Professional Documents

Culture Documents

Switch Nivel A Prueba de Explosión

Uploaded by

Heiferk AbrilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Switch Nivel A Prueba de Explosión

Uploaded by

Heiferk AbrilCopyright:

Available Formats

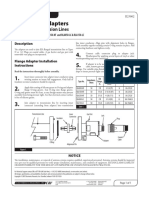

LEVEL

SERIES E, G, & P | PROXIMITY® BY DWYER

ULTRA-MAG™ EXPLOSION-PROOF LEVEL SWITCHES

For Powder and Bulk Solids

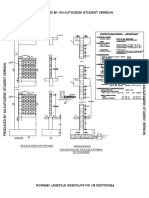

SUSPENSION HUB – 1˝ NPT

Sealed

junction box

Driving

magnet Epoxy seal DIAPHRAGM

DIAMETER 5-7/8˝ 7-1/2

Driven Sealed switch

magnet cavity

3-3/8˝

Suspension mounting

Flange

adapter ring

CONDUIT ENTRANCE 1/2˝ NPT

(6) 5/16˝

DIA. HOLES ON

8-3/8˝ B.C.

7-1/4˝

DIAPHRAGM

DIAMETER 5-7/8˝

9-1/8˝

3/8˝

VIDEO ON

3-1/8˝

Flange mounting

LI

NE

The Series E, G, & P Ultra-Mag™ Explosion-Proof Level Switches For Powder and SPECIFICATIONS

Level Switches,

Bulk Solids are explosion-proof series of level switches for powder and bulk solids Service: Compatible powder or bulk solids.

Diaphragm

that utilize a unique magnetic linkage and diaphragm design to sense the presence of Wetted Materials: Mounting flange: See model chart. Aluminum or 304 SS;

powder and bulk solids in a variety of bins, vessels, and hoppers. Diaphragm: See model chart. Urethane, Buna-N, PTFE, silicone rubber, polyester,

fluoroelastomers, white Buna-N (food grade), or EPDM.

FEATURES/BENEFITS Temperature Limits: Depends on diaphragm material, see model chart. Standard

• Uses a unique magnetic linkage which isolates the electrical compartment from switch: -40 to 185°F (-40 to 85°C); High temperature switch: -40 to 350°F (-40 to

controlled product, reducing maintenance and improving sensitivity 176°C).

• Sealed switch compartment and sealed leads yield the exceptionally reliable Pressure Limit: 60 psig (4.14 bar).

operation Enclosure Rating: General purpose or weatherproof and explosion-proof. See

• A wide selection of diaphragms and switches is available with choices of flange or model chart.

suspension mounting to fit a specific application Switch Type: See model chart.

• Extremely sensitive indication and very economical Electrical Rating: See model chart.

• Magnetic linkage makes this simple explosion-proof diaphragm switch the most Electrical Connections: 18 gage solid core, 600 V TEW 105°C, style 1015. Epoxy

rugged and reliable level control for a variety of products sealed at conduit entrance. 12˝ (304.8 mm) long.

Conduit Connection: 1/2˝ female NPT.

APPLICATIONS Process Connection: For flanged models standard is 8-3/8˝ (212.725 mm)

• Mining diameter bolt hole circle.

• Food and beverage Mounting Orientation: Flange mount or suspend depending on model.

• Silos Set Point Adjustment: Internal screw.

• Hoppers Options: Suspension kits and flange adapter rings.

Weight: 7 lb (3.18 kg).

MOUNTING SELECTION Agency Approvals: UL.

A choice of either suspension or flange mounting is available to match your application.

Flange mounting is the best choice for control of low or intermediate level in vessels

containing granular product that does not “bridge”, “rathole”, or otherwise build up on

vessel walls. Choose suspension mounting for high level in vessels and for better

operation with “bridging” product.u

Note: The mounting configuration is represented by the letter “S” for suspension or “F”

for flange which is the second digit in the part number.v

DIAPHRAGM SELECTION

A wide variety of diaphragms are available to match product bulk density, flowability,

abrasiveness and temperature requirements while providing maximum sensitivity. The

best choice for vessels subject to pressure or vacuum is “breathable” fabric (P Series),

requiring no venting. Non-porous elastomer (G Series) type diaphragms are the best

choice for more abrasive product and broader temperature range applications. Venting

is always required with the G series and if used in pressurized vessels, venting to the

tank atmosphere is required to allow pressure equalization. A slide rule “Diaphragm

Selector” is available from the factory to help you choose the diaphragm best suited

to your application.

uSuspension and Flange Mounting Kits: See page 327 (Ultra Mag™)

vPart Number: See page 327 (Ultra Mag™)

326 DWYER INSTRUMENTS, INC. | dwyer-inst.com

LEVEL

SERIES E, G, & P | PROXIMITY® BY DWYER

ULTRA-MAG™ EXPLOSION-PROOF LEVEL SWITCHES

For Powder and Bulk Solids

DIAPHRAGM SELECTION GUIDE SUSPENSION MOUNTING

Suspension mounting is normally used for high level monitoring

Suggested Suggested in vessels. For product over 20 lb/ft3, the level switch

Product Diaphragm* Product Diaphragm* (diaphragm face) should be located about 1/3 of the distance

Abrasive 3D Polypropylene powder 7A from the vessel wall to the point of entry of the product. For

Aggregate 3D Polypropylene resin 17 product less than 20 lb/ft3, the unit should be located closer to

Alumina 3D Polystyrene beads 3D the point of entry of the product, about 1/2 the distance from the 1/3

Ash, dry 3D Pot ash 3D vessel wall to the point of entry. Pressure required to depress 1/2

Baking powder 7B Powdered metal 3D the diaphragm and trip the switch is in the range of 5 to 15 oz

Baking soda 7B Powdered ore 3D in the horizontal direction (perpendicular to the diaphragm).

Barite 3D PVC powder 7A Suspension mounting provides the easiest vertical adjustment

Bark, ground 6G PVC resin 17 capability, greatest sensitivity and best maintenance conditions.

Barley, ground or meal 17 Rice 17

Barley, whole 4B Rye 3D SUSPENSION ASSEMBLY KITS

Beans, edible 4B Salt 3D Pre-assembled kits are available from the factory, or you can build your own kits using

Bentonite 3D Sand, dry 3D standard pipe fittings shown in our Proximity Bill of Materials (Form No. 101). Pipes

Bond, foundry 17 Sand, dry silica 3D and fittings are normally galvanized steel, but aluminum and SS pipes and fittings

Carbon black 7A Sand, Foundry prepared 5A are available. Units are secured to a steel cover plate that rests on a rectangular

Cement, klinker 8A Sand, shake out 3D steel flange welded into the top of the vessel. Aluminum and stainless coverplates and

Cement, portland 4B Sawdust, dry 6G flanges are also available. Standard 48˝ L x 1˝ pipe provides working depth (WD) up to

Chips, hogged fuel 6G Sea coal 3D 48˝. Longer pipe (to provide greater WD) is available. GS Series switches have upper

Coal 3D Sesame seed 3D (L1 = 28˝ standard) and lower (L2 = 20˝ standard) 1˝ pipes, with a tee (for stilling pot)

Compost 5A Shale, crushed 3D in between. A stilling pot is required to equalize pressure and keep dirt from building

Core sand, foundry 3D Silica, flour 3D up behind the diaphragm. PS series require a 1/2˝ conduit in 1˝ suspension pipe for

Corn, shelled 8A Sludge, sewage dried 1A explosion-proof applications. The 1/2˝ conduit (56˝ standard length) is a standard part

Diatomaceous earth 7A Sludge, sewage, ground 1A of the GS series assembly.

Drill mud 3D Soda ash 3D

Flour 7B Soybeans, cracked 3D

Fly ash 3D Soybean, flake 7A MODEL CHART - ALUMINUM FLANGE ADAPTER RINGS

Glass batch 3D Soybean, flour 7A Tank Tank

Gravel 3D Soybean meal 3D Model Outside Diameter Model Outside Diameter

Iron ore, crushed 3D Soybean, whole 3D 126-009 15˝ 126-016 84˝

Kaolin clay 3D Sugar beets, whole 6H 126-010 30˝ 126-017 96˝

Lime, hydrated 5A Sugar refined 7B 126-011 36˝ 126-018 10´

Lime, stone 3D Sunflower seed 7A 126-012 42˝ 126-019 12´

Oats 4B Taconite pellets 3D 126-013 48˝ 126-020 14´

Peanuts in shell 7A Talcum powder 3D 126-014 60˝ 126-021 24´

Peanuts, shelled 3D Walnut shells, crushed 3D 126-015 72˝

Perlite 7A Wheat 8A

Phosphate, rock 3D Wheat, wet 5A

Polyethylene powder 7A Wood, chips 6G MODEL CHART - “P” AND “G” SERIES SUSPENSION ASSEMBLY KITS

Polyethylene resin 17 Wood, dust 6G Model Description

Polypropylene fluff 7A

901-409 ˝P Series suspension assembly includes 1/2˝ pipe (56˝ std length), 1˝

*Diaphragm codes become 4th and 5th characters in model number. pipe (48˝ std length), 1˝ pipe coupling, 1-1/2 NPT strain relief on 1˝ pipe.

Galvanized mild steel pipe, explosion proof, standard.

901-412 ˝G˝ Series suspension assembly includes 1/2˝ pipe (56˝ std length),

Level Switches,

watertight strain relief and 1˝ coupling, upper 1˝ pipe (28˝ std length),

Diaphragm

lower 1˝ pipe (20˝ std length), strain relief with 1-1/2˝ NPT, 1˝x1˝x1˝

Tee, 1˝ street ell and 1˝ pipe-4˝ long stilling pot. Galvanized steel pipe,

explosion proof, standard.

Note: Specials include aluminum or stainless steel assemblies. Flange port and

cover assemblies are sold separately. Consult factory for details.

MODEL CHART

Example E -EX -G -S -D -3D -A EX-G-S-D-3D-A*

Certification 1 E Ultra-Mag™ explosion-proof level switches

Certification 2 EX Explosion-proof (UL) Class I, Div I and II, Groups C and D; Class II, Div I and II, Groups E, F, and G

General purpose (no code)

Basic Magnetic Pressure G Elastomeric diaphragm-venting required*. (Diaphragms 1A - 8A)

Sensing Series P Breathable fabric diaphragm-no venting required. (Diaphragms 16 and 17 only)

Mounting S Suspended (G series require suspension vent fittings)* Subtract 10 lbs./cu. ft.-greater sensitivity

(Top = Suspension/ F Flanged, aluminum standard

Side = Flanged) T Flanged, 304 SS

Housing Material D Aluminum

A Aluminum, anodized

E Aluminum, epoxy coated

Diaphragm Material 3D Urethane, .031˝ thick, (10 to 150°F), (> 30 lb/ft3)

(Temperature) 3E Urethane, orange, .062˝ thick, (10 to 150°F), (> 90 lb/ft3)

(Bulk Density) 4B Buna-N, black, .020˝ thick, (-20 to 212°F), (20 to 90 lb/ft3)

5A PTFE/glass on silicone rubber, .024˝ thick, (-40 to 350°F), (> 35 lb/ft3)

6D Silicone rubber, gray, .062˝ thick, (-40 to 350°F), (15 to 30 lb/ft3)

6E Silicone rubber on glass, red, .032˝ thick, (-40 to 350°F), (> 90 lb/ft3)

6G ˝6C˝ w/urethane overlay, (-40 to 350°F), (wood chips diaphragm with ˝A2˝)

7A Silicone rubber on glass (White), .015˝ thick, (-40 to 350°F), (5 to 40 lb/ft3)

7B Buna-N (food applications-white), .060˝ thick, (-20 to 212°F), (30 to 90 lb/ft3)

8A EPDM, black, .036˝ thick, (-40 to 275°F), (40 to 90 lb/ft3)

16 Polyester filter fabric, white, 150 micron permeability, (-30 to 275°F), (30 to 90 lb/ft3)

17 Polyester nitex, white, 15 micron permeability (-30 to 275°F), (30 to 90 lb/ft3)

Switch Type A Standard, SPDT, 15 A @ 125, 250 VAC

T High temp, SPDT, 5 A @ 125, 250 VAC; 24 VDC**

V High vibration, SPDT, 15 A @ 125, 250 VAC

G Gold contacts, SPDT, 1 A @ 125 VAC, 1/2 A @ 24 VDC

Special Controls A2 Wood chip control (with ˝6G˝ diaphragm only)

A3 High sensitivity actuator (for very light product)

*GS - G series suspended controls require suspension vent fittings. **Not UL listed.

Note: The ˝EX˝ prefix must he added to the 6-digit model number for ˝explosion-proof standard˝. General purpose units do not require the ˝EX˝ or other prefix.

DWYER INSTRUMENTS, INC. | dwyer-inst.com 327

You might also like

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABmt11280% (1)

- Perfad™ 8400: High Performance Polymeric Lubricity AdditiveDocument5 pagesPerfad™ 8400: High Performance Polymeric Lubricity AdditiveShaara NeyNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- SEAM 6 TOPIC 1 LO 1.1 - Fundamental Principles of Ship Construction, Trim, and Stability For PUBLISHINGDocument137 pagesSEAM 6 TOPIC 1 LO 1.1 - Fundamental Principles of Ship Construction, Trim, and Stability For PUBLISHINGRigel100% (4)

- FE 1400 V Belt Drive Selection For FansDocument6 pagesFE 1400 V Belt Drive Selection For FansAvery OppegardNo ratings yet

- Design of Culvert - Excel SheetDocument17 pagesDesign of Culvert - Excel Sheethafiz zain saeed67% (3)

- NEMA and IP TestingDocument4 pagesNEMA and IP TestingAnonymous j5apk2AumNo ratings yet

- Induction vs. EAF: Advantages & DisadvantagesDocument14 pagesInduction vs. EAF: Advantages & DisadvantagesniazakhtarNo ratings yet

- RA 1378 - NPC SummaryDocument21 pagesRA 1378 - NPC SummaryPrudencio BucoNo ratings yet

- Padeyes: Engineered & CertifiedDocument4 pagesPadeyes: Engineered & CertifiedMahmoudNo ratings yet

- (Clifton E. Meloan) Chemical Separations Principl (BookFi)Document767 pages(Clifton E. Meloan) Chemical Separations Principl (BookFi)RidaIhsaniBripasgara100% (1)

- Technical Overview AEROSIL Fumed Silica enDocument104 pagesTechnical Overview AEROSIL Fumed Silica enaadd50% (2)

- Experiment 4: Separation of A MixtureDocument4 pagesExperiment 4: Separation of A MixtureCynthia KimNo ratings yet

- Explosion-Proof Level Switches For Powder & Bulk SolidsDocument2 pagesExplosion-Proof Level Switches For Powder & Bulk Solidsjalfaro021No ratings yet

- Wellhead Assy - Sheet1Document1 pageWellhead Assy - Sheet1Londhe Inggihmeniko AndiewNo ratings yet

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABhansenfarms.chNo ratings yet

- Foster Pneumatic Couplers 1Document12 pagesFoster Pneumatic Couplers 1brunofernandesdacostNo ratings yet

- 020-SpecsDocument1 page020-SpecsjoeNo ratings yet

- Pistola de PlasmaDocument2 pagesPistola de PlasmaoscarNo ratings yet

- Hand Dryer and Waste Receptacle - B-38030 - TD by BobrickDocument6 pagesHand Dryer and Waste Receptacle - B-38030 - TD by Bobrickgabrielmonarchi12No ratings yet

- Continuous Cleat Coping Product DetailDocument2 pagesContinuous Cleat Coping Product DetailIrinel CopacinschiNo ratings yet

- A240CX-BD CD DD Flameproof Coil Solenoid Valves PDFDocument1 pageA240CX-BD CD DD Flameproof Coil Solenoid Valves PDFMehmet KahyaNo ratings yet

- 2022 ATV ROV Wiring DiagramsDocument9 pages2022 ATV ROV Wiring Diagrams张连杉No ratings yet

- V Belt Drive Selection For Fans FE 1400Document6 pagesV Belt Drive Selection For Fans FE 1400Parag ThakkarNo ratings yet

- Guardian G1814P Eyewash Station Wall Mounted Plastic Bowl TechdataDocument2 pagesGuardian G1814P Eyewash Station Wall Mounted Plastic Bowl TechdatamwrsbsNo ratings yet

- SW33 PerfdataDocument6 pagesSW33 Perfdataallen_worstNo ratings yet

- WhirligigDocument2 pagesWhirligigAugusto Vincensi0% (1)

- Plantilla HT24 Ansi-2013Document4 pagesPlantilla HT24 Ansi-2013servicio5No ratings yet

- 2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsDocument4 pages2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsMORELLI silvioNo ratings yet

- MAX-Brush ToolDocument2 pagesMAX-Brush ToolErnest AmadiNo ratings yet

- ASCO Solenoid Valves Serie SCB316Document2 pagesASCO Solenoid Valves Serie SCB316katja kafkaNo ratings yet

- Serie 2000Document2 pagesSerie 2000Fredy MurilloNo ratings yet

- SDW-10338830 015 01Document4 pagesSDW-10338830 015 01Tiagohowpy RamosNo ratings yet

- Connectors: Installation InstructionsDocument4 pagesConnectors: Installation InstructionsRenzzo Gomez ReatigaNo ratings yet

- Produced by An Autodesk Student VersionDocument1 pageProduced by An Autodesk Student VersionmichaelNo ratings yet

- Estructuras - E-06 - OkDocument1 pageEstructuras - E-06 - OkFRANK ALEX GIL GUZMANNo ratings yet

- Bolt and pipe diagram with measurements and specificationsDocument1 pageBolt and pipe diagram with measurements and specificationsYENEF KENEDY SOTO SOLANONo ratings yet

- Manual de Instalación y Operación Compas Autohelm ST 30 CompDocument39 pagesManual de Instalación y Operación Compas Autohelm ST 30 ComppevalpevalNo ratings yet

- Modificado 1Document1 pageModificado 1YENEF KENEDY SOTO SOLANONo ratings yet

- 50890-1000 Brochure 2005Document2 pages50890-1000 Brochure 2005Juasadf IesafNo ratings yet

- File 1448492388Document1 pageFile 1448492388Remy MendozaNo ratings yet

- Ground FLR VRF Pipe SizeDocument1 pageGround FLR VRF Pipe SizeAbdullah.N FAAliNo ratings yet

- GA - 24-50 Rev H: General Arrangement RXF 24 - 50 Screw Compressor PackageDocument1 pageGA - 24-50 Rev H: General Arrangement RXF 24 - 50 Screw Compressor Packagekemas biruNo ratings yet

- Harley-Davidson Sportster Sraightshots Hs Installation Instructions PART# 17821Document4 pagesHarley-Davidson Sportster Sraightshots Hs Installation Instructions PART# 17821xcampoNo ratings yet

- T&S Brass and Bronze Works, Inc.: 2 Saddleback Cove / P.O. Box 1088 Travelers Rest, SC 29690Document2 pagesT&S Brass and Bronze Works, Inc.: 2 Saddleback Cove / P.O. Box 1088 Travelers Rest, SC 29690Casper John Nanas MuñozNo ratings yet

- Stair Elevation 2 Stair Elevation 1: E70101B E70101BDocument1 pageStair Elevation 2 Stair Elevation 1: E70101B E70101BCursed SquadNo ratings yet

- FICHA TECNICA MAGNETICO INDUSTRIAL-espDocument2 pagesFICHA TECNICA MAGNETICO INDUSTRIAL-espDaniel CadenaNo ratings yet

- GT Series QuikStart GuideDocument8 pagesGT Series QuikStart Guide7g45frqbcpNo ratings yet

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDocument1 pageDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983No ratings yet

- Lumbermill Metaldoors TN 20230329Document1 pageLumbermill Metaldoors TN 20230329api-455371619No ratings yet

- 132K03-2995-482635S5Document40 pages132K03-2995-482635S5Fernando BorgesNo ratings yet

- Make-up Procedure mu-cplg-004Document7 pagesMake-up Procedure mu-cplg-004huyenhvtc252No ratings yet

- Flotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceDocument1 pageFlotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceMadhan MohanNo ratings yet

- Data Shett FP Valiant MachineDocument47 pagesData Shett FP Valiant MachineRICARDONo ratings yet

- Rociador Ty LDocument8 pagesRociador Ty LOscar Fernandez SanchezNo ratings yet

- VALVESDocument30 pagesVALVESHamada AttiaNo ratings yet

- installation-Side-Contact-Conductor-Bar-SystemsDocument4 pagesinstallation-Side-Contact-Conductor-Bar-Systemsventas1No ratings yet

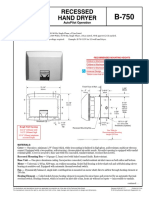

- Recessed Hand Dryer: Technical DataDocument2 pagesRecessed Hand Dryer: Technical Datakalven marquezNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocument8 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageLucila BordenaveNo ratings yet

- 004 005 D PDFDocument2 pages004 005 D PDFRangga Prasetya BaitullahNo ratings yet

- ISO Sanitary Ball Valve for Food and Chemical UseDocument1 pageISO Sanitary Ball Valve for Food and Chemical UseNhut PipingNo ratings yet

- Led110 112 114 D101 RevaDocument3 pagesLed110 112 114 D101 Revasaifasqalani39No ratings yet

- 3-8dia. Bars Per Steps: Stair Case and Water TankDocument1 page3-8dia. Bars Per Steps: Stair Case and Water TankHemam PrasantaNo ratings yet

- Cocks and Couplings For Compressed Air Malleable Iron: Dimensions (MM)Document1 pageCocks and Couplings For Compressed Air Malleable Iron: Dimensions (MM)ChristianGuerreroNo ratings yet

- Installation Instructions: Percy Single Control Monoblock and Vessel FaucetDocument8 pagesInstallation Instructions: Percy Single Control Monoblock and Vessel Faucetsilvan jasperNo ratings yet

- TP - wy51.PB751D Schematic DiagramDocument15 pagesTP - wy51.PB751D Schematic DiagramUdeni ReksikaNo ratings yet

- Fan Belt Drives ED1400Document6 pagesFan Belt Drives ED1400arielNo ratings yet

- Desv - SubmittalDocument2 pagesDesv - SubmittalALEX MIRANDANo ratings yet

- SHERA Wood CatalogDocument16 pagesSHERA Wood Cataloghk1680% (1)

- MATTHEW CORREIA Acids Bases and Salts WORKSHEETDocument4 pagesMATTHEW CORREIA Acids Bases and Salts WORKSHEETFrank MassiahNo ratings yet

- Structural Standing Seam Aluminum Roof Panel Systems: Standard Specification ForDocument5 pagesStructural Standing Seam Aluminum Roof Panel Systems: Standard Specification ForAhmad Zubair RasulyNo ratings yet

- Textile - Product ListDocument4 pagesTextile - Product ListUdin JayaNo ratings yet

- Kode Uraian Satuan Harga Satuan (RP.)Document1 pageKode Uraian Satuan Harga Satuan (RP.)saepul mgNo ratings yet

- Dossing ChemicalsDocument4 pagesDossing ChemicalsHamid UllahNo ratings yet

- Technical Data Sheet Multi Purpose GreaseDocument4 pagesTechnical Data Sheet Multi Purpose GreaseSophia RoseNo ratings yet

- Lipids ExperimentDocument5 pagesLipids ExperimentZheldinan Nicole CruzNo ratings yet

- DuraSense ECO100 IM Factsheet WebDocument1 pageDuraSense ECO100 IM Factsheet Webbinoyraj2010No ratings yet

- Metric internal circlips dimensions and specificationsDocument2 pagesMetric internal circlips dimensions and specificationsAidaNo ratings yet

- BASF Elastollan TPU PDFDocument3 pagesBASF Elastollan TPU PDFPhung LucNo ratings yet

- Copper Removal Using Ion Exchange Resin PDFDocument3 pagesCopper Removal Using Ion Exchange Resin PDFAnonymous k41BMGYDLNo ratings yet

- Esd Safe Anti-Fatigue MatDocument1 pageEsd Safe Anti-Fatigue MatFerdinand EstanislaoNo ratings yet

- Semi Gloss Enamel Technical DataDocument3 pagesSemi Gloss Enamel Technical Databhima irabattiNo ratings yet

- Netcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Document34 pagesNetcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Myo Min HeinNo ratings yet

- Standard Test Methods For Physical TestiDocument8 pagesStandard Test Methods For Physical TestiAidonNo ratings yet

- Thermal Properties of Textile Fiber Introduction of Thermal PropertyDocument6 pagesThermal Properties of Textile Fiber Introduction of Thermal PropertyRashedul IslamNo ratings yet

- Mto Civil ArsitekturDocument1 pageMto Civil Arsitekturkoko srihandokoNo ratings yet

- 150506T01 PVC NIC GMBHDocument15 pages150506T01 PVC NIC GMBHAthonioMourinhoNo ratings yet

- Powder Metallurgy: Professor DR Andanastuti Muchtar KM2833 Manufacturing Processes Sem 1 Session 2019/2020Document26 pagesPowder Metallurgy: Professor DR Andanastuti Muchtar KM2833 Manufacturing Processes Sem 1 Session 2019/2020SajjadNo ratings yet

- PART 1 - Spring CapeletDocument2 pagesPART 1 - Spring CapeletFabros VanessaNo ratings yet