Professional Documents

Culture Documents

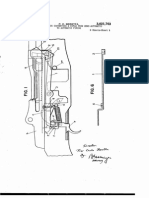

DIY Metal Bending Tool Guide

Uploaded by

africa schoolOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIY Metal Bending Tool Guide

Uploaded by

africa schoolCopyright:

Available Formats

instructables

DIY Metal Bending Tool

by kess_gr

DIY Metal Bending tool for bending of reinforcing open it.

steel, rod, round, flat, square bars.

It is a quick and simple build, made from leftover

It is very suitable for the making of concrete materials, and most of the needed tools exists at any

reinforcement cages. toolbox.

The bender can do bents using the guides of main Here is a video of this build, and the tests of the

unit bends with reinforcement bars and flat bars

at 7-12-17-22-27-32-37-42-47 cm

I have use a disk saw machine to cutting the piece for

and with the use of the addition the bushing, but if you haven't such tool, isn't critical

or prohibitive.

at 5-10-15-20-25-30-35-40-45 cm

Using your angle grinder, a very simple jig and your

Also it is easy and simple to modified, according to bench vise, you can do the cut easily and pretty good.

your needs. (See Step "Preparation of Bushing / Pivot Set").

The plans are avaliable at (.skp) format at "Plan Files Also if you haven't the needed taps for tapping, then

Step" you can weld nuts. (You can see the sketch at Step

"Plan files")

you will need Google SketchUp8 or any newer to

https://youtu.be/B6q9ix6D2Bo

DIY Metal Bending Tool: Page 1

DIY Metal Bending Tool: Page 2

DIY Metal Bending Tool: Page 3

Step 1: Tools and Materials

Tools

1. Angle grinder 115 or 125mm

2. Cutting disk ø115 x 1mm – (ø4 ½” x 0.04”) or ø125 x 1mm – (ø 5” x 0.04”)

3. Grinding disk

4. Saw machine (optional but helpful if any)

5. Hacksaw

6. Drill or Drill Press

7. Welding machine

8. Magnetic welding square

9. Tape measure & Vernier

10. Center punch & Pen Scriber

11. Flat File

12. Clamps or Vice grips

13. Drill bits: ø4mm, ø5mm, ø10mm, ø10.2mm, ø10.5mm, ø12mm, ø16mm,

14. Taps set: M6x1 & M12x1.75

15. Tap handle

16. Countersink

17. Wrench 19mm

18. Allen Wrench 5mm & 10mm

19. Bench vise

Materials

1. 1pcs Tube 38x38x3mm x500mm (main unit)

2. 1pcs Round stock steel ø25/14x32mm (bushing)

3. 1pcs Round stock steel ø34/12x20mm (roller die) if it is from hardened steel will be much better (Do

Not use a ball bearing as roller die, it is dangerous)

4. 1pcs Rod ø16x70mm 1pcs (rotating pivot)

5. 1pcs Rod ø10x600mm or 9pcs x57mm & 1pcs x22mm

6. 1pcs Flat bar 30x10~15x100mm (bending unit)

7. 1pcs Flat bar 30x3x100mm (addition)

8. 1pcs square tube 20x20x1.5mm or heavier (handle)

9. Hex Socket Bolts: 1pcs M12x60mm, 1pcs M10x30mm

10. Hex Bolts: 1pcs M12x40mm

11. Hex Socket Bolts headless 1pcs M6x10mm

12. Nuts: 4pcs M12, 1pcs M10, 1pcs M16

13. Washers: 2pcs M12

14. A piece Scotch Brite, for finishing/polishing of the rotating pivot

DIY Metal Bending Tool: Page 4

Step 2: Plan Files

You can open the files using the free version of google SketchUp8 or any newer.

DIY Metal Bending Tool: Page 5

http://www.instructables.com/ORIG/FOU/L05F/IYYTEHKR/FOUL05FIYYTEHKR.skp

(https://cdn.instructables.com/ORIG/FOU/L05F/IYYTEHKR/FOUL05FIYYTEHKR.skp)

http://www.instructables.com/ORIG/F8C/791F/IYYTEHKQ/F8C791FIYYTEHKQ.skp

(https://cdn.instructables.com/ORIG/F8C/791F/IYYTEHKQ/F8C791FIYYTEHKQ.skp)

DIY Metal Bending Tool: Page 6

Step 3: Preparation of Bushing / Pivot Set

Use a clamp and a piece of steel and create a stop at

left side of angle-iron, so as, your stock steel to can't

move to the left.

Remember Safety is First.

Using the end of the angle-iron as guide, slide the

Welding Cutting and Grinding Tools are cutting disk over it, and rotating the stock steel by

Dangerous! hand, do the cut, (the cutting disk is not needing to

pass across).

Do it at your own Risk!

Use a file, to smoothen the profiles.

Use Always the Suitable Protective Equipment.

Do a centers punch at the point that will become the

hole onto the tube (38x38x3x500mm (main unit)).

Do the hole at the tube, starting with ø4mm drill bit

and completing with ø16mm drill bit.

Cut a piece of 32mm length from the ø25/14mm

round stock steel, using a saw machine, if any. Resize the hole of bushing from ø14mm to ø16mm

Or make a jig at your bench vise (see the sketch or and clean up the edges using a countersink.

file)

Polish the ø16mm rod/axle using the drill press and a

Mount a piece of angle-iron, in the vise, piece Scotch Brite.

Mark the point of cut at the stock steel Then cut a piece 70mm length of this rod for

bushing's pivot.

Place the steel into the angle-iron, so as the cutting

point to be just next to end of the angle-iron

DIY Metal Bending Tool: Page 7

DIY Metal Bending Tool: Page 8

DIY Metal Bending Tool: Page 9

http://www.instructables.com/ORIG/F65/UCW9/IYYTP8BA/F65UCW9IYYTP8BA.skp

(https://cdn.instructables.com/ORIG/F65/UCW9/IYYTP8BA/F65UCW9IYYTP8BA.skp)

DIY Metal Bending Tool: Page 10

Step 4: Bending Unit

For the bending unit I decided to use something from The distance between the bolt's head and nut must

the leftover stuff that was good enough and needed to be the sum of [roller+2 washers+(1~1,5mm)]

do only one hole and a M12 thread.

so the roller to can be rotate freely.

Don't worry, isn't needed to make a construction like

this that is little complicated, I have used the extra (down-side) nut because my

base isn't solid and each side of 4mm thickness, can

you can use a flat bar 30x10~15x100mm (You can has only 2 complete threads (the pitch of M12 coarse

find the plan at "Plans Step"). thread is 1.75mm).

Weld the bushing,

A solid base of 10mm thickness, can be has almost 6

drill a ø10.2 hole (bushing center > hole center at complete threads, that is good enough.

base = 38mm)

use a M12 set taps to cut the threads. Make a handle of square tube 20x20x1.5mm and

mount onto the base at a 140°~150° angle.

Mount the roller die (ø34/12x20mm) into the hole at

the base of bending unit. Heat up a piece of plastic tube and pass it onto the

Socket Bolt \ washer \ roller-die \ washer \ up-side nut tube.

\ base \ down-side nut.

DIY Metal Bending Tool: Page 11

DIY Metal Bending Tool: Page 12

DIY Metal Bending Tool: Page 13

Step 5: Main Unit / Cuts & Guides

The main unit is a simple tube (38x38x3x500mm). All guides must have the same distance (50mm)

I have made the pivot holes at an earlier step between them.

(Preparation of Bushing / Pivot Set) but before the

installation of guides need to do some cuts at the Mark and then Center punches all points.

edge of tube.

Start drilling the holes with ø4mm drill bit.

Needed 30mm space at the edge of the vertical

sides, so the bending unit to can rotate and rounding Complete the holes with ø10mm drill bit.

the corners at the horizontal sides.

Cut from ø10mm rod 9 pieces 57mm length.

Mark a center line for the guides.

Place the pieces/guides into the holes.

This line must be at the whole length of tube at 16mm

from back side to front. Weld all pieces/guides at the down side of tube.

The center of first guide must be at a distance 42mm The Main unit is almost ready.

from the center of the pivot hole.

DIY Metal Bending Tool: Page 14

DIY Metal Bending Tool: Page 15

DIY Metal Bending Tool: Page 16

DIY Metal Bending Tool: Page 17

Step 6: Main Unit / Adding a Pivot Base

To attaching the bending unit to main unit needs to Insert the pivot into the nut, adjust, and then fasten

make a small base for the pivot. the screw.

Will need a M16 nut abroach with a ø16mm drill bit Pass the pivot into the holes at the main unit from

and a M6 headless socket bolt. down side.

Do a ø5mm hole in the middle of the nut side, and Weld the nut to the main unit.

then use a M6 set taps to cut the threads.

DIY Metal Bending Tool: Page 18

DIY Metal Bending Tool: Page 19

DIY Metal Bending Tool: Page 20

Step 7: Main Unit / Thickness Adjuster

For the making of Thickness Adjuster needed one M12x40mm bolt, two M12 nuts and two small pieces of steel

scrap.

Weld a nut on a piece of steel, then with the help of a magnetic square adjust and weld at the back side of tube, at

the point behind of the first guide.

Please follow the process on photos, I think that is easier than the text.

DIY Metal Bending Tool: Page 21

DIY Metal Bending Tool: Page 22

DIY Metal Bending Tool: Page 23

DIY Metal Bending Tool: Page 24

Step 8: Main Unit / Addition Guide

The tool as is can do bends as follows: Do a center punch mark over the line at 10mm from

at the first guide 70mm the left edge

at the second 70+50=120mm do a second at 32mm and a third at 82mm.

at the third 120+50=170mm and so on. At the first one, do a ø10mm hole.

Making a small and simple addition we can double At the second and third, do ø10.5~11mm holes.

the range of bends as follows:

Turn the flat bar upside down,

at the first guide 50mm

using a countersink or a bigger drill bit, do the first

at the second 50+50=100mm hole conical.

at the third 100+50=150mm and so on. Grind the edge of (ø10x22mm) rod to be conical.

For this addition will need a flat bar 30x3x100mm ant Weld and grind the weld so to be smooth.

a piece of rod bar ø10x22mm.

Mark a line at 8mm from the front side, at flat bar.

DIY Metal Bending Tool: Page 25

DIY Metal Bending Tool: Page 26

Step 9: Bending Tests

The tool is ready. Never say I can't do it.

Tested and the results are prety good. Necessity is the mother of invention.

You can see the whole video here kess https://www.youtube.com/user/kessgr

You can see the tool in action here http://www.homemadetools.net/builder/kess

Thanks for your reading.

Good Luck if you try it.

DIY Metal Bending Tool: Page 27

DIY Metal Bending Tool: Page 28

DIY Metal Bending Tool: Page 29

DIY Metal Bending Tool: Page 30

You might also like

- Airguns and Airgun DIYDocument6 pagesAirguns and Airgun DIYgorlanNo ratings yet

- Adderini Pistol PDFDocument108 pagesAdderini Pistol PDFpabloNo ratings yet

- A Do-It-Yourself Manual Tire ChangerDocument4 pagesA Do-It-Yourself Manual Tire ChangerHamzaNouman50% (2)

- COVID-22 Build GuideDocument21 pagesCOVID-22 Build GuideGrant MarkumNo ratings yet

- GG3 Operators Manual Quickstart PDFDocument5 pagesGG3 Operators Manual Quickstart PDFRebecca MathewsNo ratings yet

- Print Page - Welrod B - A Pistols - Toward A Scratch BuildDocument58 pagesPrint Page - Welrod B - A Pistols - Toward A Scratch BuildAndrew MichaelsNo ratings yet

- Getting Started with 3D Printing on a BudgetDocument9 pagesGetting Started with 3D Printing on a BudgetManuel MarengoNo ratings yet

- Air Hydrilic PumpDocument6 pagesAir Hydrilic Pumpcampa150No ratings yet

- Spring RatingDocument6 pagesSpring Ratingbrowar444No ratings yet

- DIY Sheet Metal BenderDocument6 pagesDIY Sheet Metal Benderlondemon100% (1)

- How To Build A Fuel LineDocument15 pagesHow To Build A Fuel LineMech EngrNo ratings yet

- Sent in To TFB Is Another Concept Design For AnDocument5 pagesSent in To TFB Is Another Concept Design For Aneduar laraNo ratings yet

- Easy Jig Information - 80% ArmsDocument2 pagesEasy Jig Information - 80% Arms9fakeemailNo ratings yet

- MachinaDocument2 pagesMachinaruber730% (1)

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3No ratings yet

- PG22 Aurora - 1.4: Read All Instructions Carefully. Do Not Skip or Skim. It's All Here For A ReasonDocument8 pagesPG22 Aurora - 1.4: Read All Instructions Carefully. Do Not Skip or Skim. It's All Here For A ReasonZarcano Farias100% (3)

- CZ 452 Benchrest Custom TriggerDocument9 pagesCZ 452 Benchrest Custom Triggerernst1978No ratings yet

- DIY Cold Heat Soldering IronDocument13 pagesDIY Cold Heat Soldering IronM.Faizan.NasirNo ratings yet

- Tubing BenderDocument9 pagesTubing BenderAdam Rath50% (2)

- Building a Bronze Casting Furnace for Under $150Document12 pagesBuilding a Bronze Casting Furnace for Under $150willchamNo ratings yet

- Post 4 23085 M6 Scout InfoDocument32 pagesPost 4 23085 M6 Scout InfoMike Nichlos100% (2)

- Hacksaw PDFDocument40 pagesHacksaw PDFturuceluNo ratings yet

- DIY Cheap and Sturdy Laser EngraverDocument28 pagesDIY Cheap and Sturdy Laser EngraverAnimatronic sonoroNo ratings yet

- DIY Bench Top Tubing BenderDocument17 pagesDIY Bench Top Tubing BenderMalcolm DiamondNo ratings yet

- Homemade Paintball GunDocument8 pagesHomemade Paintball GunAinis Štelemėkas0% (1)

- Af WF Doc 001 PDFDocument19 pagesAf WF Doc 001 PDFArjun S RanaNo ratings yet

- DIY PVC Crossbow: Technology Workshop Craft Home Food Play Outside CostumesDocument14 pagesDIY PVC Crossbow: Technology Workshop Craft Home Food Play Outside CostumesToe100% (1)

- 9mm Bolt RampingDocument6 pages9mm Bolt RampingMatthew NelsonNo ratings yet

- StenDocument13 pagesStendinosauro007100% (2)

- PEP22 Trigger dimensionsDocument1 pagePEP22 Trigger dimensionskolas hernandezNo ratings yet

- The DIY Gun Vise ProjectDocument4 pagesThe DIY Gun Vise ProjectShawn Armstrong100% (2)

- SAS Report Europe ConversionDocument70 pagesSAS Report Europe ConversionJairo Navarro DiasNo ratings yet

- Hobby Metal Casting Made Easy - Melting Metal and Hobby Metalcasting Information How To Build Homebuilt Backyard Foundry How To Build Furnace Plans Step by STDocument9 pagesHobby Metal Casting Made Easy - Melting Metal and Hobby Metalcasting Information How To Build Homebuilt Backyard Foundry How To Build Furnace Plans Step by STFernando SotoNo ratings yet

- Casted Lathe PDFDocument27 pagesCasted Lathe PDFFIREREALM66100% (1)

- HTI Manual PDFDocument70 pagesHTI Manual PDFRazza Willi0% (1)

- Sas12 Shotgun ExplodedDocument8 pagesSas12 Shotgun Explodedsjdarkman1930No ratings yet

- US20080086926A1Document19 pagesUS20080086926A1ProfessorNo ratings yet

- CZAR V2 Build TutorialDocument20 pagesCZAR V2 Build Tutorialgretschguy7081100% (1)

- Reinforced PVC Crossbow With Laminated StockDocument22 pagesReinforced PVC Crossbow With Laminated Stockmarius_danila8736No ratings yet

- Homemade Cannon FuseDocument9 pagesHomemade Cannon FuseKo Pyae SoneNo ratings yet

- Sheet Metal Bench Shear PDFDocument14 pagesSheet Metal Bench Shear PDFmarianrkw100% (1)

- Tools, Plans, and DIY Projects Index PDFDocument5 pagesTools, Plans, and DIY Projects Index PDFCivil War75% (4)

- Home Made Metal Spinning LatheDocument7 pagesHome Made Metal Spinning Latheuragunbaga75% (4)

- Eng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFDocument4 pagesEng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFlogostar5No ratings yet

- Introduction to 3-Gun Shooting at Rio Salado Sportsman's ClubDocument30 pagesIntroduction to 3-Gun Shooting at Rio Salado Sportsman's ClubDUXLEXNo ratings yet

- MAC DB9 Build GuideDocument11 pagesMAC DB9 Build GuideJessie Radicke0% (1)

- TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2Document18 pagesTM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2browar444No ratings yet

- Brun-Latrige Model 1900 Pocket Pistol (Video)Document5 pagesBrun-Latrige Model 1900 Pocket Pistol (Video)Roddy PfeifferNo ratings yet

- 3D Printed CETME/HK Receiver Bending JigDocument13 pages3D Printed CETME/HK Receiver Bending Jigrand0No ratings yet

- 12 Silencers - HTMDocument4 pages12 Silencers - HTMreeder45960No ratings yet

- HK94, MP5, Parts KitsDocument6 pagesHK94, MP5, Parts KitsDavid BumbaloughNo ratings yet

- @VLNNR:: Beretta 3,021,763Document8 pages@VLNNR:: Beretta 3,021,763wererNo ratings yet

- Three Trailers in One - Box, Car and Flat Top. The Box Top TrailerDocument10 pagesThree Trailers in One - Box, Car and Flat Top. The Box Top TrailerDavidNo ratings yet

- The Mac 10 Cookbook PDFDocument3 pagesThe Mac 10 Cookbook PDFCali Fornia0% (1)

- 3 in Shaper PDFDocument5 pages3 in Shaper PDFRob NairNo ratings yet

- Trijicon RECOIL TargetDocument1 pageTrijicon RECOIL TargetK Scott WyattNo ratings yet

- Building This Gun If You Have Not Already Purchased Parts For A +bow. in The Parts List, The Cost IsDocument30 pagesBuilding This Gun If You Have Not Already Purchased Parts For A +bow. in The Parts List, The Cost IsA side of nerfNo ratings yet

- DIY - Metal Roller Bender: InstructablesDocument8 pagesDIY - Metal Roller Bender: Instructablesafrica schoolNo ratings yet

- DIY Acrylic Router Base PlateDocument9 pagesDIY Acrylic Router Base Plateafrica schoolNo ratings yet

- The Gambon Stowaway Dining Set Is Perfect For Those Short On SpaceDocument2 pagesThe Gambon Stowaway Dining Set Is Perfect For Those Short On Spaceafrica schoolNo ratings yet

- FreeFurnitureMakingTips PDFDocument13 pagesFreeFurnitureMakingTips PDFJeroen Matthee JayNo ratings yet

- DIY Acrylic Router Base PlateDocument9 pagesDIY Acrylic Router Base Plateafrica schoolNo ratings yet

- DIY Acrylic Router Base PlateDocument9 pagesDIY Acrylic Router Base Plateafrica schoolNo ratings yet

- Add A Router Table To A Table Saw: Step 1: Tools and MaterialsDocument8 pagesAdd A Router Table To A Table Saw: Step 1: Tools and Materialsafrica schoolNo ratings yet

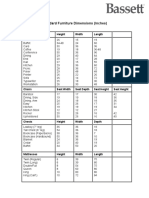

- StandardfurnituredimensionsDocument1 pageStandardfurnituredimensionsAngel De GuzmanNo ratings yet

- Automatic Tubing Drain Installation GuideDocument8 pagesAutomatic Tubing Drain Installation GuideCae IndruNo ratings yet

- ULCI4+ 14000XTB: An in-depth technical reviewDocument1 pageULCI4+ 14000XTB: An in-depth technical reviewjori ahuefafreeNo ratings yet

- Manual Beretta M92FS enDocument18 pagesManual Beretta M92FS enaurel90No ratings yet

- Wolouf CatalogueDocument3 pagesWolouf CatalogueJawad AbusamhaNo ratings yet

- Hdpe QuotationDocument3 pagesHdpe Quotationnachiketa99mithaiwalaNo ratings yet

- Spur Gear: GearsDocument6 pagesSpur Gear: GearsJayson cheekNo ratings yet

- t69 1u PDFDocument1 paget69 1u PDFRenny DevassyNo ratings yet

- Document revision and assembly drawingDocument1 pageDocument revision and assembly drawingKarikalan JayNo ratings yet

- Horizontal Pump Components ListDocument2 pagesHorizontal Pump Components Listdragos manoleNo ratings yet

- 11制动配件 brake partsDocument11 pages11制动配件 brake partsكلاركات أوناشNo ratings yet

- Seminar Report On Disc Brake: Submitted byDocument34 pagesSeminar Report On Disc Brake: Submitted bySouraj PatelNo ratings yet

- Advanced Mortar Fuze for NATO ForcesDocument2 pagesAdvanced Mortar Fuze for NATO Forcesnikilazar1No ratings yet

- Com Ref Catalogue July 2018 v1 en SG 5074710Document6 pagesCom Ref Catalogue July 2018 v1 en SG 5074710Md. Matiur RahmanNo ratings yet

- Hand Tools and Power Tools: Lesson OutcomesDocument17 pagesHand Tools and Power Tools: Lesson OutcomesAlfan FuadiNo ratings yet

- SMG Intratec Manual - Pesquisa GoogleDocument2 pagesSMG Intratec Manual - Pesquisa Googleruber73100% (1)

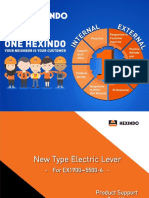

- Customer New Type Electric LeverDocument6 pagesCustomer New Type Electric Leverardan fadilahNo ratings yet

- Features: TC-MS 2112 TDocument2 pagesFeatures: TC-MS 2112 TAlain Alcázar GarcíaNo ratings yet

- Safe Working Practices: Wood Turning LathesDocument7 pagesSafe Working Practices: Wood Turning LathesCamilo CubidesNo ratings yet

- DIRECTIONAL CONTROL VALVES Part-A Question and AnswersDocument5 pagesDIRECTIONAL CONTROL VALVES Part-A Question and Answerssar_tpgitNo ratings yet

- Equipment List for Construction ProjectDocument1 pageEquipment List for Construction ProjectAriel AbastillasNo ratings yet

- Tle - Cookery 7 - Q2 - W2Document10 pagesTle - Cookery 7 - Q2 - W2LUCILLE ANDREA DAUIS100% (1)

- SP42Document10 pagesSP42Susavan MandalNo ratings yet

- Arrow 270 400 16 Inch MAXI FanDocument45 pagesArrow 270 400 16 Inch MAXI FanÖnder BüyükişcanNo ratings yet

- Reading Piping and Instrumentation DiagramsDocument18 pagesReading Piping and Instrumentation DiagramsErra ShafiraNo ratings yet

- ShopNotes 23dfggghDocument32 pagesShopNotes 23dfggghAR Rms100% (1)

- Install Interconnect Shaft Retaining RingDocument12 pagesInstall Interconnect Shaft Retaining Ringmoh12109No ratings yet

- LP1 Types of Carpentry ToolsDocument8 pagesLP1 Types of Carpentry Toolsglenn salandananNo ratings yet

- Mercedes Benz Power Steering PumpsDocument10 pagesMercedes Benz Power Steering PumpsFilipposNo ratings yet

- Limit Switch, Boom: 4100XPC Electric Shovel Machine Serial Number: Parts Manual 41235Document2 pagesLimit Switch, Boom: 4100XPC Electric Shovel Machine Serial Number: Parts Manual 41235maocaleirlNo ratings yet

- Sektion Installation Guide Fy21 Web ADocument16 pagesSektion Installation Guide Fy21 Web AmroliverridleyNo ratings yet

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Knit a Box of Socks: 24 sock knitting patterns for your dream box of socksFrom EverandKnit a Box of Socks: 24 sock knitting patterns for your dream box of socksNo ratings yet

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- Sew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsFrom EverandSew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsRating: 5 out of 5 stars5/5 (3)

- Modern Crochet…For the Beach Babe Goddess: Easy to Use StitchesFrom EverandModern Crochet…For the Beach Babe Goddess: Easy to Use StitchesRating: 3 out of 5 stars3/5 (2)

- Fabric Manipulation: 150 Creative Sewing TechniquesFrom EverandFabric Manipulation: 150 Creative Sewing TechniquesRating: 4.5 out of 5 stars4.5/5 (13)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Siren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetFrom EverandSiren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetRating: 5 out of 5 stars5/5 (3)

- Crochet: Fun & Easy Patterns For BeginnersFrom EverandCrochet: Fun & Easy Patterns For BeginnersRating: 5 out of 5 stars5/5 (3)

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetFrom EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetRating: 3.5 out of 5 stars3.5/5 (4)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Cozy Minimalist Home: More Style, Less StuffFrom EverandCozy Minimalist Home: More Style, Less StuffRating: 4 out of 5 stars4/5 (154)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Creative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsFrom EverandCreative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsRating: 4.5 out of 5 stars4.5/5 (2)

- Crafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsFrom EverandCrafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsRating: 1.5 out of 5 stars1.5/5 (3)

- Layers of Meaning: Elements of Visual JournalingFrom EverandLayers of Meaning: Elements of Visual JournalingRating: 4 out of 5 stars4/5 (5)

- How to Dress: Secret styling tips from a fashion insiderFrom EverandHow to Dress: Secret styling tips from a fashion insiderRating: 4 out of 5 stars4/5 (1)

- Delicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreFrom EverandDelicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreRating: 4 out of 5 stars4/5 (11)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Celestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesFrom EverandCelestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesRating: 3.5 out of 5 stars3.5/5 (6)

- Famous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsFrom EverandFamous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsRating: 4 out of 5 stars4/5 (4)