Professional Documents

Culture Documents

Fine and Super Fine Fillers GAA

Uploaded by

SlagalicaSlagalicaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fine and Super Fine Fillers GAA

Uploaded by

SlagalicaSlagalicaCopyright:

Available Formats

General Application Advice

For fine and super fine fillers

Application Notes

Substrate Preparation Coarse fillings

The substrate must be clean and free from all Damaged areas, honeycombs, pores and the like

loose particles, dust, oil and other contaminants. have to be re-profiled with coarse fillers. Please

Cement residues must be removed completely. refer to the data sheet “General Application Advice

The grain structure of the substrate must be expo- for coarse fillers”.

sed.

Mixing

Cement residues on exposed concrete must be The fine and super fine filler is poured into the

removed with Donnitil 3 X. measured water and stirred with a slow rotation

agitator until it has a lump free, workable consi-

Pre-wetting stency.

Before the fine or super fine filler is applied, the

substrate must be pre-wetted thoroughly. Highly Application

absorbent substrates must be pre-wetted several For application use a trowel, float or rubber float

times. A closed film of water on the substrate, as MC-Top Rubber. To achieve an even and smooth

well as water filled pores and cavities, should be surface, the filler should be finished within the sta-

avoided. After the pre-wetting the substrate must ted processing time, using MC-Top Sponge

be allowed to dry only so far that it has a matt-

moist surface before applying the fine or super Colour changes may appear during processing!

fine filler.

Multiple layer application

Saturation of the concrete substrate should be If the filler is applied in several layers then inter-

avoided to prevent formation of bubbles in the vals must be taken between the individual work

freshly laid filler. steps. Please note the relevant information in the

technical data sheet of the respective product.

Application Conditions

The application time depends on climatic conditi- After treatment

ons. Material, which has begun to stiffen must not The used fine or super fine filler must be protected

be mixed again or applied. Smoothing already har- against sun and wind to prevent it from drying out

dening fine or super fine filler must be avoided to too quickly. Surfaces threated with fine or super-

prevent the formation of cracks. fine fillers have to be protected from rain during

the first days after application.

The minimum application temperature for substra-

te, air and material is + 5 °C. At temperatures General Information

below + 5 °C the application should be stopped. The indicated application conditions in the techni-

All necessary measures should be taken to pre- cal data sheets relate to material, substrate and

vent a drop below this temperature during the air conditions.

curing phase.

Lower temperatures slow down the curing pro-

Avoid application when exposed to direct sunlight. cess, while higher temperatures accelerate it.

Note: The information on this data sheet is based on our experiences and correct to the best of our knowledge. It is, however, not binding. It has to

be adjusted to the individual structure, application purpose and especially to local conditions. Our data refers to the accepted engineering rules,

which have to be observed during application. This provided we are liable for the correctness of this data within the scope of our terms and conditi-

ons of sale-delivery-and-service. Recommendations of our employees which differ from the data contained in our information sheets are only binding

if given in written form. The accepted engineering rules must be observed at all times.

Edition 09/15. Some technical changes have been made to this print medium. Older editions are invalid and may not be used anymore. If a techni-

cally revised new edition is issued, this edition becomes invalid.

MC-Bauchemie • Am Kruppwald 1-8 • 46238 Bottrop • Tel. +49 (0) 20 41-101 50 • Fax: +49 (0) 20 41-101 588

info@mc-bauchemie.de • www.mc-bauchemie.de

You might also like

- CIPP Liner Systems GAADocument2 pagesCIPP Liner Systems GAASlagalicaSlagalicaNo ratings yet

- Team Based ManagementDocument9 pagesTeam Based ManagementSlagalicaSlagalicaNo ratings yet

- SampleDocument4 pagesSampleSlagalicaSlagalicaNo ratings yet

- Team Based Management FinalDocument14 pagesTeam Based Management FinalSlagalicaSlagalicaNo ratings yet

- Flexible Coating For Manhole Tapers GAADocument2 pagesFlexible Coating For Manhole Tapers GAASlagalicaSlagalicaNo ratings yet

- Moral Is Up Managers and Employees Are: Team Based Management Is Working Great For Our CompanyDocument1 pageMoral Is Up Managers and Employees Are: Team Based Management Is Working Great For Our CompanySlagalicaSlagalicaNo ratings yet

- SampleDocument4 pagesSampleSlagalicaSlagalicaNo ratings yet

- Oznake Auto ReleaDocument4 pagesOznake Auto ReleapagapagaNo ratings yet

- Oznake Auto ReleaDocument4 pagesOznake Auto ReleapagapagaNo ratings yet

- A Little Bit About Buffer OverflowsDocument5 pagesA Little Bit About Buffer OverflowsFTBooksNo ratings yet

- Acronis With RestoreDocument28 pagesAcronis With RestoreSlagalicaSlagalicaNo ratings yet

- Voucher 2582609 ECRDocument1 pageVoucher 2582609 ECRSlagalicaSlagalicaNo ratings yet

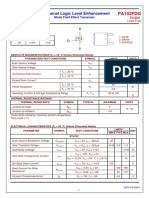

- Data Sheet PA102FDGDocument5 pagesData Sheet PA102FDGSlagalicaSlagalicaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SWP001 04 G1B - R01Document86 pagesSWP001 04 G1B - R01Roberto MontoyaNo ratings yet

- Question Bank Power Plant Performance: Decreasing EfficiencyDocument6 pagesQuestion Bank Power Plant Performance: Decreasing EfficiencyMY NAME IS NEERAJ..:):)No ratings yet

- Toyota WayDocument6 pagesToyota WayMeth RonoNo ratings yet

- ConclusionDocument1 pageConclusionEvans EjegiNo ratings yet

- Camperfiladas Asme 16 5Document8 pagesCamperfiladas Asme 16 5klara23No ratings yet

- 2016 Iridium SourcesV2Document2 pages2016 Iridium SourcesV2josegarza447No ratings yet

- Self Healing ConcreteDocument13 pagesSelf Healing ConcreteJEETHESH NAIK100% (1)

- oundSchoolManual PDFDocument166 pagesoundSchoolManual PDFTerence CruickshankNo ratings yet

- Chapter-I Part TwoDocument6 pagesChapter-I Part TwoTigst Tigst YzachewNo ratings yet

- SHPP GL Ch3.FullDocument417 pagesSHPP GL Ch3.FullLuis Faustino Rodriguez LopezNo ratings yet

- Ariel Corporation - Arielcorp - Com15Document1 pageAriel Corporation - Arielcorp - Com15Anwar Sadat100% (1)

- HIL Testing of ADAS FeaturesDocument4 pagesHIL Testing of ADAS FeaturesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Installation and Removal of High MastDocument3 pagesInstallation and Removal of High MastMohd Hafiz Muhamed100% (1)

- Doosan DBC130 Mechanical Repair ManualDocument157 pagesDoosan DBC130 Mechanical Repair ManualDarryl Hardt80% (5)

- 87716166b1472fd3f7a6a47ea68960afDocument410 pages87716166b1472fd3f7a6a47ea68960afPedroNo ratings yet

- Hydrogen Peroxide Gas GeneratorsDocument17 pagesHydrogen Peroxide Gas GeneratorsCliff ThriveNo ratings yet

- DNV Rules For Woodenships 1970Document146 pagesDNV Rules For Woodenships 1970Manuel Cares FuentesNo ratings yet

- Lab Report 4Document7 pagesLab Report 4Ha NguyenNo ratings yet

- Power Losses of Gear SystemsDocument11 pagesPower Losses of Gear Systemsarda akkayaNo ratings yet

- Stair CalculatorDocument4 pagesStair CalculatorJun PangNo ratings yet

- PCB Design TutorialDocument25 pagesPCB Design TutorialMadhu Mangal KumarNo ratings yet

- Electrical Bill of Quantities: Items Description Unit Quantitierate AmouttotalDocument2 pagesElectrical Bill of Quantities: Items Description Unit Quantitierate AmouttotalOCHITI JOHN REXNo ratings yet

- P1568Document9 pagesP1568Luis BarretoNo ratings yet

- Concrete Repair Quality ControlDocument3 pagesConcrete Repair Quality ControlRisath AzeezNo ratings yet

- Part Number Part Description Condition Quantity UOM Tag InfoDocument375 pagesPart Number Part Description Condition Quantity UOM Tag Info李聪No ratings yet

- Advanced Electronic ComponentsDocument17 pagesAdvanced Electronic Componentsprem_chandranNo ratings yet

- 06 Call - RetDocument15 pages06 Call - RetHemant KumarNo ratings yet

- Die Design ProgramDocument5 pagesDie Design ProgramSundar KaruppiahNo ratings yet

- WholeDocument389 pagesWholeCarlos Enrique Sánchez CáceresNo ratings yet

- Cap 8 Livro PDFDocument36 pagesCap 8 Livro PDFDiogo FonaNo ratings yet