Professional Documents

Culture Documents

Basic Whistle

Uploaded by

Keith Foor0 ratings0% found this document useful (0 votes)

11 views1 page1. The document provides instructions for making a basic wood whistle, including diagrams of the necessary cuts and holes.

2. Key steps include using poplar wood for its hardness, drilling a 1/2 inch hole and cutting a notch, then gluing a 1/2 inch dowel plug into the hole.

3. The position of the dowel plug is important for tuning the whistle and can be adjusted before the glue dries.

Original Description:

Original Title

basic_whistle

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document provides instructions for making a basic wood whistle, including diagrams of the necessary cuts and holes.

2. Key steps include using poplar wood for its hardness, drilling a 1/2 inch hole and cutting a notch, then gluing a 1/2 inch dowel plug into the hole.

3. The position of the dowel plug is important for tuning the whistle and can be adjusted before the glue dries.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageBasic Whistle

Uploaded by

Keith Foor1. The document provides instructions for making a basic wood whistle, including diagrams of the necessary cuts and holes.

2. Key steps include using poplar wood for its hardness, drilling a 1/2 inch hole and cutting a notch, then gluing a 1/2 inch dowel plug into the hole.

3. The position of the dowel plug is important for tuning the whistle and can be adjusted before the glue dries.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

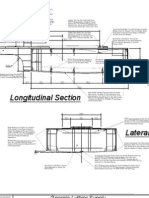

1 Whistle A A 5/8

1/2 Drill 4 1/2"

Approx. 4" Deep Max.

1/8 Max. 1/8 Drill Thru

*See Notes 5/8

45º (For a string or strap

must not break into

the 1/2 inch hole!)

5/8 (stock dimension)

I used 1" poplar stock for the whistle housing because poplar is harder than

pine and creates a sharper edge where the notch meets the drilled hole. 1

The sharper edge makes tuning the whistle much easier. You may have

your own favorite wood for this type of work or because of the small size

2

required you can use up small scrap pieces.

* I found the whistle has a better sound if this distance is kept under 1/8".

That puts the center of the 1/2" drill in the center of the stock. I cut the notch

before drilling use a nice sharp 1/2 inch bit. I have very good luck keeping a

Sub-Assebly AA

straight smooth bore at low RPM's (480 RPM) and feeding the bit slowly

when breaking thru the notch.The notch should cut at least half way through

the bore and edges should be clean, sharp and free of any loose wood

fibres. Careful light sanding helps to get as clean an edge as possible.

Be sure when you drill the 1/8 in strap hole you don't break into the 1/2 inch

2 Plug

drill or your whistle will NOT work.

1/2 Dowel

Then glue the plug (2) into the hole with its leading edge flush with the

vertical edge of the notch. Use a non-toxic white glue, remember you'll be

putting your mouth on this.

TUNING the WHISTLE

BEFORE the glue dries, test the whistle to 3/8 1/2

confirm proper assembly. If the whistle

dosen't work or sound sharp it is normally do

to the flat, which I sand, on the 1/2" dowel.

Try sanding more or replacing it with a

dowel with a smaller flat. Also slightly

adjusting the position of the dowel back and

forth in the bore is all that is required. This is

what I call tuning the whistle.

Basic Wood Whistle

Once the whistle sounds good let the glue

dry and finish it. I use a non-toxic nut oil. http://www.LackWood.com

Basic Whistle 1/2 Scale

http://www.LackWood.com PAGE 1 OF 1 PAGES

You might also like

- ISO 9001-2015 Mandatory Documents RequiredDocument1 pageISO 9001-2015 Mandatory Documents RequiredAnonymous GWDhNTOKO100% (5)

- Ukulele ConcertDocument1 pageUkulele Concertakomac100% (3)

- 5 String Kantele Plans and EbookDocument66 pages5 String Kantele Plans and Ebookmking_6100% (1)

- Adding Scales To Narex Marking Knife Blank 2Document6 pagesAdding Scales To Narex Marking Knife Blank 2Mal100% (1)

- 2023 New Value Report RippleDocument62 pages2023 New Value Report RippleThorbenNo ratings yet

- 1618 - Assignment 1 FullDocument10 pages1618 - Assignment 1 FullNam NguyenNo ratings yet

- Danish Bird HODocument3 pagesDanish Bird HOjosechumolinaNo ratings yet

- Acoustic Travel Ukulele Plans PDFDocument17 pagesAcoustic Travel Ukulele Plans PDFblancofrank545No ratings yet

- Ornitoptero PDFDocument5 pagesOrnitoptero PDFninonunezNo ratings yet

- Woomera e AtlatsDocument58 pagesWoomera e Atlatssoldatbr4183No ratings yet

- Digital Patterns: Designed by Steve GoodDocument10 pagesDigital Patterns: Designed by Steve GoodedosviracNo ratings yet

- April DemoDocument6 pagesApril DemoInform7105No ratings yet

- Wedgiesledplan 1Document6 pagesWedgiesledplan 1EmmetNo ratings yet

- Dovetail Clamp AP Instructions: What You'll Need: Included in PackageDocument2 pagesDovetail Clamp AP Instructions: What You'll Need: Included in PackageJaime MontielNo ratings yet

- Freebird PDFDocument5 pagesFreebird PDFHHOLINo ratings yet

- IRWIN ® - Wood DrillingDocument16 pagesIRWIN ® - Wood DrillingEva Lima CabralNo ratings yet

- Weekend Picture Frames: I Can Do ThatDocument8 pagesWeekend Picture Frames: I Can Do ThatJuanRodriguezNo ratings yet

- Ultimate Wooden CrateDocument17 pagesUltimate Wooden CrateJesse WaddleNo ratings yet

- Baseball Cap Rack: Woodworks: Beginner ProjectDocument7 pagesBaseball Cap Rack: Woodworks: Beginner ProjectEucap MdzNo ratings yet

- American Woodworker - 10 Weekend ProjectsDocument52 pagesAmerican Woodworker - 10 Weekend ProjectsJuanRodriguezNo ratings yet

- Img017 1Document3 pagesImg017 1api-217908378No ratings yet

- PiezoBarrel Manual v6Document7 pagesPiezoBarrel Manual v6Eric SmithNo ratings yet

- How To Make A Bamboo Flute (With Pictures) - WikiHowDocument5 pagesHow To Make A Bamboo Flute (With Pictures) - WikiHowNitin SoniNo ratings yet

- Workshop Tote Box: Project 20466EZDocument3 pagesWorkshop Tote Box: Project 20466EZBSulli100% (1)

- Building A Humidor1Document7 pagesBuilding A Humidor1apNo ratings yet

- Diy SIde Table Leather Magazine RackDocument13 pagesDiy SIde Table Leather Magazine RackDGNo ratings yet

- 143 415 Bts Instruction ManualDocument2 pages143 415 Bts Instruction ManualMohamed Mohiy El-DinNo ratings yet

- Mini-Guide For Adjusting Oboe ReedsDocument2 pagesMini-Guide For Adjusting Oboe ReedsYick THNo ratings yet

- American Woodworker - 10 Weekend ProjectsDocument53 pagesAmerican Woodworker - 10 Weekend ProjectsEmilian Baluta100% (1)

- The Infinite Oval: Tools For WoodworkingDocument2 pagesThe Infinite Oval: Tools For Woodworkingoqab18No ratings yet

- Deluxe Pocket Hole Jig Kit: InstructionsDocument2 pagesDeluxe Pocket Hole Jig Kit: InstructionsflerziNo ratings yet

- Inner Cover For Langstroth Hive: Ed RiceDocument4 pagesInner Cover For Langstroth Hive: Ed RiceFernandes HélioNo ratings yet

- Whelping Box DesignDocument12 pagesWhelping Box DesignLutafullahSaeedNo ratings yet

- Parts List (One Target)Document7 pagesParts List (One Target)nan214No ratings yet

- Bird House Building - Eng 022621Document2 pagesBird House Building - Eng 022621Nail AminovNo ratings yet

- GuitarDocument11 pagesGuitarvakarmeNo ratings yet

- HeritageSolidDeckingInstallation ENDocument2 pagesHeritageSolidDeckingInstallation ENGhislainTremblayNo ratings yet

- "Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLDocument2 pages"Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLTamara MarreroNo ratings yet

- Voicing The Renner HammerDocument6 pagesVoicing The Renner HammerModitha Lakshan100% (1)

- Elegant Box: A SmallDocument4 pagesElegant Box: A SmallcanoidoNo ratings yet

- Altoids Ukulele PlansDocument12 pagesAltoids Ukulele PlansSérgio Gomes Jordão100% (1)

- 103 - Table Saw Panel SledDocument2 pages103 - Table Saw Panel SledRob PierceNo ratings yet

- First LongbowDocument3 pagesFirst LongbowGinshun Ray SpedowskiNo ratings yet

- Live Free or DieDocument9 pagesLive Free or DieReggieNo ratings yet

- Craftsman Style Queen Sized HeadboardDocument10 pagesCraftsman Style Queen Sized Headboardvidawo1012No ratings yet

- Dowel and Tenon Cutters: U.S. Des. Pat. D547,155Document8 pagesDowel and Tenon Cutters: U.S. Des. Pat. D547,155AndreaNo ratings yet

- $20 Combat Crossbow, TheDocument8 pages$20 Combat Crossbow, TheKaryllongNo ratings yet

- Layens Hive - Free Plans - Natural BeekeepingDocument9 pagesLayens Hive - Free Plans - Natural BeekeepingjoseNo ratings yet

- Mountain Dulcimer History 1Document20 pagesMountain Dulcimer History 1Juli EtaNo ratings yet

- Crossbow 20 PDFDocument8 pagesCrossbow 20 PDFGeoffrey Hamilton-adamsNo ratings yet

- Ultimate WorkbenchDocument8 pagesUltimate WorkbenchEric Gruff0% (1)

- Teddy Bear Puzzle: Project 19090EZDocument6 pagesTeddy Bear Puzzle: Project 19090EZ- yAy3e -No ratings yet

- Making Plastic PC ReedsDocument6 pagesMaking Plastic PC ReedsJayNo ratings yet

- How To Make BokkenDocument10 pagesHow To Make Bokkenkosen58100% (1)

- Bikecart Brief SequentialDocument4 pagesBikecart Brief Sequentialapi-3710885100% (1)

- Circle CutterDocument4 pagesCircle CutterJair Marques PereiraNo ratings yet

- Ibanez Acoustic Guitar Instruction ManualDocument3 pagesIbanez Acoustic Guitar Instruction ManualLazaro MachadoNo ratings yet

- Crankbait Carving PatternsDocument5 pagesCrankbait Carving PatternsSyahir Hazmi100% (1)

- Creating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesFrom EverandCreating Wooden Boxes on the Scroll Saw: Patterns and Instructions for Jewelry, Music, and Other Keepsake BoxesNo ratings yet

- Uais Transponder Fa-100 Operator's Guide: Turning On and OffDocument2 pagesUais Transponder Fa-100 Operator's Guide: Turning On and OffNguyen Phuoc HoNo ratings yet

- Desigo CC Software Technical DataDocument14 pagesDesigo CC Software Technical DataM F Shahariar KhanNo ratings yet

- Conducting Market ResearchDocument28 pagesConducting Market ResearchHimadri JanaNo ratings yet

- Pogi C JamesDocument2 pagesPogi C JamesMikzy MercadoNo ratings yet

- Digital Marketing MaterialDocument16 pagesDigital Marketing MaterialRABIANo ratings yet

- Code MSGDocument186 pagesCode MSGricardoweberNo ratings yet

- Autodesk Product Keys 2019 PDFDocument1 pageAutodesk Product Keys 2019 PDFRubén Cuán RNo ratings yet

- Nokia Lumia 925 RM-892 - 893 - 910 L1L2 Service ManualDocument63 pagesNokia Lumia 925 RM-892 - 893 - 910 L1L2 Service ManualCretu PaulNo ratings yet

- Requirement For T&C Purpose HPUniSZADocument1 pageRequirement For T&C Purpose HPUniSZAAwalJefriNo ratings yet

- Mechanical Instruction ManualDocument16 pagesMechanical Instruction ManualMorarescu AndreiNo ratings yet

- Project Report On BPC Ltd.Document59 pagesProject Report On BPC Ltd.PeushPrabhakar63% (8)

- Disks and Cloud StorageDocument12 pagesDisks and Cloud StoragePradeepKumarMandavaNo ratings yet

- "Title": Design and Fabrication of Bluetooth Controlled Robotic Cleaning MachineDocument26 pages"Title": Design and Fabrication of Bluetooth Controlled Robotic Cleaning MachineSrushti KatkarNo ratings yet

- Sunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesDocument7 pagesSunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesAngirekula gopi krishnaNo ratings yet

- Alphabet Series Tricks - PDF: Intervals LikeDocument7 pagesAlphabet Series Tricks - PDF: Intervals LikeAbhishek A. NadgireNo ratings yet

- JIS B 1301-1996 - Chavetero PDFDocument1 pageJIS B 1301-1996 - Chavetero PDFPablo PasqualiniNo ratings yet

- GPS Submittal PDFDocument32 pagesGPS Submittal PDFshankar05No ratings yet

- A Covid-19 Based Temperature Detection and Contactless Attendance Monitoring System Using Iris RecognitionDocument18 pagesA Covid-19 Based Temperature Detection and Contactless Attendance Monitoring System Using Iris Recognitionshreya tripathiNo ratings yet

- Exin Light Zone 0 EX90L-T4-Brochure-V26032019Document1 pageExin Light Zone 0 EX90L-T4-Brochure-V26032019Alexa Burlacu0% (1)

- ST Peter, 2014, BI-Annual DR-TB Performance Report To AAHB, 15 March 2022. JohnDocument43 pagesST Peter, 2014, BI-Annual DR-TB Performance Report To AAHB, 15 March 2022. Johnሀይደር ዶ.ርNo ratings yet

- Sam Koolhoven Resume 2020Document1 pageSam Koolhoven Resume 2020Sam KoolhovenNo ratings yet

- Winter Prep - An Ounce of Prevention .Document20 pagesWinter Prep - An Ounce of Prevention .TomboNo ratings yet

- Green ComputingDocument7 pagesGreen Computingerwin.dee.cicsNo ratings yet

- Vacuum EjectorDocument6 pagesVacuum EjectorAmol KadamNo ratings yet

- 876 2280 1 PBDocument12 pages876 2280 1 PBH4nk TechnoNo ratings yet

- OSY - Chapter1Document11 pagesOSY - Chapter1Rupesh BavgeNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet