Professional Documents

Culture Documents

Unit V

Uploaded by

sureshkumar0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

unit-v

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesUnit V

Uploaded by

sureshkumarCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Repair methods for material handling equipment

The proper maintenance of material handling equipment is

extremely essential for preventing the occurrence of bottlenecks or

points of congestions. Production line flow can be maintained only if the

material hand

ling equipment is in proper working order. Out of many maintenance

techniques available, preventive maintenance is the one of the best

maintenance techniques suggested in case of material handling

equipment.

These are three stages of preventive maintenance and they are

Inspection

Repair

Overhauls

Maintenance strategies for hoists and cranes:

Portable crane:

It is necessary to keep loads within design limits on portable cranes

that are mounted on wheels platforms.

Frequent inspection of brakes, load hoist ing and lowering mechanism

Inspection of boom, base and platform for any sign of stress

Eg: cracks, bends, breaks

Over head cranes:

Keep the attachments in overhead cranes loaded within the rating

capacity.

Maintain safety factors for replacement parts according to

manufacturer specifications

Check welded connections for cracks, bends abrasion and corrosion

Maintenance strategies for conveyers:

Conveyer system need to be inspected on a regular basis. The

important areas include rollers, bearings chains and belts. All of these

moving parts are subjected to wear and tear

Check conveyers to detect any bolt slippage, dragging or defective

rollers.

Moving equipment parts are subjected to breaks caused by metal

fatigue, loose bearing and obstructions. A typical scheduled conveyor

maintenance plan:

Check/lubricate all bearings, universal joints, and pulleys.

Check chain tension, wear and lubricate

Check sprocket alignment, wear and screw set.

Check flat belt tension, wear and acing

Check V-belt tension, wear and sheave alignment.

Check general condition of system

Operate entire system after service

List any items requiring replacement or repair.

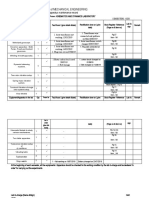

A global approach to maintenance management

Preventive Maintenance Inspections identify risks and improvement opportunities. Our vast

experience and expertise allow us to tailor preventive maintenance to each manufacturer’s

recommendations.

Routine Maintenance, such as adjusting and lubricating, is performed to keep your equipment

running while satisfying manufacturer’s maintenance instructions.

Compliance Inspections are designed to satisfy regulatory requirements. Our trained inspectors

and technicians are your go-to experts on local regulations. In some countries, regulations

require the use of a third party.

These essential Inspection and preventive maintenance tasks are bundled into service products.

Our products are combined to form our Service Programs.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

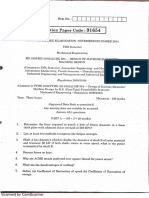

- EMM Dec 2011Document3 pagesEMM Dec 2011sureshkumarNo ratings yet

- Phase 1 Quiz QP WITH ANSWERDocument5 pagesPhase 1 Quiz QP WITH ANSWERsureshkumarNo ratings yet

- ME2304-M&M-2 Mark Question With Answer KeyDocument13 pagesME2304-M&M-2 Mark Question With Answer KeysureshkumarNo ratings yet

- CE8395 QB - by WWW - Easyengineering.net 1Document18 pagesCE8395 QB - by WWW - Easyengineering.net 1sureshkumarNo ratings yet

- Automatic Braking SystemDocument64 pagesAutomatic Braking SystemsureshkumarNo ratings yet

- Me 1012 MeDocument5 pagesMe 1012 MesureshkumarNo ratings yet

- Phase Ii Quize QP With AnswerDocument5 pagesPhase Ii Quize QP With AnswersureshkumarNo ratings yet

- Iv Unit PPT 1644379-Me1014unit4-2010-2011/: Maintenance PoliciesDocument11 pagesIv Unit PPT 1644379-Me1014unit4-2010-2011/: Maintenance PoliciessureshkumarNo ratings yet

- QP Fea 2Document1 pageQP Fea 2sureshkumarNo ratings yet

- Anna University:: Chennai - 600 025: Office of The Controller of ExaminationsDocument2 pagesAnna University:: Chennai - 600 025: Office of The Controller of ExaminationssureshkumarNo ratings yet

- Akshaya College of Engineering and Technology Department of Mechanical EngineeringDocument3 pagesAkshaya College of Engineering and Technology Department of Mechanical EngineeringsureshkumarNo ratings yet

- COURSE OUTCOMES 19 - 20 All Subjects MechanicalDocument25 pagesCOURSE OUTCOMES 19 - 20 All Subjects MechanicalsureshkumarNo ratings yet

- Unit - Iv Forced Vibration Part-A: M S C F XDocument12 pagesUnit - Iv Forced Vibration Part-A: M S C F XsureshkumarNo ratings yet

- 'G ? R/S,, Ler,: ("" T Qyq C-Ts.r.i.lea O' :'Document1 page'G ? R/S,, Ler,: ("" T Qyq C-Ts.r.i.lea O' :'sureshkumarNo ratings yet

- Anna University CHENNAI - 600 025Document2 pagesAnna University CHENNAI - 600 025sureshkumarNo ratings yet

- ME2029 DJF 2 Marks +16 Mark QuestionsDocument15 pagesME2029 DJF 2 Marks +16 Mark QuestionssureshkumarNo ratings yet

- Maintenance Policies:: Breakdown Maintenance or Reactive MaintenanceDocument11 pagesMaintenance Policies:: Breakdown Maintenance or Reactive Maintenancesureshkumar100% (1)

- List Out Various Fundamental Rules For Geometric Tolerance. Describe RSS For Tolerance Analysis Wit RSSDocument1 pageList Out Various Fundamental Rules For Geometric Tolerance. Describe RSS For Tolerance Analysis Wit RSSsureshkumarNo ratings yet

- List of Pedagogy PDFDocument1 pageList of Pedagogy PDFsureshkumarNo ratings yet

- 1.bernoulli's Equation Cannot Be Applied When The Flow IsDocument9 pages1.bernoulli's Equation Cannot Be Applied When The Flow IssureshkumarNo ratings yet

- Department of Mechanical EngineeringDocument8 pagesDepartment of Mechanical EngineeringsureshkumarNo ratings yet

- Unit Ii Balancing Part ADocument15 pagesUnit Ii Balancing Part AsureshkumarNo ratings yet

- Maintenance - Format - K&DDocument2 pagesMaintenance - Format - K&DsureshkumarNo ratings yet

- DME ND 14 - 247Document3 pagesDME ND 14 - 247sureshkumarNo ratings yet

- Dme 1Document1 pageDme 1sureshkumarNo ratings yet

- DME ND 14-1 - 248Document3 pagesDME ND 14-1 - 248sureshkumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Name Change RequestDocument2 pagesName Change RequestRonald TorresNo ratings yet

- Cadwallader & Co vs. Smith Bell & Co., 7 Phil 461 - ARTICLE 1398Document1 pageCadwallader & Co vs. Smith Bell & Co., 7 Phil 461 - ARTICLE 1398Danica CaballesNo ratings yet

- Test Bank For International Financial Management Abridged Edition 11th Edition Jeff MaduraDocument24 pagesTest Bank For International Financial Management Abridged Edition 11th Edition Jeff Madurajordanwyattgiosqackyn100% (44)

- Crompton +++ Revolut-GBP-Statement-Dec 2020Document2 pagesCrompton +++ Revolut-GBP-Statement-Dec 202013KARATNo ratings yet

- Project On "Associate Recruitment Test Paper Revision": Rahulji SinghDocument94 pagesProject On "Associate Recruitment Test Paper Revision": Rahulji SinghDeepak SinghalNo ratings yet

- DR 202221919Document40 pagesDR 202221919Lassaad Ben MahjoubNo ratings yet

- How To Create A Scheduling AgreementDocument108 pagesHow To Create A Scheduling AgreementMaxkNo ratings yet

- June 2023 SANTA MARTA MARINA AND BEACH FRONT PROPERTY THROUGH FASTBLOC BUILDING SYSTEMDocument14 pagesJune 2023 SANTA MARTA MARINA AND BEACH FRONT PROPERTY THROUGH FASTBLOC BUILDING SYSTEMLUZ MOSNo ratings yet

- 25 Rules For Day Trading SuccessDocument5 pages25 Rules For Day Trading SuccessFernando Andres Rodríguez GoncalvesNo ratings yet

- Essential Leadership Lessons From Top CEOs - Lou Gerstner, Jack Welch, Sam Walton, Howard Hughes, Lee Iacocca, Phil Knight, Walt Disney, Carlos Ghosn, Andrew S.Grove PDFDocument112 pagesEssential Leadership Lessons From Top CEOs - Lou Gerstner, Jack Welch, Sam Walton, Howard Hughes, Lee Iacocca, Phil Knight, Walt Disney, Carlos Ghosn, Andrew S.Grove PDFananth080864100% (2)

- Impact of GST On Food and Hospitality IndustryDocument98 pagesImpact of GST On Food and Hospitality IndustrySimran JaiswalNo ratings yet

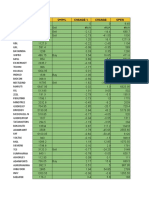

- Ticker LTP O H L Change % Change OpenDocument22 pagesTicker LTP O H L Change % Change OpenPrasanna PharaohNo ratings yet

- SPX Monthly Chart: Sept. 27, 2020 EditionDocument7 pagesSPX Monthly Chart: Sept. 27, 2020 EditionSengottu VeluNo ratings yet

- NL Dalmia Institute of Management Studies and ResearchDocument14 pagesNL Dalmia Institute of Management Studies and Researchsudipta shrivastavaNo ratings yet

- B2B Lead Generation (Event Mangement US) : SL Company Name Website AddressDocument3 pagesB2B Lead Generation (Event Mangement US) : SL Company Name Website AddressMd.Hasibul Hasan RokibNo ratings yet

- Case Ball Point PenDocument16 pagesCase Ball Point Penankur2wazzNo ratings yet

- Corporate Objectives, Strategy and Structure: Prepared By: Ms. Nelda A. Rosima InstructorDocument27 pagesCorporate Objectives, Strategy and Structure: Prepared By: Ms. Nelda A. Rosima InstructorValerie Kaye FamilaranNo ratings yet

- 11-Article Text-1499-1-10-20220406Document12 pages11-Article Text-1499-1-10-20220406lionaramadani febriosaNo ratings yet

- Akd 73673805038Document1 pageAkd 73673805038Rishaan RanjanNo ratings yet

- Katrina's ResumeDocument2 pagesKatrina's ResumeTestyNo ratings yet

- Notes For Appraisal of Flexi PipeDocument27 pagesNotes For Appraisal of Flexi PipeEason NgNo ratings yet

- Specification 201 Quality Systems PDFDocument57 pagesSpecification 201 Quality Systems PDFalejandraoy9No ratings yet

- New FileDocument3 pagesNew FileLatha SurendranNo ratings yet

- Xqo9qwu59 - Chapter 6 - Asking The Good QuestionsDocument47 pagesXqo9qwu59 - Chapter 6 - Asking The Good QuestionsMoses Kyle JimenezNo ratings yet

- Sensitivity Analysis in Excel TemplateDocument8 pagesSensitivity Analysis in Excel TemplateMohd Yousuf MasoodNo ratings yet

- Tax RTP 2 Nov 2020Document41 pagesTax RTP 2 Nov 2020KarthikNo ratings yet

- Smart Buildings - Building Technologies - Siemens SingaporeDocument12 pagesSmart Buildings - Building Technologies - Siemens SingaporeKR PANo ratings yet

- Corr Case StudiesDocument5 pagesCorr Case StudiesPrashant ChavanNo ratings yet

- Chapter-2 Regime of Patent in India and Its Global ScenarioDocument19 pagesChapter-2 Regime of Patent in India and Its Global Scenariochongtham rajeshNo ratings yet

- WAPCOS LimitedCentre For Environment and Construction ManagementDocument4 pagesWAPCOS LimitedCentre For Environment and Construction ManagementRafikul RahemanNo ratings yet