Professional Documents

Culture Documents

Perpindahan Panas Pada Pengeringan Bawang

Uploaded by

Ignatius JeremyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perpindahan Panas Pada Pengeringan Bawang

Uploaded by

Ignatius JeremyCopyright:

Available Formats

Prosiding Seminar Nasional Teknik Kimia “Kejuangan” ISSN 1693-4393

Pengembangan Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia

Yogyakarta, 18 Maret 2015

Time Estimation of Onion Leaf Drying

Mohamad Djaeni and Nurul Asiah

Department of Chemical Engineering ; Faculty of Engineering; Diponegoro University

Jl Prof H. Soedharto, SH, Tembalang Semarang, Indonesia

Phone: +62247460058; Facs: +62247460055

e-mail: m.djaeni@undip.ac.id

Abstract

The main process of the onion post harvest treatment is drying proces. High moisture content of onion leaf

and outer layer of onion must be reduced up to moisture content 12% or below (wet basis). This level keeps

onion being still fresh. The conventional drying with direct sunlight still has been widely used because of

the cheap process. However, this technique needs too long drying time as well as climate dependency. This

research evaluated convective dryer for onion leaf drying. The mass transfer coefficient, and moisture

diffusivity was estimated to predict effective drying time. Results show that the drying time was shorter as

the temperature and air velocity increased. For example, at 60oC and air velocity 0.5 m.s-1, the drying time

was about 19 hours. The drying time can be can be 5 hours shorter at higher air velocity. In addition, with

increase of air velocity, the drying time can be also speeded up, significantly. Here, the air temperature

must be kept at maximally 60oC in order to avoid onion degradation. Therefore, the increase of air velocity

is a good option to shorten drying time and retain the quality.

Keywords: convective drying, diffusivity, moisture, quality, temperature

Introduction

Onion, Allium cepa L., is known as one of the most impor-tant crops in many countries due to its functions as

seasoning, food and for medical uses (Bonaccorsi et al., 2008). This special characteristic flavor (pung ency) or

aroma, bio-logical compounds and medical functions are caused by their high organo-sulphur compounds (Mazza

and LeMaguer, 1980; Corzo-Martínez et al., 2007). Onion production is the third highest in world vegetable produc-

tion with the annual production capacity 47 million tonnes (Kumar et al, 2006). Brebes as one of the region in

Central Java-Indonesia contribute about 170.000 tons. This activity involves around 30,000 ha lands and 100.000

farmers.

The main problems of onion stock is the post harvest treatment with drying process. Reducing water content to

the desired level by drying process is one way to extend the shelf life of food product. The drying process must be

designed with minimum substantial loss of flavor, taste, color and nutrients (Kumar dkk, 2006). Besides that, the

other challenge in the food drying is the process must be operated efficiently. Conventional dryer with sunlight is

really helpful in the aspect of simplicity and low energy cost. It has been used for long time in almost of all areas,

such as farming, fishery, forestry, and herbal medicine. However, the dryer was incovenience because of climate

dependency (Djaeni et al, 2013a). The conventional drying with direct sunlight depends on climate both the quality

and continuity. In the claudy or rainy day, the drying cannot be well performed. As a result, the outer of onion

layer has high moisture content. This can degrade the onion quality during storage as indicated in germination,

smelty, bine growth, and decaying. Meanwhile, the oven dryer with fossil fuel combustion still deals with high

energy consumption and onion quality degradation.

Regarding to this issue, the development of energy efficient dryer by exploring renewable energy such as

biomass becomes more and more important.The drying process requires about 70% of total energy in post harvest

treatment (Kudra, 2004; Djaeni et al, 2013a; Gilmour et al, 2004). In addition, most of industrial drying used the

fossil fuel as energy source that was still in-efficient for energy usage. Currently, the energy efficiency of dryer

ranged 30 – 60% which took 40 – 50% of total cost for the treatment. It means that the total energy introduced was

about 1.5 – 3.0 times from real load. On the other hand, the modern drying technology has been widely developed

with attractive result respecting to the product quality. However, the development of energy efficient dryer was

scare. The fossil fuel consumption has been big issue since the feedstock is limited. Hence, the exploration of new

renewable energy from biomass is attractive idea.

Recently, there have been more studies about the effect of drying parameters on moisture removal, expressed by

kinetic models. They have been reported for different varieties of onion (Krokida et al., 2003; Sarsavadia et al.,

Program Studi Teknik Kimia, FTI, UPN “Veteran” Yogyakarta B3 - 1

Prosiding Seminar Nasional Teknik Kimia “Kejuangan” ISSN 1693-4393

Pengembangan Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia

Yogyakarta, 18 Maret 2015

1999; Sawhney et al., 1999; Kiranoudis et al., 1996;

199 ; Yald ´yz and Ertek ´yn, 2001; Wang, 2002). However, there are ar

some drying variables have significant effect on the drying kinetic, such as temperature and drying air velocity. This

research evaluated convective dryer for onion drying after post-harvest

harvest process. The major was to dry the outer layer

and leaf of onion up to moisture content of 12

1 - 16%. The mass transfer coefficient,, and moisture diffusivity was

calculated to predict effective drying time.

Materials and Methods

Materials

The local variety of onion from Brebes having initial moisture content around 85–90%

85 was used for

experimentation.

Experimental Set-Up

The onion drying was conducted in tray dryer. The aim was to dry the outer layer and leaf of onion up to

moisture content of 15 - 20%. With dry outer

outer layer and leaf, the inside part of onion can be kept fresh before used.

Normally, the raw onion harvested from farm contained one third of leaf. Both parts contained 88 - 92% water.

After drying, the average of moisture was desired at 80 - 85%.

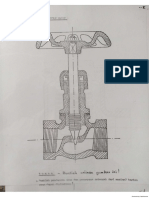

Here, the onion drying was completed by zeolite put in the side of tray (Fig. 1).). So, after removing water from

product, the wet air was directly dehumidified by zeolite. The air temperature and humidity were measured by

KW0600561, Krisbow®, Indonesia (noted as T-RH). RH). The air velocity was measured with an anemometer

KW0600562, Krisbow ®, Indonesia (Djaeni et al, 2013b).

Fig. 1.. Onion drying with zeolite (Note: TD-1:

TD Tray Dryer, AD-1: 1: Adsorber Box, ZE-1:

ZE zeolite, HE-1: Air

Heater, BL-1: Blower. The tray dryer dimension was 0.6 x 0.4 x 0.6 m)

The ambient air was heated up to 50oC by electric heater. The air passed the dryer to dry 2 kg of onion. The mass

of the sample was measured in every 1 h during drying process using a digital balance, measuring to an a accuracy of

0.001 g. The digital balance was kept very close to the drying unit and the weight measurement

measureme process took about

10 s time. Experiments were stopped when the moisture content of the material up to desired level. The moisture

content versus time was observed as input to find effective drying time. The effective drying time can be estimated

based on the previous research (Djaeni et al, 2013b). The process was repeated for different air temperature.

Estimating Drying Time

The first theory of mass transfer in thin layer drying was described by Lewis (1921) based on Newton’s law. The

theory expressed as follows:

M-Me

MR = = exp -kt (1)

M0 - Me

where: MR is the moisture ratio; M is the moisture content at time t and M0 and Me, the initial and equilibrium

moisture contents, respectively, on a dry basis; and k is mass transfer coefficient.

The value of k can be calculated by:

Program Studi Teknik Kimia, FTI, UPN “Veteran” Yogyakarta B3 - 2

Prosiding Seminar Nasional Teknik Kimia “Kejuangan” ISSN 1693-4393

Pengembangan Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia

Yogyakarta, 18 Maret 2015

ShD

k= (2)

L

The initial moisture content of the material was measured by drying in an oven at 105 oC for 24 h and expressed

as kg water/kg dry solids which varied around 9.00 kg water/kg dry solids (AOAC, 1990).

The Diffusivity equation was developed by Crank (1975) can be used for various regularly shaped bodies such as

rectangular, cylindrical and spherical products. For long drying period, this solution can be written in a logarithmic

form as follows (Sun et al., 2007; Tutuncu & Labuza, 1996 )

8 π2 Deff t

ln MR =ln - (3)

π2 4L0 2

where Deff is the effective diffusivity (m2.s-1); L0 is the half thickness of slab (m). The form of Eq. (3) can be

applicable for particles with slab geometry by assuming uniform initial moisture distribution. Diffusivities are

typically determined by plotting experimental drying data in terms of ln MR versus drying time t in Eq. (3), because

the plot demonstrates a straight line with the slope of ( π2 /Deff )/(4 L02).

The relation between diffusivity and the drying mass transfer coefficient can be presented based on sherwood

number (Sh) as follow:

Sh=2,0+0,55Re0,53 Sc1/3 (4)

Schmidt and Reynold number can be calculated by:

v

Sc= a (5)

D

(6)

Where va is drying air velocity (m.s-1), L is characteristic travelled length (m), µ is dynamic viscosity of air and ρ

is density of air. By applying these equations, the value of drying time can be estimated by Lewis equation

(Equation 1). (Nguyen, T.K., 2011; Takhar, P.S., 2011; Marinos-Kouris, D., and Maroulis, Z.B., 2006 ; Falabella,

M. C., Suarez, C. and Viollaz, P. E., 1991)

Result and Discussion

The effect of operational temperature

The response of moisture content reduction as a function of time was illustrated in drying curve Fig. 2. In this

experiment, the operational temperature of onion leaf was varied in the range of 40, 50, and 60oC. The result

showed that the higher temperature give higher drying rate. In general, the water removal was affected by air

temperature. Higher air temperature, higher water removal (Djaeni et al, 2013b). With higher temperature, the

relative humidity of air was lower. Furthermore, the sensible heat of air for evaporating water was higher. It can

enhance the driving force for mass transfer. Besides that, at higher temperature the drying process needed higher

energy power which followed by larger driving force for heat transfer (Methakhup et al, 2005).

10.0

moisture (gr moisture/gr dried material)

9.0

8.0

7.0

6.0

5.0 40 C

4.0

50 C

3.0

60 C

2.0

1.0

0.0

0 5 10 15 20

time (h)

Fig.2. The response of moisture content in onion leaf versus time at different operational temperature for air

velocity 0.5 m.s-1

The initial moisture content of onion was very high 9 (gr moisture/gr dried material) or 90% wet basis. At

initial, the drying rates were higher. It reduced gradually until the drying process completed. The high drying rate

Program Studi Teknik Kimia, FTI, UPN “Veteran” Yogyakarta B3 - 3

Prosiding Seminar Nasional Teknik Kimia “Kejuangan” ISSN 1693-4393

Pengembangan Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia

Yogyakarta, 18 Maret 2015

was caused by the higher moisture diffusion in the falling rate period. The decrease of drying rate was due to the

more energy absorbed by the water at the product surface.

The water diffusivity, mass transfer coefficient and drying time were predicted using equation 1- 6. Firstly, the

moisture diffusivity in onion leaf was estimated using Equation 3. After that, the constant of drying rate is calculated

with Equation 2. The value of mass transfer coefficient used to estimate the drying time. The results were depicted

in Table 1.

Regarding to the Table 1, at higher temperature, the diffusivity of moisture in onion leaf was higher. In general

the values of Deff for food materials dried using the conventional and solar drying methods in the range of 10-11- 10-9

m2.s-1 for food materials dried using (Madamba, Driscoll, & Buckle, 1996). In this study, the moisture diffusivity

was obtained in the range of 10-10 - 10-9 m2.s-1. The results show that the drying time was shorter as the higher

temperature. At drying air temperature 40 oC the drying time was very low. It needed more than 80 h to remove the

moisture content from 90% to 16 % wet basis. When the drying temperature increased to 60 oC, the drying time that

needed to decrease water content until 12% wet basis can be speeded up to be 19 h.

Table 1. The value of water diffusivity, mass transfer coefficient and drying time in various operational air

temperature for air velocity 0.5 m.s-1

Temperature Diffusifity k Drying time Moisture reduction

(OC) (m2.s -1) (s-1) (h) (%wet basis)

40 5.274 x10-10 1.7534 x10-5 86 90-16

-9 -5

50 2.434 x10 8.0925 x10 23 90-13

60 2.596 x10-9 8.3050 x10-5 19 90-12

The effect of operational air velocity

Plots of moisture reduction with drying time at various operational air velocities were illustrated in Fig. 3. From the

curve we can see that with increase of air velocity, the drying time can be also speeded up.

10

moisture dry (gr water/gr dried material)

9

8

7

6

5 air velocity 0.5 m/s

4 air velocity 1 m/s

3 air velocity 1.5 m/s

2

1

0

0 5 10 15 20

time (h)

Fig.3. The response of moisture content in onion leaf versus time at different operational air velocity for air

temperature 60oC

The drying time at various air velocities were also estimated using equation above. The results were depicted in

Table 2. The increase of air velocity enhanced the Sherwood number in which caused the constant of drying rate

being higher. For example, the drying time can be accelerated 5 hours by increasing 2 fold operational drying air

velocities to remove 78% water content. Hence, it can be noted that for heat sensitive products such as paddy, the

increase of air velocity can be a potential option to speed up drying time instead of increasing operational

temperature. This notification can also accommodate the previous recommendation pointed by Djaeni et al (2009).

Program Studi Teknik Kimia, FTI, UPN “Veteran” Yogyakarta B3 - 4

Prosiding Seminar Nasional Teknik Kimia “Kejuangan” ISSN 1693-4393

Pengembangan Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia

Yogyakarta, 18 Maret 2015

Table 2. The value of mass transfer coefficient and drying time in various operational air velocities for air

tempeature 60 0C

Operational air velocities k Drying time Moisture reduction

(m.s -1) (s-1) (hours) (%wet basis)

0.5 8.3050 x10-5 19 90-12

-4

1 1.1377 x10 14 90-12

1.5 1.4258 x10-4 11 90-12

Conclusion

The experiment was evaluated convective dryer for onion leaf drying at various drying air temperatures and air

velocities. The results showed that parameter gave the positive effect on drying rate and drying time. The mass

transfer coefficient, and moisture diffusivity was calculated to predict effective drying time. The works confirmed

that the drying time was shorter as the temperature and air velocity increased. For example, at 60oC and air velocity

0.5 m.s-1, the drying time was about 19 h. Furthermore, the drying time can be accelerated 5 h by increasing 2 fold

operational drying air velocities to remove 78% water. In addition, with increase of air velocity, the drying time can

be also speeded up, significantly. Here, the air temperature must be kept at maximally 60oC in order to avoid onion

degradation. Therefore, the increase of air velocity is a good option to shorten drying time and retain the quality.

The results can be a potential option for energy efficient dryer development.

Acknowledgments

This research was funded by Ministry of Research and Higher Education, Indonesia. The research has been

conducted at Laboratory of Process Engineering, Department of Chemical Engineering, Faculty of Engineering,

Diponegoro University.

References

Association of Offi cial Analytical Chemists (AOAC). (1990). Of ficial methods of analysis (15th ed.). Washington,

DC.

Bonaccorsi, P., Caristi, C., Garg iulli, C. and Leuzzi, U., 2008, Flavonol glucosides in Allium species: A

comparative study by means of HPLC–DAD–ESI-MS–MS. Food Chemistry, 107: 1668–1673.

Boudhrioua, N.; Bonazzi,C.; Daudin, J.D (2003). Estimation of moisture diffusivity in gelatin–starch gels using

time-dependent concentration–distance curves at constant temperature. Food Chemistry 82 (1), 139-149.

Corzo-Martínez, M., Corzo, N. and Villamiel, M., 2007, Biolog ical properties of onions and g arlic. Trends in Food

Science & Technology, 18: 609–625.

Crank, J. (1975). The mathematics of dif fusion. Oxford, England: Clarendon Press.

Djaeni, M.; Ayuningtyas, D.; Asiah, N.; Hargono, H. Ratnawati, R.; Jumali, J.; Wiratno, W. (2013b). Paddy drying

in mixed adsorption dryer with zeolite: Drying rate and time estimation. Reaktor 14(3): 173 – 178.

Djaeni, M.; Bartels P.V.; van Asselt, C.J.; Sanders J.P.M.; van Straten, G.; van Boxtel, A.J.B. (2009). Assessment of

a Two-Stage Zeolite Dryer for Energy Efficient Drying. Journal of Drying Technology 27(10): 1205 – 1216.

Djaeni, M.; Sasongko, S.B.; Prasetyaningrum, A.; Jin, X.; and van Boxtel, AJB. (2012). Carrageenan drying with

dehumidified air: drying characteristics and product quality. International Journal of Food Engineering

8(3);Article 32. DOI: 10.1515/1556-3758.2682

Djaeni, M.; Sasongko, S.B.; van Boxtel, A.J.B. (2013a). Enhancement of energy efficiency and food product quality

using adsoprtion dryer with zeolite. Int. Journal of Renewable Energy Development 2(2): 81 – 86.

Falabella, M. C., Suarez, C. and Viollaz, P. E. (1991). Drying Kinetics of Corn in Contact with a Solid Adsorbent.

Journal of Food Engineering. 13: 273-283.

Gilmour, J.E.; Oliver, T.N.; Jay, S .(2004). Energy use for drying process: The potential benefits of airless drying.

In: Energy aspects in drying; Kudra T. Drying Technology 22(5): 917 – 932.

Jangam, S.V. and Mujumdar, A.S. (2010). Basic Concepts and Definitions. Drying of Foods, Vegetables and Fruits.

Ed. Jangam, S.V., Law, C.L. and Mujumdar, A.S. ISBN - 978-981-08-6759-1. Singapore. 1: 1-30.

Krokida, M.K., Karathanos, V.T. and Maroulis, Z.B., 2003, Drying kinetics of some veg etables. Journal of Food

Eng ineering, 59 (4): 391–403.

Kiranoudis C.T.; Maroulis Z.B.; Marinos-Kouris D. (1996). Drying of solids: Selection of some continuous

operation dryer types. Computer & Chem. Eng.; Vol. 20, Supplement 1, S177-182.

Program Studi Teknik Kimia, FTI, UPN “Veteran” Yogyakarta B3 - 5

Prosiding Seminar Nasional Teknik Kimia “Kejuangan” ISSN 1693-4393

Pengembangan Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia

Yogyakarta, 18 Maret 2015

Kudra T. (2004). Energy aspects in drying. Drying Technology 22(5): 917 – 932.

Kumar, D.G.P., Hebbar, H.U., Ramesh, M.N. (2006). Suitability of thin layer models for infrared-hot air-drying of

onion slices. Swiss Society of Food Science and Technology.

Lewis W K (1921). The rate of drying of solid materials. Journal of Industrial Engineering Chemistry, 13(5), 427–

432.

Madamba, P. S., Driscoll, R. H., & Buckle, K. A . (1996). Thin-layer drying character-istics of garlic slices. Journal

of Food Engineering, 29,75 e97.

Marinos-Kouris, D., and Maroulis, Z.B. (2006). Transport Properties in The Drying of Solids. Handbook of

Industrial Drying. Taylor & Francis Group, LLC.

Mazza, G. and LeMaguer, M., 1980, Flavour retention during dehydration of onion (Allium cepa L.), In Linko, P.,

Malkki, Y., Olkku, J., & Larinkari, J. (Eds.), Food Process Engineering. (Academic Press, London).

Methakhup, S., Chiewchan, N., & Devahastin, S. (2005). Effects of drying methods and conditions on drying

kinetics and quality of Indian gooseberry flake. Lebensmittel Wissenschaft und Technologie, 38,579 e 587.

Nguyen, T.K. (2011). Convective Mass Transfer. Mass Transfer. California State Polytechnic University, Pomona.

USA.

Revilla, G.O.; Velázquez, T.G.; Cortés, S.L.; Cárdenas, S.A. (2006). Immersion drying of wheat using Al-PILC,

zeolite, clay, and sand as particulate media. Drying Technology, vol. 24, issue 8, 1033-1038.

Sarsavadia, P.N., Sawhney, R.L., Pang avhane, D.R. and Singh, S.P.,1999, Drying behaviour of brined onion slices.

Journal of Food Eng ineering, 40(3): 219–226.

Sawhney, R.I., Sarsavadia, P.N., Pang avhane, D.R. and Singh, S.P.,1999, Determination of drying constants and

their dependence on drying air parameters for thin layer onion drying. Drying Technology, 17(1–2): 299–315.

Sun, J., Hu, X., Zhao, G., Wu, J., Wang, Z., Chen, F., et al. (2007). Characteristics of thin-layer infrared drying of

apple pomace with and without hot air pre-drying. Food Science and Technology International, 13 (2), 91 e97.

Takhar, P.S. (2011). Hybrid mixture theory based moisture transport and stress development in corn kernels during

drying: Coupled fluid transport and stress equations. Journal of Food Engineering. 105 : 663-670.

Tutuncu, M. A ., & Labuza, T. P. (1996). Effect of geometry on the effective moisture transfer diffusion coef fi

cient. Journal of Food Engineering, 30, 433e 447.

Wang, J., 2002, A single-layer model for far-infrared radiation drying of onion slices. Drying Technology, 20(10):

1941–1953.

Yald ´yz, O. and Ertek ´yn, C., 2001, Thin layer solar drying of some veg etables. Drying Technology, 19(3–4):

583–597.

Program Studi Teknik Kimia, FTI, UPN “Veteran” Yogyakarta B3 - 6

Prosiding Seminar Nasional Teknik Kimia “Kejuangan” ISSN 1693-4393

Pengembangan Teknologi Kimia untuk Pengolahan Sumber Daya Alam Indonesia

Yogyakarta, 18 Maret 2015

Lembar Tanya Jawab

Moderator : Jarot Raharjo (Pusat Teknologi Material, BPPT)

Notulen : Adi Ilcham (UPN “Veteran” Yogyakarta)

1. Penanya : Nur Hidayati (Universitas Muhammadiyah Surakarta)

Pertanyaan : Selain prediksi waktu, apakah nutrisi juga diuji?

Jawaban : Setelah dikeringkan, dilakukan pengujian terhadap nutrisi bawang.

2. Penanya : Sri Suhenry (UPN “Veteran” Yogyakarta)

Pertanyaan : • Berapa kadar air minimum untuk bawang setelah dikeringkan?

• Bagaimana kesimpulan proses dari penelitian ini?

Jawaban : • Kadar air kurang dari 12%. Dengan kadar air tersebut mikroba tidak bisa tumbuh

dan self life dapat diperpanjang.

• Kesimpulan yang didapat adalah untuk suhu pengeringan 60oC dan laju alir udara

0,5 m/det, waktu pengeringan dari kadar air 90% menjadi 12% diperlukan waktu 19

jam.

Program Studi Teknik Kimia, FTI, UPN “Veteran” Yogyakarta B3 - 7

You might also like

- 2021 Heterocycles Midterm ExamDocument24 pages2021 Heterocycles Midterm ExamNgô Tuấn KiệtNo ratings yet

- Innovative Energy Conversion from Biomass WasteFrom EverandInnovative Energy Conversion from Biomass WasteArif DarmawanNo ratings yet

- EWAD-TZ D-EIMAC00904-14 IOM Installation Manuals EnglishDocument229 pagesEWAD-TZ D-EIMAC00904-14 IOM Installation Manuals EnglishAmir ShamshiriNo ratings yet

- Drying of EggplantDocument12 pagesDrying of EggplantsubhashNo ratings yet

- Drying ChilliesDocument9 pagesDrying ChilliesRiris M SimatupangNo ratings yet

- Pradana 2019 IOP Conf. Ser. Earth Environ. Sci. 292 012070 PDFDocument8 pagesPradana 2019 IOP Conf. Ser. Earth Environ. Sci. 292 012070 PDFBrian BuenoNo ratings yet

- Design and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalDocument4 pagesDesign and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalBahynorerama DpNo ratings yet

- Case Studies in Thermal Engineering: Engkos Achmad Kosasih, Ahmad Zikri, Muhammad Irfan DzakyDocument9 pagesCase Studies in Thermal Engineering: Engkos Achmad Kosasih, Ahmad Zikri, Muhammad Irfan DzakyrizzaNo ratings yet

- Maisaroh 2022 IOP Conf. Ser. Earth Environ. Sci. 1116 012065Document15 pagesMaisaroh 2022 IOP Conf. Ser. Earth Environ. Sci. 1116 012065lp manaluNo ratings yet

- Author's Accepted ManuscriptDocument11 pagesAuthor's Accepted Manuscriptchaima rekikNo ratings yet

- 7 12v2i3 7Document6 pages7 12v2i3 7getsweetNo ratings yet

- Hany Et AlDocument13 pagesHany Et AlprevrtljivacNo ratings yet

- Theoretical and Experimental Analysis of Drying Various Geometrical Forms of Red PepperDocument5 pagesTheoretical and Experimental Analysis of Drying Various Geometrical Forms of Red PepperAnonymous 4SIk3AdnNo ratings yet

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Document7 pagesDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupNo ratings yet

- Banana PDFDocument9 pagesBanana PDFhoaNo ratings yet

- Microwave/air and Microwave ®nish Drying of Banana: Medeni MaskanDocument8 pagesMicrowave/air and Microwave ®nish Drying of Banana: Medeni MaskanSỹ TrươngNo ratings yet

- Corn Drying With Zeolite in The Fluidized Bed Dryer Under Medium TemperatureDocument6 pagesCorn Drying With Zeolite in The Fluidized Bed Dryer Under Medium TemperatureRamón CorreaNo ratings yet

- Modeling of Drying Process and Energy Consumption of Onion (Ex-gidankwanoSpp.) Slices in A Hybrid Crop DryerDocument12 pagesModeling of Drying Process and Energy Consumption of Onion (Ex-gidankwanoSpp.) Slices in A Hybrid Crop DryerAJER JOURNALNo ratings yet

- Effect of Temperature and Air Velocity on Drying Rate and Constant of Cocoa BeansDocument7 pagesEffect of Temperature and Air Velocity on Drying Rate and Constant of Cocoa BeansLaura NogueraNo ratings yet

- Drying kinetics of Üryani plum in a convective hot-air dryerDocument7 pagesDrying kinetics of Üryani plum in a convective hot-air dryerJanela FloresNo ratings yet

- Effect of Microwave On Fluidized Bed Drying of Beetroot (BetaDocument7 pagesEffect of Microwave On Fluidized Bed Drying of Beetroot (BetaAJER JOURNALNo ratings yet

- Drying Characteristics and Quality Evaluation of Kiwi Slices Under Hot Air Natural Convective Drying MethodDocument9 pagesDrying Characteristics and Quality Evaluation of Kiwi Slices Under Hot Air Natural Convective Drying MethodNovanto GuruhNo ratings yet

- Hierbabuena CaracterísticasDocument13 pagesHierbabuena CaracterísticasArley Salazar HincapieNo ratings yet

- Agriengineering 02 00027Document15 pagesAgriengineering 02 00027Martha AlbaNo ratings yet

- Energy and Quality Aspects For Fixed Deep Bed Drying of PaddyDocument10 pagesEnergy and Quality Aspects For Fixed Deep Bed Drying of PaddyPhuwanai PalakachenNo ratings yet

- Convective and Microwave Drying Characteristics of Sorbus Fruits Sorbus Domestica L 2015 Procedia Social and Behavioral SciencesDocument10 pagesConvective and Microwave Drying Characteristics of Sorbus Fruits Sorbus Domestica L 2015 Procedia Social and Behavioral SciencesMildred CullenNo ratings yet

- JFAV 08-012 - PERASIRIYAN - OPTIMIZATION - DRYER-with-cover-page-v2Document8 pagesJFAV 08-012 - PERASIRIYAN - OPTIMIZATION - DRYER-with-cover-page-v2Super MoelasisNo ratings yet

- Analysis of Some Physical Properties 0f Dried Fish To Determine The Parameters of A Multi Season Solar DryerDocument6 pagesAnalysis of Some Physical Properties 0f Dried Fish To Determine The Parameters of A Multi Season Solar DryerCarl John MantacNo ratings yet

- Drying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateDocument6 pagesDrying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateAJER JOURNALNo ratings yet

- Single-Layer Drying Characteristics and COLOUR Kinetics of RED CHILLIDocument10 pagesSingle-Layer Drying Characteristics and COLOUR Kinetics of RED CHILLIaivangtrNo ratings yet

- Drying Characteristics of Mango Slices Using The Refractance Window™ Technique PDFDocument7 pagesDrying Characteristics of Mango Slices Using The Refractance Window™ Technique PDFcedu126No ratings yet

- 2nd Meet DryingDocument113 pages2nd Meet DryingKenesei György100% (1)

- Onion drying using desiccantsDocument8 pagesOnion drying using desiccantsDandy eight8No ratings yet

- Eltawil 2017Document27 pagesEltawil 2017Thanh Đình Lộc LêNo ratings yet

- Drying Characte 5 Risticof Anchovydrying David PublishingDocument8 pagesDrying Characte 5 Risticof Anchovydrying David PublishingVILLAINZ83No ratings yet

- Drying Technology As An Application in Post-Harvest ProcessingDocument6 pagesDrying Technology As An Application in Post-Harvest Processinganwar hussainNo ratings yet

- Pengaruh Pengeringan Konvensional Terhadap Karakteristik Fisik Indigo BubukDocument7 pagesPengaruh Pengeringan Konvensional Terhadap Karakteristik Fisik Indigo BubukRyan ProxyNo ratings yet

- Case Studies in Thermal Engineering: SciencedirectDocument8 pagesCase Studies in Thermal Engineering: SciencedirectTU NGO THIENNo ratings yet

- Analisis Las Transferencias de Calor y Masa Durante El Secado de Alimentos Por MicroondasDocument11 pagesAnalisis Las Transferencias de Calor y Masa Durante El Secado de Alimentos Por MicroondasAngeliika AviilaNo ratings yet

- Experimental Characterization and Modeling of Thin-Layer Drying of Mango SlicesDocument7 pagesExperimental Characterization and Modeling of Thin-Layer Drying of Mango SliceswilsonNo ratings yet

- Improved Procedure for Natural Convection Garlic DryingDocument7 pagesImproved Procedure for Natural Convection Garlic DryingHakim SemaiNo ratings yet

- 13 Ijasrdec201813Document6 pages13 Ijasrdec201813TJPRC PublicationsNo ratings yet

- Case Studies in Thermal Engineering: S. Nabnean, P. NimnuanDocument11 pagesCase Studies in Thermal Engineering: S. Nabnean, P. NimnuanCarlos BispoNo ratings yet

- Yogendrasasidhar 2018Document54 pagesYogendrasasidhar 2018zhor El hallaouiNo ratings yet

- Review On The Design of A Tray Dryer System For Agricultural ProductsDocument10 pagesReview On The Design of A Tray Dryer System For Agricultural ProductsDwinaRahmayaniNo ratings yet

- Simulation Model To Predict Drying in The Automated Grain DryerDocument7 pagesSimulation Model To Predict Drying in The Automated Grain DryerhawxflyNo ratings yet

- Performance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitDocument7 pagesPerformance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitVishvesh T SNo ratings yet

- Biodrying As A Biological Process To Diminish Moisture in Gardening and Harvest WastesDocument13 pagesBiodrying As A Biological Process To Diminish Moisture in Gardening and Harvest WastesHAMZA ZAKINo ratings yet

- Design of Tray Dryer Hybrid System (Solar-Heater) For Drying Salted FishDocument9 pagesDesign of Tray Dryer Hybrid System (Solar-Heater) For Drying Salted FishIsti MaulidyaNo ratings yet

- Evaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementDocument7 pagesEvaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementMildred CullenNo ratings yet

- Design and Evaluation of Combined Solar and Biomass Dryer For Small and Medium Enterprises For Developing CountriesDocument9 pagesDesign and Evaluation of Combined Solar and Biomass Dryer For Small and Medium Enterprises For Developing Countries11751175No ratings yet

- 001 - Performance Analysis of Solar Drying System For Red Chili PDFDocument8 pages001 - Performance Analysis of Solar Drying System For Red Chili PDFAlex Samuel SilvaNo ratings yet

- Experimental and Numerical Investigation of Heat and Mass Transfer During Drying of Hayward Kiwi FruitsDocument8 pagesExperimental and Numerical Investigation of Heat and Mass Transfer During Drying of Hayward Kiwi Fruitsbourock26No ratings yet

- Role of Various Nano-Particles in Prevention of Fungal Decay MoldDocument8 pagesRole of Various Nano-Particles in Prevention of Fungal Decay MoldChandan Kumar RayNo ratings yet

- Renewable Energy: Fevzi Gulcimen, Hakan Karakaya, Ayd In DurmusDocument10 pagesRenewable Energy: Fevzi Gulcimen, Hakan Karakaya, Ayd In DurmusMajid KhanNo ratings yet

- 1522 2037 1 PBDocument13 pages1522 2037 1 PBabetieNo ratings yet

- Drying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerDocument5 pagesDrying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerMuhammad Maulana SidikNo ratings yet

- Effect of Time and Temperature On Moisture Content, Shrinkage, and Rehydration of Dried OnionDocument14 pagesEffect of Time and Temperature On Moisture Content, Shrinkage, and Rehydration of Dried OnionFranz MarasiganNo ratings yet

- 3different Varieties of Tomato 2018Document10 pages3different Varieties of Tomato 2018kamalNo ratings yet

- Consruction of A Direct Solar Dryer For Perishable Farm ProductsDocument9 pagesConsruction of A Direct Solar Dryer For Perishable Farm ProductsijsretNo ratings yet

- A Study of Efficient Drying Parameters For Bed Dryers: Christopher Tremblay, Dongmei ZhouDocument8 pagesA Study of Efficient Drying Parameters For Bed Dryers: Christopher Tremblay, Dongmei ZhouavgpaulNo ratings yet

- Journal of Food Engineering: Adisak Nathakaranakule, Petcharat Jaiboon, Somchart SoponronnaritDocument7 pagesJournal of Food Engineering: Adisak Nathakaranakule, Petcharat Jaiboon, Somchart SoponronnaritEsma EserNo ratings yet

- 10 PDFDocument7 pages10 PDFHARSHITNo ratings yet

- Ghanta Ku 0099D 12191 DATA 1Document259 pagesGhanta Ku 0099D 12191 DATA 1nicoNo ratings yet

- Coppra - Specification: Kenya StandardDocument13 pagesCoppra - Specification: Kenya StandardIgnatius JeremyNo ratings yet

- DuplikatDocument241 pagesDuplikatIgnatius JeremyNo ratings yet

- Effect of Hot Air Velocity On Drying Kinetics Undergoing STR Drying of PaddyDocument9 pagesEffect of Hot Air Velocity On Drying Kinetics Undergoing STR Drying of PaddyIgnatius JeremyNo ratings yet

- Forsthoffer's Rotating Equipment Handbooks Vol 3 CompressorsDocument411 pagesForsthoffer's Rotating Equipment Handbooks Vol 3 CompressorskarthickmectrNo ratings yet

- Basic Humidification InformationDocument21 pagesBasic Humidification InformationtalhawasimNo ratings yet

- Needle ValveDocument1 pageNeedle ValveIgnatius JeremyNo ratings yet

- Food drying technology and effect on propertiesDocument8 pagesFood drying technology and effect on propertiesIgnatius JeremyNo ratings yet

- Adsorption Kinetic Models: Physical Meanings, Applications, and Solving MethodsDocument18 pagesAdsorption Kinetic Models: Physical Meanings, Applications, and Solving MethodsNórida Pájaro GómezNo ratings yet

- Distillation Operations: Methods, Operational and Design IssuesDocument10 pagesDistillation Operations: Methods, Operational and Design IssuesIgnatius JeremyNo ratings yet

- Performance Evaluation of Greenhouse Dryer With Opaque North WallDocument11 pagesPerformance Evaluation of Greenhouse Dryer With Opaque North WallIgnatius JeremyNo ratings yet

- Mass and Heat Transfer During Two-Phase Flow in Porous Media - Theory and ModelingDocument23 pagesMass and Heat Transfer During Two-Phase Flow in Porous Media - Theory and ModelingIgnatius JeremyNo ratings yet

- AQA Chemistry A-Level Sample-Chapter Book-1Document34 pagesAQA Chemistry A-Level Sample-Chapter Book-1davin gunawanNo ratings yet

- Measurement Chemical Potential BA Net AlDocument23 pagesMeasurement Chemical Potential BA Net AlIgnatius JeremyNo ratings yet

- PH: Principles and Measurement: December 2016Document8 pagesPH: Principles and Measurement: December 2016Peace OliverNo ratings yet

- Lampiran A Data Fisik: Chemical Engineering Thermodynamics Edisi 8, Mcgraw-Hill Education, New York, PPDocument2 pagesLampiran A Data Fisik: Chemical Engineering Thermodynamics Edisi 8, Mcgraw-Hill Education, New York, PPIgnatius JeremyNo ratings yet

- Minutesof 51 ST PACDocument27 pagesMinutesof 51 ST PACIgnatius JeremyNo ratings yet

- Use Chemical Potential Anoua AlDocument16 pagesUse Chemical Potential Anoua AlIgnatius JeremyNo ratings yet

- Temperature: Oral, Rectal, and Axillary: Using A Glass ThermometerDocument2 pagesTemperature: Oral, Rectal, and Axillary: Using A Glass ThermometerIgnatius JeremyNo ratings yet

- Double Indicator TheoryDocument3 pagesDouble Indicator TheoryIrfan NunkooNo ratings yet

- Lampiran F (Literatur)Document12 pagesLampiran F (Literatur)Ignatius JeremyNo ratings yet

- Performance Evaluation of Greenhouse Dryer With Opaque North WallDocument11 pagesPerformance Evaluation of Greenhouse Dryer With Opaque North WallIgnatius JeremyNo ratings yet

- Lampiran F Literatur DistilasiDocument15 pagesLampiran F Literatur DistilasiIgnatius JeremyNo ratings yet

- Safety Data Sheet for Activated CharcoalDocument7 pagesSafety Data Sheet for Activated CharcoalEliya Maya SistaNo ratings yet

- ASI Grain Drying SourcebookDocument56 pagesASI Grain Drying SourcebookSaidAnwarNo ratings yet

- LAMPIRAN E GRAFIK CONTROL STATIONDocument29 pagesLAMPIRAN E GRAFIK CONTROL STATIONIgnatius JeremyNo ratings yet

- Buku Kalibrasi Termometer PDFDocument100 pagesBuku Kalibrasi Termometer PDFanthony tiensunNo ratings yet

- DuPont La PorteDocument161 pagesDuPont La PorteIgnatius JeremyNo ratings yet

- Title: Relationship Between PH and Chemiluminescence of Luminol Author: Rolando Efraín Hernández RamírezDocument2 pagesTitle: Relationship Between PH and Chemiluminescence of Luminol Author: Rolando Efraín Hernández RamírezEfraínNo ratings yet

- Baulkham Hills 2020 Chemistry Trials & SolutionsDocument35 pagesBaulkham Hills 2020 Chemistry Trials & SolutionsNhân Lê Nguyễn ThiệnNo ratings yet

- Mastertop 295 floor re-surfacingDocument3 pagesMastertop 295 floor re-surfacingFrancois-No ratings yet

- CSO201A 12012023 (Lecture From 50123 To 120123)Document38 pagesCSO201A 12012023 (Lecture From 50123 To 120123)Abhishek ChaudharyNo ratings yet

- Periodic Table of ElementsDocument4 pagesPeriodic Table of ElementsAbidan Patrick (COOL DUDE PRO)No ratings yet

- OsmosisDocument11 pagesOsmosisalive computerNo ratings yet

- Assignment PhyChemDocument4 pagesAssignment PhyChemimPERFECTme09No ratings yet

- Partial Horizontal Tank Volumes CalculatorDocument1 pagePartial Horizontal Tank Volumes CalculatorNasrul AdliNo ratings yet

- Chemistry Questions Paper (Clear Version)Document6 pagesChemistry Questions Paper (Clear Version)Aditi ThakurNo ratings yet

- Melissa EnglishDocument10 pagesMelissa Englishmarwa kaddourNo ratings yet

- Material Specifications Forged Products Manufactured With The Forging Rev.04Document13 pagesMaterial Specifications Forged Products Manufactured With The Forging Rev.04Emre TekinNo ratings yet

- How cell size affects diffusionDocument5 pagesHow cell size affects diffusionAlgrin Acosta0% (1)

- Experiment 2Document10 pagesExperiment 2gokturktlgNo ratings yet

- HCWM Training Module 15 Non Incineration Treatment and Disposal SpanishDocument64 pagesHCWM Training Module 15 Non Incineration Treatment and Disposal SpanishJose DiazNo ratings yet

- CFD-Coal Combustion simulaiton-EDMDocument16 pagesCFD-Coal Combustion simulaiton-EDMwawang13198No ratings yet

- Representing Enthalpy Changes OtherDocument4 pagesRepresenting Enthalpy Changes OtherJennifer LohNo ratings yet

- Adobe Scan 10-Jan-2023Document6 pagesAdobe Scan 10-Jan-2023Bhumisht JatiNo ratings yet

- Biosprint 96 Dna Handbook: Sample & Assay TechnologiesDocument56 pagesBiosprint 96 Dna Handbook: Sample & Assay TechnologiesEvandro VettorazziNo ratings yet

- Luxury DIY Sulfate Shampoo - Recipe BookDocument11 pagesLuxury DIY Sulfate Shampoo - Recipe Bookralucaxjs100% (1)

- STPM-Matter-Gas-Kinetic-Theory-Mass-SpectrometryDocument8 pagesSTPM-Matter-Gas-Kinetic-Theory-Mass-SpectrometryPang Wei Na100% (3)

- Unsaturated Polyester Resins PDFDocument48 pagesUnsaturated Polyester Resins PDFsriatul2006No ratings yet

- QP Spec For Pre-Commissioning and New Commissioning of New Pipelines (QP-SPC-L-012-R1)Document29 pagesQP Spec For Pre-Commissioning and New Commissioning of New Pipelines (QP-SPC-L-012-R1)RajeshwariNo ratings yet

- Stabilization of Pavement Subgrade Soils Containing Rich Chloride SaltsDocument13 pagesStabilization of Pavement Subgrade Soils Containing Rich Chloride Saltskamrul_07No ratings yet

- Indian Standard: Methods of Test For Aggregates For ConcreteDocument19 pagesIndian Standard: Methods of Test For Aggregates For ConcreteAnuradhaPatraNo ratings yet

- Periodic Classification of Elements PDFDocument8 pagesPeriodic Classification of Elements PDFanjupal80% (5)

- Acids, Bases & Salts: IndicatorsDocument7 pagesAcids, Bases & Salts: IndicatorsView TubeNo ratings yet

- Wa0007Document13 pagesWa0007Amogh R.GowdaNo ratings yet

- Biochemistry-5th-Edition Compress RemovePdfPagesDocument59 pagesBiochemistry-5th-Edition Compress RemovePdfPagesWaseem AlnaasNo ratings yet