Professional Documents

Culture Documents

Sertifikat Control Valve Fisher

Sertifikat Control Valve Fisher

Uploaded by

FIRMANSYAH0 ratings0% found this document useful (0 votes)

16 views59 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views59 pagesSertifikat Control Valve Fisher

Sertifikat Control Valve Fisher

Uploaded by

FIRMANSYAHCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 59

&

EMERSON Sen ees

eee

a

einem

ies

CERTIFICATE OF COMPLIANCE

IssuED To: PT. CONTROL SYSTEMS

CUSTOMER P/O NO: Pojwaioasrvi2012

Emerson Process Management REF: 171-120359F AST

ITEM NUMBER: 999001

Emerson Process Management Menufacturing (M) Scn. Bhd. certfied that items herein were manufactured and shipped in

conformance to contract specications and in accordance with quality control standards commen to the control valve industry.

We further certity that all items shipped herein are free from defects in material andor workmanship.

Emerson Process Management Nanutacturing (M) Sdn. Bhd.

du.

Ausorised Signature

Date27 sep, 2012

ys

EMERSON

Emerson Prosese Nanagerent

Manafecuing (M) Seb. Bhd,

Lot 13111, Mule Labu

‘owaean Perindustian Mii

TIR07 Nal, Neger Sembilan

Malaysia

TEL-505-7892523

FAX 606-7998454

CERTIFICATE OF ORIGIN

coNsIaNEE:

‘YOUR ORDER No.:

cust, Po No:

DESCRIPTION:

ITEM NUMBER:

We hereby certity that the above geods are China origin,

Emerson Process Management Nanufactuting (M) Sdn. Bhd.

Pde.

‘Aumerises Signature

ete 27 Sep 2012

PL CONTROL SYSTEMS

Inspection certificate

S Certificat de Réception

; i narson Procass Nanogen Fania Vai

Abnahmeprifzeugnis ae ee

EMERSON. EN 10204-8.1 Kean es aes

5 ‘wong Dersomment are,

Process Managem Soi7a0 nym,

s Managemen Hen

ae 22602.3803

srzoeeiesoa

toa: 10 Aug, 2012

Customer EWERSONPROGESS WoNT [orderNe ___POUAGIanTaOT Faher Rel sa2-vesrsres

Shan NANUPACTURINS Roconende Renan Oao0t

Autrogeter Boxter Fatorrot 930230

Tem Fea No Travan ea No ORT

fen Reeptie noes tato

Postion Kem Soa Ne

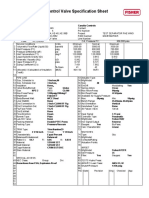

Tape % Sis z Rating eer

pe fer40 Branson Gases

Blurene Tyre sea Korn Buckeute

Al rans of fe contrac"

‘Nous cartons que ia Ivratson susponmnée a ote venhie ot est conforma aux stbulaians os Tacceptation da s commande,

Wir bestésigen, dass dle obenganannioliferung goprt wurde und den verelrbarungan dar Auragabeeitiung antirch

Dimension & vieual check

Controle viel & dinensionnet

‘mass & Semprotung

Function test

seal de fonctonnement

Furkionspedtung

Pressure and leak tests /Eprouves de résistance ot ossais d'étanchéité / Druok und Dichtheltspritung

Satisfeclory /Saistalannt/ Zutadaratslord

Salifactory /Satstalsant/ Zuiodorstolond

poke ‘Alloa

Weeees ses ceiiesy Potente) Need onda cy Leite names neasi ree

Stage Boss ts | out, | Fsaategere a ["fatun || vig /carnra

Serger praanor |" Egat" | incon ‘cctago

‘Helium wid

a rae Tan [Sado a Roto

ial epeton 5 E Sanders E Gy

ysrate Te Water PORTS Tatar Pe Nota

[Oreatona FE E Standard F aK

Seat Leat Tet ie sara Tan [Sass eaTsO [ease

Material test certificates /Cerlficels maléres / Bescheinigungen aber Werkstofforatungen

Cortficat de reception 3.1

r "Al wees and weldng recedes are ques in asordance wth ASHE. ler and Pressure Vessel code secien IX ad al penomal

Brlomng ndarcvs examinaeons re quaiiedte Mai TaN Tea

r ‘Tu proses ragetordt Canada una CRN

r Accrting to NACE NRO175 ‘SO 15158 / Svar NACE MRC17S150 45156 Nich NACE MRO17E 18016168

r ‘Aocoring to NAGE NRO1/S-2002 / Sunvant NACE MRO17S-2002/ Nech NACE MRON752002

ts ‘Accaringto NAGE NROIOS Suan NACE MRO‘ / Nach NACE NROIO3

‘Descriplonibeeciptovaezelching Nae [fest Watie Contaichoe Nr

BONNET [ASME Satos, Fv 708102 [NAGE MROIO3 & MROTTORSO Tese) [COT

VALVE BODY ASME SA2TO WES FNSZTBTOT [em

Additional Statements

Extemal Inspection’ inspection exterieur / Externe Inspeition Works Inspection/ L'expert de l'usinel Werkssachverstinaiger

Bai Jim ~ QA DOCUMENTATION TECH

Gow Baa

Certificate of Conformity

ss Attestation de conformité

Werkbeschenigung Ertomen Pricees Menecerent Tia Vera

EMERSON. EN enh Wing Dovobqnat Ne,

ent eR cnn

9228712800

22289120508,

vwrameronprosssir

Manager

DDate}Oatun: 10 Aug, 2012

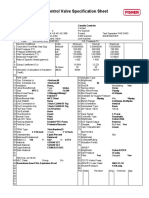

Customer EVERSON PROGESS NGMT Order No POLATMENIIND Fisher Ret S82 .VBBI6T68

Giont NANUFACTURING Ko commande RerFleher 000008

Aultraggebor Basta ar Fishor ret.

em Teg No evanez ‘Serial No PETISSS

ten Norepere No de sare

Position Kana Wr Soran fir

Type = Size 7 Rating cA

Type Dimension Claeee

Saurav Nennwote Bivckstre

We heroby certify, that the material described above complies with the requirement of the order.

"Nous certfions que la livraison susnommée a été vérifiée est conforme aux stipulations de 'acceptation de ta commands.

Wir bestatigen, dass die obengenannte Lieferung den Vereinberurgen der Auftrag entspricht.

The following parts were made from materials complying ASTM, ASME, DIN, AFNOR, BS or other Standard

specifications.

La matiére des composants est conforme aux normes ASTM, ASME, DIN, AFNOR, BS ou autres normes.

‘Der Werskstoft der nacnstehenden Sautelle entspricht den Anforderungen des ASTMASME, DIN, AFNOR, BS Norm oder

anderen Normen.

Parti Pidce/ Teil Material / Waiériaux/ Werkstor

CAGEFO™ [ASTWATAT CB7CU-1, FMS20B18, HOO NON-PRESS RETARING

PLUG BAL, FTVBE 10/416 SSTHT HRC 38 MIN, FUS20B63

[SEAT RING TYPE S100 8 SST HT ARCS MIN, FMSZOBGT

STeMPuUS [S31600 al

Works Inspection/ Liexpert de lusine/ Werkssachverstindiger

Bai Jim --QA DOCUMENTATION TECH

Tom Bai

JIANGSU JINSHI MACHINERY GROUP.

J IM, P JINHU CASTING & FORGING CO.LTD

INSPECTION CERTIFICATE,

ADD:GUANTANG TOWN JINHU COUNTRY JIANGSU PROVINCE, CHINA,

‘TEL :0086-517-96871118 FAX:0006-517-86871181

Inspection Certificate (EN 10204:2004 3.4.) Contifieate-No.: G0177-1-2R33022502A

Customer {35MM EHD HLA,

‘Order-No.:UET12022JHZ0 Description:2’Bonnet

Line item number:03 Pattern number NONE

(Material: ASME SA105-2010 , FMS 206102 Rev.D Part number:2R33022302A

Molting process-Heat Treatment: N $00C*250min

‘A\Chomical analysie

Gusta: c Ms Pe Si 5 ou Ni or Wo y o

% % * m % % % % % % %

‘ASME SA105-2010, [aa 064.05 | <0.035 |010.035} 250 oe | 230 <2

ev RT 510 300 38 81 165

(©) Dimensional check and NOT

Testing : etait Result

Nisual inspection & dimensional check IFosteara12 Reva 0K

[bimension inepection loo 0K

[No Woicing Performed

1) Devry Condition; Nornaling

Moot the oairaments of NAGE IO 15154MRDITS& MRO 203,

Wehereby cat tha the ma sted and napected in accordance with

snd sustorofreod

creed AEH iene 3/2508 Aooroved 8

“ile: Inpector fe Chotkor Tile OA. Bret a2

naan ANHUI YINGLIU ELECTROMECHANICAL CO.,LTD

INSPECTION CERTIFICATE.

‘wes

and ADD:No.96 PIHE ROAD, HUOSHAN COUNTY,ANHUI PROVINCE, CHINA

TEL:0006-564-5026508 FAX:0086-5645098500

Inspection cates (EN 102043.) Contest. 242085624

Customer FISHER

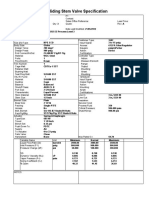

Order No 188904 Deseo VALVE BODY; 2CLA00& 600 RF

Line tem umber atm umber A1202:2

Matera: ASME SA216 2010 WCC , FMS 208401 Rev.W¥ (meets WB and WCC requirements) Part number:2R314822012

1ss-Heat Treatment: +N 9200°2.5h Heat No.L94652

A\Ghomical analysis

¢ we] st P 3 co | mo | m | cw v a] om | wi ic

Heat No.

* * % % % * % % * % % % %

Specification | <025 | <120 | Bristle

We Raraby Goya We aaa ECTIDGT AGE Tas BOOT TET SE SOMTTGE WITT TEAR OTS COTTA

Nous cone sia rleon susormea 2 Vrie ot st cofore a Sipuatons de Facepiatin dl commando

Wirbecstzen dss le obongenannt efourg gop wurde und dor varenbarungon dr Aufapabestipung onsen

Dimension & visual check Satin | Sastlsant/Zutiodontatond

(Conde vol &drvensionel

‘nace &Senpeting ‘

unetion test Satstaioy | Sastisart/Zutiodenstaend

seal oe fontenrement

Funstonspntang

Pressure and leak ess Eprewes de résistance of soos tinct / Druck und Dice

bribes Test duration] i

TAWA ue curation} eeu conform to! [Allowable Leckage|Actal Leakege/ Ful

‘Wirogen’ Pressurefanuaesy} Résutetcontore a | 1 Fst Tiebe | alto Comessene|

scsi — ‘Expeins | Zulesi9e Loctago| Lockage

area aR Bara Fr Standard Teak

Fra renecton Standart lox

Fycosate Test WATER [esoPse [A Stendar [Roteak

Sportal Siar lox

Seat ook Tes AR SPSS ri iss ea Scr oscrR

avo ne Test Stand lox

Water sk Sot RGSS TOOTSIE TSSTEST BSSTONGT GOTTA rar

‘Carica de recepfon 34

e ‘Al welders and weling procedure are quali in acordance wth ASME. Soler and Preaure Ves code scien IX andl personnel

etoming nondestustve examinations are cuafld to ASNT] SNT-TC-TA.

Oo ‘This prodaceregterecn Canad under CRN

o tn czordance with metalic requramerts f NACE NRO{75 SO 15186. Envronmentlresicions may spply fo wated pasando boling.

Sufvat NAGE MRO'TS ISO 15156) Nach NAGE MRO} 75180 5166

o Ineccoreance wih metalurgalreqUremerts of NACE NRO17S-2002.Envronmental resticions may acoly to weted pars anor botin./

Subant WAGE WROTTS.2002 7 Nach NACE NAD'TS:2002

D In accorcance wih mclurgca requremens of NACE NRO175-200. Environmental reticent may acy to weted pars arbor.

Subvart Ge WROI7S-2003/ Nach HACE MAD'75-2002

o Inaccordancs wit metalurialrequremerts of NACE NRO10S.Envrenmenal escions may spoly to weld parts andlor teling./Suivat

NAGE WE0163/ Nach NACE MOTOS.

DescriptonDescistonBezeichyna Materaiiarasders Heat Nao Goulde/Gharge Nr

BONNET [ASME SATO, FMSOBROD ca3063

[VALVE BODY ASME SA2i6 WOC FUSEOIOT aera

‘Asivonal Statarents

External Inspection’ Inspecton exterieu/Exleme Inspetion Wiorks Inspection! L'xper de usin! Workssarn

Zunotan Satan

pu.

EN 10208 341 ose2sss

‘ Certificate of Conformity (FisueR)

z be ER

& Attestation de conformité a)

Werkbeschenigung Waeuocurs (Seno

EMERSON EN 10204.2.4 a3. Mk Lab

F awasan Perndutvan Mia

‘iat? Wie, Negos Seman

Process Management om arbi

‘eveue T9240

Fax 806-7 98464

DaberDatu: 5 Sep, 2012

tomer PT. CONTROUSYSTENS [Ordecno ____ POGADAGNTZOT2 Fisher Ref 171 420950

Stent Nocinmanca Recsner 000008

Autragoeber Best ne Fisarrot 9922360

em Free Ne. PUNE Serial Wo OBR

tom Rovere Nove see

Postion Keone Seon

ype = So z Rating Le00

Type . Birorsion Sas

Barone Nennwot Drette

We hereby certify, that the material described above complies with the requirement of the order.

Nous certfions que la livaison susnommée a été vérifize est conforme aux stipulations de 'acceptation de la commande,

Wir bestatigen, dass die obengenannte Lieferung den Vereinbarungen der Auftrag entspricht.

‘The following parts were made from materials complying ASTM, ASME, DIN, AFNOR, BS or other Standard

‘specifications.

La matiére des composanis est conforme aux normes ASTM, ASME, DIN, AFNOR, BS ou autres normes.

Der Werskstotf der nachstehenden Bauteile entspriaht den Anforderungen des ASTM.ASME, DIN, AFNOR, BS Norm oder

anderen Normen.

Part Piece / Teil Material / Matériaux Werkstom

[ERSE EO [ASTM ATAT CBTOU-T, FMS20B10, HO00NON-PRESS RETANNG

PLUG BAL [541600 FOS 75

ISEATRING TYPE aT016 SST AT HAG 56 MIN, FISOB6A

STEMPLUG [RSTM ARTS 531600 COND, COLD FIN, GND & POL

Works Inspection! L'expert de lusine! Werkssachverstandiger

Zuhallah Salleh —

du.

JIANGSU JINSHI MACHINERY GROUP

J M, P JINHU CASTING & FORGING CO.LTD

INSPECTION CERTIFICATE

‘ADD:GUANTANG TOWN JINHU COUNTRY, JIANGSU PROVINCE, CHINA

‘TEL:0086-517-86871118 FAX:0086-517-0671181

Inspection Certificate (EN 10204:2004 3.1.) Cetificate-No.: @B398-3-2R330223024

Customer: SSMU KAD AMAT.

‘Ordor-No:UET12017-JHZD Descrption:2"Bonnet

Line item number04 Pattorn numbor:NONE

Materia: ASME SA108.2010 , FMS 208102 Rev.D Part number-2R33022302A

Melting process-Heat Treatment: N 800%C"250min

‘AyChomical analysis

mute e Mo P 81 8 ou Wi cr wo v o

% % % % % % % % % % %

asmesaiesaoio | <0.95 | 0.6+4.08 | s [soe f[fwf[eleflvfe

Haat ,

x [se [s |) ts [* [Ts fs )s*]*]

asuesaroszor0 |

Ghecked By: fk Revi pay Avproved®y: Zonet

Tile raptor e Te Tile: @.Checkor Te: @.A Manager Date: March 20,2012

hake ANHUI YINGLIU ELECTROMECHANICAL CO.,LTD

gh Co INSPECTION CERTIFICATE

ADD:No.96 PIHE ROAD, HUOSHAN COUNTY,ANHUI PROVINCE, CHINA

‘TEL:0086-564-5036508 FAX:0086-564-5036500

Inspection Cortifieato (EN 10204-3.1.) Cortficat-No. 201207377

Customer: FISHER

Order-No. 182895

Line tem number:005

Description: VALVE BOD)

Pattorn number:A1282-2

Y; 2 CL.400 & 800 RF

Matorial: ASME SAZ16 2010 WCC , FM'S 208101 Rev.W (moots WCB and WCC requirements) Part number:28314922012

Melting process-Heat Treatment: #N 9200"2.8h Heat No.:L94036

AA)Chemical analysis

c a s P 3 cr Mo Nr cu v a ND w cE

Hoat No,

% % % % % % % * % * % % %

Specification | * | « * [*|*«|« | -*

asuesarosao10 | * |* | * | * | * a a

fasnesaioeane |

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Kidde Co2 Product Manual 050128 PDFDocument299 pagesKidde Co2 Product Manual 050128 PDFFIRMANSYAHNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aquamaster 3 Flow Measurement: Saving Every Drop of Energy and Cost Naturally!Document7 pagesAquamaster 3 Flow Measurement: Saving Every Drop of Energy and Cost Naturally!FIRMANSYAHNo ratings yet

- 719pro Ssdan0000Document4 pages719pro Ssdan0000FIRMANSYAHNo ratings yet

- General Specifications: FCN/FCJ Autonomous Controller FunctionsDocument7 pagesGeneral Specifications: FCN/FCJ Autonomous Controller FunctionsFIRMANSYAHNo ratings yet

- General Specifications: Model CHS5700 FAST/TOOLS Integration Engineering PackageDocument3 pagesGeneral Specifications: Model CHS5700 FAST/TOOLS Integration Engineering PackageFIRMANSYAHNo ratings yet

- Differential Pressure Gauge Model 1130/1131/1132/1133: Max. Static Pressure 400 BarDocument2 pagesDifferential Pressure Gauge Model 1130/1131/1132/1133: Max. Static Pressure 400 BarFIRMANSYAHNo ratings yet

- For IND570 Applications: ServicesDocument2 pagesFor IND570 Applications: ServicesFIRMANSYAHNo ratings yet

- Control Valve Specification Sheet - LCV 2inch 600# R 1Document1 pageControl Valve Specification Sheet - LCV 2inch 600# R 1FIRMANSYAHNo ratings yet

- 11.temperatur Gauge - Wika PDFDocument7 pages11.temperatur Gauge - Wika PDFFIRMANSYAHNo ratings yet

- Data Sheet Fisher Pressure Control Valve-GatramasDocument5 pagesData Sheet Fisher Pressure Control Valve-GatramasFIRMANSYAHNo ratings yet

- In Any Lighting Conditions: Easy-to-Read DisplayDocument2 pagesIn Any Lighting Conditions: Easy-to-Read DisplayFIRMANSYAHNo ratings yet

- Control Valve Specification Sheet - PCV 3inch 600# R 1Document1 pageControl Valve Specification Sheet - PCV 3inch 600# R 1FIRMANSYAHNo ratings yet

- Data Sheet Control Valve FisherDocument9 pagesData Sheet Control Valve FisherFIRMANSYAHNo ratings yet

- Control Valve REv1 PDFDocument2 pagesControl Valve REv1 PDFFIRMANSYAHNo ratings yet

- Shoulder Type Machinery Eye BoltsDocument1 pageShoulder Type Machinery Eye BoltsFIRMANSYAHNo ratings yet

- Pressure Control ValveDocument1 pagePressure Control ValveFIRMANSYAHNo ratings yet

- DS PM0202 en Co 3672Document4 pagesDS PM0202 en Co 3672mkfe2005No ratings yet

- Product Bulletin Fisher Yd Ys Control Valves en 125150 PDFDocument24 pagesProduct Bulletin Fisher Yd Ys Control Valves en 125150 PDFFIRMANSYAHNo ratings yet

- MT8102iE1 Datasheet ENGDocument2 pagesMT8102iE1 Datasheet ENGAtul Kumar MauryaNo ratings yet

- Ball Valve - GLTDocument19 pagesBall Valve - GLTFIRMANSYAHNo ratings yet

- Beban Total - ScurveDocument1 pageBeban Total - ScurveFIRMANSYAHNo ratings yet

- Preliminary CalculationDocument1 pagePreliminary CalculationFIRMANSYAHNo ratings yet

- Ecf-Rtc Roof Fan PDFDocument12 pagesEcf-Rtc Roof Fan PDFFIRMANSYAHNo ratings yet

- Drawing ReferenceDocument1 pageDrawing ReferenceFIRMANSYAHNo ratings yet

- DAQMaster EN Cat 20200115 WDocument2 pagesDAQMaster EN Cat 20200115 WFIRMANSYAHNo ratings yet