Professional Documents

Culture Documents

Plastistrength® 551 - TDS

Uploaded by

fredCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plastistrength® 551 - TDS

Uploaded by

fredCopyright:

Available Formats

Plastistrength ® 551

Acrylic Process Aid

PRODUCT DESCRIPTION PACKAGING

Plastistrength® 551 process aid is a medium molecular weight acrylic Plastistrength® 551 process aid is packaged in 20 kg bags and 500 kg

process aid that brings enhanced processability at low use levels to and 1000 lb bulk bags.

most rigid and flexible vinyl compounds such as siding, profile, pipe,

calendered sheet, and blow-molded bottles.

STARTING FORMULATION

RECOMMENDATIONS

TYPICAL PHYSICAL PROPERTIES

Rigid Bottle General

Physical Form White Powder PVC Resin (K-57) 100.0 phr

Specific Gravity 1.17 Methyl/Octyl Organotin Stabilizer 1.5 - 2.0

Bulk Density 0.45 g/cc Internal Lubricant 1.5 - 2.0

Particle Size 2% Max on 40 Mesh External Lubricant 0.1 - 0.2

Percent Volatiles 1.2% Max Plastistrength® 551 Process Aid 1.5 - 2.0

Plastistrength 770 Process Aid

®

0.5 -1.0

Clearstrength 350 or 320 Impact Modifier

®

12.0 - 15.0

PRODUCT BENEFITS Toner As required

1. Plastistrength 551 process aid imparts good melt strength to vinyl

®

Rigid Calendered Film and Sheet General

formulations during processing. PVC Resin (K-60) 100.0 phr

2. Plastistrength 551 process aid generates even control over fusion at

® Methyl/Octyl Organotin Stabilizer 0.6 - 1.5

reduced use levels for ease of processing and maximum development of Internal Lubricant 1.5 - 2.0

physical properties. External Lubricant 0.1 - 0.2

3. Plastistrength 551 process aid has been extensively tested in

®

Plastistrength 551 Process Aid

®

1.5 - 2.0

weatherable applications and is widely used in exterior PVC building Plastistrength® 770 Process Aid 0.7 -1.0

products where good weathering performance is critical.

Clearstrength 320 Impact Modifier

®

6.0 - 12.0

Toner As required

SUGGESTIONS FOR USE

Weatherable Profile NA Europe

Plastistrength 551 process aid is recommended for applications such

® PVC Resin (K65-68) 100 phr 100 phr

as vinyl siding, profiles, calendaring, pipes and fittings. Plastistrength® Methyl Organotin Stabilizer 1.0 - 1.5 –

551 is commonly used in PVC formulations for food or pharmaceutical Ca/Zn one-pack – 3.5 - 4.0

packaging. Dedicated information on formulation and regulatory status is Calcium Stearate 1.2 - 1.5 –

available upon request. Parrafin Wax (165oF) 1.0 - 1.2 –

Customers should evaluate Plastistrength 551 process aid in their own

® Plastistrength® 551 Process Aid 0.8 - 1.1 0.5 - 1.1

laboratories to establish optimum conditions for use in their processes Plastistrength® 770 Process Aid 0.3 - 0.5 0.0 - 0.5

and applications. Arkema’s Technical Service Team is available to Durastrength® 200 Impact Modifier 5.0 - 6.0 5.0 - 6.0

discuss your application requirements, provide formulation guidance and Calcium Carbonate (0.7 μm) 0.0 - 5.0 0.0 - 13.0

laboratory testing as needed. Titanium Dioxide 9.0 - 10.0 3.5 - 5.5

environmental and Durastrength ® Impact Modifiers for more information

safety information Durastrength ® acrylic impact modifiers contact

deliver outstanding impact characteristics

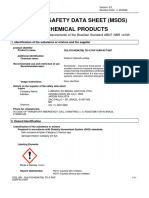

BEFORE HANDLING THIS MATERIAL, for outdoor durable applications in PVC Please contact your local account

READ AND UNDERSTAND THE MSDS and Engineering Resins. manager or our headquarters:

(MATERIAL SAFETY DATA SHEET) / SDS

In Europe:

Arkema France - A French “société anonyme“, registered in the Nanterre (France) Trade and Companies Register under the number 319 632 790

(SAFETY DATA SHEET) FOR ADDITIONAL Plastistrength ® Process Aids

Plastistrength ® process aids offer ARKEMA

INFORMATION ON SAFETY, HEALTH

producers a complete line of melt Arkema Coating Resins

AND ENVIRONMENTAL INFORMATION.

strengtheners and metal release agents 420 Rue d’Estienne d’Orves

The MSDS/SDS are available on our for PVC and Engineering Resins. 92705 COLOMBES Cedex, France

Website www.arkema.com or upon Plastistrength ® process aids can improve Tel: +33 (0) 149 008 080

request at our Customer Service fusion, surging, and aesthetics. www.arkema.com/en/products/contact

Department. Arkema believes strongly

in Responsible Care ® as a public Clearstrength ® Impact Modifiers In US:

commitment. Clearstrength ® MBS impact modifiers Arkema Inc.

are designed for extreme impact or Arkema Coating Resins

more technical impact/clarity combination in PVC and 410 Gregson Dr

information available Engineering Resins. Cary, NC 27511

Ask your Arkema account manager for Tel: +1 (877) 331-6696

Biostrength ® Additives

further information on high quality Arkema www.arkema.com/en/products/contact

The Biostrength ® product line of impact

additives for use in PVC, PC, PBT, ABS, modifiers, melt strengtheners and metal

PLA and other polymer systems. Arkema In Asia:

release agents are designed to improve

produces a full line of impact modifiers, Arkema Pte Ltd.

properties and enhance processability

processing aids and epoxidized vegetable 10, Science Park Road, #01-01A,

of polylactic acid (PLA) and other

oils. In addition, Arkema’s Technical The Alpha Singapore Science Park II,

biopolymers compounds.

Service staff is also available to assist Singapore 117684 Tel: +65 6419 9199

NA-BCook-BCraig/ 5-2017

compounders and processors with www.arkema.com/en/products/contact

formulation and processing advice.

VISIT US AT OUR WEBSITE

www.additives-arkema.com

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of the product and of the information referred to

herein are beyond our control, Arkema expressly disclaims any and all liability as to any results obtained or arising from any use of the product or reliance on such information; NO WARRANTY OF FITNESS FOR ANY

PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED, IS MADE CONCERNING THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN. The

information provided herein relates only to the specific product designated and may not be applicable when such product is used in combination with other materials or in any process. The user should thoroughly test any

application before commercialization. Nothing contained herein constitutes a license to practice under any patent and it should not be construed as an inducement to infringe any patent and the user is advised to take

appropriate steps to be sure that any proposed use of the product will not result in patent infringement. See SDS for Health & Safety Considerations.

Arkema has implemented a Medical Device Policy regarding the use of Arkema products in medical device applications that are in contact with the body or circulating bodily fluids:

(http://www.arkema.com/en/social-responsibility/responsible-product-management/medical-device-policy/index.html). Arkema has designated Medical grades to be used for such medical device applications. Products

that have not been designated as medical grades are not authorized by Arkema for use in medical device applications that are in contact with the body or circulating bodily fluids. In addition, Arkema strictly prohibits the

use of any Arkema products in Medical Device applications that are implanted in the body or in contact with bodily fluids or tissues for greater than 30 days. The Arkema trademarks and the Arkema name shall not be

used in conjunction with customers’ medical devices, including without limitation, permanent or temporary implantable devices, and customers shall not represent to anyone else, that Arkema allows, endorses or permits the

use of Arkema products in such medical devices. It is the sole responsibility of the manufacturer of the medical device to determine the suitability (including biocompatibility) of all raw materials, products and components,

including any medical grade Arkema products, in order to ensure that the final end-use product is safe for its end use; performs or functions as intended; and complies with all applicable legal and regulatory requirements

(FDA or other national drug agencies) It is the sole responsibility of the manufacturer of the medical device to conduct all necessary tests and inspections and to evaluate the medical device under actual end-use requirements

and to adequately advise and warn purchasers, users, and/or learned intermediaries (such as physicians) of pertinent risks and fulfill any postmarket surveillance obligations. Any decision regarding the appropriateness

of a particular Arkema material in a particular medical device should be based on the judgment of the manufacturer, seller, the competent authority, and the treating physician.

Clearstrength® and Plastistrength® are registered trademarks of Arkema

Biostrength® and Durastrength® are registered trademarks of Arkema Inc.

Responsible Care® is a registered trademark of the American Chemistry Council Inc.

2017 Arkema Inc. All rights reserved.

www.plastistrength.com

You might also like

- Workbook For Organic Chemistry - Supplemental Problems and SolutionsDocument449 pagesWorkbook For Organic Chemistry - Supplemental Problems and SolutionsĐặng Nhung100% (1)

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- Durastrength ® 4000 - SDSDocument14 pagesDurastrength ® 4000 - SDSfredNo ratings yet

- Durastrength ® 4000 - SDSDocument14 pagesDurastrength ® 4000 - SDSfredNo ratings yet

- AngloGold Fire Assay Training ManualDocument42 pagesAngloGold Fire Assay Training ManualKenneth OrtizNo ratings yet

- Engineering Encyclopedia: Special Chemical Cleaning ProblemsDocument24 pagesEngineering Encyclopedia: Special Chemical Cleaning Problemscvg ertdNo ratings yet

- 0824746295Document395 pages0824746295Valeria RomeroNo ratings yet

- Atlas Copco Roto Inject Fluid JECDocument2 pagesAtlas Copco Roto Inject Fluid JECアラファト イスラム教No ratings yet

- Plastistrength® 550 - TDSDocument2 pagesPlastistrength® 550 - TDSfredNo ratings yet

- TDS - Plastistrength 770 - ArkemaDocument2 pagesTDS - Plastistrength 770 - ArkemaOscar Jimenez GonzalezNo ratings yet

- Technical Data Sheet Priomat® Pore Filler 3311: Substrate Application Recoating StorageDocument4 pagesTechnical Data Sheet Priomat® Pore Filler 3311: Substrate Application Recoating StorageАртем ШевчукNo ratings yet

- Thermolite 890F TDS Rev v3Document3 pagesThermolite 890F TDS Rev v3Qwerty RoyalNo ratings yet

- TDS - 57006 AddNox Anti Block MBDocument1 pageTDS - 57006 AddNox Anti Block MBRajiv DubeyNo ratings yet

- ELASTOSIL R 40170 S en 2021.07.01 v6Document3 pagesELASTOSIL R 40170 S en 2021.07.01 v6M J VoraNo ratings yet

- Product BulletinDocument1 pageProduct BulletinWHWENNo ratings yet

- ELASTOSIL R 40155 S en TdsDocument3 pagesELASTOSIL R 40155 S en Tdsxyzdominika275No ratings yet

- Ficha Tecnica NPT QUICK FLASH ADDITIVE M00009Document1 pageFicha Tecnica NPT QUICK FLASH ADDITIVE M00009Stéphanie BaltazarNo ratings yet

- Butonal NS 175 TDSDocument2 pagesButonal NS 175 TDSPT. PITAGORAS KONSULTANNo ratings yet

- Intraplast N 200 100816Document2 pagesIntraplast N 200 100816Brijendra Mani PandeyNo ratings yet

- Sinopec Crystal GreaseDocument2 pagesSinopec Crystal GreaseImran ImranNo ratings yet

- MOLYKOTE PA-744 Anti-Friction Coating 80-3214A-01-1Document2 pagesMOLYKOTE PA-744 Anti-Friction Coating 80-3214A-01-1Guillermo FormosoNo ratings yet

- Plasite 4550: Selection & Specification DataDocument4 pagesPlasite 4550: Selection & Specification DataAzar SKNo ratings yet

- CASTROL BIO TAC OG - Pds - Rev. 17.08.2022Document2 pagesCASTROL BIO TAC OG - Pds - Rev. 17.08.2022Massimiliano VolaNo ratings yet

- Specialty Lubricants: Molykote G-4500/G-4501 Multi-Purpose Synthetic GreaseDocument2 pagesSpecialty Lubricants: Molykote G-4500/G-4501 Multi-Purpose Synthetic GreaseRildo CarvalhoNo ratings yet

- Biograde WS-50Document4 pagesBiograde WS-50Xuân Giang NguyễnNo ratings yet

- MOLYKOTE G-Rapid Plus Paste 71-0084F-01Document2 pagesMOLYKOTE G-Rapid Plus Paste 71-0084F-01sungkarsNo ratings yet

- DAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and AdditivesDocument2 pagesDAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and Additives8612106535No ratings yet

- K R I T I L E N® Masterbatches: Additives Technical InformationDocument10 pagesK R I T I L E N® Masterbatches: Additives Technical InformationAnas AbdoNo ratings yet

- ELASTOSIL R 40275 S en 2019.11.05Document3 pagesELASTOSIL R 40275 S en 2019.11.05Jorge MendezNo ratings yet

- Data Sheet - BW30-PRO-400Document2 pagesData Sheet - BW30-PRO-400satheesh kumarNo ratings yet

- Glide 450 - eDocument1 pageGlide 450 - eTarkan AKÇAYNo ratings yet

- Durastrength 480: Technical InformationDocument6 pagesDurastrength 480: Technical InformationCnbc TrNo ratings yet

- Addocat® PP: Plastic Additives / PUR AdditivesDocument3 pagesAddocat® PP: Plastic Additives / PUR Additivessriatul2006No ratings yet

- ELASTOSIL R 40150 S en TdsDocument4 pagesELASTOSIL R 40150 S en Tdsxyzdominika275No ratings yet

- Product Features: Improved Collapse ResistanceDocument6 pagesProduct Features: Improved Collapse ResistanceCarolina CortesNo ratings yet

- 517hoja-tecnica-MOLYKOTE® Longterm W 2Document2 pages517hoja-tecnica-MOLYKOTE® Longterm W 2Sophia RoseNo ratings yet

- Specialty Lubricants: Molykote® G-Rapid PlusDocument2 pagesSpecialty Lubricants: Molykote® G-Rapid PlusD CNo ratings yet

- ADCOTE 548-81R + Coreactant F (TDS)Document4 pagesADCOTE 548-81R + Coreactant F (TDS)Wasif AzimNo ratings yet

- Araldite 2015: Advanced MaterialsDocument6 pagesAraldite 2015: Advanced MaterialsFilipe Alberto MagalhaesNo ratings yet

- Molykote G RapidDocument2 pagesMolykote G RapidSukhDeolNo ratings yet

- CT-4130 PDSDocument2 pagesCT-4130 PDSMark WuNo ratings yet

- Tinuvin 123: Printing & Packaging Industrial CoatingsDocument2 pagesTinuvin 123: Printing & Packaging Industrial Coatingsfatimah fahira siregarNo ratings yet

- FilmTec BW30 PRO 365 PDS 45 D03747 enDocument2 pagesFilmTec BW30 PRO 365 PDS 45 D03747 enMasoud AmirzadehfardNo ratings yet

- pt522msds PDFDocument2 pagespt522msds PDFSkySupplyUSANo ratings yet

- Castrol Fork Oil 15W España Ficha TécnicaDocument2 pagesCastrol Fork Oil 15W España Ficha TécnicaLeiltonNo ratings yet

- Masterinject 1315 TdsDocument2 pagesMasterinject 1315 TdsMoatz HamedNo ratings yet

- MOLYKOTE High-Vacuum Grease 22-0911H-01Document2 pagesMOLYKOTE High-Vacuum Grease 22-0911H-01kippcamNo ratings yet

- 0325-11-28-15 Datasheet File Plastiment V105Document2 pages0325-11-28-15 Datasheet File Plastiment V105Wayan Partama Bayu AdhitamaNo ratings yet

- Jet-Lube Magic WrenchDocument1 pageJet-Lube Magic WrenchDon HowardNo ratings yet

- S C P (P) S: DescriptionDocument2 pagesS C P (P) S: DescriptionEng-Medrar AlkateryNo ratings yet

- Araldite 2011 Structural Adhesive: Advanced MaterialsDocument6 pagesAraldite 2011 Structural Adhesive: Advanced MaterialsrezaeibehrouzNo ratings yet

- Klueberpaste UH1!84!201 GB enDocument2 pagesKlueberpaste UH1!84!201 GB enHicham BoukhariNo ratings yet

- Texamatic 1888: Automatic Transmission & Power Steering FluidDocument2 pagesTexamatic 1888: Automatic Transmission & Power Steering Fluidhoussem houssemNo ratings yet

- Condensia Catalogue BrochureDocument24 pagesCondensia Catalogue Brochure吉启周No ratings yet

- MOLYKOTE® G-Rapid Plus Solid Lubricant PasteDocument2 pagesMOLYKOTE® G-Rapid Plus Solid Lubricant PasteBart AertsNo ratings yet

- 4406 Synthetic HD Industrial Gear OilDocument2 pages4406 Synthetic HD Industrial Gear OilYoong TanNo ratings yet

- Polyglass HA VE HADocument2 pagesPolyglass HA VE HAGautamNo ratings yet

- ClayGuard NPH TDS PDFDocument1 pageClayGuard NPH TDS PDFAlejandra RodriguezNo ratings yet

- AkzoNobel EN2007 Interpon F2010Document2 pagesAkzoNobel EN2007 Interpon F2010muvinkumarNo ratings yet

- Araldite 2047-1: Advanced MaterialsDocument6 pagesAraldite 2047-1: Advanced MaterialsLiberio AragaoNo ratings yet

- Sikaflex - 221Document2 pagesSikaflex - 221Abdul Wahid PaperwalaNo ratings yet

- ADDITOL-AQ-1681 EN LetterDocument1 pageADDITOL-AQ-1681 EN LetterFabio Enrique Gomez RamirezNo ratings yet

- Sigunit - P1 AF: Accelerating Shotcrete Admixture PowderDocument3 pagesSigunit - P1 AF: Accelerating Shotcrete Admixture PowderBudhi KurniawanNo ratings yet

- Intraplast Z 2011-10 - 1 PDFDocument3 pagesIntraplast Z 2011-10 - 1 PDFSilver Ian UmaliNo ratings yet

- Sitren PSR 100 0209 en 2000 IfDocument2 pagesSitren PSR 100 0209 en 2000 IfSuryasai RednamNo ratings yet

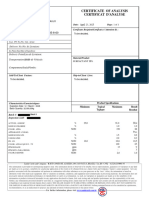

- Coa - Surfact 30 - ZaniniDocument1 pageCoa - Surfact 30 - ZaninifredNo ratings yet

- Stockosorb 660 - PTDocument2 pagesStockosorb 660 - PTfredNo ratings yet

- MSDS - Sulfochem (TM) TD-3 PHP SurfactantDocument11 pagesMSDS - Sulfochem (TM) TD-3 PHP SurfactantfredNo ratings yet

- Zanini, Curtis & Company - August 2022Document27 pagesZanini, Curtis & Company - August 2022fredNo ratings yet

- Zanini, Curtis & Company - August 2022Document27 pagesZanini, Curtis & Company - August 2022fredNo ratings yet

- Zanini, Curtis & Company - August 2022Document27 pagesZanini, Curtis & Company - August 2022fredNo ratings yet

- Plastistrength® 551 - SDSDocument14 pagesPlastistrength® 551 - SDSfredNo ratings yet

- Plastistrength® 562 - SDSDocument14 pagesPlastistrength® 562 - SDSfredNo ratings yet

- Plastistrength® 550 - SDSDocument14 pagesPlastistrength® 550 - SDSfredNo ratings yet

- Durastrength® 200 - TDSDocument3 pagesDurastrength® 200 - TDSfredNo ratings yet

- Durastrength ® 4000 - TDSDocument2 pagesDurastrength ® 4000 - TDSfredNo ratings yet

- PD - 1136 (1159) ® - SDSDocument14 pagesPD - 1136 (1159) ® - SDSfredNo ratings yet

- 51-Msds Planigrout 310 CDocument8 pages51-Msds Planigrout 310 CJanella ChancanNo ratings yet

- A Simple Method For The Syntheses of Nanomaterials: ElectrodepositionDocument10 pagesA Simple Method For The Syntheses of Nanomaterials: ElectrodepositionMouna KallelNo ratings yet

- Titration Flow Chart JanaDocument2 pagesTitration Flow Chart JanaAnuvab JanaNo ratings yet

- Biology Checklist 1Document5 pagesBiology Checklist 1Destinee SullivanNo ratings yet

- Role of Additives in Formulation Development & ProcessingDocument38 pagesRole of Additives in Formulation Development & ProcessingAjay Kumar0% (1)

- Exp 5Document3 pagesExp 5AgentJanuaryNo ratings yet

- The Discovery of Fluoride and FluorineDocument8 pagesThe Discovery of Fluoride and FluorineFuture LeadersNo ratings yet

- Silo - Tips Periodic Table Valency and FormulaDocument7 pagesSilo - Tips Periodic Table Valency and Formulamainakdas73No ratings yet

- © 2015 Pearson Education LTDDocument77 pages© 2015 Pearson Education LTDCamille AndreaNo ratings yet

- Formulae of Ionic CompoundsDocument1 pageFormulae of Ionic CompoundsWalter PerryNo ratings yet

- Organic Molecules.Document9 pagesOrganic Molecules.Aimal SafdarNo ratings yet

- Membrane FoulingDocument8 pagesMembrane FoulingSushanta BeheraNo ratings yet

- Pump Sizing Calculation (Photo)Document25 pagesPump Sizing Calculation (Photo)anto3harrish3fdoNo ratings yet

- Michael L. Shuler, Fikret Kargi - Bioprocess Engineering - Basic Concepts-Prentice Hall (2001) (077-113)Document37 pagesMichael L. Shuler, Fikret Kargi - Bioprocess Engineering - Basic Concepts-Prentice Hall (2001) (077-113)Dome VillavicencioNo ratings yet

- A2AS CHEM REVISED Support 20837Document6 pagesA2AS CHEM REVISED Support 20837Tianming KingsleyNo ratings yet

- S Block ChemhaackDocument13 pagesS Block ChemhaackDrushya SalunkeNo ratings yet

- Iyi Crocycl - Iicci-Iefviistry: Xxvifi Interna Fional Sylvjposjulvi OnDocument2 pagesIyi Crocycl - Iicci-Iefviistry: Xxvifi Interna Fional Sylvjposjulvi Onufuk sancar VuralNo ratings yet

- 5 BiosensorDocument20 pages5 Biosensortehreem iftikharNo ratings yet

- 5a-Composite (RBCS) Composition and Classification 22-3-23Document28 pages5a-Composite (RBCS) Composition and Classification 22-3-23Amish TariqNo ratings yet

- SOLUTION Test 2023Document3 pagesSOLUTION Test 2023साहिल PandeyNo ratings yet

- Grade Xii Practical ContentDocument7 pagesGrade Xii Practical ContentAvi ANo ratings yet

- Mass Transfer Operations 2020Document325 pagesMass Transfer Operations 2020EJ TanNo ratings yet

- Experiment No.6Document4 pagesExperiment No.6alandanwar266No ratings yet

- Full Download Biology The Dynamic Science 3rd Edition Russell Test BankDocument35 pagesFull Download Biology The Dynamic Science 3rd Edition Russell Test Bankwendelngosseuk100% (25)

- Ilane Grafted Natural Rubber and Its Compatibilizationeffect On Silica-Reinforced Rubber Tire Compounds PDFDocument20 pagesIlane Grafted Natural Rubber and Its Compatibilizationeffect On Silica-Reinforced Rubber Tire Compounds PDFnurulhudaabdullahNo ratings yet

- Tehnički List - BASIC MALTA M15Document3 pagesTehnički List - BASIC MALTA M15MARKO MATUHANo ratings yet