Professional Documents

Culture Documents

Dryer Pressure Rating: Technical White Paper Series

Dryer Pressure Rating: Technical White Paper Series

Uploaded by

nitantharaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dryer Pressure Rating: Technical White Paper Series

Dryer Pressure Rating: Technical White Paper Series

Uploaded by

nitantharaniCopyright:

Available Formats

Dryer Pressure Rating

Gregory L. Wedel

President

Kadant Johnson Inc.

Gerald L. Timm

Vice President, Research & Development

Kadant Johnson Inc.

Technical White Paper Series

© Kadant Johnson 2006 Dryer Pressure Rating

EXECUTIVE SUMMARY

Paper is dried by direct contact with the hot surfaces of paper drying cylinders. These cylinders

are heated with pressurized steam. Steam condenses inside the dryer cylinders as it transfers its

heat to the dryer shell.

Since the steam is saturated inside the dryer, the steam temperature is directly related to the

steam pressure. As the steam pressure is increased, the steam temperature also increases. This

causes an increase in the dryer surface temperature and hence the drying rate of the paper. This

phenomenon has been used for decades for controlling the drying rate of papermaking

machines.

In order to contain the steam pressure in the dryers, the drying cylinders are designed and

manufactured to meet pressure vessel codes, the most common of which is the ASME Boiler and

Pressure Vessel Code. The thickness of the dryer shell is dictated by these codes. The required

thickness depends on the dryer pressure rating and the shell material.

As the dryer pressure rating increases, the increase in steam temperature may not be sufficient

to offset the increase in conductive resistance of the shell. In fact, it is possible for a dryer with a

higher steam pressure rating that is operating at its rated pressure to have less drying capacity

than a dryer with a lower steam pressure rating that is operating at its rated pressure. This

technical paper explores this phenomenon.

CONTENTS

Executive Summary 1

Introduction 2

Analysis 3

Analytical Results 5

Conclusions 8

References 8

© Kadant Johnson 2006 Dryer Pressure Rating

INTRODUCTION

Paper is dried by direct contact with the hot surfaces of paper drying

cylinders. These cylinders are heated with pressurized steam. Steam

condenses inside the dryer cylinders as it transfers its heat to the dryer

shell. Since the steam is saturated inside the dryer, the steam

temperature is directly related to the steam pressure, as shown in the

temperature-pressure curve in Figure 1.

As the steam pressure is increased, the steam temperature also

increases. This causes an increase in the dryer surface temperature and

hence the drying rate of the paper. This phenomenon has been used for

decades for controlling the drying rate of papermaking machines.

In order to contain the steam pressure in the dryers, the drying

cylinders are designed and manufactured to meet pressure vessel

codes, the most common of which is the ASME Boiler and Pressure

Vessel Code. The thickness of the dryer shell is dictated by these codes.

The required thickness depends on the dryer pressure rating and the

shell material.

As a first-order approximation, the shell thickness must be increased

directly with the pressure rating of the dryer. A thicker dryer shell has a

higher resistance to conductive heat transfer from the steam inside the

dryer to the outside surface of the dryer. This increase in heat transfer

resistance is partially offset by the corresponding increase in the

operating steam temperature.

As the dryer pressure rating increases, however, the increase in steam

temperature may not be sufficient to offset the increase in conductive

resistance of the shell. In fact, it is possible for a dryer with a higher

steam pressure rating that is operating at its rated pressure to have less

drying capacity than a dryer with a lower steam pressure rating

operating at its rated pressure.

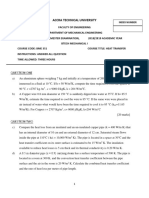

Figure 1

Saturated Steam Temperature, F

400

350

300

250

200

0 50 100 150 200 250 300

Steam Pressure, psig

© Kadant Johnson 2006 Dryer Pressure Rating 2

ANALYSIS

Dryer Shell Thickness

For this review, we consider only the ASME Boiler and Pressure Vessel

Code. For unfired pressure vessels, the dryer shell thickness is

determined by the following equation.1

t = P R / ( s E + 0.4 P) (1)

where: t = minimum required dryer shell thickness, inches

P = internal design pressure rating, psi

R = dryer shell outside radius, inches

s = maximum allowable shell stress, psi

E = joint efficiency (1.0)

In practice, paper dryer shells are machined to a thickness slightly

larger (say 1/16”) than the minimum required by the pressure vessel

code in order to ensure that the dryer does not have to be de-rated

because it is too thin. Further, many paper dryer manufacturers today

will increase the thickness of the shell to account for the centrifugal

forces on the shell resulting from operation at high rotational speeds.

For simplicity, this effect is ignored in this review. This is a reasonable

assumption for dryers operating at speeds less than 3000 fpm.

Dryer Shell Stress

The shell material determines the allowable stress. Most paper dryers

are manufactured from gray cast iron (SA278). The class (grade) of cast

iron is typically 30, 35, or 40. These classes correspond to shell tensile

strengths of 30, 35, and 40 kpsi. For these cast iron grades, the ASME

Boiler and Pressure Vessel Code limits the dryer pressure rating to 160

psig (the traditional upper limit of paper dryer pressure ratings). By

appropriate heat treatment and dryer design, however, the Code does

allow ratings up to 250 psi.2

Overall Heat Transfer

The dryer section drying capacity is related to the overall heat transfer

coefficient between the steam and the paper. This coefficient consists of

three thermal resistances: Condensate, shell, and sheet, as shown in the

following equation:

U = 1 / [(1/hc) + (1/hd) + (1/hs) ] (2)

where: U = overall heat transfer coefficient, Btu/hr-ft2-F

hc = condensate heat transfer coefficient, Btu/hr-ft2-F

hd = dryer shell heat transfer coefficient, Btu/hr-ft2-F

hs = sheet contact heat transfer coefficient, Btu/hr-ft2-F

© Kadant Johnson 2006 Dryer Pressure Rating 3

The dryer shell heat transfer coefficient is the ratio of the shell thermal

conductivity and the shell thickness, as shown below:

hd = k / t (3)

The thermal conductivity of the dryer shell depends on the grade of

iron (class) and its average temperature. In general, the thermal

conductivity decreases with increasing shell strength (class of iron) and

with increasing steam pressure (dryer shell temperature).

Drying Capacity

The drying rate from paper dryer cylinders is directly related to the

overall heat transfer coefficient and the difference between the steam

temperature and the paper temperature, as shown below:

Ev = U ( Ts – Tp) / hfg (4)

where: Ev = drying rate, lb/hr-ft2

Ts = steam temperature, F

Tp = paper temperature, F

hfg = latent heat of evaporation of water, Btu/lb

The steam temperature is dictated by the steam pressure (as outlined

above). The sheet temperature is related to a number of operating

parameters: Grade of paper, steam temperature, overall heat transfer

coefficient, ventilation efficiency, and sheet dryness. The paper

temperature can be measured on an operating machine using an

infrared pyrometer or calculated from detailed drying models.

For this review, the Kadant Johnson Can-By-Can™ drying rate

program is used to determine the sheet temperature. For simplicity, the

grade of paper, sheet dryness, and ventilation are assumed to be

constant so that the only parameters that affect the sheet temperature

are the steam temperature and overall heat transfer coefficient.

ANALYTICAL RESULTS

Using the above analysis format, the shell thickness required by the

ASME code was calculated for various code pressures for a 72”

diameter dryer. For this study, the dryer shell is assumed to be Class 40.

The minimum required thickness was increased by 1/16” to account for

typical manufacturing targets. The sheet contact coefficient is assumed

to be constant at 100 Btu/hr-ft2-F, the shell thermal conductivity is

assumed to be constant at 27 Btu/hr-ft-F, and the condensate coefficient

is assumed to be constant at 400 Btu/hr-ft2-F (typical of conventional

dryer bars). Table 1 summarizes these results.

© Kadant Johnson 2006 Dryer Pressure Rating 4

Table 1

MAWP Shell Steam Paper Shell hd Overall U Evapora on

psi inches F F Btu/hr/ft2/F Btu/hr/ft2/F lb/hr/ft2

125 1.17 352.9 219.7 276 62.0 8.52

150 1.39 365.9 224.8 233 59.5 8.66

175 1.61 377.5 229.9 201 57.2 8.70

200 1.83 387.9 235.1 177 55.1 8.68

225 2.04 397.4 240.3 159 53.2 8.61

250 2.26 406.1 245.6 144 51.4 8.50

The results are shown graphically in the following four figures.

Figure 2 shows the design shell thickness as a function of the Maximum

Allowable Working Pressure of the dryer (MAWP). The shell thickness

increases nearly linearly with increasing MAWP.

Figure 3 shows the dryer shell coefficient. As indicated by Equation (3),

the shell coefficient decreases as the shell thickness increases.

Figure 4 shows the overall heat transfer coefficient as a function of the

MAWP. Although the overall coefficient decrease with increasing dryer

pressure rating, this loss in heat transfer coefficient is partially offset by

an increase in the corresponding steam temperature.

In Figure 5, the overall drying capacity, as indicated by Equation (4), is

shown as a function of the dryer steam pressure rating. The data in this

graph is based on having each of the dryer cylinders not only rated for

the listed pressures, but are also operating at their rated pressures.

As illustrated in Figure 5, there is a clear point of maximum drying

capacity. Using dryers with steam pressure rating above this maximum

results in a loss in drying capacity, even when the dryers are operating

at their maximum rated pressures.

In this example, increasing the dryer rating from 125 psi to 150 psi

increases the drying capacity of the machine by 1.6%. Increasing the

dryer rating from 150 psi to 175 psi increases the drying capacity by

only an additional 0.6%.

Increasing the dryer rating from 175 psi to 200 psi does not provide any

increase at all in drying capacity and a further increase in pressure

rating causes a net loss in drying capacity.

© Kadant Johnson 2006 Dryer Pressure Rating 5

Figure 2

2.5

Design Shell Thickness, Inches

2

1.5

0.5

0

100 150 200 250

Maximum Allowable Working Pressure, psi

Figure 3

300

Shell Coefficient, Btu/hr-ft2-F

250

200

150

100

50

0

100 150 200 250

Maximum Allowable Working Pressure, psi

© Kadant Johnson 2006 Dryer Pressure Rating 6

Figure 4

65

Overall Coefficient, Btu/hr-ft2-F

60

55

50

45

100 120 140 160 180 200 220 240 260

Maxim um Allowable Working Pressure, psi

Figure 5

9.0

8.9

8.8

Drying Rate, lb/hr-ft2

8.7

8.6

8.5

8.4

8.3

8.2

8.1

8.0

100 150 200 250

Maximum Allowable Working Pressure, psi

In addition to the impact of increased pressure rating on the drying

capacity, there are also five other factors that should be considered:

High-pressure dryers must operate at higher pressures to achieve

the listed rates.

Higher steam pressures must be available in order to operate at a

higher MAWP.

This could reduce the amount of power that can be generated by

the turbo-generator.

The capital cost of the thicker dryer shell will be higher.

The thicker shells have higher thermal inertia, resulting in slower

response times and increased overshoot and undershoot during

sheet break recovery.

© Kadant Johnson 2006 Dryer Pressure Rating 7

CONCLUSIONS

Using paper dryer cylinders with increased pressure rating can increase

the drying capacity of the dryers, but only up to a point. Above this

point, there is a loss in drying capacity. Before committing to using

high-pressure dryers, the overall drying rate and penalty should be

evaluated.

The example shown in this study was for a particular grade of paper,

for dryers equipped with dryer bars, and for a dryer shell made from

Class 40 gray cast iron. If any of these parameters are changed, a similar

analysis should be conducted to determine the potential for increasing

the overall drying capacity. If, for example, the shell is made from

another material that is recognized by ASME for paper dryer

applications, other than Class 40 gray cast iron, the dryer pressure

rating that produces the maximum drying capacity may be higher or

lower. Each such material option requires detailed evaluation.

The above analysis is based on fundamental heat transfer equations.

The analysis assumes that the sheet can tolerate higher dryer surface

temperatures without picking, sticking, or casehardening the sheet. For

some applications, problems with picking can limit the dryer surface

temperatures, particularly in the wet end dryers, making it difficult to

benefit from dryers with high pressure ratings.

REFERENCES

1. ASME Boiler and Pressure Vessel Code, Section VIII Division 1,

Rules for construction of pressure vessels, Appendix 1, Section 1-1

(a)(1), 2001.

2. ASME Boiler and Pressure Vessel Code, Section VIII Division 1,

Part UCI-3(a)(1) and Part UCI-3(b), 2001.

© Kadant Johnson 2006 Dryer Pressure Rating 8

Kadant Johnson is a global leader in the design, manufacture, and

service of dryer drainage systems, rotary joints, syphon systems,

and related equipment for the dryer section of the paper machine. For

more information about Kadant Johnson products and services, email

info@kadant.com or visit www.kadant.com.

Steam and Condensate Systems

Dryer Section Surveys

Dryer Management System® control software

Stationary Syphons

Rotating Syphons

Rotary Joints

Turbulator® Bars

Thermocompressors

Desuperheaters

Direct Injection Water Heaters

Vortec™ Vacuum Generators

Sight Flow Indicators

Flexible Metal Hoses

Installations Services

You might also like

- Optimising Sweep Gas Flow in A Flare HeaderDocument5 pagesOptimising Sweep Gas Flow in A Flare HeaderMahesh100% (1)

- 17-Chillers Level 2 Air-Cooled (TDP-622)Document52 pages17-Chillers Level 2 Air-Cooled (TDP-622)Hany Rifaat100% (2)

- 2 Catalog Solid FlameDocument4 pages2 Catalog Solid FlamenitantharaniNo ratings yet

- FT-C ManualDocument80 pagesFT-C ManualnitantharaniNo ratings yet

- Environmental Science in Building PDFDocument350 pagesEnvironmental Science in Building PDFmaxmanfren100% (4)

- How Stem Finish Affects Friction and FE With Graphite-Based Control Valve Packing PDFDocument22 pagesHow Stem Finish Affects Friction and FE With Graphite-Based Control Valve Packing PDFAlexandreAguilarNo ratings yet

- Da Manual PDFDocument4 pagesDa Manual PDFJer SowNo ratings yet

- Technical Specification - HvacDocument46 pagesTechnical Specification - Hvacdhanu_lagwankarNo ratings yet

- Audco AIL Ball ValvesDocument19 pagesAudco AIL Ball ValvesnitantharaniNo ratings yet

- Appendix-2 Ejector System TroubleshootingDocument13 pagesAppendix-2 Ejector System Troubleshootingmahmoud abd elfatahNo ratings yet

- 2004 Rev Vacuum EjectorDocument5 pages2004 Rev Vacuum EjectorIndranil HatuaNo ratings yet

- Air LeakageDocument2 pagesAir LeakageanurudhNo ratings yet

- Sensible HeatDocument31 pagesSensible Heat12001301100% (2)

- Hot Oil System DesignDocument25 pagesHot Oil System DesignnitantharaniNo ratings yet

- Jacketed Vessel Design CalculusDocument4 pagesJacketed Vessel Design Calculusmaspiqdo100% (1)

- Handbook: For Sack Kraft Papers and Paper SacksDocument62 pagesHandbook: For Sack Kraft Papers and Paper SacksHakan Şahinoğlu100% (1)

- CC Power PlantsDocument48 pagesCC Power PlantsSam100% (1)

- Heating Coil DesignDocument2 pagesHeating Coil DesignUtku ÖzenNo ratings yet

- Thermocompressor PDFDocument4 pagesThermocompressor PDFYogesh GhanekarNo ratings yet

- Ball Mill Heating and CoolingDocument19 pagesBall Mill Heating and CoolingMehmet CNo ratings yet

- 05 - Short Circuit Strength of Power TransformersDocument10 pages05 - Short Circuit Strength of Power Transformersjm.mankavil6230No ratings yet

- PAPER CIGRE Drying of Power Transformers in The Field Applying The LFH Technology in Combination With Oil Reclamation 2006Document8 pagesPAPER CIGRE Drying of Power Transformers in The Field Applying The LFH Technology in Combination With Oil Reclamation 2006Alonso Lioneth100% (1)

- Vacuum PumpsDocument2 pagesVacuum PumpsNilton Bruno Salazar MartinezNo ratings yet

- Vacuum EjectorDocument6 pagesVacuum EjectorAmol KadamNo ratings yet

- AMMONIA Syn Gas Drying With Z4-01Document4 pagesAMMONIA Syn Gas Drying With Z4-01raghu4594No ratings yet

- Lecture Notes II - DRYING OF SOLIDSDocument18 pagesLecture Notes II - DRYING OF SOLIDSmohammedNo ratings yet

- Symp. Cambridge, 1981, (Fundamental Research Committee, Ed.), PP 343-364, FRC, ManchesterDocument30 pagesSymp. Cambridge, 1981, (Fundamental Research Committee, Ed.), PP 343-364, FRC, ManchesterRagabAbdoNo ratings yet

- Selected Design and Development of Vacuum ChamberDocument3 pagesSelected Design and Development of Vacuum Chamberpatel_saunak7470No ratings yet

- Low Pressure Air Drying Whitepaper LR InekoDocument10 pagesLow Pressure Air Drying Whitepaper LR InekoGandhiNo ratings yet

- Plasma SprayDocument5 pagesPlasma SprayZahid AnwerNo ratings yet

- Design Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeDocument6 pagesDesign Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeNeeraj SamadhiyaNo ratings yet

- Mist/Steam Cooling For Advanced Turbine SystemsDocument15 pagesMist/Steam Cooling For Advanced Turbine SystemsRAVI KUMARNo ratings yet

- 114 Paper Industry en 170705Document12 pages114 Paper Industry en 170705Christian MendozaNo ratings yet

- Separation and Purification Technology: William L. LuybenDocument3 pagesSeparation and Purification Technology: William L. LuybenKrishna RamaNo ratings yet

- Evaporator Vacuum System and Barometric CondenserDocument2 pagesEvaporator Vacuum System and Barometric CondensersalcedopozasNo ratings yet

- High Performance Cutting With Abrasive Waterjets Beyond 400 MpaDocument4 pagesHigh Performance Cutting With Abrasive Waterjets Beyond 400 MpaVishnu Rao M.No ratings yet

- Paper Mills Roller Coverings: Chemical ResistanceDocument8 pagesPaper Mills Roller Coverings: Chemical ResistancefapivaNo ratings yet

- Steam Jet EjectorDocument13 pagesSteam Jet EjectorNeesha VijayNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0278088 A1Document10 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0278088 A1dollarrbillNo ratings yet

- Interstage Coolers A Hot ItemDocument5 pagesInterstage Coolers A Hot Itemlbh6417320No ratings yet

- Heat and Mass Transfer Process in Exhaust Wet ScrubberDocument5 pagesHeat and Mass Transfer Process in Exhaust Wet ScrubberGracylla RoseNo ratings yet

- Wet Vs Dry Gas Cleaning in The Steel IndustryDocument6 pagesWet Vs Dry Gas Cleaning in The Steel IndustryDinesh KumarNo ratings yet

- Explosion DoorDocument15 pagesExplosion DoorGaluhNo ratings yet

- 1 State Key Laboratory of Electrical Insulation and Power Equipment, Xi'an Jiaotong University, Xi'an, 710049, P.R. ChinaDocument1 page1 State Key Laboratory of Electrical Insulation and Power Equipment, Xi'an Jiaotong University, Xi'an, 710049, P.R. Chinavishale70No ratings yet

- Basic Design CalculationsDocument6 pagesBasic Design Calculationsmulusewbelay86No ratings yet

- Evaporación 67 99Document1 pageEvaporación 67 99Piedad PintoNo ratings yet

- Jacketed Vessel DesignDocument4 pagesJacketed Vessel Designhero100% (1)

- 2018-01 - Nitrogen + Syngas - Packed Absorbers For Deep CO2 RemovalDocument11 pages2018-01 - Nitrogen + Syngas - Packed Absorbers For Deep CO2 RemovalAbdullaNo ratings yet

- Barrel Temperature An Tec 2008Document7 pagesBarrel Temperature An Tec 2008Zenebe DebeluNo ratings yet

- MCE416 Moodle 3 Fluid Power and FlowDocument33 pagesMCE416 Moodle 3 Fluid Power and FlowPaul KonduNo ratings yet

- Understanding Process Vacuum Condensers: Issue 3Document4 pagesUnderstanding Process Vacuum Condensers: Issue 3pothanNo ratings yet

- Water Vapor Migration and Condensation Control in BuildingsDocument11 pagesWater Vapor Migration and Condensation Control in BuildingsQuora EarningNo ratings yet

- Drivepower 2nded 161024201601Document20 pagesDrivepower 2nded 161024201601Eduardo GuidoNo ratings yet

- MAE 570 Aeropropulsion: Gas Turbine CombustorDocument38 pagesMAE 570 Aeropropulsion: Gas Turbine CombustorLuiz Felipe Disconzi LopesNo ratings yet

- Gas TurbineDocument7 pagesGas TurbineBadadmasi MaiwdaNo ratings yet

- Aspects Regarding Fouling of Steam Condenser - A Case StudyDocument8 pagesAspects Regarding Fouling of Steam Condenser - A Case Study10 000 de cartiNo ratings yet

- Piston VS TornilloDocument4 pagesPiston VS TornilloVictor Hugo Rodriguez CelyNo ratings yet

- Goulds-Paper StockDocument10 pagesGoulds-Paper StockDavid Alejandro GomezNo ratings yet

- Researchpaper Design Modification in Engine ExhaustDocument7 pagesResearchpaper Design Modification in Engine ExhaustDovah KiinNo ratings yet

- Compressed Air DryerDocument9 pagesCompressed Air DryermawooaNo ratings yet

- Condensate Line SizingDocument23 pagesCondensate Line SizingNirnay Patil100% (2)

- Steam Condensor Gas RemovalDocument7 pagesSteam Condensor Gas Removales9857No ratings yet

- B U L L E T I N: Application EngineeringDocument2 pagesB U L L E T I N: Application EngineeringMaria DazaNo ratings yet

- Principles of Vacuum CoatingDocument14 pagesPrinciples of Vacuum CoatingJorgeOchoaNo ratings yet

- High Vacuum Techniques-1Document15 pagesHigh Vacuum Techniques-1Nicholas MorganNo ratings yet

- A Continous Press Veneer DryerDocument3 pagesA Continous Press Veneer DryerFernandoNo ratings yet

- FEM Analysis of Ring Type Compressor Valve SeatDocument6 pagesFEM Analysis of Ring Type Compressor Valve SeatBelagaviNo ratings yet

- Performance Increase of Steam Turbine Condensers by CFD AnalysisDocument10 pagesPerformance Increase of Steam Turbine Condensers by CFD AnalysisAbdullah RobbaniNo ratings yet

- High Speed Compressors 15-Jun-2012Document10 pagesHigh Speed Compressors 15-Jun-2012ANILNo ratings yet

- Biermann's Handbook of Pulp and Paper - Cap 06Document22 pagesBiermann's Handbook of Pulp and Paper - Cap 06chau_riberNo ratings yet

- IPPTA 104-49-59 Innovative Steam ShowerDocument11 pagesIPPTA 104-49-59 Innovative Steam ShowerAmri ZalNo ratings yet

- 400 TIG - ARC Iwi ManualDocument13 pages400 TIG - ARC Iwi ManualnitantharaniNo ratings yet

- Installation Manual - OrificeDocument15 pagesInstallation Manual - OrificenitantharaniNo ratings yet

- Hot Water Solution IOM-786Document46 pagesHot Water Solution IOM-786nitantharaniNo ratings yet

- Machine Details - v2 - GOC For Flow MeterDocument3 pagesMachine Details - v2 - GOC For Flow MeternitantharaniNo ratings yet

- Orifice Straight LengthsDocument1 pageOrifice Straight LengthsnitantharaniNo ratings yet

- Line Sizing and Fluid VelocityDocument3 pagesLine Sizing and Fluid VelocitynitantharaniNo ratings yet

- Steam Injection Liquid Heating System: Process Heating Solutions WorldwideDocument2 pagesSteam Injection Liquid Heating System: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- Variable Flow: Process Heating Solutions WorldwideDocument2 pagesVariable Flow: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- Steam Injection Liquid Heating System: Process Heating Solutions WorldwideDocument2 pagesSteam Injection Liquid Heating System: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- Clean in Place: Process Heating Solutions WorldwideDocument1 pageClean in Place: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- Steam Injection Liquid Heating System: Process Heating Solutions WorldwideDocument2 pagesSteam Injection Liquid Heating System: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- CP Pickheaters Jacketed Heating Special Report PDFDocument25 pagesCP Pickheaters Jacketed Heating Special Report PDFnitantharaniNo ratings yet

- Corn Grain Cooking: Process Heating Solutions WorldwideDocument1 pageCorn Grain Cooking: Process Heating Solutions WorldwidenitantharaniNo ratings yet

- 5 CombiflameDocument8 pages5 CombiflamenitantharaniNo ratings yet

- Nozzle Design ReportDocument4 pagesNozzle Design ReportnitantharaniNo ratings yet

- Section - 15985 Temperature Control Specifiers GuideDocument6 pagesSection - 15985 Temperature Control Specifiers GuideAntonio LebrunNo ratings yet

- BS EN 16798-7-2017Document64 pagesBS EN 16798-7-2017Tài Nguyễn ĐứcNo ratings yet

- Zemansky, Dittman, Heat and Thermodynamics, Chapter 2Document20 pagesZemansky, Dittman, Heat and Thermodynamics, Chapter 2gungnirr0% (1)

- 204 - Modular ADT Air Handling Unit CatalogueDocument12 pages204 - Modular ADT Air Handling Unit CatalogueundeadmithNo ratings yet

- Energy and Buildings: F. Barreca, C.R. FicheraDocument7 pagesEnergy and Buildings: F. Barreca, C.R. FicheraFRANCESCONo ratings yet

- Application Brochure Water-Based Air Conditioning PDFDocument16 pagesApplication Brochure Water-Based Air Conditioning PDFEldin JelecNo ratings yet

- An Effect of Different Parameters of Fins On Heat Transfer of IC Engine-Review StudyDocument9 pagesAn Effect of Different Parameters of Fins On Heat Transfer of IC Engine-Review StudyArturo FigueroaNo ratings yet

- Lecture 5: Heat Transfer in Food ProcessingDocument34 pagesLecture 5: Heat Transfer in Food ProcessingTaytoNo ratings yet

- ٣Document227 pages٣Sayed TawfeekNo ratings yet

- Steam Jet RefrigerationDocument14 pagesSteam Jet RefrigerationSAATVIK JAINNo ratings yet

- ME-341A - Heat and Mass TransferDocument34 pagesME-341A - Heat and Mass TransferMukul ChandraNo ratings yet

- 1996 CASALE HEtraysDocument10 pages1996 CASALE HEtraysFatima KazmiNo ratings yet

- Department of Chemical Engineering Heat Transfer Lab (CHD-228)Document8 pagesDepartment of Chemical Engineering Heat Transfer Lab (CHD-228)prasoonNo ratings yet

- Prasanth LeeDocument46 pagesPrasanth LeePRASANTHNo ratings yet

- Types of Ac SystemsDocument26 pagesTypes of Ac SystemsVarsha PatelNo ratings yet

- Carta Psicrométrica 760 MMHGDocument1 pageCarta Psicrométrica 760 MMHGMarcos MarchettoNo ratings yet

- Building ServicesDocument9 pagesBuilding ServicesPriya SinghalNo ratings yet

- BoQ - Insulation Works (Group 2)Document4 pagesBoQ - Insulation Works (Group 2)Bhavanishankar ShettyNo ratings yet

- BtechMech Heat TransferDocument2 pagesBtechMech Heat TransferAdamsNo ratings yet

- Stirling Engine & ApplicationsDocument32 pagesStirling Engine & ApplicationsLASINNo ratings yet

- As Fulfillment of The Equirements For TheDocument58 pagesAs Fulfillment of The Equirements For TheTechnicus Proyectos ElectromecánicosNo ratings yet

- Aermac Bufer Saf - enDocument2 pagesAermac Bufer Saf - ensloba68No ratings yet