Professional Documents

Culture Documents

Pulsed Nd:YAG Lasers 15 To 220 W Output: ISO 9001:2000 Certified

Uploaded by

Jose ValenciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pulsed Nd:YAG Lasers 15 To 220 W Output: ISO 9001:2000 Certified

Uploaded by

Jose ValenciaCopyright:

Available Formats

KLS 246

Pulsed Nd:YAG lasers

15 to 220 W output

• Unique in the field of fine cutting, precision drilling and scribing

• Outstanding beam quality at high peak powers

• For conventional beam and/or fiber beam delivery

• Optimum flexibility for a full line of processing and production demands

• Multiple interfaces and user-friendly controls

KLS 246 ... a unique tool for micromachining

Modern applications in the medical device industry, electronics, the auto industry and precision engineering

demand increasingly flexible tools for highest precision processing with minimum thermal side effects.

The KLS 246 lasers have proven themselves under the most punishing industrial conditions.

• Outstanding beam quality at high peak powers up to 6 kW • Flexible, cost-efficient production solutions thanks to optional

clearly distinguishes the KLS 246 series of pulsed Nd:YAG fiber beam delivery to as many as four workstations in time-

lasers from the competition. sharing and/or energy-sharing with a single laser source.

• Provides precision processing with extremely small spot dia- • Compact industrial design guarantees simple and foolproof

meters starting at <20 µm, especially for conventional beam integration in your production environment. The LASAG inter-

delivery. High pulse frequencies of up to 5 kHz guarantee face is compatible with every current CNC, PLC or PC control

optimum cutting quality and superior productivity. system.

• Reproducible mechanical/optical interface between the optical • Superior serviceability is a matter of course thanks to modular

system and the processing head provides quick changeover and design and remote diagnosis via modem.

superior flexibility for optimum processing and systems integration.

KLS 246 ... examples of versatile industrial applications

Fine cutting of medical Cutting of solder-screen stencils,

implants (stents) etched parts and molded parts

• Fulfills highest requirements • High cutting speeds up to

for cutting quality, dimensio- 4 m/min

nal stability and heat input. • Aspect ratios up to 1:20

• Tube diameter ≥ 0.4 mm • Material thicknesses up to 2 mm

• Minimum kerf width < 20 µm • Oxide-free and burr-free cutting

• Smooth cutting kerfs

Scribing of connecting rods

Drilling of filters and bearings

• Hole diameters down • Creation of predetermined

to < 30 µm breaking lines with reprodu-

• High-speed drilling of up to cible kerf geometry

600 holes per second with • High aspect ratio

single-shot drilling • Kerf depths up to 2 mm

• Aspect ratios up to 1:30 for • Minimum kerf width of ap-

percussion drilling prox. 60 µm

Materials suitable for machining with Nd:YAG lasers

• Steel and stainless steel • Sintered carbide, diamond

• Light metal • Nickel and cobalt alloys

• Nonferrous metals, precious • Ceramics and semiconducting material

metals • Composites

KLS 246 ... for more flexible beam delivery

The type of processing, workpiece, handling and production environment determine the beam delivery to be used. The KLS 246

series of lasers provides you with solutions for any industrial situation.

Compact optical system

• Resonator and processing

head are attached directly to

the machine

• Conventional beam delivery

and short beam path assure

outstanding beam quality and

LLEK

precise processing results

• Optional module for additional optical

components e.g. beam-expander

• Coupling module handles up to four fibers

• Industrial mounting plate for resonator and

processing head

BAK 4

• Industrial standard processing head with mounting plate

• Focal lengths from 50 to 300 mm

• Can be swiveled ±90°

• Wide variety of cutting, drilling and welding nozzles

• Optional collision protection and height sensing

• Observation with monocular, binocular and/or CCD TV cameras

• Illumination or ring light

KLS 246 ... for convenient integration

All LASAG lasers have a variety of interface options.

Built-in terminal Hand-terminal PC-terminal Remote diagnostic modem

Universal power input

Flexible connection to the optical system

External cooling water

USER

SYSTEM

KLS 246 Specifications (see also detailed data sheet)

Laser source with cavity -040 FC -046 -102 -302 -306

Laser type pulsed Nd:YAG solid-state laser

Wavelength 1064 nm

Beam diameter mm 2.5 4.0 6.0 6.0 6.0

Pulse length ms 0.012-0.3 0.02-20 0.02-20 0.1-20 0.1-20

Pulse repetition rate Hz 0.1-5000 0.1-1000 0.1-1000 0.1-1000 0.1-1000

Pulse energy max. *) J 0.002-0.18 15 30 50 50

Peak power at 3 ms max. *) kW 0.6**) 4.0 6.0 3.0 5.5

Average power max.*) W 15 100 150 220 220

*) measured without beam delivery with new flashlamp **) at 0.3 ms

Line power

Configuration 3-phase + ground, ±10 %

multitap transformer for 3x200 V 208 V 230 V 380 V 400 V 480 V

Power consumption max. 9 kVA

Line frequency 50 Hz or 60 Hz

Cooling water connection

Water inlet max. 20°C/8 bar

Pressure drop to outlet min. 4 bar

Cooling power max. 8.5 kW , depending on laser output

Weight

Laser unit 200 kg

Optical system 35 kg

Ambient conditions

Ambient temperature 10 – 35° C

Relative humidity max. 80 %

Emissions

Noise at 1m, idle 60 dBA

EMC complies with EN 50081-2 and EN 6100-6-2

Compliance with standards

CE compliant, EN 60825-1, EN 60204-1, EN 207, EN 12626

IEC 825-1, FDA-CDRH: U.S. 21 CFR 1040.10, ISO 11553

Subject to change

87.1547 © LASAG JH 01-05/7000

Switzerland

LASAG AG • C.F.L. Lohnerstrasse 24 • CH-3602 Thun • Switzerland

Phone +41-33-227 45 45 • Fax +41-33-227 45 73 • lasers@lasag.ch • www.lasag.com

USA

LASAG Industrial-Lasers • A Division of The SWATCH Group (US) Inc.

1615 Barclay Boulevard • Buffalo Grove, IL 60089 • U.S.A.

Phone +1-847-483 6300 • Fax +1-847-483 6333 • lasers@lasag.com • www.lasag.com

Germany

LASAG Industrial-Lasers • A Division of The SWATCH Group (Deutschland) GmbH

Maximilianstrasse 46 • D-75172 Pforzheim • Germany

Phone +49-7231-3872 670 • Fax +49-7231-3872 679

lasag-d@swatchgroup.com • www.lasag.com

Japan

LASAG Industrial-Lasers • A Division of The SWATCH Group (Japan) KK

Dai-ni Marutaka Bldg. 13-8 • Ginza, Tokyo, 104-0061 • Japan

Phone +81-3-5565 1452 • Fax +81-3-3545 3312 • lasag@jp.swatchgroup.com

ISO 9001:2000 certified

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Clear - Brown - Tan - Black - Blue - Light Blue - White - Orange - Beige - Red - Gray - Maroon - Green - Purple - Silver - Yellow - Pink - NaturalDocument1 pageClear - Brown - Tan - Black - Blue - Light Blue - White - Orange - Beige - Red - Gray - Maroon - Green - Purple - Silver - Yellow - Pink - NaturalJose ValenciaNo ratings yet

- Series Instruction Manual: High-Accuracy Digital Contact SensorDocument16 pagesSeries Instruction Manual: High-Accuracy Digital Contact SensorCzipó BalázsNo ratings yet

- AS 94380 LaserMarker COMMUNICATIONIF UM 14758E GB WW 1018-1 PDFDocument52 pagesAS 94380 LaserMarker COMMUNICATIONIF UM 14758E GB WW 1018-1 PDFOnyx YuukiNo ratings yet

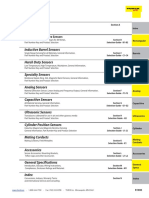

- B1052 InstrumentationDocument240 pagesB1052 InstrumentationJose Valencia0% (1)

- B1008 Proximity SensorsDocument616 pagesB1008 Proximity SensorsJose ValenciaNo ratings yet

- Manual: Movifit Function Level "Technology" With PROFINET-IO InterfaceDocument212 pagesManual: Movifit Function Level "Technology" With PROFINET-IO InterfaceJose Valencia0% (1)

- Operating Instructions: Decentralized Drive SystemsDocument200 pagesOperating Instructions: Decentralized Drive SystemsJose ValenciaNo ratings yet

- Valencia Jose ConditionalsDocument4 pagesValencia Jose ConditionalsJose ValenciaNo ratings yet

- Photography For Beginers PDFDocument12 pagesPhotography For Beginers PDFDheeraj YadavNo ratings yet

- NatGeo GuideToPhotographyDocument15 pagesNatGeo GuideToPhotographyAna@PetreNo ratings yet

- Student Name: José de Jesús Valencia Sánchez Career: Managing of Projects Engineering ID: 19005630 Subject: Future-Assignment 2 Text File English LLLDocument3 pagesStudent Name: José de Jesús Valencia Sánchez Career: Managing of Projects Engineering ID: 19005630 Subject: Future-Assignment 2 Text File English LLLJose ValenciaNo ratings yet

- Photography Masterclass Workbook PDFDocument273 pagesPhotography Masterclass Workbook PDFMahmoud Khairy100% (1)

- A5E33482052 004 AD en-USDocument220 pagesA5E33482052 004 AD en-USgunbrownNo ratings yet

- .Load CellpdfDocument34 pages.Load Cellpdfchandrakrishna8No ratings yet

- 6SL3225-0BE25-5AA1 Datasheet enDocument2 pages6SL3225-0BE25-5AA1 Datasheet enJose ValenciaNo ratings yet

- Motion Control System Information PDFDocument349 pagesMotion Control System Information PDFJose ValenciaNo ratings yet

- STEP 7 - System and Standard Functions For TI-S7-ConverterDocument106 pagesSTEP 7 - System and Standard Functions For TI-S7-Convertertricky777No ratings yet

- Anatomia de Un Plan de Negocio - Linda Pinson PDFDocument282 pagesAnatomia de Un Plan de Negocio - Linda Pinson PDFJose Samuel96% (25)

- 6SL3246-0BA22-1FA0 Datasheet enDocument1 page6SL3246-0BA22-1FA0 Datasheet enJose ValenciaNo ratings yet

- B0003 - 12 2017 Final PrintDocument2 pagesB0003 - 12 2017 Final PrintJose ValenciaNo ratings yet

- .Load CellpdfDocument34 pages.Load Cellpdfchandrakrishna8No ratings yet

- PGA1 1106 enDocument624 pagesPGA1 1106 enGuru KiranNo ratings yet

- 6SL3210 1PE18 0AL1 Datasheet enDocument2 pages6SL3210 1PE18 0AL1 Datasheet enJose ValenciaNo ratings yet

- Datasheet DM470 enDocument8 pagesDatasheet DM470 enAlberto Hai ReNo ratings yet

- 05 - Hpl2010-En. Dil PDFDocument117 pages05 - Hpl2010-En. Dil PDFAntonio HerreraNo ratings yet

- Catalogo Interruptores EatonDocument88 pagesCatalogo Interruptores EatonChristian CortesNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manual de Servicio cdj1000mk3Document116 pagesManual de Servicio cdj1000mk3Eiber Eloy Azuaje MejíasNo ratings yet

- Soft-Tissue Lasers in OrthodonticsDocument5 pagesSoft-Tissue Lasers in OrthodonticsEsmeralda SoriaNo ratings yet

- Diode Laser ArraysDocument464 pagesDiode Laser Arrayscelina ouaroufNo ratings yet

- Assessment of Laser Effects On Skin RejuvenationDocument8 pagesAssessment of Laser Effects On Skin RejuvenationOrel LachianiNo ratings yet

- Power Scaling of Kw-Diode Lasers Optimized For Material Processing ApplicationsDocument9 pagesPower Scaling of Kw-Diode Lasers Optimized For Material Processing ApplicationsDu RoyNo ratings yet

- CMA1530C-G-F: Al WaelDocument8 pagesCMA1530C-G-F: Al WaelThecch MG RamziNo ratings yet

- WhitePaper TecraCoinDocument59 pagesWhitePaper TecraCoinManikanta DevarakondaNo ratings yet

- Academic Year 2020 - 2021 - ODD Semester PH8151 - Engineering Physics Unit-I Properties of MatterDocument52 pagesAcademic Year 2020 - 2021 - ODD Semester PH8151 - Engineering Physics Unit-I Properties of MatterBala NandaNo ratings yet

- Free Electron LasersDocument260 pagesFree Electron Lasershorenhop pyparousNo ratings yet

- Welcome To The Lecture On Unconventional Machining ProcessesDocument26 pagesWelcome To The Lecture On Unconventional Machining ProcessesFaysal Ahmed100% (1)

- Tksa 60 - Alineador Laser de EjesDocument4 pagesTksa 60 - Alineador Laser de EjesdayrNo ratings yet

- Iiest Physics Course BookletDocument6 pagesIiest Physics Course BookletGURUDUTTA PALNo ratings yet

- Laser Welder - Presentation 060117ADocument20 pagesLaser Welder - Presentation 060117Aaman_singh0705No ratings yet

- A MATLAB Programs For Data Analysis (Kramers-Kronig Relations)Document25 pagesA MATLAB Programs For Data Analysis (Kramers-Kronig Relations)YuriyAKNo ratings yet

- YW50 - Welding HeadDocument9 pagesYW50 - Welding HeadconsuelomaraNo ratings yet

- Seminar On Non Conventional MachiningDocument34 pagesSeminar On Non Conventional MachiningMohit Gulati60% (5)

- Quotation of Pain Relief Laser Therapy Device-ZJKCDocument5 pagesQuotation of Pain Relief Laser Therapy Device-ZJKCsanthigiNo ratings yet

- Pico LegendDocument11 pagesPico LegendmohamedsobehNo ratings yet

- Specialized Surgical EquipmentDocument73 pagesSpecialized Surgical EquipmentNicole Soo50% (2)

- CO10A Laser Marking System - General ArrangementsDocument10 pagesCO10A Laser Marking System - General ArrangementsMIguel Alvarez VazquezNo ratings yet

- DATASHEET Hotfind L Series IRDocument2 pagesDATASHEET Hotfind L Series IRalfredo_07No ratings yet

- PC To PC Communication Using LaserDocument53 pagesPC To PC Communication Using Lasersandarbh588% (8)

- Picore Product Introduction (2021) - NewDocument23 pagesPicore Product Introduction (2021) - Newsamuel lumbaNo ratings yet

- 1 AutocorrelationDocument38 pages1 AutocorrelationpadikkatteNo ratings yet

- Gas LasersDocument4 pagesGas LasersPayal SinghalNo ratings yet

- CD & DVD Working Principle-1Document7 pagesCD & DVD Working Principle-1mrana_56No ratings yet

- GLM 50 Professional: Downloaded From Manuals Search EngineDocument12 pagesGLM 50 Professional: Downloaded From Manuals Search EngineludelanesNo ratings yet

- National Registry of RMP With LCP Chapter 1 - General Practitioner AUGUST 2023Document74 pagesNational Registry of RMP With LCP Chapter 1 - General Practitioner AUGUST 2023Drchee HbNo ratings yet

- DEH 6350SD Pioneer PDFDocument77 pagesDEH 6350SD Pioneer PDFJorge ChapiNo ratings yet

- Ec6016 Oed Rejinpaul IqDocument1 pageEc6016 Oed Rejinpaul IqvlsiprabhuNo ratings yet