Professional Documents

Culture Documents

Cube

Cube

Uploaded by

Aquino ArviOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cube

Cube

Uploaded by

Aquino ArviCopyright:

Available Formats

Pre-Starting Checks Model CUBE Pre-Starting Belt Tension Checks

4. Always loosen tension enough to install belts

1. Check all fasteners and set screws for tightness. without stretching, see

The wheel should rotate freely and be aligned as Figure 10.

shown in Figure 8.

Do not force the

G - Overlap H - Gap belt(s). Forcing belts

Model

inch (mm) inch (mm)

with break the cords

CUE 060-095 – 3/32 (2) Do not force

Figure

and cause belt failure. belt(s) 10 belt(s). Forcing the

CUE 099-161 1/4 (6) – will break the cords and

CUE 180-200 1/2 (13) – 5. For units with two groove pulleys,

cause adjust so the

belt failure

CUBE 099-161 1/4 (6) – tension is equal in both belts.

.

CUBE 180-300 1/2 (13) – 6. If adjustments are made, it is very important

CUBE 360-480 3/4 (19) –

to check the pulleys for proper alignment.

Misaligned pulleys lead to excessive belt wear

vibration, noise and power loss, see Figure 11.

CORRECT WRONG WRONG WRONG

G H

Do not force belt(s). Forcing the

belt(s) will break the cords and

cause belt failure

Figure 8 - Wheel Overlap and Gap Dimension

Figure 11

2. Wheel position is preset and the unit is test run 7. Belt tension can be adjusted by loosening four

at the factory. Movement may occur during fasteners on the drive frame, see Figure 12. The

shipment and realignment may be necessary. motor plate slides on

CUE unit - Centering height alignment can be

the slotted adjusting

CORRECT WRONG

accomplished by loosening the set screws in arms and drive frame

the wheel and moving the wheel to the desired angles in the same

position. Deflection = manner. Belt

Belt Span

64

Span

CUBE unit - Centering can be accomplished

by Four (4) fasteners in WRONG WRONG

Slack

loosening the bolts holding the drive Side

frame to total.

the vibration isolators and repositioning the drive Identical fasteners on

frame. opposing side must

Figure 12

CUBE unit - Wheel and inlet cone overlap can be

also be loosened.

adjusted by loosening the set screws in the wheel 8a. Sizes 099-161: Belts should be tensioned just

and moving the wheel to the desired position. enough to prevent slippage at full load. Belts

3. All CUE and CUBE units - Check wheel should have a slight bow on the slack side while

rotation (viewing from the shaft side) by running at full load; see Figure 13a.

momentarily energizing 8b. Sizes 180-480: Belt tension should be adjusted

the unit. Rotation should to allow 1/64 in. (0.397 mm) of deflection per inch

correspond to the rotation of belt span. For example, a 15 in. (381 mm) belt

decal on the unit, see span should have 15/64 in. (0.234 mm) (or about

Figure 9. If wheel rotation 1/4 in. (6 mm)) of deflection with moderate thumb

Counterclockwise

is incorrect, reverse two of Airflow

pressure at mid-point between pulleys; see

the wiring leads or check Figure 13b.

motor wiring for single

phase. Figure 9Clockwise

Airflow

WARNING

Correct direction of wheel rotation is critical.

Reversed rotation will result in poor air performance,

motor overloading and possible motor burnout. Slack

Side

AVERTISSEMENT

La turbine doit impérativement tourner dans le bon

sens. Une rotation en sens inverse entraînerait Figure 13a Figure 13b

de mauvaises performances de soufflage, une

surcharge du moteur voire un grillage du moteur.

9. The adjustable motor pulley is factory set for

the RPM specified. Speed can be increased by

closing or decreased by opening the adjustable

motor pulley.

10. Any increase in speed represents a substantial

increase in the horsepower required by the unit.

11. Motor amperage should always be checked to

avoid serious damage to the motor when speed

is varied.

IMPORTANT

The fan has been checked for mechanical noises at

the factory prior to shipment. If mechanical noise

should develop, suggested corrective actions are

offered in the Troubleshooting section.

IMPORTANT

Over tightening will cause excessive bearing wear

and noise. Too little tension will cause slippage at

startup and uneven wear.

Operation

1. Before starting up or operating fan, check all

fasteners for tightness. In particular, check the

setscrews in wheel hub (and pulleys, if applicable).

2. While in the OFF position or before connecting the

fan to power, turn the fan wheel by hand to be sure

it is not striking the venturi or any obstacle.

3. Start the fan and shut it off immediately to check

rotation of the wheel with directional arrow in the

motor compartment, Reference Figure 9.

4. When the fan is started, observe the operation and

check for any unusual noises.

5. With the system in full operation and all ductwork

attached, measure current input to the motor and

compare with the nameplate rating to determine if

the motor is operating under safe load conditions.

6. Keep inlets and approaches to fan clean and free

from obstruction.

IMPORTANT

Adjust (tighten) belt tension after the first

24-48 hours of operation.

Inspection

Inspection of the fan should be conducted at the

first 30 minute and 24 hour intervals of satisfactory

operation.

30 Minute Interval - Inspect bolts, setscrews

and motor mounting bolts. Adjust and tighten as

necessary.

24 Hour Interval - Check all internal components. On

CUBE unit only, inspect belt alignment and tension.

Adjust and tighten as necessary.

You might also like

- Reference Only: Supplement To Service Manual Boom Cable TensioningDocument204 pagesReference Only: Supplement To Service Manual Boom Cable TensioningOperacional Transtop100% (3)

- Ford Ranger PX MK II SpecificationsDocument62 pagesFord Ranger PX MK II SpecificationsTulio MooreNo ratings yet

- Manual Book Suzuki Katana sj410 PDFDocument2 pagesManual Book Suzuki Katana sj410 PDFAditya Hendra100% (1)

- Back To BasicsDocument13 pagesBack To BasicsBruno SantosNo ratings yet

- Manual de Operación de Grua National Crane Mod. 800DDocument232 pagesManual de Operación de Grua National Crane Mod. 800DJose Villamil Ruiz100% (1)

- Kalmar DRF 450 Drive AxleDocument8 pagesKalmar DRF 450 Drive Axletuấn anh nguyễnNo ratings yet

- Farm Equipment TractorsDocument131 pagesFarm Equipment TractorsLalit Kumar100% (1)

- SIMCOM - Piper Meridian G1000 - Piper Meridian G1000 Emerg Proc Handbook - Rev 0Document113 pagesSIMCOM - Piper Meridian G1000 - Piper Meridian G1000 Emerg Proc Handbook - Rev 0erickvoliveiraNo ratings yet

- VW, Audi 7-Speed DSG Clutch Installer & Remover: Item Description OEMDocument12 pagesVW, Audi 7-Speed DSG Clutch Installer & Remover: Item Description OEMAnonymous WzR5h9g8VNo ratings yet

- Cummins EQB140-20 SO10863 Parts CatalogueDocument10 pagesCummins EQB140-20 SO10863 Parts CatalogueChen Caroline0% (1)

- Manual TerexDocument44 pagesManual TerexjulioNo ratings yet

- 90 MM 1Document6 pages90 MM 1Pedro PgNo ratings yet

- Diagrama 389453Document214 pagesDiagrama 389453sandro ronaldNo ratings yet

- Company Profile PT Indotruck UtamaDocument16 pagesCompany Profile PT Indotruck Utamakingkong_lucu100% (1)

- Pre-Starting Checks: Avertissement DangerDocument2 pagesPre-Starting Checks: Avertissement DangerAquino ArviNo ratings yet

- Ballscrew - Troubleshooting GuideDocument14 pagesBallscrew - Troubleshooting GuideHải TạNo ratings yet

- Installation and Arrangement of Universal DrivelinesDocument4 pagesInstallation and Arrangement of Universal DrivelinesSrecko PantovicNo ratings yet

- Installation and Arrangement of Universal DrivelinesDocument6 pagesInstallation and Arrangement of Universal DrivelinesPrateek KesarwaniNo ratings yet

- ML Couplings Instruction ManualDocument4 pagesML Couplings Instruction ManualGer BosNo ratings yet

- Catalogue EnglishDocument20 pagesCatalogue EnglishGabriel MoreiraNo ratings yet

- sp2052 2Document4 pagessp2052 2Marian VinatoruNo ratings yet

- V-Belt Drives 0905Document3 pagesV-Belt Drives 0905FV AllanNo ratings yet

- Avim101 PDFDocument2 pagesAvim101 PDFMahendra SinghNo ratings yet

- AllignmentDocument2 pagesAllignmentVishnu Vardhan . CNo ratings yet

- 11 2E 后悬架Document15 pages11 2E 后悬架Alexander cesar neyra sotoNo ratings yet

- Mounting Instruction (Short Version) : 1. Preparation 2. Lift Gear Mounting 3. Make Lift OperationalDocument1 pageMounting Instruction (Short Version) : 1. Preparation 2. Lift Gear Mounting 3. Make Lift OperationalVinícius CorrêaNo ratings yet

- Technical Poster Drive Shafts 1Document1 pageTechnical Poster Drive Shafts 1Floyd PriceNo ratings yet

- Manual Qs Rc5Document1 pageManual Qs Rc5Director Tecnico AdministrativoNo ratings yet

- Section 10 Rudder and Rudder Trim Control SystemsDocument9 pagesSection 10 Rudder and Rudder Trim Control SystemsMario VolpattiNo ratings yet

- Crosby Thimble Eye Bundle Clips Warning & Application InstructionsDocument1 pageCrosby Thimble Eye Bundle Clips Warning & Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- 8-2 Group 2 Operational Checks and TroubleshootingDocument3 pages8-2 Group 2 Operational Checks and Troubleshootingstefan corjucNo ratings yet

- Complementos para Tractor 0189481001578561250Document6 pagesComplementos para Tractor 0189481001578561250Helmuth Martin NeumannNo ratings yet

- Manual - S40Document2 pagesManual - S40Arnaud MarcelNo ratings yet

- Preparations of Bodywork: Section 2Document6 pagesPreparations of Bodywork: Section 2julio vicencioNo ratings yet

- Assembly C7 TrolleysDocument4 pagesAssembly C7 TrolleysmahmoudglobaltechNo ratings yet

- Correct Adjustment of AL-KO International Mechanical BrakesDocument2 pagesCorrect Adjustment of AL-KO International Mechanical BrakesngazawooNo ratings yet

- Business Class M2 Workshop Manual-3-2Document145 pagesBusiness Class M2 Workshop Manual-3-2Dinator CortésNo ratings yet

- Manual - Rotary 3 Speed HubsDocument2 pagesManual - Rotary 3 Speed Hubsbostin011No ratings yet

- Y5 Feed Brake Adjustment PMDSDocument3 pagesY5 Feed Brake Adjustment PMDSarmando olivaresNo ratings yet

- Toro Belt ReplacementDocument9 pagesToro Belt ReplacementsuspectnixNo ratings yet

- Cruise Control Kit For FLHR/S Models: GeneralDocument6 pagesCruise Control Kit For FLHR/S Models: GeneralAdrián CasarrubiasNo ratings yet

- 20 PDFsam Steel TechnicalDocument1 page20 PDFsam Steel TechnicalLuísNo ratings yet

- Rode IrosDocument20 pagesRode IrosGiovani BottegaNo ratings yet

- Camshaft (1Nz Fe/2Nz Fe) : ReplacementDocument8 pagesCamshaft (1Nz Fe/2Nz Fe) : ReplacementMaung KyawNo ratings yet

- Sling Procedures Support ManualDocument12 pagesSling Procedures Support ManualJULIONo ratings yet

- Cople Jse1-0237aea-03-16Document15 pagesCople Jse1-0237aea-03-16Jorge GascaNo ratings yet

- Timing Belt (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Document5 pagesTiming Belt (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Ben GreenNo ratings yet

- Anexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDocument4 pagesAnexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDidier solanoNo ratings yet

- Freno Warner 1Document4 pagesFreno Warner 1javier castilloNo ratings yet

- Front+axle New ModelDocument16 pagesFront+axle New ModelTimkenNo ratings yet

- Sibre Data Sheet Drum Coupling ABC VDocument18 pagesSibre Data Sheet Drum Coupling ABC VGabriel MoreiraNo ratings yet

- Ma 4211000 WMDocument5 pagesMa 4211000 WMCarlos ReyesNo ratings yet

- Kalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)Document151 pagesKalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)ValeriNo ratings yet

- Service Information: Trek Madone 7-Series Brake AssemblyDocument4 pagesService Information: Trek Madone 7-Series Brake AssemblyLucasNo ratings yet

- Ge Ge752 User Manual 61 62Document2 pagesGe Ge752 User Manual 61 62RICHARDNo ratings yet

- Removal: 2Uz-Fe Engine Mechanical - CamshaftDocument14 pagesRemoval: 2Uz-Fe Engine Mechanical - CamshaftmarranNo ratings yet

- CouplingsDocument17 pagesCouplingsEmre YamanNo ratings yet

- T REX - Installation - Manual - R1 5 30 17Document1 pageT REX - Installation - Manual - R1 5 30 17eyya 007No ratings yet

- DELTA-P-VALVE MEP-4802-DPV - DatasheetDocument4 pagesDELTA-P-VALVE MEP-4802-DPV - Datasheetboukhalfa.oman.muscatNo ratings yet

- 035 - 22 - Technical Manual - Mechanical Groupsets Ergopower Commands - Campagnolo - REV00!07!13Document8 pages035 - 22 - Technical Manual - Mechanical Groupsets Ergopower Commands - Campagnolo - REV00!07!13asfilbike bicicletasNo ratings yet

- Ns/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Document3 pagesNs/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Luca TrottaNo ratings yet

- Barrel Couplings For Drums, Model: Mechanical Components For Lifting, Hoisting, Transport and Storage MachineryDocument7 pagesBarrel Couplings For Drums, Model: Mechanical Components For Lifting, Hoisting, Transport and Storage MachineryBruno SantosNo ratings yet

- Wheel Balancing: 9. Installation of Wheel Assembly To VehicleDocument1 pageWheel Balancing: 9. Installation of Wheel Assembly To VehiclemiguelNo ratings yet

- Sturmey Archer S RF5 Hub InstructionsDocument2 pagesSturmey Archer S RF5 Hub InstructionsAndré VuzNo ratings yet

- 1988 - Tosio - A New Sugar Mill PDFDocument4 pages1988 - Tosio - A New Sugar Mill PDFShan ShahNo ratings yet

- PS - Og - PCM Driver B-100 - en - BDocument2 pagesPS - Og - PCM Driver B-100 - en - Bcarlos eduardo gutierrez gomezNo ratings yet

- SMS2018v002 DX3012Document4 pagesSMS2018v002 DX3012Akun BackupNo ratings yet

- Fuel Injection TimingDocument4 pagesFuel Injection TimingmanuelNo ratings yet

- MindaDocument11 pagesMindaankurtalNo ratings yet

- Wireless Power Transfer For Electric Vehicle: University of Padova, ItalyDocument142 pagesWireless Power Transfer For Electric Vehicle: University of Padova, ItalyVenkat GoudNo ratings yet

- Good Reasons To Swap From Trench Cutter To Hydraulic GrabDocument10 pagesGood Reasons To Swap From Trench Cutter To Hydraulic Grabrigaz6366No ratings yet

- LA Auto ShowDocument53 pagesLA Auto ShowRoberto Ortega MicalizziNo ratings yet

- Parts Manual: EH25-2 EngineDocument28 pagesParts Manual: EH25-2 EngineBaggerkingNo ratings yet

- Volkswagen Emission Scandal - EditedDocument7 pagesVolkswagen Emission Scandal - EditedAdityaNo ratings yet

- Back To The FutureDocument129 pagesBack To The FutureAnNo ratings yet

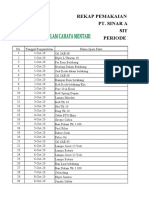

- Pemakaian Spare Parts Per Unit Oktober 2020Document63 pagesPemakaian Spare Parts Per Unit Oktober 2020marsianus santosoNo ratings yet

- Cat C27: Diesel Generator SetsDocument4 pagesCat C27: Diesel Generator SetsJose LibrerosNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Mt80hp4ave MT80 4viDocument5 pagesMt80hp4ave MT80 4viIRAN FREONNo ratings yet

- HRC Couplings: Technical Changes Reserved, Some Items May Not Be Available From Stock. PTI Europa A/S - Pti - EuDocument1 pageHRC Couplings: Technical Changes Reserved, Some Items May Not Be Available From Stock. PTI Europa A/S - Pti - EuVijay BhureNo ratings yet

- SeaStar Jackplates ManualDocument1 pageSeaStar Jackplates Manualteopol2No ratings yet

- General Specification Complete PBBDocument19 pagesGeneral Specification Complete PBBAbelRamadhanNo ratings yet

- 795f Ac Truck ErmDocument55 pages795f Ac Truck ErmReference mapiyeNo ratings yet

- D250E II/D300E II Articulated Truck Operator StationDocument1 pageD250E II/D300E II Articulated Truck Operator StationJulio EspinozaNo ratings yet

- x3 CatalogueDocument10 pagesx3 Cataloguestefanovicana1No ratings yet

- Hyd Micro ProjectDocument20 pagesHyd Micro ProjectOmkar Moze CE - J1 - 88No ratings yet

- Q.Upd2.459.07.11-OPTIMA DAYA KAPITAL - Herwindo & Agung-LPG EquipDocument2 pagesQ.Upd2.459.07.11-OPTIMA DAYA KAPITAL - Herwindo & Agung-LPG EquipErwin P. AjaNo ratings yet

- SincoTec - News - 2021 - English Brochure TribometersDocument6 pagesSincoTec - News - 2021 - English Brochure Tribometershugo vignoloNo ratings yet

- Failure Mechanism-Based Reliability Assessment Framework: A Case Study in An Automotive ComponentDocument9 pagesFailure Mechanism-Based Reliability Assessment Framework: A Case Study in An Automotive ComponentmaruvadatarunNo ratings yet