Professional Documents

Culture Documents

Araldite 2047-1: Advanced Materials

Uploaded by

Liberio AragaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Araldite 2047-1: Advanced Materials

Uploaded by

Liberio AragaoCopyright:

Available Formats

Advanced Materials

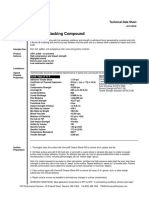

Araldite® 2047-1

Structural Adhesives

TECHNICAL DATA SHEET

Araldite® 2047-1

Methacrylate adhesive requiring minimal surface pretreatment

Key properties • Gap filling

• Good properties on otherwise difficult to bond substrates

• High impact resistance over a wide temperature range

• Good performance particularly at low temperatures

Description Araldite® 2047-1 is a cold curing two-part methacrylate adhesive for metal and plastic bonding. Depending on the

method of processing, Araldite® 2047-1 fills joints up to a gap width of approximately 5mm. With many bonds, an

expensive pretreatment of the parts to be joined is not necessary, or can be reduced to a minimum. The adhesive can

be processed at temperatures up to 40 °C. Higher temperatures shorten the setting time.

Product data

Component A Component B

Property Mixed Adhesive

(resin) (hardener)

Colour (visual) (A112)* beige red brownish

Specific gravity 1.3 1.15 1.3

Viscosity at 25°C (Pas) 50 - 80 20 - 60 thixotropic

Gel time (100 gm at 25°C) - - 9 -11 minutes

Time to peak exotherm (22 gr) (A179)* 10- 25 minutes

* Specified data are on a regular basis analysed. Data which is described in this document as 'typical' is not

analysed on a regular basis and is given for information purposes only. Data values are not guaranteed or

warranted unless if specifically mentioned.

Processing Pretreatment

The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded. At the

very least, joint surfaces should be cleaned with a good degreasing agent such as acetone, iso-propanol (for plastics)

or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Low grade alcohol,

gasoline (petrol) or paint thinners should never be used. The strongest and most durable joints are obtained by either

mechanically abrading or chemically etching (“pickling”) the degreased surfaces. Abrading should be followed by a

second degreasing treatment

Mix ratio Parts by weight Parts by volume

Component A (resin) 100 100

Component B (hardener) 8.8 10

®

Araldite 2047-1 is available in cartridges incorporating mixers and can be applied as ready to use adhesive with the

aid of the tool recommended by Huntsman Advanced Materials.

May 2016 Araldite® 2047-1 Page 1 of 6

Application of adhesive

The resin/hardener mix may be applied manually or robotically to the pretreated and dry joint surfaces. Huntsman's

technical support group can assist the user in the selection of an suitable application method as well as suggest a

variety of reputable companies that manufacture and service adhesive dispensing equipment.

A layer of adhesive 0.05 to 0.10 mm thick will normally impart the greatest lap shear strength to the joint. Huntsman

stresses that proper adhesive joint design is also critical for a durable bond. The joint components should be

assembled and secured in a fixed position as soon as the adhesive has been applied.

For more detailed explanations regarding surface preparation and pretreatment, adhesive joint design, and the dual

syringe dispensing system, visit www.araldite2000plus.com.

Equipment maintenance

All tools should be cleaned with hot water and soap before adhesives residues have had time to cure. The removal of

cured residues is a difficult and time-consuming operation.

If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition,

avoid skin and eye contact.

Typical times to minimum shear strength

Temperature °C 10 15 23 40

Cure time to reach Hours - - - -

LSS > 1MPa Minutes 25 20 15 5

Cure time to reach Hours 2 - - -

LSS > 10MPa Minutes - 45 25 15

LSS = Lap shear strength.

Typical cured Unless otherwise stated, the figures given below were all determined by testing standard specimens made by lap-

properties jointing 114 x 25 x 1.6 mm strips of aluminium alloy. The joint area was 12.5 x 25 mm in each case.

The figures were determined with typical production batches using standard testing methods. They are provided solely

as technical information and do not constitute a product specification.

Average lap shear strengths of typical metal-to-metal joints (ISO 4587) (typical average values)

Cured for 16 hours at 40°C and tested at 23°C. Pretreatment - Sand blasting, isopropanol degreasing

Alum inium

Steel 37/11

Stainless steel V4A

Galvanised steel

Copper

Brass

MPa 0 5 10 15 20

May 2016 Araldite® 2047-1 Page 2 of 6

Average lap shear strengths of typical plastic-to-plastic joints (ISO 4587) (typical average values)

Cured for 16 hours at 40°C and tested at 23°C. Pretreatment - Lightly abrade and isopropanol degrease.

CFRP

EP-GRP

UP-GRP

SMC

ABS

PVC

PMMA

PC

PA 6.6

MPa 0 3 6 9 12 15 18

Lap shear strength versus temperature (ISO 4587) (typical average values)

On aluminium, cure: 16 hours at 40°C, Pretreatment - Sand blasting, isopropanol degreasing

MPa

25

20

15

10

0

°C -40 -20 0 20 40 60 80 100

May 2016 Araldite® 2047-1 Page 3 of 6

Lap shear strength versus immersion in various media (ISO 4587) (typical average values)

On aluminium, cured for 16 hours at 40°C and tested at 23°C. Pretreatment - Sand blasting, isopropanol degreasing.

Unless otherwise stated, L.S.S. was determined after immersion for 30, 60 and 90 days at 23°C

30 days 60 days 90 days Cure: 16 hours at 40°C

As-made value

IMS

Fuel (unleaded)

Ethyl acetate

Acetic acid, 10%

Xylene

Lubricating oil

Paraffin

Water at 23°C

Water at 60°C

Water at 90°C

MPa 0 3 6 9 12 15 18 21

Lap shear strength versus tropical weathering (ISO 4587) (typical average values)

(40°C/ 92% RH), on aluminium, cured for 16 hours at 40°C and tested at 23°C.

Pretreatment - Sand blasting, isopropanol degreasing

As m ade value

After 30 days

After 60 days

After 90 days

MPa 0 3 6 9 12 15 18 21

May 2016 Araldite® 2047-1 Page 4 of 6

Lap shear strength versus heat ageing (ISO 4587) (typical average values)

On aluminium, cured for 16 hours at 40°C and tested at 23°C. Pretreatment - Sand blasting, isopropanol degreasing

As-made value

30 days/ 70°C

60 days/ 70°C

90 days/ 70°C

MPa 0 3 6 9 12 15 18 21

Lap shear strength versus thermal cycling (ISO 4587) (typical average values)

On aluminium, cured for 16 hours at 40°C and tested at 23°C.

Pretreatment - Sand blasting, isopropanol degreasing

100 cycles of 6 hours duration from -30°C to 70°C: 17.75 MPa

Tensile properties (ISO 527). Cure 7 days at 23°C (typical average values) - tested at 23°C

Tensile strength 19 MPa

Tensile modulus 830 MPa

Elongation at break 30 -40 %

Shear properties (ISO 6721). Cure 16hrs at 40°C (typical average values)

Shear Modulus

at 23°C 500 - 600 MPa

at 50°C 200 - 300 MPa

at 75°C 40 -50 MPa

Glass transition temperature (typical average values) ( ISO 6721)

Cure: 16 hours at 40°C 80°C by DMA

May 2016 Araldite® 2047-1 Page 5 of 6

Storage Araldite® 2047-1 must be stored at 2 – 8 °C , provided the components are stored in sealed containers. The expiry

date is indicated on the label.

Handling Caution

precautions Our products are generally quite harmless to handle provided that certain precautions normally taken when handling

chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with

foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact

with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or

plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed

at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided.

Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is

recommended. These precautions are described in greater detail in the Material Safety Data sheets for the individual

products and should be referred to for fuller information.

Huntsman Advanced Materials warrants only that its products meet the specifications agreed with the user. Specified

data are analysed on a regular basis. Data which is described in this document as ' typical' or 'guideline' is not

analysed on a regular basis and is given for information purposes only. Data values are not guaranteed or warranted

unless if specifically mentioned.

The manufacture of materials is the subject of granted patents and patent applications; freedom to operate patented

processes is not implied by this publication.

While all the information and recommendations in this publication are, to the best of Huntsman Advanced Material’s

knowledge, information and belief, accurate at the date of publication, nothing herein is to be construed as a

warranty, whether express or implied, including but without limitation, as to merchantability or fitness for a

particular purpose. In all cases, it is the responsibility of the user to determine the applicability of such

information and recommendations and the suitability of any product for its own particular purpose.

The behaviour of the products referred to in this publication in manufacturing processes and their suitability in any

given end-use environment are dependent upon various conditions such as chemical compatibility, temperature, and

other variables, which are not known to Huntsman Advanced Materials. It is the responsibility of the user to evaluate

the manufacturing circumstances and the final product under actual end-use requirements and to adequately advise

Huntsman Advanced Materials

(Switzerland) GmbH and warn purchasers and users thereof.

Klybeckstrasse 200 Products may be toxic and require special precautions in handling. The user should obtain Safety Data Sheets from

CH - 4057 Basel Huntsman Advanced Materials containing detailed information on toxicity, together with proper shipping, handling

Switzerland

and storage procedures, and should comply with all applicable safety and environmental standards.

Tel: +41 (0)61 299 11 11 Hazards, toxicity and behaviour of the products may differ when used with other materials and are dependent on

Fax: +41 (0)61 299 11 12 manufacturing circumstances or other processes. Such hazards, toxicity and behaviour should be determined by the

www.aralditeadhesives.com user and made known to handlers, processors and end users.

Except where explicitly agreed otherwise, the sale of products referred to in this publication is subject to the general

terms and conditions of sale of Huntsman Advanced Materials LLC or of its affiliated companies including without

limitation, Huntsman Advanced Materials (Europe) BVBA, Huntsman Advanced Materials Americas Inc., Huntsman

Advanced Materials (UAE) FZE, Huntsman Advanced Materials (Guangdong) Company Limited, and Huntsman

Advanced Materials (Hong Kong) Ltd.

Huntsman Advanced Materials is an international business unit of Huntsman Corporation. Huntsman Advanced

Materials trades through Huntsman affiliated companies in different countries including but not limited to Huntsman

Advanced Materials LLC in the USA and Huntsman Advanced Materials (Europe) BVBA in Europe.

All trademarks mentioned are either property of or licensed to Huntsman Corporation or an affiliate thereof in one or

more, but not all, countries.

Copyright © 2016 Huntsman Corporation or an affiliate thereof. All rights reserved

May 2016 Araldite® 2047-1 Page 6 of 6

You might also like

- Araldite 2014-2: Advanced MaterialsDocument6 pagesAraldite 2014-2: Advanced MaterialsAnonymous r3MoX2ZMTNo ratings yet

- Araldite 2015: Advanced MaterialsDocument6 pagesAraldite 2015: Advanced MaterialsFilipe Alberto MagalhaesNo ratings yet

- Araldit-STANDARD Datasheet PDFDocument3 pagesAraldit-STANDARD Datasheet PDFsiva shanmugamNo ratings yet

- Araldite FT 420 AB ENDocument5 pagesAraldite FT 420 AB ENantoine DelesvauxNo ratings yet

- Araldite Standard PDFDocument3 pagesAraldite Standard PDFGRAVYMATRIX VENTURESNo ratings yet

- Araldite AV 138M-1 With Hardener HV 998: Advanced MaterialsDocument4 pagesAraldite AV 138M-1 With Hardener HV 998: Advanced MaterialsMajid TorabiNo ratings yet

- COLLANTE FCB 130 - Araldite - FT - AV138M-1 - HV998 - ENDocument4 pagesCOLLANTE FCB 130 - Araldite - FT - AV138M-1 - HV998 - ENMax SalogniNo ratings yet

- Advanced Materials Araldite AV 4738 HardDocument5 pagesAdvanced Materials Araldite AV 4738 HardAnup RaiNo ratings yet

- Two Component Clear Epoxy Adhesive: Araldite CrystalDocument3 pagesTwo Component Clear Epoxy Adhesive: Araldite CrystalreinpolyNo ratings yet

- Technical Data Sheet: Primerless MMA AdhesivesDocument3 pagesTechnical Data Sheet: Primerless MMA AdhesivespronavNo ratings yet

- Araldite 3112 US eDocument4 pagesAraldite 3112 US ebinodNo ratings yet

- Scotch-Weld: Structural AdhesiveDocument4 pagesScotch-Weld: Structural AdhesiveAfzal ImamNo ratings yet

- PPG Amercoat 370 Data SheetDocument3 pagesPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiHrvoje RuzicNo ratings yet

- Araldite 2011 Structural Adhesive: Advanced MaterialsDocument6 pagesAraldite 2011 Structural Adhesive: Advanced MaterialsrezaeibehrouzNo ratings yet

- Scotch-Weld: Epoxy AdhesiveDocument6 pagesScotch-Weld: Epoxy AdhesiveJun Bryan Ramirez AbangNo ratings yet

- Loctite Ea E-30 HV - TdsDocument2 pagesLoctite Ea E-30 HV - TdsVivek Anand100% (4)

- 253 PDS AiDocument4 pages253 PDS AiAchraf BoudayaNo ratings yet

- Folheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01Document2 pagesFolheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01marcosNo ratings yet

- Araldite 2011Document2 pagesAraldite 2011nrd9771No ratings yet

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- FC SBU Monile INT 20230526Document2 pagesFC SBU Monile INT 20230526nblinoNo ratings yet

- ChemflakeDocument5 pagesChemflakeManohar SeetharamNo ratings yet

- TDS Adhesion CompoundDocument6 pagesTDS Adhesion CompoundNhien ManNo ratings yet

- EU - TDS - Interpon D2525 STF TextureDocument3 pagesEU - TDS - Interpon D2525 STF TextureWilson ThomasNo ratings yet

- Loctite EA 907™: Technical Data SheetDocument2 pagesLoctite EA 907™: Technical Data Sheetuzzy2No ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Tds Plexus Ma420 EngDocument2 pagesTds Plexus Ma420 EngCarlos SantosNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 pagesSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNo ratings yet

- Crestabond Brochure UkDocument8 pagesCrestabond Brochure UkNduong NguyenNo ratings yet

- Ad222 Transfer Pet White Top S8030 BG42WHDocument6 pagesAd222 Transfer Pet White Top S8030 BG42WHArmanFauziNo ratings yet

- Bar-Rust 231LV Surface Tolerant EpoxyDocument4 pagesBar-Rust 231LV Surface Tolerant EpoxyAhmed IbrahimNo ratings yet

- Loctite 2432: Technical Data SheetDocument2 pagesLoctite 2432: Technical Data SheetFabio ParceroNo ratings yet

- Aerodur Hs Primer 37092: ® Akzonobel Aerospace CoatingsDocument4 pagesAerodur Hs Primer 37092: ® Akzonobel Aerospace CoatingsAdc CdaNo ratings yet

- Tpu WHT 6420 TdsDocument1 pageTpu WHT 6420 TdsJose Miguel Navarrete RoaNo ratings yet

- Technical Datasheet For: Epsotechpv Ra1 D6: Overview and StructureDocument2 pagesTechnical Datasheet For: Epsotechpv Ra1 D6: Overview and StructureAlexandre BernelinNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Loctite PC 9020 Nordbak Backing Compound LDSDocument2 pagesLoctite PC 9020 Nordbak Backing Compound LDSWilder Carbajal MayhuaNo ratings yet

- PO Lapox EpogroutDocument4 pagesPO Lapox Epogroutjohn paulNo ratings yet

- Plasite 4100 PDS-3Document5 pagesPlasite 4100 PDS-3Linnie McleodNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument3 pagesProduct Data Sheet: Akzonobel Powder CoatingsFerhat ÖzcanNo ratings yet

- Moylkote DX Paste Technical Data SheetDocument2 pagesMoylkote DX Paste Technical Data SheetMihai AlexNo ratings yet

- Epofine 4859 - Finehard 4859Document3 pagesEpofine 4859 - Finehard 4859Karishma PrabhuNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- ADMIX Epoflex SRDocument2 pagesADMIX Epoflex SRbeto pagoadaNo ratings yet

- AkzoNobel EN2007 Interpon F2010Document2 pagesAkzoNobel EN2007 Interpon F2010muvinkumarNo ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- Product Information: Kemperol V210Document3 pagesProduct Information: Kemperol V210sri projectssNo ratings yet

- Conseal Touch-Up: Technical Data SheetDocument4 pagesConseal Touch-Up: Technical Data SheetSyilla ShopeNo ratings yet

- Durostone PCB Solder eDocument6 pagesDurostone PCB Solder eaisyahhamidNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Brujita AmigurumiDocument22 pagesBrujita AmigurumiCris Acuña100% (5)

- Fossil Fuels: Grade Level: 4 - 6Document12 pagesFossil Fuels: Grade Level: 4 - 6api-438357435No ratings yet

- Progress in Organic Coating-PaperDocument22 pagesProgress in Organic Coating-Paperjibin k p100% (1)

- Tabel Data PercobaanDocument13 pagesTabel Data PercobaanikeuNo ratings yet

- Friction and Friction Coefficients For Various MaterialsDocument7 pagesFriction and Friction Coefficients For Various MaterialsHilman NurzenNo ratings yet

- FuelsDocument44 pagesFuelsfirst lastNo ratings yet

- BS 534 1990Document27 pagesBS 534 1990Upendranath BhupalNo ratings yet

- Application of FRP Composites For Underwater PilesDocument9 pagesApplication of FRP Composites For Underwater Pileswendydy6No ratings yet

- BS 5135 Welding of Ferrtic SteelDocument54 pagesBS 5135 Welding of Ferrtic SteelRajan Steeve100% (1)

- The Electrical Conductivity of SolutionsDocument17 pagesThe Electrical Conductivity of SolutionsHARIYANTO100% (1)

- Kut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide SealantDocument4 pagesKut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide Sealanthafee83No ratings yet

- Powdered Detergent: Adamson University College of Engineering Department of Chemical EngineeringDocument6 pagesPowdered Detergent: Adamson University College of Engineering Department of Chemical EngineeringHoneylet Recaña TayactacNo ratings yet

- XYPEX Concentrate-Ds-1Document4 pagesXYPEX Concentrate-Ds-1Keops MontealegreNo ratings yet

- 1100-Data Sheets PDFDocument3 pages1100-Data Sheets PDFPaturu VijayNo ratings yet

- Quote AnalysisDocument4 pagesQuote AnalysisGokul NathNo ratings yet

- Class 10 SP-1 Crude OilDocument2 pagesClass 10 SP-1 Crude OilJohn DoeNo ratings yet

- Lectura 3. The Concept of Active Site in Heterogeneous CatalysisDocument23 pagesLectura 3. The Concept of Active Site in Heterogeneous CatalysisTRIANA FORERO GABRIEL RICARDONo ratings yet

- SSP-UTENSILS SailDocument27 pagesSSP-UTENSILS SailSandipNo ratings yet

- Fibers in Asphalt and CementDocument36 pagesFibers in Asphalt and CementForsythe LearningNo ratings yet

- Metallurgy: MCQ On Unit 1 & 2Document3 pagesMetallurgy: MCQ On Unit 1 & 2Ashutosh AvasekarNo ratings yet

- BADM 20190117 2020-CatalogDocument116 pagesBADM 20190117 2020-CatalogmilamoNo ratings yet

- Chemical Analysis of Gypsum and Gypsum Products (Metric) : Standard Test Methods ForDocument18 pagesChemical Analysis of Gypsum and Gypsum Products (Metric) : Standard Test Methods ForMohammed Ali100% (1)

- 1 Lecture 4: Post-Tensioning Systems and Devices: ECE 411 Design of Concrete Structures II Dr. Moonis ZaheerDocument11 pages1 Lecture 4: Post-Tensioning Systems and Devices: ECE 411 Design of Concrete Structures II Dr. Moonis ZaheerGhansham Rajaram Avhad.No ratings yet

- Annex IX - Bill of QuantityDocument6 pagesAnnex IX - Bill of QuantityIshteyak AlamNo ratings yet

- Physical Testing of Quicklime, Hydrated Lime, and Limestone: Standard Test Methods ForDocument20 pagesPhysical Testing of Quicklime, Hydrated Lime, and Limestone: Standard Test Methods Forعمر عمرNo ratings yet

- Pt100 RTD & Thermocouple Probes For Industrial ApplicationsDocument2 pagesPt100 RTD & Thermocouple Probes For Industrial ApplicationsTrung DũngNo ratings yet

- Vega AVUM Gas TankDocument14 pagesVega AVUM Gas TankrenatobellarosaNo ratings yet

- Rebar Splicing HandbookDocument72 pagesRebar Splicing HandbookKenshin HimuraNo ratings yet

- DensityDocument2 pagesDensityPeeyush TripathiNo ratings yet

- Chemicals: Project Specification 106Document4 pagesChemicals: Project Specification 106Hernán GarcíaNo ratings yet