Professional Documents

Culture Documents

HMIS Top Drive System

HMIS Top Drive System

Uploaded by

Suat YamanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HMIS Top Drive System

HMIS Top Drive System

Uploaded by

Suat YamanCopyright:

Available Formats

System Description

HMIS Top Drive System

250TON HMIS 475HP

DOCUMENT NAME: 880025 REV 2

SYSTEM DESCRIPTION COPYRIGHT AND DISCLAIMER

Tesco Corporation ("TESCO") has made every effort to ensure that this document contains accurate

and current information for the TESCO top drive, however, the document is intended to be used in

conjunction with a complete training program and on-site supervision and TESCO does not

warrant or guarantee that the information contained herein is either complete or accurate in every

respect, and the reader hereby protects, indemnifies and holds harmless Tesco Corporation together

with its directors, officers, employees and agents from and against all liability for personal injury,

death or property damage to any person arising directly or indirectly from the use by the reader of the

information contained in the document.

Tesco Corporation © 2007

Contact Information

Corporate Head Office

3993 W. Sam Houston Parkway No., Suite 100

Houston, Texas, 77043

USA

www.tescocorp.com

Telephone: (713) 359-7000

Fax: (713) 359-7001

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

I

REVISION INFORMATION SYSTEM DESCRIPTION

Revision Information

Version Date Description of Changes

A April 2004 Engineering review, revisions, and additions.

1 Oct 2007 Added caution symbols to all warnings and caution notes. Added more safety warnings.

Updated revision numbering to comply with new engineering numbering standards.

2 Nov 2007 New revision to remove CE-ATEX standards from manual.

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

II

SYSTEM DESCRIPTION

TABLE OF CONTENTS

CHAPTER 1: ABOUT THIS DOCUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2: TOP DRIVE SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction and General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Shipping Containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Container 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Container 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Container 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Top Drive Components ............................................................5

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Load Collar and Load Nut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mudsaver Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pipe Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Counter-Balance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Swivel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Top Drive Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Handling Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Prime Mover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pump Drive and Filter Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hydraulic Oil Reservoir/Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Torque Arrest System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Extend Frame and Extend Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Torque Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Torque Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Torque Beam, Torque Anchor and T-bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power (Closed-Loop) Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auxiliary Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Case Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Driller’s Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Elevators and Elevator Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Grabber Drill Pipe Guides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rotary Table Stabilizer Bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rotary Hose and Standpipe Extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Torque Arrest System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

III

SYSTEM DESCRIPTION

Other Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

ENGINEERING SIGN-OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

IV

SYSTEM DESCRIPTION

CHAPTER 1: ABOUT THIS DOCUMENT

This document contains a description of the major components of the 250TON HMIS 475HP

Top Drive System with integrated quill.

A complete HMIS Top Drive System consists of the following:

• top drive

• power unit

• interconnecting service loop and reel

• torque arrest system

• associated buildings, containers and equipment

This document provides a brief description of each major component, as well as a list of avail-

able spares and options.

Table 1-1: Where to find more information

For information on Refer to

• installation HMIS Installation Guide

• rig up

• commissioning

• pre-operational checklists

• rig out procedures

• setting torque and speed HMIS Operations Guide

• driller's panel functions and operating descriptions

• making connections

• drilling ahead

• tripping

• freeing stuck pipe

• load path inspections HMIS Maintenance Guide

• maintenance/service schedules

• component disassembly and reassembly

TESCO manufactured parts and part numbers HMI Parts List

• electrical schematics System schematics

• hydraulic schematics

• cooling schematics

• gearbox lubrication schematics

available options and spares TESCO Representative

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

1

ABOUT THIS DOCUMENT SYSTEM DESCRIPTION

This page has been left blank intentionally.

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

2

SYSTEM DESCRIPTION

CHAPTER 2: TOP DRIVE SYSTEM DESCRIPTION

INTRODUCTION AND GENERAL SPECIFICATIONS

The HMIS top drive is designed for use on small drilling rigs and workover rigs. The HMIS

top drive is powered using an independent hydraulic power unit.

To create the optimum power supply system required for each of its top drives, TESCO com-

bines industry proven prime movers with its own series of hydraulic pump drives and filtration

equipment.

The HMIS top drive is powered using one of the following power unit configurations:

• 475 hp prime mover with a two-pump drive (Detroit Diesel Series 60)-most common

• 460 hp prime mover with a two-pump drive (Caterpillar 3406B)

Metric unit conversions (in brackets) have been provided for convenience only. All prod-

uct specifications use the original imperial units unless indicated otherwise.

Note: All weight values are approximate.

Table 2-1: HMIS Top Drive specifications

Specification Details

Top Drive 250TON HMIS 475HP

Rated Capacity 250 ton (226.8 metric ton)

Weight of the top drive plus: 8,900 lb. (4,037 kg)

• elevators

• elevator links

• counter balance

• swivel

Length 13 ft. 5 in. (4.089 m)

Width 33 in. (0.84 m)

Horsepower Dependent on the prime mover:

475 hp (354.2 kW)–2 pump drive

460 hp (343.0 kW)–2 pump drive

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

3

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Table 2-2: Torque Arrest System specifications

Specification Details

Weight of the following: 7,200 lb. (3265.87 kg)

• torque track

• anchor beam

• torque bushing

• extend frame

• clamps

Std Track Length 91 ft. (27.7 m); more length is available

SHIPPING CONTAINERS

The HMIS top drive is typically shipped in ocean shipping containers. Each container is 20 ft

(length) x 8 ft (width) x 8 ft 6 in. (height) (6.1 m x 2.4 m x 2.6 m).

Container 1

Approximate weight: 20,000 lb. (9071.85 kg)

Contents:

• top drive and transportation stand

• multi-conductor cable storage reels

• links

• spare parts

Note: Some countries require that spare parts be shipped separately from the original

equipment. In these cases, spare parts will be crated and shipped in a separate container.

Container 2

Approximate weight: 18,000 lb. (8164.66 kg)

Contents:

• power unit (without the hose reel skid)

Container 3

Approximate weight: 18,000 lb. (8164.66 kg)Contents:

• torque arrest system components

• one rig up basket

• hose reel skid

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

4

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

TOP DRIVE COMPONENTS

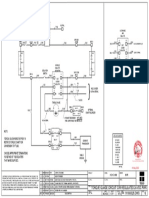

Figure 2-1: HMIS Top Drive general assembly

1. Torque Bushing 72 in.

2. Swivel Link and

Counter-Balance

3. Swivel

4. 11-Station Manifold

5. Spoon Assembly

6. Motor Manifold

7. Link Carrier Assembly

8. Gearbox and Spline Drive

Assembly

9. Load Nut and Load Collar

10.Link Tilt Cylinders

11.Mudsaver Valve

12.Grabber (with legs)

13.Elevator Link Tilt Assembly

14.Elevator

15.Torque Track Assembly

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

5

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Gearbox

• The gearbox couples one hydraulic motor to the gear train.

• The motor is a bi-directional hydraulic vane type, and it has pressure ratings of 4,000 psi

(27.6 MPa) continuous and 4,500 psi (31.0 MPa) intermittent.

• The HMIS top drive system is configured with a standard gear ratio of 2.19:1. An

optional 1.64:1 gear ratio is also available.

• The gearbox houses gear reduction and forced lubrication systems as required for the

unit.

• The integral drive hub is internally splined to accept the integrated swivel and quill.

Load Collar and Load Nut

The load collar and load nut transfer loads from the elevator links to the quill.

Mudsaver Valve

The mudsaver valve is a double-ball crank valve that acts as a mudsaver. It replaces the upper

and lower Kelly cock. The valve does not descend below the rotary table, except in emergency

situations, and it is always easily accessible. The mudsaver valve actuator can be operated

remotely from the driller’s panel.

Caution: The actuated upper ball valve is not for well control; it

functions solely as a mudsaver. The manual operating lower valve

! is for well control. Ensure that the valve selected can fit into the

existing casing.

Pipe Handling

The pipe handling abilities of the HMIS include the following:

• Elevator Link Tilt Cylinders: These allow extension and retraction of the elevators 35°

forward from the vertical position and 55° backward from the vertical position.

• Grabber (back-up wrench): The grabber acts as a back-up tong for making or breaking

connections at any point in the mast. The grabber will accommodate tool joints from

2-3/8 in. to 5 in. OD.

Counter-Balance

The top drive features an automatic thread feed compensation for make up and break out oper-

ations.

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

6

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

Swivel

The HMIS top drive features a drilling swivel with an integrated one-piece quill. This configu-

ration offers the following advantages:

• no connections from the swivel bearing to the top of the mudsaver valve

• increased reliability/reduced maintenance

• decrease in the overall length and weight of the top drive

• readily available replacement parts

Top Drive Power Supplies

The top drive motor is powered by two axial piston pumps, which are located on the rear of the

prime mover. All top drive robotic functions are powered by an auxiliary hydraulic system,

which is located on the prime mover module.

Handling Frame

The top drive is shipped in its own handling frame. This frame allows you to transport and

handle the top drive by using standard rig moving equipment.

POWER UNIT

The HMIS Top Drive power unit consists of the following:

• prime mover module, which includes the pump drive and filter manifold, the oil reser-

voir and cooling system, and the auxiliary system components

• hose storage reel

Prime Mover

The prime mover is a skid-mounted diesel engine (Detroit Diesel Series 60). Prime movers are

equipped with a fuel day tank, an air starter, standard instrumentation packages, and appropri-

ate safety and emergency shutoffs.

Pump Drive and Filter Manifold

The pump drive/filter manifold is skid-mounted and includes the following equipment:

• variable displacement, bi-directional axial piston pumps (two)

• flow meters and temperature gauges

• a series of hydraulic oil filters

• hot oil shuttle (to assist with oil cooling)

• auxiliary hydraulic pump and motor

The auxiliary hydraulic equipment includes the following:

• a gear pump (2,000 psi, 7 gal/min; 13.79 MPa, 26.5 liters/minute)

• 10 hp (7.46 kW) explosion-proof electric motor

• associated filters and controls

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

7

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Hydraulic Oil Reservoir/Cooler

The hydraulic oil reservoir/cooler is skid-mounted and contains the hydraulic oil storage reser-

voir and cooling system components. All reservoirs are equipped with a level gauge, tempera-

tures gauges, and return oil filters.

Cooling System Components

The cooling system components provide cooling for hydraulic oil used by the power and aux-

iliary hydraulics systems. An air/oil heat exchanger (controlled by a thermostat) cools the

hydraulic oil before it is returned to the tank.

Figure 2-2: HMIS power unit configuration

1. Prime Mover (Detroit Diesel Series 60)

2. Air/Oil Cooler

3. Hose Reel Module

4. Auxiliary Hydraulic Pump and Motor

5. Oil Reservoir

6. Variable displacement, bi-directional axial pumps (not visible in this illustration)

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

8

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

TORQUE ARREST SYSTEM

The torque arrest system is typically shipped in the second standard sea container. It consists

of the following components:

• extend frame

• torque bushing

• extend arms

• extend hydraulic cylinders

• torque track

• T-bar

• torque beam, torque beam clamps, stabilization devices, and all required rig up items

Extend Frame and Extend Arms

The extend frame is pinned to the top drive. It allows you to extend the top drive away from

the torque track.

Torque Bushing

The torque bushing is attached to the extend frame. Ultra High Molecular Weight (UHMW)

inserts reduce friction as the top drive moves along the torque track. No lubrication is required.

Torque Track

The torque track, in conjunction with the torque beam and T-bar, transfers reactive torque to

the lower section of the derrick and the substructure.The track is suspended from the crown by

a cable hanging assembly, and is mounted with a simple clamp anchoring arrangement. Track

components can be configured to fit most mast heights.

Torque Beam, Torque Anchor and T-bar

The torque beam is mounted on the rig, typically to the lowest strongback. It is then connected

to the torque track via a T-bar. An offset torque anchor beam and post is available for use on

service rigs. This torque anchoring system compensates for the 3.5° lean of the service rig

mast.

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

9

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

Figure 2-3: HMIS torque arrest system

1. “F” Clamps

2. Torque Track

3. Turnbuckles

4. “F” Clamps

5. “F” Clamp Assembly

6. Nuts, Washers and

Ready Rod

7. Torque Track

8. Final Assembly,

72 in. Torque Bushing

9. Gearbox

10.Optional Torque

Anchor Assembly

11.Mast

12.Torque Beam

Assembly

13.Torque Track

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

10

SYSTEM DESCRIPTION TOP DRIVE SYSTEM DESCRIPTION

SERVICE LOOP

The hoses are spooled onto the hose reel prior to shipping.

Power (Closed-Loop) Hydraulic Hoses

• two 225 ft. (68.58 m) x 1-1/2 in., 5,000 psi (34.5 MPa) hoses (one supply, one return);

these supply closed-loop hydraulic oil from the pump drive module to the top drive

motor

Auxiliary Hydraulics

• one 225 ft. (68.58 m) x 3/4 in. R2, 2,000 psi (13.8 MPa) hydraulic hose; this supplies

hydraulic oil from the pump drive module to the top drive robotics system

Case Drain

• one 225 ft. (68.58 m) x 1-1/4 in. 1,625 psi (11.2 MPa) hydraulic hose; this returns auxil-

iary hydraulic oil and motor case drain flow from the top drive to the hydraulic oil reser-

voir

Control Cables

The 225 ft. control cable is spooled onto its own cable reel. The 160 ft. control cable remains

attached to the main electrical panel on the power unit and hangs from a cable hook during

storage.

• one 225 ft. (68.58 m) 37-conductor cable: this cable connects the driller's panel to the top

drive

• one 160 ft. (48.77 m) 37-conductor cable: this cable connects the driller's panel to the

main electrical panel on the power unit

DRILLER’S PANEL

The driller’s panel is a stainless steel enclosure that is mounted on the drill floor during instal-

lation procedures. It contains all controls, indicators, mounts, gauges and connectors required

to operate the top drive. There is an optional air-purge system available for the driller’s panel.

All controls are electrically activated hydraulic (24 VDC) non-earth ground.

880025 REV 2 250TON HMIS 475HP ©TESCO CORPORATION, 2007

11

TOP DRIVE SYSTEM DESCRIPTION SYSTEM DESCRIPTION

OPTIONS

The following options are available. For more detailed information, contact a TESCO repre-

sentative.

Elevators and Elevator Links

Elevators rated at 150 and 250 tons (136.1 and 226.8 metric tons), associated inserts for vari-

ous drill pipe sizes, and accessories are available. A variety of link lengths is also available.

Subs

A complete selection of commonly used saver, casing, cross-over and drill collar handling

subs is available. Non-standard subs can be manufactured if requested; delivery can be deter-

mined at time of order.

Grabber Drill Pipe Guides

These are used to guide the drill string into the grabber box. The drill pipe guide must match

the box of the drill pipe in use. There is a range of sizes available.

Rotary Table Stabilizer Bushings

These urethane bushings fit the standard rotary table profile and protect the table and Blowout

Preventer (BOP) from excessive wear. There is a range of sizes available.

Rotary Hose and Standpipe Extension

All equipment and accessories for these modifications are available.

Torque Arrest System

Other Available Options

• air purge system for the driller's panel and top drive junction box

• workshop/parts containers with workbench and storage cupboards

• camera system

©TESCO CORPORATION, 2007 250TON HMIS 475HP 880025 REV 2

12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 1MA1 2H Rms 20230824Document22 pages1MA1 2H Rms 20230824mohammedalmaghafi2008No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Example CDCT Appendix 25Document53 pagesExample CDCT Appendix 25Osama AshourNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ideco TL-200 - 120Document12 pagesIdeco TL-200 - 120Gustavo RiveraNo ratings yet

- Case Study ToshibaDocument6 pagesCase Study ToshibaRachelle100% (1)

- Physical Traces PDFDocument150 pagesPhysical Traces PDFVíctor Martínez GarcíaNo ratings yet

- CKA CKAD Candidate Handbook v1.2Document28 pagesCKA CKAD Candidate Handbook v1.2Ranjeit ShekhawatNo ratings yet

- Georgia v. Susan McCoy: Bond Hearing TranscriptDocument107 pagesGeorgia v. Susan McCoy: Bond Hearing TranscriptDefiantly.netNo ratings yet

- Green BuildingDocument29 pagesGreen BuildingsadafScribd100% (2)

- Partes para Bombas Triplex Continental EmscoDocument4 pagesPartes para Bombas Triplex Continental EmscoGustavo RiveraNo ratings yet

- Partes para Bombas Triplex PZDocument2 pagesPartes para Bombas Triplex PZGustavo Rivera100% (1)

- Iron Roughneck PW163 PDFDocument51 pagesIron Roughneck PW163 PDFGustavo RiveraNo ratings yet

- BOMBAS DE LODO CapacidadDocument9 pagesBOMBAS DE LODO CapacidadGustavo RiveraNo ratings yet

- TL 120 200BDocument10 pagesTL 120 200BGustavo Rivera50% (2)

- 91000015rev4 PDFDocument1 page91000015rev4 PDFGustavo RiveraNo ratings yet

- Instrucciones de ManejoDocument2 pagesInstrucciones de ManejoGustavo RiveraNo ratings yet

- Pieter Eras Mus: R ErasmDocument1 pagePieter Eras Mus: R ErasmGustavo RiveraNo ratings yet

- Manual de Partes Unit 1168 HMI PDFDocument231 pagesManual de Partes Unit 1168 HMI PDFGustavo RiveraNo ratings yet

- EM000039Rev1 PDFDocument1 pageEM000039Rev1 PDFGustavo RiveraNo ratings yet

- 881006RevA PDFDocument1 page881006RevA PDFGustavo RiveraNo ratings yet

- C BOP Parts List PDFDocument9 pagesC BOP Parts List PDFGustavo RiveraNo ratings yet

- Aceites Codigo JDE Parte Numero SHELL Parte Numero MOBIL UM: Mobilux EP-2Document2 pagesAceites Codigo JDE Parte Numero SHELL Parte Numero MOBIL UM: Mobilux EP-2Gustavo RiveraNo ratings yet

- EG-3P/EG-6P/EG-10P: Proportional ActuatorsDocument4 pagesEG-3P/EG-6P/EG-10P: Proportional ActuatorsGustavo RiveraNo ratings yet

- Copia de Choke - Manifold.SparesDocument4 pagesCopia de Choke - Manifold.SparesGustavo RiveraNo ratings yet

- Virtual CockpitDocument10 pagesVirtual CockpitNavaneeth Krishnan BNo ratings yet

- Midterm Exam Oli MarkDocument4 pagesMidterm Exam Oli MarkLloyd BaylonNo ratings yet

- 8051 Microcontroller Book PDFDocument26 pages8051 Microcontroller Book PDFswati pasiNo ratings yet

- EF SET CertificateDocument1 pageEF SET Certificatedwadadw dawdadawNo ratings yet

- 9D Research GroupDocument9 pages9D Research Groupapi-291828723No ratings yet

- Engineering: About Me ContactDocument1 pageEngineering: About Me ContactDebbie DebzNo ratings yet

- PRAGATI NOTA R & W ENK Level 3 ReviwedDocument33 pagesPRAGATI NOTA R & W ENK Level 3 ReviwedNaik Nagaraj100% (1)

- It's Just A MovieDocument10 pagesIt's Just A MoviepicilohatNo ratings yet

- Android Application Secure Design/Secure Coding GuidebookDocument385 pagesAndroid Application Secure Design/Secure Coding GuidebookFrancesco Bicco Iberite100% (1)

- Cell As A Unit of Life (Science Form 1 - Short Notes)Document2 pagesCell As A Unit of Life (Science Form 1 - Short Notes)jrpyroNo ratings yet

- Lista de Precios Agosto 2022Document9 pagesLista de Precios Agosto 2022RuvigleidysDeLosSantosNo ratings yet

- Spinal Cord Injury: Causation & PathophysiologyDocument10 pagesSpinal Cord Injury: Causation & Pathophysiologycpradheep100% (3)

- TEMS Pocket 7.3.2 For Sony Ericsson W995 and W995a - User's ManualDocument226 pagesTEMS Pocket 7.3.2 For Sony Ericsson W995 and W995a - User's ManualpavlodeNo ratings yet

- Cue Cards May To August 2022Document29 pagesCue Cards May To August 2022Muskan Aggarwal 1702721No ratings yet

- PATIENT CASE HPI J.O. Is A 5 Yo Girl Who Is Brought To The PediatricDocument5 pagesPATIENT CASE HPI J.O. Is A 5 Yo Girl Who Is Brought To The PediatricKyla ValenciaNo ratings yet

- High Voltage Lab: Experiment No. 2 TITLE: Study of The Characteristics of Impulse VoltageDocument12 pagesHigh Voltage Lab: Experiment No. 2 TITLE: Study of The Characteristics of Impulse VoltageTanmoy Saha100% (1)

- Fabrication of Hydraulic Scissor Lift: February 2020Document10 pagesFabrication of Hydraulic Scissor Lift: February 2020atashi baran mohantyNo ratings yet

- Data Driven Fault DetectionDocument12 pagesData Driven Fault DetectionRita AppiahNo ratings yet

- SDL Trados Studio 2009 - Keyboard Shortcuts Editor MenuDocument2 pagesSDL Trados Studio 2009 - Keyboard Shortcuts Editor MenuEugenio Andres HolmesNo ratings yet

- Foreword: 'V' Family! You Are Now The Proud Owner of The New Bajaj V15 / V12Document40 pagesForeword: 'V' Family! You Are Now The Proud Owner of The New Bajaj V15 / V12Hussain MohtashamNo ratings yet

- 3d ICs Full Seminar Report 2Document31 pages3d ICs Full Seminar Report 2Shweta R Burli0% (1)

- Tugas Mike P5-3ADocument6 pagesTugas Mike P5-3Awinda dwi lestariNo ratings yet

- Helpless When She Smiles LyricsDocument2 pagesHelpless When She Smiles LyricsAleja NogueraNo ratings yet