Professional Documents

Culture Documents

Hydraulic Fracturing: Key Points

Hydraulic Fracturing: Key Points

Uploaded by

Martin GriffinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Fracturing: Key Points

Hydraulic Fracturing: Key Points

Uploaded by

Martin GriffinCopyright:

Available Formats

HYDRAULIC FRACTURING

FACT SHEET APRIL 2011

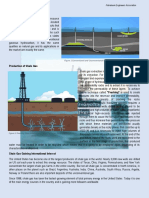

Hydraulic fracturing, commonly referred to as fracking, is a

proven technological advancement which allows natural gas KEY POINTS

and oil producers to safely recover natural gas and oil from

• Fracking is essential for the production of natural gas

deep shale formations. This discovery has the potential to and oil from shale formations.

not only dramatically reduce our reliance on foreign fuel

• Fracking fluids are comprised of approximately 98%

imports, but also to significantly reduce our national carbon water and sand and are handled in self-contained

dioxide (CO2) emissions and to accelerate our transition to systems.

a carbon-light environment. Simply put, deep shale natural • Freshwater aquifers are protected by multiple layers of

gas and oil formation development is critical to America’s protective steel casing surrounded by cement; this is

energy needs and its economic renewal. administered and enforced under state regulations.

Experts have known for years that natural gas and oil • Deep shale natural gas and oil formations exist many

deposits existed in deep shale formations, but until recently thousands of feet underground.

the vast quantities of natural gas and oil in these formations

were not thought to be recoverable. Today, through the use

of fracking, combined with sophisticated horizontal drilling,

extraordinary amounts of natural gas and oil from deep What is fracking?

shale formations across the United States are being safely

produced. Fracking is the process of creating fissures, or fractures, in

underground formations to allow natural gas and oil to

Fracking has been used by the natural gas and oil industry flow. In Chesapeake Energy Corporation’s (Chesapeake’s)

since the 1940s and has become a key element of natural gas deep shale natural gas and oil plays, water, sand and other

and oil development worldwide. In fact, this process is used additives are pumped under high pressure into the

in nearly all natural gas wells drilled in the United States formation to create fractures. The fluid is approximately

today. Properly conducted modern fracking is a highly 98% water and sand, along with a small amount of special-

engineered, controlled, sophisticated and safe procedure. purpose additives. The newly created fractures are

“propped” open by the sand, which allows the natural gas

and oil to flow into the wellbore and be collected at the

surface. Normally a fracking operation is only performed

once in the life of a well. Variables such as rock formations

and thickness of the targeted shale formation are studied by

scientists before fracking is conducted. The result is a highly

sophisticated process that optimizes the network of

fractures and keeps them safely contained within the

boundaries of the deep shale natural gas or oil formation.

Fracking Fluid Makeup

In addition to water and sand, other additives are used to

allow fracking to be performed in a safe and effective

manner. Additives used in fracking fluids include a number

of compounds found in common consumer products.

Chesapeake’s major deep shale play operating areas

© 2011 Chesapeake Energy Page 1 of 3

Hydraulic Fracturing April 2011

Other: ~2%

Water and Sand: ~98% Acid

Corrosion Inhibitor

Iron Control

Anti-Bacterial Agent

Scale Inhibitor

Clay Stabilizer

Friction Reducer

Gelling Agent

Breaker

Crosslinker

pH Adjusting Agent

Surfactant

Example of Typical Deep Shale Fracturing Fluid Makeup

A representation showing the percent by volume of typical deep shale natural gas or oil hydraulic fracturing fluid components (see graphic)

reveals that approximately 98% of the fracking fluid is comprised of freshwater and sand. This fluid is injected into deep shale natural gas or oil

formations and is typically confined by many thousands of feet of rock layers.

Product Purpose Downhole Result Other Common Uses

Water and Sand: ~ 98%

Some stays in formation while remainder returns with natural

Water Expand fracture and deliver sand formation water as "produced water" Landscaping, manufacturing

(actual amounts returned vary from well to well)

Sand Allows the fractures to remain Stays in formation, embedded in fractures Drinking water filtration, play sand,

(Proppant) open so the gas can escape (used to "prop" fractures open) concrete and brick mortar

Other Additives: ~ 2%

Helps dissolve minerals and initiate Reacts with minerals present in the formation to create salts, water, Swimming pool chemical and

Acid

cracks in the rock and carbon dioxide (neutralized) cleaner

Bonds to metal surfaces (pipe) downhole. Any remaining product not

Corrosion Used in pharmaceuticals, acrylic

Prevents the corrosion of the pipe bonded is broken down by micro-organisms and consumed or

Inhibitor fibers and plastics

returned in produced water.

Prevents precipitation of metal (in Reacts with minerals in the formation to create simple salts, carbon Food additive; food and beverages;

Iron Control

pipe) dioxide and water all of which are returned in produced water lemon juice

Eliminates bacteria in the water Reacts with micro-organisms that may be present in the treatment

Anti-Bacterial Disinfectant; sterilizer for medical

that produces corrosive by- fluid and formation. These micro-organisms break down the product

Agent and dental equipment

products with a small amount of the product returning in produced water.

Product attaches to the formation downhole. The majority of product

Prevents scale deposits downhole Used in household cleansers, de-

Scale Inhibitor returns with produced water while remaining reacts with micro-

and in surface equipment icer, paints, and caulk

organisms that break down and consume the product.

Reacts with clays in the formation through a sodium - potassium ion

Prevents formation clays from Used in low-sodium table salt

Clay Stabilizer exchange. Reaction results in sodium chloride (table salt) which is

swelling substitute, medicines, and IV fluids

returned in produced water.

Remains in the formation where temperature and exposure to the

Friction “Slicks” the water to minimize "breaker" allows it to be broken down and consumed by naturally Used in cosmetics including hair,

Reducer friction occurring micro-organisms. A small amount returns with produced make-up, nail and skin products

water.

Used in glass cleaner, multi-surface

Used to increase the viscosity of Generally returned with produced water, but in some formations may

Surfactant cleansers, antiperspirant,

the fracture fluid enter the gas stream and return in the produced natural gas

deodorants and hair-color

Combines with the "breaker" in the formation thus making it much Cosmetics, baked goods, ice

Thickens the water in order to

Gelling Agent easier for the fluid to flow to the borehole and return in produced cream, toothpaste, sauces, and

suspend the sand

water salad dressings

Used in hair coloring, as a

Reacts with the "crosslinker" and "gel" once in the formation making

Allows a delayed break down the disinfectant, and in the

Breaker it easier for the fluid to flow to the borehole. Reaction produces

gel manufacture of common

ammonia and sulfate salts which are returned in produced water.

household plastics

Maintains fluid viscosity as Combines with the "breaker" in the formation to create salts that are Used in laundry detergents, hand

Crosslinker

temperature increases returned in produced water soaps and cosmetics

Maintains the effectiveness of Reacts with acidic agents in the treatment fluid to maintain a neutral Used in laundry detergents, soap,

pH Adjusting

other components, such as (non-acidic, non-alkaline) pH. Reaction results in mineral salts, water water softener and dish washer

Agent

crosslinkers and carbon dioxide; a portion of each is returned in produced water. detergents

© 2011 Chesapeake Energy Page 2 of 3

Hydraulic Fracturing April 2011

Fracking and Groundwater Protection Furthermore, the Ground Water Protection Council issued a

Unlike shallow natural gas and oil projects, such as shallow report in April of 2009 stating that the potential for fracking

coal bed methane (CBM), the producible portions of deep in deep shale natural gas and oil wells to impact groundwater

shale natural gas and oil formations exist many thousands of is extremely remote, as low as one in 200 million.

feet below the surface. Across the U.S. the average depth of Information Sources

a Chesapeake well is more than 7,700 feet (almost one and United States Department of Energy

one half miles below the Earth’s surface and many thousands Ground Water Protection Council

of feet below fresh water formations). This number varies Dr. Michael Economides

depending on the development area. Chesapeake does not

conduct any production or fracking activities in fresh About Chesapeake

groundwater aquifers. In fact, across Chesapeake’s deep Chesapeake Energy Corporation is the second-largest

shale gas operations, groundwater aquifers and producing producer of natural gas and the most active driller of new

natural gas and oil formations are separated by thousands of wells in the U.S. Headquartered in Oklahoma City, the

feet of protective rock barriers. company's operations are focused on discovering and

developing unconventional natural gas and oil fields onshore

in the U.S. Chesapeake owns leading positions in the

How deep is 7,700 feet? Barnett, Fayetteville, Haynesville, Marcellus and Bossier

Over six Empire State Buildings stacked end to natural gas shale plays and in the Eagle Ford, Granite Wash,

end Cleveland, Tonkawa, Mississippian, Wolfcamp, Bone

1 ½ times deeper than the deepest part of the Spring, Avalon, Niobrara and Williston Basin

Grand Canyon unconventional liquids plays. The company has also

More than 25 football fields laid out goal line to goal vertically integrated its operations and owns substantial

line

midstream, compression, drilling and oilfield service assets.

Further information is available at www.chk.com.

State natural gas and oil regulatory programs place great

emphasis on protecting groundwater. Current well

construction requirements consist of installing multiple

layers of protective steel casing surrounded by cement that

is specifically designed and installed to protect freshwater

aquifers.

The measures required by state regulatory agencies in the

exploration and production of deep shale natural gas and oil

formations have been very effective in protecting drinking

water aquifers from contamination attributable to fracking.

Based on reviews of state natural gas and oil agencies, there

has not been a documented case of drinking water

contamination related to the fracking of a deep shale natural

or oil well.

Not to scale Approximate distance from

surface: 7,700 feet

© 2011 Chesapeake Energy Page 3 of 3

You might also like

- Doctor - Who.episode - Guide CompleteDocument2 pagesDoctor - Who.episode - Guide CompleteMartin GriffinNo ratings yet

- Hydraulic FracturingDocument6 pagesHydraulic Fracturingner68100% (1)

- Hydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesFrom EverandHydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesNo ratings yet

- 2.0 Food Analysis: Proximate Analysis Physical Chemical Analysis Photometric AnalysisDocument42 pages2.0 Food Analysis: Proximate Analysis Physical Chemical Analysis Photometric AnalysisPiku100% (4)

- IB Chemistry-Revision On Naming Ionic CompoundsDocument3 pagesIB Chemistry-Revision On Naming Ionic CompoundsRania ShabanNo ratings yet

- Paper On Hydraulic FracturingDocument10 pagesPaper On Hydraulic FracturingUjjwalNo ratings yet

- AADE 05 NTCE 64 - HartleyDocument6 pagesAADE 05 NTCE 64 - HartleyaymenmoatazNo ratings yet

- 28IJAERS 11202024 Effectof PDFDocument10 pages28IJAERS 11202024 Effectof PDFIJAERS JOURNALNo ratings yet

- Water Shut Off Review - Slumberger - Technology With Cover Page v2Document23 pagesWater Shut Off Review - Slumberger - Technology With Cover Page v2Aminollah PayvandNo ratings yet

- J of Applied Polymer Sci - 2014 - Barati - A Review of Fracturing Fluid Systems Used For Hydraulic Fracturing of Oil andDocument11 pagesJ of Applied Polymer Sci - 2014 - Barati - A Review of Fracturing Fluid Systems Used For Hydraulic Fracturing of Oil andNio Naxs BruntaxNo ratings yet

- SPE 94523 A New Inhibitive Water-Based Fluid: A Completely Cationic SystemDocument8 pagesSPE 94523 A New Inhibitive Water-Based Fluid: A Completely Cationic SystemDaniel Navarro EstradaNo ratings yet

- Evaluation of The Effectiveness of Mud Acid in Well StimulationDocument7 pagesEvaluation of The Effectiveness of Mud Acid in Well StimulationRaed fouadNo ratings yet

- Hydraulic FracturingDocument2 pagesHydraulic FracturingJeff LewisNo ratings yet

- Sand Brochure July 2016Document2 pagesSand Brochure July 2016Jack CianfaglioneNo ratings yet

- Your Guide To Hydraulic FracturingDocument1 pageYour Guide To Hydraulic FracturingMartin GriffinNo ratings yet

- SPE 89476 Formation Damage in Gas Sandstone Formations by High-Temperature Borate Gels Due To Long Term Shut-In PeriodsDocument11 pagesSPE 89476 Formation Damage in Gas Sandstone Formations by High-Temperature Borate Gels Due To Long Term Shut-In PeriodsRicardo Zapien RamirezNo ratings yet

- The Challenge of Water Control: Oilfield Review January 2000Document23 pagesThe Challenge of Water Control: Oilfield Review January 2000Diana MNo ratings yet

- QueenDocument15 pagesQueenQunazatulshima BatubaraNo ratings yet

- Spe 94352 Case History Evaluation of Rpms On Conform Fracturing ApplicationsDocument8 pagesSpe 94352 Case History Evaluation of Rpms On Conform Fracturing ApplicationsWaleed Barakat MariaNo ratings yet

- Hydraulic Fracturing in Tight Gas ReservoirsDocument35 pagesHydraulic Fracturing in Tight Gas ReservoirsDedipya0% (1)

- Jonah Project WorkDocument45 pagesJonah Project WorkjonahotuankemeNo ratings yet

- Water Problem and Water Control PDFDocument22 pagesWater Problem and Water Control PDFwikenblessyNo ratings yet

- 2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Document14 pages2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Hanif Budhi CundomanikNo ratings yet

- 1 s2.0 S2405656122000128 MainDocument14 pages1 s2.0 S2405656122000128 Mainorderin aja yukNo ratings yet

- IADC/SPE 72290 Drilling Fluids Design and Management For Extended Reach DrillingDocument7 pagesIADC/SPE 72290 Drilling Fluids Design and Management For Extended Reach Drillinggplese0No ratings yet

- 1 s2.0 S0167732222012727 MainDocument13 pages1 s2.0 S0167732222012727 MainSanjay singhNo ratings yet

- A Fieldscale Simulation Study of Surfactant and Polymer Flooding Insandstone Heterogeneous Reservoir 2157 7463 1000366Document6 pagesA Fieldscale Simulation Study of Surfactant and Polymer Flooding Insandstone Heterogeneous Reservoir 2157 7463 1000366David LópezNo ratings yet

- Minerals 12 00620Document9 pagesMinerals 12 00620VineetNo ratings yet

- A Novel Graphenetriolein Complex-Based Lubricant For Improving High Temperature Water-Based Drilling FluidDocument10 pagesA Novel Graphenetriolein Complex-Based Lubricant For Improving High Temperature Water-Based Drilling FluidrafaelfaioliNo ratings yet

- Project Report 2013Document45 pagesProject Report 2013Bhupendrapal SinghNo ratings yet

- Paper 7 Parcial 3Document14 pagesPaper 7 Parcial 3enrique Dominguez diazNo ratings yet

- Recovery of Bitumen From Oil or Tar Sands Using Ionic LiquidsDocument5 pagesRecovery of Bitumen From Oil or Tar Sands Using Ionic LiquidsDanielMadridDíazNo ratings yet

- Candice Palmer, Zbigniew Sito : Air Products and ChemicalsDocument8 pagesCandice Palmer, Zbigniew Sito : Air Products and ChemicalsNightNo ratings yet

- 1 s2.0 S2405656120300900 MainDocument10 pages1 s2.0 S2405656120300900 MainMohammad EshghiNo ratings yet

- 10 - Hole CleaningDocument5 pages10 - Hole CleaningFarouq EngNo ratings yet

- Deep Learning and Time-Series Analysis For The Early Detection of Lost Circulation Incidents During Drilling OperationsDocument14 pagesDeep Learning and Time-Series Analysis For The Early Detection of Lost Circulation Incidents During Drilling OperationsLukombo N'LanduNo ratings yet

- IX - Drilling Fluids ManualDocument332 pagesIX - Drilling Fluids Manualjovicad100% (1)

- What Is Shale GasDocument2 pagesWhat Is Shale Gasابوالحروف العربي ابوالحروفNo ratings yet

- Petrol 109318Document19 pagesPetrol 109318dancelikedaveNo ratings yet

- SPE/IADC-214628-MS Enzyme-Based Cleanup Fluid For High Temperature Filtercake Removal ApplicationsDocument16 pagesSPE/IADC-214628-MS Enzyme-Based Cleanup Fluid For High Temperature Filtercake Removal ApplicationsFarresForrzaNo ratings yet

- Hydraulic Fracturing To Improve ProductionDocument4 pagesHydraulic Fracturing To Improve ProductionOmar ZamoraNo ratings yet

- Garnett1999 PDFDocument11 pagesGarnett1999 PDFwsanchez_soteloNo ratings yet

- Spe 108045 MSDocument9 pagesSpe 108045 MSDavidNo ratings yet

- Anticorrosive Rubber Lining 2017Document6 pagesAnticorrosive Rubber Lining 2017Ebrahim MohamadikhahNo ratings yet

- SPE 30320, Mechanisms of Formation Damage and Permeability Impairment Associated With The Drilling, Completion and Production of Low API Gravity Oil ReservoirsDocument13 pagesSPE 30320, Mechanisms of Formation Damage and Permeability Impairment Associated With The Drilling, Completion and Production of Low API Gravity Oil ReservoirsjoreliNo ratings yet

- Petroleum: Aghil Moslemizadeh, Seyed Reza ShadizadehDocument12 pagesPetroleum: Aghil Moslemizadeh, Seyed Reza Shadizadehwaleed mosalamNo ratings yet

- Enhanced Oil Recovery by Low-Salinity Water Spontaneous ImbibitionDocument10 pagesEnhanced Oil Recovery by Low-Salinity Water Spontaneous ImbibitionLusiana OliviaNo ratings yet

- HydraulicFracturing IIDocument4 pagesHydraulicFracturing IIAnonymous AEt3M9T100% (1)

- Polymer Surfactant Assisted EORDocument27 pagesPolymer Surfactant Assisted EORAnurag GuptaNo ratings yet

- An Overview On Oil Contaminated Sand and Its Engineering ApplicationsDocument8 pagesAn Overview On Oil Contaminated Sand and Its Engineering ApplicationsOlumide AjayiNo ratings yet

- Unconventional Resources: Shale Gas: Abhishek Agrawal, Amit Giri and Nilesh Agrawal, Petroleum Engineering, ISM DhanbadDocument5 pagesUnconventional Resources: Shale Gas: Abhishek Agrawal, Amit Giri and Nilesh Agrawal, Petroleum Engineering, ISM Dhanbadnitesh kumarNo ratings yet

- Suitability of Local Demulsifier As An Emulsion Treating Agent in Oil and Gas ProductionDocument8 pagesSuitability of Local Demulsifier As An Emulsion Treating Agent in Oil and Gas ProductionJonathan FariasNo ratings yet

- Belhaj2019 Article TheEffectOfSurfactantConcentraDocument13 pagesBelhaj2019 Article TheEffectOfSurfactantConcentraIhsan ArifNo ratings yet

- Bennion OverviewDocument8 pagesBennion OverviewDaniel Felipe Becerra ArcilaNo ratings yet

- SPE-191947-MS Novel Eco-Friendly Cationic Surfactant For Improving Oil Recovery From Carbonate ReservoirsDocument11 pagesSPE-191947-MS Novel Eco-Friendly Cationic Surfactant For Improving Oil Recovery From Carbonate ReservoirsGabriel SNo ratings yet

- AADE-15-NTCE-13 High Performance Brine Drilling Fluid Proves Cost Effective in Eagle Ford ShaleDocument6 pagesAADE-15-NTCE-13 High Performance Brine Drilling Fluid Proves Cost Effective in Eagle Ford ShaleReza AsakerehNo ratings yet

- NDDFDocument10 pagesNDDFDil Dhadakne DoNo ratings yet

- Waterflooding Management Challenges and SolutionsDocument9 pagesWaterflooding Management Challenges and Solutionsartha firmNo ratings yet

- Boron in Oil and Gas ProductionDocument5 pagesBoron in Oil and Gas Productionsyaza mohamadNo ratings yet

- Efficiency of Grinding Stabilizers in Cement ClinkerDocument6 pagesEfficiency of Grinding Stabilizers in Cement ClinkerNam HuynhNo ratings yet

- Hydraulic Fracturing NotesDocument1 pageHydraulic Fracturing NotesMartin GriffinNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Simplifying Project Management Six Power Tips For Doing More With LessDocument7 pagesSimplifying Project Management Six Power Tips For Doing More With LessMartin GriffinNo ratings yet

- Rules of Project ManagementDocument2 pagesRules of Project ManagementMartin GriffinNo ratings yet

- Stresses EquationsDocument12 pagesStresses EquationsMartin GriffinNo ratings yet

- Area and Volume ShapesDocument3 pagesArea and Volume ShapesMartin GriffinNo ratings yet

- Design-A Strategic IssueDocument6 pagesDesign-A Strategic IssueMartin GriffinNo ratings yet

- GeoStrata Magazine IndexDocument1 pageGeoStrata Magazine IndexMartin GriffinNo ratings yet

- Elastic Properties of Soils: Foundation Analysis and Design (5th Edition)Document2 pagesElastic Properties of Soils: Foundation Analysis and Design (5th Edition)Martin GriffinNo ratings yet

- Type ClassificationDocument4 pagesType ClassificationMartin GriffinNo ratings yet

- Common Rock PropertiesDocument3 pagesCommon Rock PropertiesMartin GriffinNo ratings yet

- Geotechnical Properties: MVDocument11 pagesGeotechnical Properties: MVMartin GriffinNo ratings yet

- Circular Dichroism & Optical Rotatory Dispersion: CHEM 305Document26 pagesCircular Dichroism & Optical Rotatory Dispersion: CHEM 305Sailesh KoshyNo ratings yet

- 2016 Klea 410A Phys Props Data 1Document6 pages2016 Klea 410A Phys Props Data 1Deepesh ShettyNo ratings yet

- A Colorimetric Detection of Acrylamide in Potato Chips Based On Nucleophile-Initiated Thiol-Ene Michael AdditionDocument8 pagesA Colorimetric Detection of Acrylamide in Potato Chips Based On Nucleophile-Initiated Thiol-Ene Michael AdditionDinh Tan TranNo ratings yet

- Annex A Psi-Guidelines-For-Structural-Engineers-2Document4 pagesAnnex A Psi-Guidelines-For-Structural-Engineers-2dianfeng.envistaNo ratings yet

- Activity Guide Activity 5-Friction: (Adapted and Modified From "Friction Quantitative Lab" by Steve Banasiak)Document5 pagesActivity Guide Activity 5-Friction: (Adapted and Modified From "Friction Quantitative Lab" by Steve Banasiak)Ronel AlbanNo ratings yet

- He Design Report Group 2Document29 pagesHe Design Report Group 2Aji PratamaNo ratings yet

- BCH 314 TutorialDocument7 pagesBCH 314 TutorialNosibusiso KhaliphaNo ratings yet

- RedoksDocument33 pagesRedokssanty_vanftowsNo ratings yet

- Dry Gas Seal, Final PresentationDocument20 pagesDry Gas Seal, Final Presentationwaqas pirachaNo ratings yet

- Maximum Allowable Stress Values ASME Pressure Vessel CodeDocument1 pageMaximum Allowable Stress Values ASME Pressure Vessel CodeBill HNo ratings yet

- Experiment Le Chateliers ReportDocument3 pagesExperiment Le Chateliers Reportade sianayNo ratings yet

- Quantum and Solid State Physics: Aakash Jog 2015-16Document153 pagesQuantum and Solid State Physics: Aakash Jog 2015-16Anonymous zYmMPgsyVNo ratings yet

- ASTM D4253-16 Maximum Index Density and Unit Weight of Soil Using A Vibratory TableDocument19 pagesASTM D4253-16 Maximum Index Density and Unit Weight of Soil Using A Vibratory TableAbeiku Naanye Bondziedu ImpraimNo ratings yet

- Project Details: EDGE Assessment: v3.0.0 HomesDocument24 pagesProject Details: EDGE Assessment: v3.0.0 HomesSheila Natividad MendozaNo ratings yet

- 3 Chapter 3Document33 pages3 Chapter 3temesgenNo ratings yet

- 09931169B FIAS Software GuideDocument159 pages09931169B FIAS Software GuideAnderson DavidNo ratings yet

- Henry's Law AND Raoult's Law IMP QuestionDocument25 pagesHenry's Law AND Raoult's Law IMP QuestionSonu JainNo ratings yet

- Assessment: Directions: Choose The Letter of The Correct Answer. Write Your Answers On A Separate Sheet of PaperDocument5 pagesAssessment: Directions: Choose The Letter of The Correct Answer. Write Your Answers On A Separate Sheet of Paperkim aaron marcelinoNo ratings yet

- Chapter 10 Phase TransformationDocument20 pagesChapter 10 Phase TransformationVinicius SudrajatNo ratings yet

- Model For Biomass Char Combustion in The Riser of A Dual Fluidized Bed Gasification Unit: Part 1 - Model Development and Sensitivity AnalysisDocument9 pagesModel For Biomass Char Combustion in The Riser of A Dual Fluidized Bed Gasification Unit: Part 1 - Model Development and Sensitivity AnalysisNui Computercenter Swu OnkNo ratings yet

- Crystal Structures of Solid StateDocument26 pagesCrystal Structures of Solid StaternsseturajNo ratings yet

- Chapter 15 - Section A - Mathcad Solutions: 1 M 1 M (Table F.3)Document25 pagesChapter 15 - Section A - Mathcad Solutions: 1 M 1 M (Table F.3)Khalid M MohammedNo ratings yet

- Enthalpy, Spontaneity, EntropyDocument16 pagesEnthalpy, Spontaneity, EntropyJeremy MacalaladNo ratings yet

- Small Particles of SilicaDocument2 pagesSmall Particles of SilicaProdi S1 Teknik MesinNo ratings yet

- 01 Chapter 1 ppk1Document26 pages01 Chapter 1 ppk1Stanley YohanesNo ratings yet

- Habashi F. Handbook of Extractive Metallurgy I (Wiley, 1998) (ISBN 3527287922) (T) (494s) - OcredDocument494 pagesHabashi F. Handbook of Extractive Metallurgy I (Wiley, 1998) (ISBN 3527287922) (T) (494s) - OcredjonathanNo ratings yet

- Solar RefrigerationDocument40 pagesSolar RefrigerationRajatNo ratings yet

- Simulation of Supercritical Water Gasification of Biomass by Aspenplus®Document15 pagesSimulation of Supercritical Water Gasification of Biomass by Aspenplus®salehmashrur 98No ratings yet