Professional Documents

Culture Documents

S.No Description/Test Offered Conductor

Uploaded by

Madhav0 ratings0% found this document useful (0 votes)

7 views3 pagesThis document describes the specifications for a 20 pair telephone cable with the following key details:

1. The cable has a 0.75mm2 copper conductor, PTFE insulation, aluminum foil shielding, and an extruded FRLS PVC outer sheath.

2. Electrical testing shows the cable can withstand voltages up to 1.5kV and has an insulation resistance of at least 2GΩ per km.

3. The cable is rated for operating temperatures between -15°C to 85°C and packaged on 500m spools.

Original Description:

specifications

Original Title

351212_SPECIFICATIONS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes the specifications for a 20 pair telephone cable with the following key details:

1. The cable has a 0.75mm2 copper conductor, PTFE insulation, aluminum foil shielding, and an extruded FRLS PVC outer sheath.

2. Electrical testing shows the cable can withstand voltages up to 1.5kV and has an insulation resistance of at least 2GΩ per km.

3. The cable is rated for operating temperatures between -15°C to 85°C and packaged on 500m spools.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesS.No Description/Test Offered Conductor

Uploaded by

MadhavThis document describes the specifications for a 20 pair telephone cable with the following key details:

1. The cable has a 0.75mm2 copper conductor, PTFE insulation, aluminum foil shielding, and an extruded FRLS PVC outer sheath.

2. Electrical testing shows the cable can withstand voltages up to 1.5kV and has an insulation resistance of at least 2GΩ per km.

3. The cable is rated for operating temperatures between -15°C to 85°C and packaged on 500m spools.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

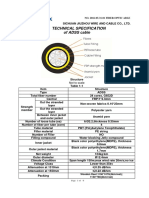

INDENT NO: 351212

S.NO DESCRIPTION/TEST OFFERED

CONDUCTOR

1 Conductor material SPC

2 Conductor cross section 0.75mm2

3 No. of wire/dia. of each strands(mm) 7/0.37mm

4 Conductor Dia.(Nom) 1.11mm

5 Conductor Resistance 25.9 ohm/ KM

INSULATION

8 Insulation material (core) PTFE wrapped and sintered

9 Insulated core dia. 1.61 to 1.81mm

10 Insulation thickness 0.30 ± 0.05 mm

11 No of pairs 20 pair twisted cable

12 Core color Colour coded

13 Cable construction Twisted Pair

12 Isolator Polyester tape

Each pair screened with Al-Mylar film along with ATC drain

14 Core Insulation

wire 7/0.30mm with 100%coverage &25% overlap

SHIELDING

100% Screening with Al-Mylar tape along with ATC drain wire

15 Shielded

7/0.5Sqmm.

OUTER SHEATH

16 Sheath material EXTRUDED FRLS PVC

17 Color Black

18 Thickness 2.0mm

19 Overall O.D(nom) 25.00mm

Signature Not Verified

Digitally signed by P RAGHAVI

SOWMYA

Date: 26.02.2021 11:57:55

1. Sequential marking i.e. Length in meters (Eg.1m, 2m….)

20 Printing on Jacket 2. No. of pairs x cross sectional area screened FRLS cable

500V at every one meter.

21 Operating voltage 500VAC

ELECTRICAL TEST

a) Spark test a) 3.4 KVAC for 0.20sec

b) High voltage test b) 1.5KVAC for 1 min , 1.0KVAC for 1 min

22

Core to core 1.5 KVAC for 1min

Core to shield 1.0 KVAC for 1min

23 Mutual capacitance (Core to core) 100< nF/Km at 800Hz

24 Insulation resistance by 500V Meggar (min) 2 GΩ x Km

25 Temperature range -15oC to +85oC

Packing

26 Spool 500 meter spool

27 Shipping tolerance 5%

FRLS Properties for outer sheathh

Oxygen index when tested as per ASTM

28 D2863 (Min) 29%

Temperature Index when tested as per ASTM

29 D2843(Min) 250 Deg. C

Smoke density rating when tested as per

ASTMD2843 (Max.)

30 60% Max

Acid gas generation when tested as per IEC

31 60754 part 1(MAX) 20% Max

You might also like

- Home Power Magazine - Issue 057 - 1997-02-03Document113 pagesHome Power Magazine - Issue 057 - 1997-02-03David LɘonardoNo ratings yet

- BGA Construction and ReworkDocument24 pagesBGA Construction and ReworkyogeshleostarNo ratings yet

- Ingenuity CT Service ManualDocument823 pagesIngenuity CT Service ManualJaime100% (1)

- What Is Pilot PollutionDocument30 pagesWhat Is Pilot PollutionSharmistha Talukder Khastagir100% (4)

- Iflex 5 GroveDocument79 pagesIflex 5 GroveJorge YuniorNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- MV Cables Data Sheet - SampleDocument5 pagesMV Cables Data Sheet - SampleAvoor KhanNo ratings yet

- Cruisair Seawater PumpsDocument2 pagesCruisair Seawater PumpsorlandoNo ratings yet

- OPGW GTP of Various VendorsDocument19 pagesOPGW GTP of Various VendorsRamphani Nunna100% (1)

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- RC - Local1x120mm CU XLPE CUT AWA PVC20kV (TD) - 20230131122332.677 - XDocument2 pagesRC - Local1x120mm CU XLPE CUT AWA PVC20kV (TD) - 20230131122332.677 - XAnonymous wx4I4YQONo ratings yet

- RRU AISG Cable Assembly SpecificationDocument9 pagesRRU AISG Cable Assembly SpecificationBayu AndriantoNo ratings yet

- Loose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJDocument5 pagesLoose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJPetyo GeorgievNo ratings yet

- Gauranteed Techncial Particulars (GTP)Document2 pagesGauranteed Techncial Particulars (GTP)Kibria SiddiqueNo ratings yet

- 300 RM 31.5 Ka 1sec SpecificationDocument4 pages300 RM 31.5 Ka 1sec SpecificationAbdullah Al AsikNo ratings yet

- IEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONDocument7 pagesIEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONmedazzNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- 3x120 MM CU-XLPE-CUT-SWA-PVC 15 KV (TD)Document2 pages3x120 MM CU-XLPE-CUT-SWA-PVC 15 KV (TD)HaikalNo ratings yet

- Instrumentation Cables PDFDocument4 pagesInstrumentation Cables PDFhaisamsarwarNo ratings yet

- TDS 1x300 11kV CTS+LEADDocument2 pagesTDS 1x300 11kV CTS+LEADNabeelNo ratings yet

- 33kV Cable GTPDocument2 pages33kV Cable GTPVipin Kr DhimanNo ratings yet

- PO1541 - Ojas Infra - GSF MV TDS-v1.1Document16 pagesPO1541 - Ojas Infra - GSF MV TDS-v1.1Sanjay GadhaveNo ratings yet

- Datos CableDocument3 pagesDatos CablePablo Briceño NavarroNo ratings yet

- Technical Data Sheet 11 2013-03-25 9842LS ApplicationDocument2 pagesTechnical Data Sheet 11 2013-03-25 9842LS ApplicationSugeng WahyudiNo ratings yet

- Shandong Baoshida Cable Co, LTD.: Technical ParameterDocument3 pagesShandong Baoshida Cable Co, LTD.: Technical ParameterkmiqdNo ratings yet

- 1CX240MM2 Cu-Xlpe-PvcDocument2 pages1CX240MM2 Cu-Xlpe-PvcMohammed SalahNo ratings yet

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2Document2 pages3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2HaikalNo ratings yet

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2Document2 pages3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2HaikalNo ratings yet

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD)Document2 pages3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD)HaikalNo ratings yet

- 1X16 RM BYADocument1 page1X16 RM BYAjamilNo ratings yet

- APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSDocument4 pagesAPPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSSanjay GadhaveNo ratings yet

- Technical Spec NA2XSEYBY 3x300mm2Document2 pagesTechnical Spec NA2XSEYBY 3x300mm2Suyanto Âñd Fámïly100% (1)

- Annex 02-Technical Specfication for MV FSY-YJLSY63-15KV技术规格书菲律宾6.6Document3 pagesAnnex 02-Technical Specfication for MV FSY-YJLSY63-15KV技术规格书菲律宾6.6carlremNo ratings yet

- Cable Nac 81602Document1 pageCable Nac 81602Andres Varea RomoNo ratings yet

- DA202 (Specifications)Document1 pageDA202 (Specifications)hanryNo ratings yet

- XHIOLE (Cbe) 1x"S"/35 12/20kV: Product Specification EPM100051Document2 pagesXHIOLE (Cbe) 1x"S"/35 12/20kV: Product Specification EPM100051Fahad UsmanNo ratings yet

- Wire, 10 AWG, 5000 V, Tefzel - Focal 3393 - CorrectedDocument1 pageWire, 10 AWG, 5000 V, Tefzel - Focal 3393 - CorrectedMarilton SiqueiraNo ratings yet

- Phoenix Contact 0311126 enDocument46 pagesPhoenix Contact 0311126 enGiorgi AbashidzeNo ratings yet

- Xlpe Oscr Pe Swa PVC 1.5 Black 500vDocument2 pagesXlpe Oscr Pe Swa PVC 1.5 Black 500vJason SecretNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- YOFC DataSaheet de ADSS Cable-All Dry ADSS Cable - 100m 200m Span Single JacketDocument8 pagesYOFC DataSaheet de ADSS Cable-All Dry ADSS Cable - 100m 200m Span Single JacketEstefany Murga LauraNo ratings yet

- Cable Adss 24C G.652D - Span 100M-120MDocument3 pagesCable Adss 24C G.652D - Span 100M-120MbanpraNo ratings yet

- 4x10mm NCU-XLPE-PVC 1 KV (TD)Document2 pages4x10mm NCU-XLPE-PVC 1 KV (TD)nadeem UddinNo ratings yet

- Technical Data Sheet FOR Optical Fiber Cable Duct ApplicationsDocument5 pagesTechnical Data Sheet FOR Optical Fiber Cable Duct ApplicationsAngel Hernando MartinezNo ratings yet

- 1 - Specification 18th May 2021Document4 pages1 - Specification 18th May 2021JR DadisNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- RC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)Document2 pagesRC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)HaikalNo ratings yet

- TDS 3x150 11kV CTS+LEADDocument2 pagesTDS 3x150 11kV CTS+LEADNabeelNo ratings yet

- BCC 23120008Document2 pagesBCC 23120008abdulkawi alasharyNo ratings yet

- Fibra Optica KeezeteckDocument6 pagesFibra Optica KeezeteckAndres Alberto ParraNo ratings yet

- Sr. No. 3B Datasheet 1.5PX6CYWY 100Document2 pagesSr. No. 3B Datasheet 1.5PX6CYWY 100hemantmech099200No ratings yet

- 16AWG 4 Wires Cable SpecificationDocument3 pages16AWG 4 Wires Cable SpecificationWise SoNo ratings yet

- Cable DetailsDocument10 pagesCable DetailsSurya PrakashNo ratings yet

- XLPE Cu 115kV, 300mm2 1-Core, CuXLPECWS (31.5ka) APL HDPE Data SheetDocument2 pagesXLPE Cu 115kV, 300mm2 1-Core, CuXLPECWS (31.5ka) APL HDPE Data SheetJean CarlosNo ratings yet

- Cable Video Surveillance HR6Document1 pageCable Video Surveillance HR6elbac08No ratings yet

- SOUTHERN CABLE 630mmsq Cu XLPEDocument3 pagesSOUTHERN CABLE 630mmsq Cu XLPERozaimi GhazaliNo ratings yet

- Datacom Copper - 2020 Low ResDocument40 pagesDatacom Copper - 2020 Low ResHA STAR GEN CONTNo ratings yet

- DA202F 8P (Specifications)Document1 pageDA202F 8P (Specifications)hanryNo ratings yet

- 4x16 AWG TC 600V Overall Shielded Control Cable - 8KDP104109 - V - 1 - R - 10Document2 pages4x16 AWG TC 600V Overall Shielded Control Cable - 8KDP104109 - V - 1 - R - 10omarNo ratings yet

- Brochure - Aerial SCPT 12 24 CoreDocument3 pagesBrochure - Aerial SCPT 12 24 Coretomi mulkiNo ratings yet

- Fo Adss 48 Spam 200 HengtongDocument3 pagesFo Adss 48 Spam 200 Hengtongwilliams eduardo gonzales niñoNo ratings yet

- Technical Data Sheet: Belden Wire & Cable B.VDocument2 pagesTechnical Data Sheet: Belden Wire & Cable B.VMohammed Salman MirzaNo ratings yet

- OPGW-24B1.3-105 (58 100.0) ITU-TG.652.D Fibers: Characteristics of Cable Cable Construction and ParameterDocument5 pagesOPGW-24B1.3-105 (58 100.0) ITU-TG.652.D Fibers: Characteristics of Cable Cable Construction and ParameterAdanNo ratings yet

- Test Report: SL Unit Required Observed No Value Value 01 Physical 120 120 Test Description of TestDocument1 pageTest Report: SL Unit Required Observed No Value Value 01 Physical 120 120 Test Description of TestSarowar HossainNo ratings yet

- Rel 003Document0 pagesRel 003Bence M ZoltanNo ratings yet

- Maintenance Instructions System: From Serial No. 20.000Document43 pagesMaintenance Instructions System: From Serial No. 20.000Simon DelgusteNo ratings yet

- Automatic Control System and Control LoopsDocument60 pagesAutomatic Control System and Control Loopsmoovendan pNo ratings yet

- ZesaruxDocument18 pagesZesaruxthedrummNo ratings yet

- E 477 ContentDocument52 pagesE 477 ContentbhavikNo ratings yet

- PH Metre de PaillasseDocument1 pagePH Metre de PaillasseKarim NazefNo ratings yet

- Budi Rahardjo's CV v.14Document20 pagesBudi Rahardjo's CV v.14budi rahardjoNo ratings yet

- Chap.10 Lsis Inv (Modbus)Document7 pagesChap.10 Lsis Inv (Modbus)Diego MagaNo ratings yet

- Gree DehumiDocument1 pageGree DehumiAnkhi BaroiNo ratings yet

- MV Switchgear Circuit Breaker Inspection and Test Procedure: October 2019Document5 pagesMV Switchgear Circuit Breaker Inspection and Test Procedure: October 2019noman ahmadNo ratings yet

- KDL46EX700Document42 pagesKDL46EX700elrudo11No ratings yet

- Air-Main Charging Systems: DHS 4.0 Series Compact Assistants That Make A Big DifferenceDocument12 pagesAir-Main Charging Systems: DHS 4.0 Series Compact Assistants That Make A Big DifferenceandreaNo ratings yet

- Sonet SDH LectureDocument36 pagesSonet SDH LectureStar LightNo ratings yet

- Microwave Lab ManualDocument56 pagesMicrowave Lab ManualPrem Sharma100% (1)

- Aicte STTP E&e Nmamit NitteDocument2 pagesAicte STTP E&e Nmamit NitteakshayaNo ratings yet

- Module 04 Practice MCQ Part 01: # A) To Protect It From ACDocument15 pagesModule 04 Practice MCQ Part 01: # A) To Protect It From ACPrem MauryaNo ratings yet

- Paper I: Electrical Engineering Syllabus For IES ExamDocument9 pagesPaper I: Electrical Engineering Syllabus For IES ExamSrinivasu RajuNo ratings yet

- Home Automation Using IoTDocument14 pagesHome Automation Using IoTAnkit Singh100% (1)

- NetSure 701 A50 - User ManualDocument96 pagesNetSure 701 A50 - User ManualJune JangNo ratings yet

- Manual SD-1GP EN Pt2e-1723Document54 pagesManual SD-1GP EN Pt2e-1723Asad Raza QureshiNo ratings yet

- Problem Set 3Document6 pagesProblem Set 3VASANTHKUMAR M SNo ratings yet

- Unit 2 SignalsDocument3 pagesUnit 2 SignalsDigitallogicdlNo ratings yet

- Yamaha DVRS 100Document144 pagesYamaha DVRS 100videosonNo ratings yet

- Solar Powered ICCP Systems OverviewDocument2 pagesSolar Powered ICCP Systems OverviewncharalaNo ratings yet