagesChecklist of Mandatory Documentation Required by ISO 13485:2016Gonzalo MazaNo ratings yet

- Iec 60601-1-2.2014 + Amd1.2020Document222 pagesIec 60601-1-2.2014 + Amd1.2020Al Ben MorNo ratings yet

- MDR Guideline Medical Devices LabelingDocument7 pagesMDR Guideline Medical Devices Labelingarade43100% (1)

- Vector SbsDocument2 pagesVector SbsHau TranNo ratings yet

- Cardioline Ar1200view - User Manual PDFDocument56 pagesCardioline Ar1200view - User Manual PDFgroningerwinklerNo ratings yet

- RAPS Brochure PDFDocument16 pagesRAPS Brochure PDFdvdynamic1No ratings yet

- Medical Device Design Using Polymer CompoundsDocument6 pagesMedical Device Design Using Polymer CompoundsAkash DoshiNo ratings yet

- ISO 13485 OverivewDocument6 pagesISO 13485 OverivewMarlin PohlmanNo ratings yet