Professional Documents

Culture Documents

Owner/Operator Manual: MODEL 83513 Air Operated Chassis Pump

Uploaded by

Putro 10Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Owner/Operator Manual: MODEL 83513 Air Operated Chassis Pump

Uploaded by

Putro 10Copyright:

Available Formats

MODEL 83513

AIR OPERATED CHASSIS PUMP

SERIES F

OWNER/OPERATOR MANUAL

SPECIFICATIONS

Airmotor effective dia. in. 2.5

Air inlet 1/4 NPTF

Material outlet 1/4 NPTF

Ratio 50:1

Delivery output, cubic inches per minute 80

Delivery in cubic inches per cycle .35©

Minimum air pressure 30 p.s.i.

Maximum air pressure 150 p.s.i.

Max output pressure 7500 p.s.i.

Noise level @120 psig <85dBA

DESCRIPTION The owner/operator shall retain this

manual for future reference to impor-

Model 83513 is an air operated chassis tant warnings, operating and mainte-

pump designed to pump low and medi- nance instructions.

um viscosity materials (grease) from

drums and pails. SAFETY INFORMATION

OWNER/OPERATOR Read and understand all warnings, cau-

RESPONSIBILITY tions and instruction before operating

this equipment. Extreme caution should

be used when operating this equipment

It is the owners/operators responsibility

as personal injury and/ or property dam-

to properly use and maintain this equip-

age can result from equipment misuse.

ment.

Adequate personal protection is recom-

mended to prevent splashing of materi-

The instructions and warnings con-

al on the skin or in the eyes. ALWAYS dis-

tained in this manual shall be read and

connect air coupler from pump when the

understood by the owner/operator prior

pump is not being used.

to operating this equipment.

If an owner/operator does not under-

stand English, the contents of this man-

ual shall be explained in the owners/

operators native language to assure

the owner/operator comprehends.

It is the owners/operators responsibility

to maintain the legibility of all warning

and instruction labels.

© Indicates change

© Copyright 2002

One Lincoln Way

St. Louis, MO 63120-1578

Printed in USA Section- A5

Page - 56A

Phone +1.314.679.4200

Web site:

Fax +1.800.424.5359

www.lincolnindustrial.com

July 2002 Form 403233

FAILURE TO HEED THE FOLLOWING WARNINGS INCLUDING MISUSE, OVER PRESSURIZING, MODIFYING PARTS,

USING INCOMPATIBLE CHEMICALS AND FLUIDS, OR USING WORN OR DAMAGED PARTS, MAY RESULT IN EQUIPMENT

DAMAGE AND/OR SERIOUS PERSONAL INJURY, FIRE, EXPLOSION, OR PROPERTY DAMAGE.

· Do not exceed the stated maximum working pressure of the pump, or of the lowest rated component in your system.

· Do not alter or modify any part of this equipment.

· Do not operate this equipment with combustible gas.

· Do not attempt to repair or disassemble the equipment while the system is pressurized.

· Make sure all grease connections are securely tightened before using this equipment.

· Always read and follow the grease manufacturers recommendations regarding grease compatibility, and the use of

protective clothing and equipment.

· Check all equipment regularly and repair or replace worn or damaged parts immediately.

· Never point the dispensing valve at any part of the body or at another person.

· Never try to stop or deflect material from dispensing valve or leading connection or component with your hand or body.

· Always check equipment for proper operation before each use, making sure safety devices are in place and operating

properly.

· Always follow the pressure relief procedure after shutting off the pump, when checking or servicing any part of the system,

and when installing, cleaning or changing any part of the system.

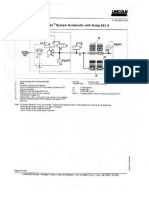

INSTALLATION

Typical drum and pail hookups are described as follows only

as a guide in selecting and installing a system.

Contact a Lincoln factory representative for assistance in de- The pump was tested in lightweight oil which was left in

signing a system for a specific requirement. to protect the pump from corrosion. Flushing the pump

before connecting it to the system might be desired to

prevent possible contamination of the grease you are

pumping.

This pump can develop 7500 PSI working pressure at

150 PSI maximum incoming air pressure. Be sure that all

system equipment and accessories are rated to with-

stand the maximum working pressure of this pump. To reduce the risk of injury from splashing or static

DO NOT exceed the maximum working pressure of the sparking when flushing the pump with solvents, always

lowest rated component in the system. hold a metal part of the dispensing valve firmly to the

side of a grounded metal pail and operate pump at

IMPORTANT: Accessory item whip hoses for dispensing lowest possible fluid pressure.

valve are rated 4500 PSI. DO NOT exceed 90 PSI air

pressure to pump when using whip hoses.

Clean/flush the pump with mineral spirits or oil based sol-

TYPICAL SYSTEM HOOKUP vents if necessary.

Determine the drum or pail system for your requirement.

Assemble the cleaned pump and supply line together with

Obtain an air line filter/regulator/lubricator to use with the any required accessory.

inlet air supply and the correct sized air and grease lines

hoses with any required reducers, connectors and accesso- Mount the assembled pump to the drum or pail.

ries.

Connect the material output line/hose to the pump.

Clean/flush the supply lines, hoses, reducers, connectors

and accessories with mineral spirits or oil based solvent to Connect the air regulator to the pump.

purge any contaminants such as dirt, moisture, or metal

shavings that could damage the pump or system Make sure all connections are securely tightened.

components. Blow dry with air.

Page Number - 2 Form 403233

ACCESSORIES necessary. Prime the pump to remove all air from the

Filter/Regulator/Lubricator and Gauge. system, or flush the pump and relieve pressure.

Eyebolt Kit.

Follower Plate - 120 lb., 400 lb. In a circulating system, the pump runs continuously and

Drum Cover - 120 lb., 400 lb. slows down or speeds up as supply demands, until the air

Drum Cover with Tie Rods. supply is shut off.

1709 Hoist.

In a direct supply system, with adequate air pressure

PRESSURE RELIEF PROCEDURE supplied to the motor, the pump starts when the gun or

Always perform this procedure when the pump is shut off dispensing valve is opened and stalls against pressure

and before checking, servicing, installing, cleaning or when it is closed.

repairing any part of this system.

Use the air regulator to control pump speed and grease

Perform the following procedure: pressure. Always use the lowest pressure required to

A. Disconnect the air supply to the pump. achieve the desired results. Higher pressures will cause

B. Point the dispensing valve away from yourself and pump packings to wear prematurely.

others.

C. Open the dispensing valve into an appropriate container MAINTENANCE

until the pressure is relieved.

If the above procedure does not relieve the pressure, the

dispensing valve or hose may be restricted. To relieve the

pressure, very slowly loosen the hose end coupling. Then To prevent personal injury, perform PRESSURE

loosen completely and clear the dispensing valve and/or RELIEF PROCEDURE before and after operating

hose.

the pump and before any maintenance.

LUBRICATION

OPERATION An air line filter/regulator/lubricator is recommended for use

INSPECTION BEFORE USING PUMP with your Lincoln pump to remove harmful dirt and moisture

Prior to operation or maintenance a visual inspection from your compressor air supply, and to provide automatic air

shall be made. Check pump system for leaks, worn or motor lubrication.

missing parts.

If an air line lubricator is not used, the following procedure

Any pump that appears to be damaged in any way, is should be performed daily:

badly worn or operates abnormally shall be removed from

use until repairs are made. Contact a factory authorized A. Disconnect air coupler from air fitting.

service center for repairs. B. Fill air coupler with NO. 10 SAE motor oil and reconnect to

air fitting.

If overpressurizing of the equipment is believed to have C. Operate pump to distribute lubricant.

occurred, contact a factory authorized service center for

inspection of the pump. MATERIAL RESTRICTION PREVENTION

Flush the system as required with a compatible solvent

Annual inspection by a factory authorized service center to prevent material buildup when pumping material that

is recommended. dries or hardens.

CORROSION PREVENTION

To prevent personal injury, perform PRESSURE RELIEF

PROCEDURE before and after operating the pump.

To reduce the risk of injury from splashing or static

To start pump, turn on the main air supply. Slowly open the

sparking when flushing the pump with solvents, always

air regulator. Regulate air pressure from 20-40 psig and

hold a metal part of the dispensing valve firmly to the

throttle to prime pump. Open the dispensing valve to allow

side of a grounded metal pail and operate pump at

air to be purged from the system. Allow pump to cycle until

lowest possible fluid pressure.

grease without air pockets flows from dispensing valve,

then close dispensing valve.

To prevent water or air corrosion, never leave the pump filled

with water or air. Flush the pump first with a compatible sol-

After pump is primed, adjust air pressure to achieve a

vent and then again with mineral spirits or oil based solvent.

smooth flow of grease from the dispensing valve. Do not

allow pump to operate when out of material. Pump will

accelerate quickly and run too fast, resulting in costly

damage to the pump.

If the pump accelerates quickly or is running too fast, stop it

immediately. Check the grease supply and refill it if

Form 403233 Page Number - 3

DISASSEMBLY

To prevent personal injury, perform

PRESSURE RELIEF PROCEDURE

before and after operating the pump

and before performing any disas-

sembly or assembly.

NOTE

If complete disassembly is required,

order the repair kit and replace ALL

gaskets, 0-rings and packings.

A. Remove valve cap (11470) and trip

rod pin (11472).

B. Unscrew four nuts (51009) from tie

rods (10294) and remove trip rod

collar (11471).

C. Unscrew trip sleeve (11947) from trip

rod (90691) and lift air valve casting

(237563©) off of air cylinder (61041).

D. Remove packing nut (11904) and

packing cap (11905) from air valve

casting.

E. Remove four valve cover screws

(236868) and cover (236286).

F. Remove four toggle plate screws

(236869), toggle assembly (91331)

and trip shoe (11475).

G. Remove four valve seat screws

(236870), springs (55138), valve

guide plate (45605) and valve slide

seat and gasket (83063).

H. Unscrew trip rod packing nut

(245425) from air valve casting and

remove all packing parts.

I. Unscrew pump tube from outlet body

(40537).

J. Remove air cylinder (61041) and air

passage tube (61502) from outlet

body.

K. Extend air motor piston rod (11340)

out bottom of outlet body. Place

wrenches on air piston bolt (11329)

and on wrench flats of piston rod and

unscrew piston rod. Thread piston

rod through gland packing to allow

removal of pump tube.

© Indicates change

Page Number - 4 Form 403233

L. Unscrew gland packing nut (12333)

from outlet body and remove all

gland parts.

M. Remove priming tube (61275) from

bushing extension (61273).

N. Extend plunger rod (11723) out

bushing extension and unscrew

priming plunger (11724) to allow

removal of priming check parts and

plunger rod (11723). ©

0. Remove bushing extension (61273)

and unscrew plunger and bushing

assembly (90554) from pump tube.

Unscrew coupling nut (11345) from

plunger adapter (11344) to allow

removal of plunger and bushing

assembly intact, reducing the

chance of losing ball stop (57027)

and check ball (69102).

ASSEMBLY

To assemble, perform DISASSEMBLY

procedures in reverse. Tighten fasten-

ers per stated torque specifications.

IMPORTANT: To prevent damage to air

piston packing and pump gland

packing, and to help increase packing

life, lubricate air cylinder and air piston

rod before assembly. Thread piston

rod through gland packing when

assembling pump.

Before tightening four valve seat

screws (236870), align valve slide and

seat plate (83063), slide valve gasket

(38162) and air valve casting (237563)

by placing a rod through the center

hole.

Start all fasteners by hand to avoid

stripping threads when reassembling.

REPAIR

Repair is limited to replacement of

listed service parts. Special proce-

dures and tools are required. Contact

Lincoln Customer Service, One Lincoln

Way, St. Louis, MO 63120-1578, (314)

679-4200 for your nearest authorized

service center.

When ordering replacement parts, list:

part number, description, model

number and series letter.

© Indicates change

Form 403233 Page Number - 5

TROUBLESHOOTING

If the following procedures do not

correct the problem, contact a factory

authorized service center. When

submitting equipment to be repaired,

be sure to state the nature of the

problem and indicate if a repair cost

estimate is required.

PROBLEMS

AIRMOTOR DOES NOT OPERATE.

· Check air supply to pump.

· Check for broken trip rod.

· Broken toggle or foreign object

lodged in priming tube. Check for

rust, worn or scored parts.

AIR SEEPAGE FROM AIR EXHAUST

WHILE PUMP IS NOT OPERATING

· Check valve slide (83063), seat ©

and gasket. Check trip rod packing

(236835) and gasket (33039) for

cut or damaged packing.

LOSS OF PRESSURE, VOLUME OR

CONTINUOUS OPERATION OF PUMP

WHEN NOT IN NORMAL USE.

· Remove and clean lower inlet

checks. Check for foreign material.

· Inspect sealing surfaces between

upper and lower inlet checks.

Replace if rough or pitted.

©

· Replace shovel rod if rough or

pitted. Replace shovel rod packing

(35073).

· Inspect lubricant supply line for

leaks or breaks.

LUBRICANT LEAKING FROM WEEP

HOLE IN OUTLET CASTING.

Replace 0-ring (34572) and U-cup

(38165). Make sure gland nut (12333)

is tight.

EXCESSIVE AMOUNT OF AIR IN

LUBRICANT OR EXCESSIVE AMOUNT

OF LUBRICANT COMING FROM AIR

EXHAUST.

NOTE

Some lubricant exhausts

with air normally.

· Replace gland packing (34180),

gland gasket (31050), 0-ring

(34572) and U-cup packing

(38165).

© Indicates change.

Page Number - 6 Form 403233

IMPORTANT TO LUBRICATE AIR VALVE MECHANISM

Start fasteners by hand to

avoid stripping threads when A. Disconnect air to pump.

reassembling. B. Perform pressure relief procedure.

C. Remove four cover screws, cover plate and cover

plate gasket.

D. Remove air valve casting from the pump and

disassemble.

E. Clean or flush the air valve casting to remove any

chips or other foreign particles.

D. Before replacing toggle assembly, pack cavity with

grease using approximately 1-1/2 ounces of N.L.G.I.

No. 1 (light grade) water repellent grease.

F. Replace cover plate gasket, cover plate and cover

screws. Tighten to prevent air leaks.

G. Periodic inspection of parts at least once a year is

advised.

Form 403233 Page Number - 7

Part Qty Description Part Qty Description Part Qty Description

10294 4 Tie rod 30003% 1 Packing nut gasket 51009 4 Tie rod nut

11329 1 Air piston bolt 30011% 1 Valve cap gasket 55138 4 Spring

11337 1 Air piston nut 31047%# 1 Check seat gasket 56038% 2 Spring

11340% 1 Air motor piston rod 31048% 2 Connector gasket 57027 2 Ball stop

11344 1 Plunger adapter 31049 1 Bushing gasket 61041# 1 Air cylinder

11345 1 Coupling nut 31050% 1 Gland gasket 61273 1 Bushing extension

11346 1 Coupling stud 31054% 2 Pump tube gasket 61502 1 Air passage tube

11349 1 Piston rod connector 33014% 1 Air cylinder gasket 68531 1 Eye bolt

11470 1 Valve cap 33039% 1 Gasket 69102%* 4 Ball ©

11471 1 Trip rod collar 34090% 1 Air piston packing 83063 1 Valve slide & seat

11472% 1 Trip rod pin 34110# 1 Plunger packing 90544 1 Plunger & bushing assy

11475# 1 Trip shoe 34158% 1 Cover gasket 90691# 1 Trip rod

11702%* 1 Check washer 34180% 2 Gland packing 91331# 1 Toggle plate

11721%* 1 Priming check 34368% 1 0-ring 236286 1 Cover

11722 1 Check stop 34572% 1 0-ring 236615 1 Muffler cover

11723%* 1 Plunger rod 35073%* 1 Priming check packing 236616%# 1 Packing washer

11724%* 1 Priming plunger 38162% 1 Slide valve gasket 236833 1 Muffler

11725%* 1 Priming check seat 38165% 1 U-cup packing 236835%# 4 Trip rod packing

11726%* 1 Check seat 40537 1 Outlet body 236868 6 Valve cover screw

11904 1 Packing nut 45605 1 Valve guide plate 236869 4 Toggle plate screw

11905 1 Packing cap 48212 2 Air piston washer 236870 1 Valve seat bolt

11947 1 Trip sleeve 48213 1 Gland packing washer 236975 1 Extension adapter

12333 1 Gland packing nut 48237 1 Plunger pack’g washer 237563 1 Air valve casting ©

14940 1 Gland packing spacer 48268 1 Gland pack’g washer 239719 1 Priming tube

245425 1 Trip rod packing nut

% Included in 83054 Pump Repair Kit.

* Included in 83001 Power Pump Tube Repair Kit.

© Indicates change

# Recommended Service Part

LIMITED WARRANTY

Lincoln warrants that lubrication equipment, materials dispensing equipment and other related equipment manufactured

by it will be free from defects in material and workmanship during the one (1) year following the date of purchase. If equip-

ment proves to be defective during this warranty period, it will be repaired or replaced without charge, provided that factory

examination indicates the equipment to be defective. To obtain repair or replacement, it must be shipped, transportation

charges prepaid, with proof of date of purchase to a Lincoln authorized Warranty and Service Center within the one (1) year

following the date of purchase.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equipment damaged from

accident, overload, abuse, misuse, negligence, faulty installation or abrasive or corrosive materials, or to equipment

repaired or altered by anyone not authorized by Lincoln to repair or alter the equipment. This warranty applies only to

equipment installed and operated according to the recommendations of Lincoln or its authorized field personnel. No other

express warranty applies to lubrication equipment, materials dispensing equipment, and other related equipment manu-

factured by Lincoln.

ANY IMPLIED WARRANTIES applicable to lubrication equipment, materials dispensing equipment, and other related

equipment manufactured by Lincoln INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTIC-

ULAR PURPOSE, WILL LAST ONLY FOR ONE (1) YEAR FROM THE DATE OF PURCHASE. SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

In no event shall Lincoln be liable for incidental or consequential damages. The liability of Lincoln on any claim for loss or

damage arising out of the sale, resale, or use of lubrication equipment, materials dispensing equipment, and other

related equipment shall in no event exceed the purchase price. SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT

APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

Page Number - 8 Form 403233

You might also like

- MODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Document4 pagesMODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Putro 10100% (1)

- Roto-Xtend Duty Fluid: Safety Data SheetDocument7 pagesRoto-Xtend Duty Fluid: Safety Data SheetPEDRO PABLO DUQUENo ratings yet

- MODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Document4 pagesMODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Putro 10100% (1)

- Mead Pneumatic HandbookDocument40 pagesMead Pneumatic Handbookjoydeep100% (5)

- Piping Fabrication and Erection ProcedureDocument15 pagesPiping Fabrication and Erection ProcedureMuhammadChabibi83% (6)

- LIFT - CYLINDERS 10 03 srm0135Document36 pagesLIFT - CYLINDERS 10 03 srm0135carlos maradiagaNo ratings yet

- Brake Systems r1600Document21 pagesBrake Systems r1600RubenJosefina100% (2)

- Lincoln Grease PumpDocument8 pagesLincoln Grease PumpNina J NinjulNo ratings yet

- TSR KuDocument16 pagesTSR KuAngsaNo ratings yet

- Omm PC800,850-8R - Pen00419-00Document399 pagesOmm PC800,850-8R - Pen00419-00Andri Assoi100% (1)

- Final Drive ChecklistDocument2 pagesFinal Drive Checklistkathir drayNo ratings yet

- D3K2Document4 pagesD3K2Agung ArdhanaNo ratings yet

- Parts Manual Compressor Model: MHP825 - W - CU Code: C HP915, XP1000 - W - CU Code: BDocument125 pagesParts Manual Compressor Model: MHP825 - W - CU Code: C HP915, XP1000 - W - CU Code: BFSO COMPRESORESNo ratings yet

- Improve Safety and Efficiency of Tyre MaintenanceDocument4 pagesImprove Safety and Efficiency of Tyre MaintenanceRui FerreiraNo ratings yet

- Sem 660DDocument2 pagesSem 660DDebby Wahyuni100% (1)

- 455 ZXDocument51 pages455 ZXPreeti SinghNo ratings yet

- Maintain and Operate Your SP661E Harvester HeadDocument33 pagesMaintain and Operate Your SP661E Harvester HeadDrow RangerNo ratings yet

- Owner'S Manual: Honda CBR250R/RADocument137 pagesOwner'S Manual: Honda CBR250R/RAدانیال کیفیNo ratings yet

- Price List Fky 2019Document34 pagesPrice List Fky 2019Dian MichaelNo ratings yet

- Catalogo Bomba ABS 200-150-40Document8 pagesCatalogo Bomba ABS 200-150-40HERBERT FERREIRA ALMEIDA FERRAZNo ratings yet

- PC Scoopy FiDocument102 pagesPC Scoopy FiPermadi SandinantoNo ratings yet

- Estimating owning and operating costs of construction equipmentDocument21 pagesEstimating owning and operating costs of construction equipmentCarlosNo ratings yet

- Field Assembly ManualDocument40 pagesField Assembly Manualmikhail.glotovNo ratings yet

- Catalouge Bucket Wearplate & AccessoriesDocument18 pagesCatalouge Bucket Wearplate & Accessoriesaribawayuni16No ratings yet

- 18MRH-X242A Axle Service ManualDocument60 pages18MRH-X242A Axle Service Manualheiner duran100% (1)

- DM-45 Sales BrochureDocument4 pagesDM-45 Sales Brochurejuancaf773557100% (1)

- Maintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursDocument3 pagesMaintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursAsim Ghosh100% (1)

- Kawasaki Ninja 250 SL Standard 158468Document1 pageKawasaki Ninja 250 SL Standard 158468EKO FITRIYANTONo ratings yet

- Faster, Easier, Safer: Cat Advansys Tips and AdaptersDocument2 pagesFaster, Easier, Safer: Cat Advansys Tips and AdaptersKawasakiNo ratings yet

- Coolant Flyer EAMEDocument1 pageCoolant Flyer EAMEHubertt Chacon AntonioNo ratings yet

- CAT395Document10 pagesCAT395Bilal VURALNo ratings yet

- PASX710 SP CatalogueDocument67 pagesPASX710 SP CatalogueLuis Antonio Chiapas GarciaNo ratings yet

- Bucyrus: Technical ManualDocument5 pagesBucyrus: Technical ManualBrian CareelNo ratings yet

- Hensley XS Mining Brochure - Komatsu - LRDocument8 pagesHensley XS Mining Brochure - Komatsu - LRYanto DaryantoNo ratings yet

- GD705A-5 Adjusting ValveDocument3 pagesGD705A-5 Adjusting ValveSurya FaniNo ratings yet

- Cat NGEO EL350: (Natural Gas Engine Oil)Document2 pagesCat NGEO EL350: (Natural Gas Engine Oil)Alfonso Alberto ArguelloNo ratings yet

- FD70-100NH CatalogueDocument4 pagesFD70-100NH CatalogueLui DavidNo ratings yet

- High Chiept PCR & Maint - BWPDocument27 pagesHigh Chiept PCR & Maint - BWPMuhammadSyarifudinNo ratings yet

- 3412 - Piaggio Fly 125 150 4t Workshop Manual PDFDocument223 pages3412 - Piaggio Fly 125 150 4t Workshop Manual PDFTomSernaNo ratings yet

- HarisDocument28 pagesHarisZen PNo ratings yet

- CM20180319 16263 55470Document56 pagesCM20180319 16263 55470sujonahmed6895No ratings yet

- Hino DutroDocument3 pagesHino DutroMohdDedeNo ratings yet

- Manual Book Isuzu TBR E2 PDFDocument2 pagesManual Book Isuzu TBR E2 PDFYoPiNo ratings yet

- A. MAN. F-013A Rev 0.0 Program Pemeriksaan Undercarriage - D155 OKDocument6 pagesA. MAN. F-013A Rev 0.0 Program Pemeriksaan Undercarriage - D155 OKMiswanto LantaNo ratings yet

- C15C18T4F PDFDocument126 pagesC15C18T4F PDFomarNo ratings yet

- Air Conditioner Presentation A1Document29 pagesAir Conditioner Presentation A1Nova KurniawanNo ratings yet

- Manual Hidraulico Excavadora 395Document19 pagesManual Hidraulico Excavadora 395Ramon MontesNo ratings yet

- Wheel Dozers & Soil CompactorsDocument19 pagesWheel Dozers & Soil CompactorsJorge Gutierrez100% (1)

- YTG30TLV LeafletDocument1 pageYTG30TLV LeafletandriNo ratings yet

- Stieber TDocument96 pagesStieber Tadem özdilNo ratings yet

- GROUP 1 NEDP BATCH 2 DOCUMENTDocument132 pagesGROUP 1 NEDP BATCH 2 DOCUMENTElsa Qorirotul Aini Susilo100% (1)

- Fuel Filter PartsDocument20 pagesFuel Filter PartsNaimahSulistianingsih100% (1)

- Vania Karunia Heavy Equipment Maintenance RecordsDocument14 pagesVania Karunia Heavy Equipment Maintenance RecordsSuhendraNo ratings yet

- Operating and Maintenance InstructionsDocument238 pagesOperating and Maintenance InstructionsTaras KutsykNo ratings yet

- fd50cn PDFDocument12 pagesfd50cn PDFJuan Amanqui GarciaNo ratings yet

- SEBF 8737 головка С-9Document6 pagesSEBF 8737 головка С-9Евгений АбрамовNo ratings yet

- Cat Deo 15W40 - Pehj0059-02 PDFDocument2 pagesCat Deo 15W40 - Pehj0059-02 PDFpaolo88No ratings yet

- PM Clinic GD655-5Document9 pagesPM Clinic GD655-5Naughty VongNo ratings yet

- XE700D液压挖掘机技术规格书Document22 pagesXE700D液压挖掘机技术规格书abangNo ratings yet

- Cat12k ElectricoDocument2 pagesCat12k ElectricoAlexis CentuNo ratings yet

- XE215C ExcavatorDocument2 pagesXE215C Excavatorasme acehNo ratings yet

- 612 Trencher ManualDocument144 pages612 Trencher Manualwwmcn2No ratings yet

- DL550 - Specification Sheet - 20160502Document27 pagesDL550 - Specification Sheet - 20160502AbdelrahmanNo ratings yet

- Pompa Lincoln AnginDocument8 pagesPompa Lincoln AnginGuntur SoebankNo ratings yet

- Basic Lay Out 653 & 603Document1 pageBasic Lay Out 653 & 603Putro 10No ratings yet

- User Manual: Centro-Matic Injector SL-11Document6 pagesUser Manual: Centro-Matic Injector SL-11Putro 10No ratings yet

- Instruction Manual: MODEL 813 3/4" Universal Digital FlowmeterDocument4 pagesInstruction Manual: MODEL 813 3/4" Universal Digital FlowmeterPutro 10No ratings yet

- Automate Process and Factory SystemsDocument9 pagesAutomate Process and Factory SystemsRam RajeshNo ratings yet

- Test on Vane pump and plotting performance curvesDocument6 pagesTest on Vane pump and plotting performance curvesShivanand TalwarNo ratings yet

- Cavity Vent ValveDocument2 pagesCavity Vent ValveRama kalyanNo ratings yet

- Technical Information: PVG 32 Proportional ValvesDocument80 pagesTechnical Information: PVG 32 Proportional ValvesStelian CrisanNo ratings yet

- Rescue BoatsDocument11 pagesRescue BoatsElmer SullonNo ratings yet

- EH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 4th PartDocument15 pagesEH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 4th Partthan zaw win100% (1)

- 1776279Document82 pages1776279Tengku Nizarul AslamiNo ratings yet

- Husky 515 Plastic Pumps: D X X X X XDocument3 pagesHusky 515 Plastic Pumps: D X X X X XA.N. HamdaniNo ratings yet

- Installation & Operation Manual for Coolant Circulating Heating SystemDocument23 pagesInstallation & Operation Manual for Coolant Circulating Heating SystemRUBENNo ratings yet

- FCC Series 10 Low Pressure Globe Control Valves CatlogDocument15 pagesFCC Series 10 Low Pressure Globe Control Valves CatlogBASKARNo ratings yet

- Process Engineer - PSV Installation-GuideDocument3 pagesProcess Engineer - PSV Installation-GuideMannu SatPuteNo ratings yet

- Special Report: Design A Staggered Depressurization Sequence For Flare SystemsDocument4 pagesSpecial Report: Design A Staggered Depressurization Sequence For Flare Systemsdigeca100% (1)

- BNG Usaha Industri 2017Document12 pagesBNG Usaha Industri 2017NadeNo ratings yet

- Hydraulic schematic legend for S250 and S300 excavatorsDocument2 pagesHydraulic schematic legend for S250 and S300 excavatorsРуденко РоманNo ratings yet

- Falla Segunda 4al60 PDFDocument5 pagesFalla Segunda 4al60 PDFMartin SantoyoNo ratings yet

- Penlon SP Service ManualDocument164 pagesPenlon SP Service ManualRAUL LANDIMNo ratings yet

- Heatec: Tec-NoteDocument11 pagesHeatec: Tec-Notepowerslave123No ratings yet

- Masoneilan 78-80H - 08-80H Transfer Valve Manual (English)Document10 pagesMasoneilan 78-80H - 08-80H Transfer Valve Manual (English)zakariaNo ratings yet

- Kombi 3 PlusDocument8 pagesKombi 3 PlusYalcin DogrulNo ratings yet

- MastDocument6 pagesMastHugh O'Brien GwazeNo ratings yet

- R559Document24 pagesR559tomognNo ratings yet

- Blakeborough DesuperheatersDocument12 pagesBlakeborough DesuperheatersMohamed LabibNo ratings yet

- Instrukcija ECL 300 - C66 (English)Document73 pagesInstrukcija ECL 300 - C66 (English)slat19711No ratings yet

- Renewal Parts YK (Stype F)Document56 pagesRenewal Parts YK (Stype F)Thang TV100% (2)

- Isx 870 IfsmDocument20 pagesIsx 870 IfsmhaviettuanNo ratings yet

- 21 Cargo Ventilation & Heating Sys Pres PDFDocument14 pages21 Cargo Ventilation & Heating Sys Pres PDFlsthanhlsthanhNo ratings yet