Professional Documents

Culture Documents

V. Repair and Preservation: One Month After Installation

Uploaded by

tuan0 ratings0% found this document useful (0 votes)

26 views1 pageThis document outlines various repair and maintenance items for a machine tool and the recommended checking periods. It lists 27 items such as removing chips, cleaning coolant nozzles, checking hydraulic oil and coolant flows, checking for oil leaks, inspecting tools for damage, and checking safety devices. Most items should be checked daily, weekly, or monthly, while others are checked every six months, yearly, or biennially to keep the machine functioning properly.

Original Description:

Original Title

109

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines various repair and maintenance items for a machine tool and the recommended checking periods. It lists 27 items such as removing chips, cleaning coolant nozzles, checking hydraulic oil and coolant flows, checking for oil leaks, inspecting tools for damage, and checking safety devices. Most items should be checked daily, weekly, or monthly, while others are checked every six months, yearly, or biennially to keep the machine functioning properly.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 pageV. Repair and Preservation: One Month After Installation

Uploaded by

tuanThis document outlines various repair and maintenance items for a machine tool and the recommended checking periods. It lists 27 items such as removing chips, cleaning coolant nozzles, checking hydraulic oil and coolant flows, checking for oil leaks, inspecting tools for damage, and checking safety devices. Most items should be checked daily, weekly, or monthly, while others are checked every six months, yearly, or biennially to keep the machine functioning properly.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

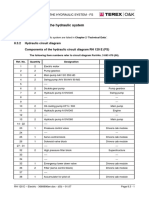

V.

REPAIR AND PRESERVATION

2-2. Check and Repair Items

Note: Checking Period,

CRT display

Checking and Repairing period Reference

Period

Item Daily Weekly Monthly Six- Yearly Biennially Reference

monthly

1. Remove chips inside the 2-3-1

machine

2. Remove chips above the 2-3-1

tool post

3. Remove chips above the tail 2-3-1

stock

4. Remove chips from each 2-3-1

slider cover

5. Clean coolant nozzle 3-6-3

(if clogged)

6. Treatment of chip 2-3-1

7. Clean coolant tank 3-6-2

8. Coolant filter 3-6-2

9. Check the hydraulic oil flow 2-3-3

10. Check the coolant flow 2-3-3

11. Check the lubricating flow 2-3-3

12. Hydraulic oil pressure 35 2-3-4

2

kgf/cm

13. Check the lubricating oil 3-5-1

supply

14. Check the coolant supply 3-6-1

15. Hydraulic oil strainer 3-4-2

16. Lubricating pump filter 3-5-2

17. Clean around the machine 2-3-1

18. Oil leakage 2-3-3

19. Remove the tool chip and 2-4-2

check if damaged and

broken

20. Loosen bolt

21. Turret tool sank 2-4-2

22. Check Operating Panel

23. Clean the Electric Panel

24. Operation of emergency

stop switch

25. Vibration, noise and

increased temperature

26. Check the operation of

safety device

27. Check the tension of spindle ( ) 2-6-2

belt one month after

installation

5-23

You might also like

- Satoh S650G Repair ManualDocument219 pagesSatoh S650G Repair ManualrepropNo ratings yet

- Lycoming O320-H2AD 76 Overhaul ManualDocument39 pagesLycoming O320-H2AD 76 Overhaul Manualdale84% (19)

- GB RockBreaker Manual PDFDocument84 pagesGB RockBreaker Manual PDFSerkanAl100% (5)

- Service Manual JCB 8027Z, 8032Z Mini Excavator (Preview)Document6 pagesService Manual JCB 8027Z, 8032Z Mini Excavator (Preview)Amip Folk0% (1)

- K3V112DT Instruction Manual: Kawasaki Precision Machinery of America 5080 36 Street S.E. Grand Rapids, MI 49512Document40 pagesK3V112DT Instruction Manual: Kawasaki Precision Machinery of America 5080 36 Street S.E. Grand Rapids, MI 49512Luis Carlos Ramos100% (10)

- Procedure To Destroy Occultic or Cursed ObjectsDocument5 pagesProcedure To Destroy Occultic or Cursed ObjectsJuan Jaylou Ante100% (1)

- Alkin AirTex ManualDocument37 pagesAlkin AirTex ManualBryan PenningtonNo ratings yet

- UF6 ManualDocument24 pagesUF6 ManualPhil Ruby Tigers0% (1)

- DangerDocument1 pageDangertuanNo ratings yet

- 206L4FM206L4FM01S02Document16 pages206L4FM206L4FM01S02enila upretiNo ratings yet

- Motor Yamaha 2.5 Parte 2 de 3Document68 pagesMotor Yamaha 2.5 Parte 2 de 3usuario29000No ratings yet

- Frequency Cleaning / Inspection Points Lubricating Points Type of LubricantDocument3 pagesFrequency Cleaning / Inspection Points Lubricating Points Type of LubricantKrishnamurthy NatarajanNo ratings yet

- Partie 1Document60 pagesPartie 1Alain GARNIERNo ratings yet

- Colt Manual CM116 - M16A2 Light Machine Gun - M16A2LMG (Password Cracked)Document78 pagesColt Manual CM116 - M16A2 Light Machine Gun - M16A2LMG (Password Cracked)sniper_spotterNo ratings yet

- Cg-840 Machinery Inspection BookDocument24 pagesCg-840 Machinery Inspection Bookgreatenick.nbNo ratings yet

- Perventive MaintenanceDocument1 pagePerventive MaintenancePeracha EngineeringNo ratings yet

- Operation and Maintenance of Hydropower Stations PDFDocument26 pagesOperation and Maintenance of Hydropower Stations PDFtranhuutuongNo ratings yet

- Tiger 1050data 2Document1 pageTiger 1050data 2pctechmtbNo ratings yet

- 702-01 Checks During Standstill Periods: Man B&WDocument6 pages702-01 Checks During Standstill Periods: Man B&WRobert LuuNo ratings yet

- Scheduled Maintenance Check Sheet: Tiger 1050ccDocument2 pagesScheduled Maintenance Check Sheet: Tiger 1050ccAlvaro Rodrigo Tobar AlvarezNo ratings yet

- Rig Inspection & SurveyDocument102 pagesRig Inspection & SurveyhshobeyriNo ratings yet

- Carrier Sanyo 16NK IOMDocument193 pagesCarrier Sanyo 16NK IOMDewanjee AshrafNo ratings yet

- Maintenance & Repair Manual: Ariel CorporationDocument169 pagesMaintenance & Repair Manual: Ariel CorporationMuhammad Rosihan100% (1)

- MST - 800VD - 80001 & UP Op ManualDocument136 pagesMST - 800VD - 80001 & UP Op ManualBradley StewartNo ratings yet

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataDocument12 pages8.3 Description of The Hydraulic System: 8.3.1 Technical DataFuad JahićNo ratings yet

- Attribute - Group - Id Sort - Order Name (En-Gb) 1 1 Purification Process 2 2 Technical Specification 3 3 Warranty: 4 4 Additional InformationDocument2 pagesAttribute - Group - Id Sort - Order Name (En-Gb) 1 1 Purification Process 2 2 Technical Specification 3 3 Warranty: 4 4 Additional InformationsojeckNo ratings yet

- Service Manual Blood Collection Mixer ...Document64 pagesService Manual Blood Collection Mixer ...Shan Ahmad100% (1)

- Moduspec ChecklistDocument99 pagesModuspec ChecklistS DNo ratings yet

- Daytona 675 Service ScheduleDocument1 pageDaytona 675 Service SchedulealexNo ratings yet

- Mechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7Document58 pagesMechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7patar marpaungNo ratings yet

- Safety Barriers 18: S.p.A. Identification Code 3 108 RevisionDocument1 pageSafety Barriers 18: S.p.A. Identification Code 3 108 RevisionsnnsnnsnnNo ratings yet

- Installation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterDocument78 pagesInstallation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterevgenyNo ratings yet

- 8-Maintenance and InspectionDocument10 pages8-Maintenance and InspectionmominzadahNo ratings yet

- Remove and Assambly Implement Control ValveDocument12 pagesRemove and Assambly Implement Control ValveAlberto BastidasNo ratings yet

- Maintenance of TransformerDocument4 pagesMaintenance of Transformerdownload4sumitNo ratings yet

- GV 250 SM 2Document22 pagesGV 250 SM 2Fabrizio FloresNo ratings yet

- MC174CRMDocument224 pagesMC174CRMГригорий ГригорянNo ratings yet

- IOM IR-420 - BKZ: For Drip Tape Applications (Sizes 1.5 ''-4" DN40-100) DescriptionDocument2 pagesIOM IR-420 - BKZ: For Drip Tape Applications (Sizes 1.5 ''-4" DN40-100) DescriptionOscar RhenalsNo ratings yet

- Hanbell Maintenance ManualDocument89 pagesHanbell Maintenance ManualLOUIE100% (1)

- lm2500 PocketguideDocument311 pageslm2500 PocketguideMohammed YusufNo ratings yet

- Agrolux 4.80e Workshop ManualDocument438 pagesAgrolux 4.80e Workshop ManualMinn Thet Naing100% (1)

- 16 1yanmar 8N21AL VDocument420 pages16 1yanmar 8N21AL VFrank1100% (1)

- Hydraulic FluidsDocument299 pagesHydraulic FluidsDavid KarayofNo ratings yet

- Mantenimiento ScrollDocument33 pagesMantenimiento ScrollproyectosNo ratings yet

- SHARP SV 4328 5127 6332 Maintenance ManualDocument144 pagesSHARP SV 4328 5127 6332 Maintenance ManualmacNo ratings yet

- Cannon HandbookDocument319 pagesCannon HandbookmerdanNo ratings yet

- OM AbsorptionChiller DirectTypeDocument147 pagesOM AbsorptionChiller DirectTypeatiqNo ratings yet

- Integral Acc DriveDocument133 pagesIntegral Acc DriveJoseSantiagoMontañoBucio100% (1)

- Section 2: Normal ProceduresDocument16 pagesSection 2: Normal Proceduresandres felipe sandoval porrasNo ratings yet

- Electro-Motive Division General M O T O R S C0Rpof2AtlonDocument6 pagesElectro-Motive Division General M O T O R S C0Rpof2Atlonamir barekatiNo ratings yet

- Installation, Operation, and Maintenance Instruction For Water Cooled ChillerDocument29 pagesInstallation, Operation, and Maintenance Instruction For Water Cooled Chillergovind yadavNo ratings yet

- MCH-6 - r00 01-2015Document28 pagesMCH-6 - r00 01-20154h9dhj64cwNo ratings yet

- C2500 ЭлектросхемыDocument32 pagesC2500 ЭлектросхемыЕвгений ГубаревNo ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- Heinen & HopmanDocument39 pagesHeinen & HopmanSebastian Przybylowicz100% (1)

- P2 Training For Hyva - PPT - Modo de CompatibilidadDocument55 pagesP2 Training For Hyva - PPT - Modo de CompatibilidadJose OrjuelaNo ratings yet

- SM MC405 3 2020Document358 pagesSM MC405 3 2020Keith De SchryverNo ratings yet

- Hartl Powercrusher PC1 Impact Crusher Service ManualDocument22 pagesHartl Powercrusher PC1 Impact Crusher Service ManualMax Perminov100% (1)

- Maintenance Manual: Container Reach StackerDocument30 pagesMaintenance Manual: Container Reach StackerMisael EchavarriaNo ratings yet

- 080 - User Handbook N0000322GB - HDocument69 pages080 - User Handbook N0000322GB - HNam Lê XuânNo ratings yet

- LYC 60294 9 2 Overhaul 76series1975 1996 PDFDocument230 pagesLYC 60294 9 2 Overhaul 76series1975 1996 PDFDAVID WRIGHT100% (2)

- 1 Scrum Master Skills m1 Slides PDFDocument66 pages1 Scrum Master Skills m1 Slides PDFSohaib Omer SalihNo ratings yet

- A View From Elkab The Tomb and Statues oDocument87 pagesA View From Elkab The Tomb and Statues oBeatriz FélixNo ratings yet

- Bombardier Zefiro Technical Description enDocument15 pagesBombardier Zefiro Technical Description ennickerlesstezla100% (1)

- PGCC 2022 HandbookDocument17 pagesPGCC 2022 HandbookhasnainNo ratings yet

- Geometry Sparkcharts Geometry Sparkcharts: Book Review Book ReviewDocument3 pagesGeometry Sparkcharts Geometry Sparkcharts: Book Review Book ReviewAyman BantuasNo ratings yet

- Database NotesDocument4 pagesDatabase NotesKanishka SeneviratneNo ratings yet

- 1908 The Watchower and Herald of Christ's PresenceDocument193 pages1908 The Watchower and Herald of Christ's PresenceTimothy RichesNo ratings yet

- Usability Test Report MemoDocument2 pagesUsability Test Report MemoTiffany PetersonNo ratings yet

- Eyu-Ethiopia FinanceOperations Manual January2020 v1 EnglishDocument104 pagesEyu-Ethiopia FinanceOperations Manual January2020 v1 EnglishHenockNo ratings yet

- Jess's Heart Is Racing at 100 Miles Per Hour.Document3 pagesJess's Heart Is Racing at 100 Miles Per Hour.vexagon wallowNo ratings yet

- BDU-BIT-Electromechanical Engineering Curriculum (Regular Program)Document187 pagesBDU-BIT-Electromechanical Engineering Curriculum (Regular Program)beselamu75% (4)

- Formalismo Geométrico de La Mecánica Cuántica y Sus Aplicaciones A Modelos MolecularesDocument51 pagesFormalismo Geométrico de La Mecánica Cuántica y Sus Aplicaciones A Modelos Moleculareshugo_valles_2No ratings yet

- Fixed Asset Examples Excel TemplateDocument6 pagesFixed Asset Examples Excel TemplateHR BabitaNo ratings yet

- Lesson: Identifying Author's Bias For or Against: Quarter 3 Wk-1Document4 pagesLesson: Identifying Author's Bias For or Against: Quarter 3 Wk-1Mary Cris Navarro LiboonNo ratings yet

- Microprocessor AEE Part4Document144 pagesMicroprocessor AEE Part4PeterNo ratings yet

- Boss DD-6Document28 pagesBoss DD-6Justin Alexander SanzonENo ratings yet

- Sow English Year 2 2023Document12 pagesSow English Year 2 2023Noramaliza GhazaliNo ratings yet

- AlerTox Sticks Soy PLUS ManualDocument8 pagesAlerTox Sticks Soy PLUS ManualLuis Miguel Matos OteroNo ratings yet

- Economics Key WordsDocument30 pagesEconomics Key WordsJanetNo ratings yet

- Garmin GNC 250xl Gps 150xlDocument2 pagesGarmin GNC 250xl Gps 150xltordo22No ratings yet

- Billy Mitchel: The Fundamental Principles of Modern Monetary Economics (MMT/PDF)Document6 pagesBilly Mitchel: The Fundamental Principles of Modern Monetary Economics (MMT/PDF)mrwonkish100% (1)

- Project PlanDocument3 pagesProject PlanEarl Dave NangganNo ratings yet

- TranscriptDocument1 pageTranscriptGursharanjit SinghNo ratings yet

- Inter-Bank Fund Transfer: Case Study 6Document5 pagesInter-Bank Fund Transfer: Case Study 6Ravi RanjanNo ratings yet

- Joint Inspection Report FormatDocument2 pagesJoint Inspection Report FormatRAMAKRISHNAN RNo ratings yet

- Addicted1 - The Inquietude of YouthDocument867 pagesAddicted1 - The Inquietude of YouthIlsa Krisdwiyani100% (1)

- Construction ProjectsDocument13 pagesConstruction ProjectsMuhammad SafdarNo ratings yet