Professional Documents

Culture Documents

F316L Austenitic Stainless Steel: Related Specifications

Uploaded by

RAVIKIRAN BARDEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F316L Austenitic Stainless Steel: Related Specifications

Uploaded by

RAVIKIRAN BARDECopyright:

Available Formats

Beeley Wood Works

Beeley Wood Lane

Sheffield S6 1ND

United Kingdom

T: +44 (0)114 231 2271

F: +44 (0)114 232 4983

E: info@abbeyfp.co.uk

F316L Austenitic Stainless Steel

Related Specifications

ASTM A182 F316L

ASTM A276 316L

UNS S31600

W.Nr. 1.4404

BS EN 10088-3 1.4404

F316L is an Austenitic Cr-Ni stainless steel. It is a low carbon derivative of F316

The Material is always supplied in the Solution Annealed condition.

F316L, like its higher carbon relative is now typically used in many industries including Food processing, Brewing,

Marine, Automotive, Aerospace, Mining, Medical, Oil and Gas, especially for weldments where its immunity to carbide

precipitation assures optimum corrosion resistance.

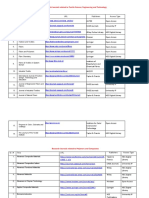

Typical Chemical composition

Carbon 0.03% Max

Silicon 1.00% Max

Manganese 2.00% Max

Phosphorous 0.045

Sulphur 0.030

Chromium 16.0 - 18.0

Nickel 10.0 - 14.0

Molybdenum 2.00-3.00

Mechanical Property Requirements – Solution Annealed condition

Yield Tensile Strength Elongation Hardness

205 Mpa Min 515 Mpa Min 30% Min 215 HB Max

Forging

This alloy can be readily forged at temperatures 1000 – 1200Deg.C

Hot working below 927Deg.C should be avoided.

The low carbon content of these alloys ensures no heavy scale but excessive soak times should still be avoided to

avoid enlarged grain size, suggest 15minutes per inch (25mm) of maximum ruling section

Heat Treatment

This alloy is not hardenable by heat treatment and is therefore supplied in the Annealed condition.

Anneal 1040Deg.C minimum, ensuring that sufficient time is allowed for the centre to achieve furnace temperature

and hold for a time commensurate with the ruling section, followed by rapid cooling in Water.

Machining

F316L is readily machinable in the annealed condition by milling, drilling, turning, etc as required.

Cutting edges should be kept sharp and cuts should be kept light but deep enough to avoid work hardening.

Coolants and lubricants should be used in large quantity.

Corrosion Resistance

F316L has excellent corrosion resistance when exposed to a range of corrosive environments. It is usually regarded

as Marine grade stainless, however it is not resistant to warm sea water. Warm Chloride environments can cause pit-

ting and crevice corrosion. F316L will also suffer from stress corrosion cracking above 60Deg.C

Registered in England and Wales. Company Registration No: 1644542

Oxidation Resistance

This alloy has good resistance to oxidation in intermittent service upto 870Deg.C and in continuous service upto

925Deg.C. Whilst continuous use between 425 – 860Deg.C is not recommended for F316 if corrosion resistance in

water is required this lower carbon variant, F316L, is recommended due to its resistance to carbide precipitation.

When high strength at temperatures above 500Deg.C is required, grade F316H is recommended.

Welding

Austenitic stainless steels are generally considered to be weldable by the common fusion and resistance techniques

but special consideration is required to avoid hot cracking of the weld metal. F316L was developed from standard

F316 to be more amenable to welding and the lower carbon content increases the immunity to grain boundary car-

bide precipitation, making it suited to use in heavy gauge (>6mm) welded components.

Registered in England and Wales. Company Registration No: 1644542

You might also like

- Hastelloy C276 / Alloy C276 / UNS N10276 / DIN 2.4819Document3 pagesHastelloy C276 / Alloy C276 / UNS N10276 / DIN 2.4819SamkitNo ratings yet

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Document3 pagesHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitNo ratings yet

- QA F316 Austenitic Stainless Steel PDFDocument2 pagesQA F316 Austenitic Stainless Steel PDFJAFFERNo ratings yet

- UNS S31254 F44 - Super Austenitic Stainless Steel: Related SpecificationsDocument1 pageUNS S31254 F44 - Super Austenitic Stainless Steel: Related SpecificationsLeon PeterNo ratings yet

- 817M40 PDFDocument2 pages817M40 PDFSamir ChaudharyNo ratings yet

- Uns N06625Document1 pageUns N06625robertNo ratings yet

- Alloy904L SpecSheetDocument2 pagesAlloy904L SpecSheetROYAL LION GAMERNo ratings yet

- Alloy904L SpecSheet PDFDocument2 pagesAlloy904L SpecSheet PDFPieter BrodeouxNo ratings yet

- KME CuNI Welding ProcedureDocument11 pagesKME CuNI Welding ProcedureJoaoNo ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- Monel® Alloy 400: C MN S Si Ni Cu FeDocument2 pagesMonel® Alloy 400: C MN S Si Ni Cu FeD_D_76No ratings yet

- 316 & 316LDocument4 pages316 & 316LMechanicalNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNo ratings yet

- LM6 Aluminium Casting Alloyhb11Document4 pagesLM6 Aluminium Casting Alloyhb11Nader MohamedNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesMellierNo ratings yet

- Stainless Steel 1.4571 - 316ti: Alloy DesignationsDocument3 pagesStainless Steel 1.4571 - 316ti: Alloy DesignationsRohit choudharyNo ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Manganese Steel: Hard, Abrasive and Unique Are Some of The Qualities Our Manganese Steel Can Be, What Do You Need?Document3 pagesManganese Steel: Hard, Abrasive and Unique Are Some of The Qualities Our Manganese Steel Can Be, What Do You Need?hhNo ratings yet

- Stainless 316, 316L, 317, 317L: Element Percent by Weight Maximum Unless Range Is Specified 316 316L 317 317LDocument3 pagesStainless 316, 316L, 317, 317L: Element Percent by Weight Maximum Unless Range Is Specified 316 316L 317 317LAvijit SharmaNo ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Hastelloy B3 / Alloy B3 / UNS N10675 / DIN 2.4600Document3 pagesHastelloy B3 / Alloy B3 / UNS N10675 / DIN 2.4600SamkitNo ratings yet

- Tooling Materials&Heat TreatmentDocument13 pagesTooling Materials&Heat TreatmentVinod MadireddyNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- 2005 Carbon SteelDocument65 pages2005 Carbon SteelmageshkumarNo ratings yet

- 316 Stainless Steel: Corrosion Resistant AlloyDocument3 pages316 Stainless Steel: Corrosion Resistant AlloyDeepak SinghNo ratings yet

- 316-316l Pipes SuppliersDocument4 pages316-316l Pipes SuppliersSvamitva Steel IndustriesNo ratings yet

- Hastelloy C22 / Alloy C22 / UNS N06022 / DIN 2.4602Document3 pagesHastelloy C22 / Alloy C22 / UNS N06022 / DIN 2.4602SamkitNo ratings yet

- Stainless Steel 304 Data Sheet from thyssenkruppDocument3 pagesStainless Steel 304 Data Sheet from thyssenkruppYoucef KherroubiNo ratings yet

- Alloy304-304L-APR2013Document3 pagesAlloy304-304L-APR2013J A S JASNo ratings yet

- astm-a182-a182m-f904lDocument1 pageastm-a182-a182m-f904lestimationNo ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Alloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelDocument2 pagesAlloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelManoj PaneriNo ratings yet

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazNo ratings yet

- Oaisdokas 123123Document5 pagesOaisdokas 123123Justine Lloyd BautistaNo ratings yet

- 316 316L 317L Spec SheetDocument9 pages316 316L 317L Spec SheetbluecreteNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetermusatNo ratings yet

- Aisi 321 Stainless Steel Uns s32100 Din 1.4541Document3 pagesAisi 321 Stainless Steel Uns s32100 Din 1.4541Shariq KhanNo ratings yet

- Hastelloy X / Alloy X / UNS N06002 / DIN 2.4619Document3 pagesHastelloy X / Alloy X / UNS N06002 / DIN 2.4619SamkitNo ratings yet

- Aluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsDocument4 pagesAluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsMadhu SudanNo ratings yet

- TNI2TIDocument2 pagesTNI2TIKureiNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- 321 Stainless Steel: UK Supplier of Sheet, Plate & BarDocument3 pages321 Stainless Steel: UK Supplier of Sheet, Plate & BarDeepak SinghNo ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- LM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical CompositionDocument3 pagesLM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical Compositionsankar4582No ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- 4 Lead and Its AlloysDocument36 pages4 Lead and Its AlloysmohansaiNo ratings yet

- Monel k500 Alloy k500 Uns n05500 Din 2.4375Document3 pagesMonel k500 Alloy k500 Uns n05500 Din 2.4375SamkitNo ratings yet

- LM29 Alloy Guide for Aluminium CastingDocument6 pagesLM29 Alloy Guide for Aluminium CastingThangapandian NNo ratings yet

- aisi-317-stainless-steelDocument4 pagesaisi-317-stainless-steelVan Ryzal PurbaNo ratings yet

- Ch13 Materials ApplicationsDocument69 pagesCh13 Materials ApplicationsRhanganath ArivudainambiNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- Introduction To Iron Making and Blast Furnace TechnologyDocument24 pagesIntroduction To Iron Making and Blast Furnace TechnologyDevansh MankarNo ratings yet

- Bolts - ASTM F3125Document4 pagesBolts - ASTM F3125rahuljoagNo ratings yet

- Material No.: EscriptionDocument2 pagesMaterial No.: EscriptionMd Omar FaruqueNo ratings yet

- Aalco Metals LTD Stainless Steel 14571 Bar 40Document3 pagesAalco Metals LTD Stainless Steel 14571 Bar 40raduonoNo ratings yet

- 1020 Carbon Steel Bar GuideDocument3 pages1020 Carbon Steel Bar GuidethyskieNo ratings yet

- GasketDocument38 pagesGasketuripssNo ratings yet

- Ped Guidelines enDocument261 pagesPed Guidelines enfklicekNo ratings yet

- Valve Range Strainer SupplierDocument8 pagesValve Range Strainer SupplierRAVIKIRAN BARDENo ratings yet

- ASME B16.10 RF/BWE Valve Face To Face Dimension Ball/GGC/PlugDocument1 pageASME B16.10 RF/BWE Valve Face To Face Dimension Ball/GGC/PlugRAVIKIRAN BARDENo ratings yet

- Casting Material CA15BASD PDFDocument4 pagesCasting Material CA15BASD PDFAditya GuptaNo ratings yet

- Materials For Fastner'sDocument1 pageMaterials For Fastner'sRAVIKIRAN BARDENo ratings yet

- ASME B16.11 Socket Weld End Dimensions: Adelaide Brisbane PerthDocument1 pageASME B16.11 Socket Weld End Dimensions: Adelaide Brisbane PerthRAVIKIRAN BARDENo ratings yet

- L&T Process Ball Valves PDFDocument16 pagesL&T Process Ball Valves PDFUnna MalaiNo ratings yet

- Bellow Seal Valve: Energy Environment Solutions For Sustainable GrowthDocument2 pagesBellow Seal Valve: Energy Environment Solutions For Sustainable GrowthRAVIKIRAN BARDENo ratings yet

- ASTM Valve Bolting SpecificationDocument2 pagesASTM Valve Bolting SpecificationDeepak UpadhyayNo ratings yet

- Chegg SolutionsDocument9 pagesChegg SolutionsRambabu R100% (1)

- VOC Leak Detection Method DeterminationDocument7 pagesVOC Leak Detection Method DeterminationCésar Oswaldo Aguilera Ojeda100% (1)

- API 600 - TrimDocument3 pagesAPI 600 - TrimRAVIKIRAN BARDENo ratings yet

- Ansi B16 Valve Face To Face Dimensions: Ball Valves Ball ValvesDocument3 pagesAnsi B16 Valve Face To Face Dimensions: Ball Valves Ball ValvesRAVIKIRAN BARDENo ratings yet

- Stainless SteelDocument89 pagesStainless Steelmarinom1No ratings yet

- Bill of Material - Globe Valve - Model 3000Document1 pageBill of Material - Globe Valve - Model 3000RAVIKIRAN BARDENo ratings yet

- Bill of Material - Globe Valve - Model 3000Document1 pageBill of Material - Globe Valve - Model 3000RAVIKIRAN BARDENo ratings yet

- GT SeriesDocument2 pagesGT SeriesRAVIKIRAN BARDENo ratings yet

- BS en 60534-1-2005 Industrial-Process Control Valves - Part 1 Control Valve Terminology and GeneDocument16 pagesBS en 60534-1-2005 Industrial-Process Control Valves - Part 1 Control Valve Terminology and Genepenjualgas100% (1)

- 2 PDFDocument12 pages2 PDFRAVIKIRAN BARDENo ratings yet

- Duty CycleDocument2 pagesDuty CycleRAVIKIRAN BARDENo ratings yet

- Piston Act CatlogueDocument3 pagesPiston Act CatlogueRAVIKIRAN BARDENo ratings yet

- SE Lecture 6Document8 pagesSE Lecture 6666667No ratings yet

- Ex Protection PDFDocument41 pagesEx Protection PDFSiddharth Sahu100% (1)

- 6x600revised120210 PDFDocument17 pages6x600revised120210 PDFRAVIKIRAN BARDENo ratings yet

- 6 Review of Fundamentals Fluid FlowDocument11 pages6 Review of Fundamentals Fluid FlowPRASAD326100% (1)

- Fluid FlowDocument11 pagesFluid FlowRAVIKIRAN BARDENo ratings yet

- BS en 60534-1-2005 Industrial-Process Control Valves - Part 1 Control Valve Terminology and GeneDocument16 pagesBS en 60534-1-2005 Industrial-Process Control Valves - Part 1 Control Valve Terminology and Genepenjualgas100% (1)

- PTR 3480 PDFDocument7 pagesPTR 3480 PDFRAVIKIRAN BARDENo ratings yet

- Lesson Plan WavefrontDocument6 pagesLesson Plan Wavefrontafifahyuliani100% (1)

- ITN524 Midterm PDFDocument4 pagesITN524 Midterm PDF_Vezir_No ratings yet

- Properties of NR EPDM Blends With or Without Methyl Methac...Document12 pagesProperties of NR EPDM Blends With or Without Methyl Methac...CY KuoNo ratings yet

- Iso-Tc 25 N 470Document49 pagesIso-Tc 25 N 470ashey7777No ratings yet

- Jurnal Nano3 PDFDocument5 pagesJurnal Nano3 PDFamaliaNo ratings yet

- Thesis Optical Fiber Communication PDFDocument7 pagesThesis Optical Fiber Communication PDFAaron Anyaakuu100% (2)

- ME 200 Thermodynamics I Property Tables (IIDocument13 pagesME 200 Thermodynamics I Property Tables (IIpsychic_jason0071319No ratings yet

- Waelz Kiln LiningDocument4 pagesWaelz Kiln LiningCeyhun Tatar100% (1)

- A K Singh Q P - 12 Odd-2Document2 pagesA K Singh Q P - 12 Odd-2Saurabh SinghNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShivam PanchalNo ratings yet

- A Multi Axial Fatigue Analysis Method ForDocument13 pagesA Multi Axial Fatigue Analysis Method ForShivanand ArwatNo ratings yet

- Seminar HeraeusDocument91 pagesSeminar HeraeusArif Tirto AjiNo ratings yet

- GasCalc Module enDocument2 pagesGasCalc Module ensppramNo ratings yet

- FMHM BitsDocument5 pagesFMHM BitsallakagopichandNo ratings yet

- Agente de Acoplamiento Modelo BasicoDocument18 pagesAgente de Acoplamiento Modelo BasicoCarlosNo ratings yet

- Strength of Materials 1Document31 pagesStrength of Materials 1Marcelo Abrera100% (1)

- Factor That Affect The Fatigue Life of RubberDocument22 pagesFactor That Affect The Fatigue Life of RubberLong Nông DânNo ratings yet

- AP Chemistry - Study GuideDocument79 pagesAP Chemistry - Study GuideRaabiah AzeezNo ratings yet

- MR Sunia Baravilala: School of Building & Civil EngineeringDocument11 pagesMR Sunia Baravilala: School of Building & Civil EngineeringBoynikioa Taitusi BiciNo ratings yet

- Chapter 8pt2Document23 pagesChapter 8pt2Stephen Rey CaldeaNo ratings yet

- DSMTS-0072.5 Cr2O3Document4 pagesDSMTS-0072.5 Cr2O3Remco van den BergNo ratings yet

- Guoyin Shen, Ho-Kwang Mao and Russell J. Hemley - Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating With Multimode Nd:YAG LaserDocument5 pagesGuoyin Shen, Ho-Kwang Mao and Russell J. Hemley - Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating With Multimode Nd:YAG LaserDeez34PNo ratings yet

- Hydrothermal Synthesis of ZnO NanoparticlesDocument4 pagesHydrothermal Synthesis of ZnO NanoparticlesSubhashini VedalaNo ratings yet

- 2019 Gel-Pak 8 Page Brochure RevBDocument5 pages2019 Gel-Pak 8 Page Brochure RevBCharles BuergerNo ratings yet

- The Process of Crafting Lab Grown Diamonds!Document4 pagesThe Process of Crafting Lab Grown Diamonds!Diamonds DivaNo ratings yet

- Research Journals in Textiles and PolymersDocument6 pagesResearch Journals in Textiles and PolymersSajid Zeb AwanNo ratings yet

- A11 Thermodynamics PDFDocument15 pagesA11 Thermodynamics PDFEMAMBOCUS Muhammad Ibraheem JunaidNo ratings yet

- Klueberbio ALO 32-4000 009019 PI GB enDocument2 pagesKlueberbio ALO 32-4000 009019 PI GB enMuhammad SaputraNo ratings yet

- Anomalous Power Law Dispersions in Ac Conductivity and Permittivity ShownDocument4 pagesAnomalous Power Law Dispersions in Ac Conductivity and Permittivity ShownSebastião JuniorNo ratings yet