0% found this document useful (0 votes)

677 views14 pagesCNC Programming and Simulation Guide

The document discusses various topics related to computer numerical control (CNC) including:

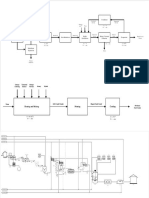

1. CNC involves replacing conventional controllers with a small computer to perform basic NC functions via stored programs.

2. Direct numerical control (DNC) uses a larger computer to control multiple machine tools in real time through direct connection.

3. Adaptive control (AC) machining measures process variables like cutting force and temperature and adjusts feed/speed to compensate for changes.

Uploaded by

suswagatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

677 views14 pagesCNC Programming and Simulation Guide

The document discusses various topics related to computer numerical control (CNC) including:

1. CNC involves replacing conventional controllers with a small computer to perform basic NC functions via stored programs.

2. Direct numerical control (DNC) uses a larger computer to control multiple machine tools in real time through direct connection.

3. Adaptive control (AC) machining measures process variables like cutting force and temperature and adjusts feed/speed to compensate for changes.

Uploaded by

suswagatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd