Professional Documents

Culture Documents

Service Bulletin: Subject: Installation Procedures For Interconnect Shaft

Uploaded by

moh12109Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Bulletin: Subject: Installation Procedures For Interconnect Shaft

Uploaded by

moh12109Copyright:

Available Formats

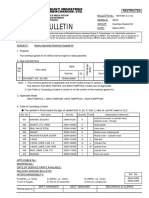

SERVICE BULLETIN

NOTICE: The Type of Change and Recommended Compliance specified reflects Solar’s best judgment regarding the

Service Bulletin. All questions should be directed to your Solar Field Service Representative. Solar, Saturn,

Centaur, Taurus, Mercury, Mars, Titan, SoLoNOx, and Turbotronic are trademarks of Solar Turbines Incorporated.

Cat and Caterpillar are trademarks of Caterpillar Inc. Specifications subject to change without notice.

NUMBER: 10.8/103

ISSUED: January 1992

REVISED:

PRODUCT: Mars, Centaur

MODEL(S): Compressors, Mechanical Drive

Specifics:

SUBJECT: INSTALLATION PROCEDURES FOR INTERCONNECT

SHAFT

Type of Change: Product Information

Recommended

Compliance: Next maintenance

Purpose:

To provide detailed instructions for installation of the snap-ring type interconnect shaft.

GENERAL INFORMATION:

Disengagement of the interconnect shaft on Centaur and Mars compressor and mechanical drive

units can occur if the retaining ring is not firmly seated in the groove of the coupling. The retaining

ring (Item 26, Figure 1) can dislodge from the seat (groove) in the driven coupling (25). This ring

is designed to restrict the end movement of the shaft assembly. Without the ring to limit movement,

the entire shaft assembly can move aft allowing the driver coupling (7), on the forward end of the

shaft, to disengage from the driver hub (1).

The installation procedures have now been revised and expanded to ensure that the retaining ring

is firmly seated in the coupling. The new procedures have been validated in the field; change page

inserts for the manuals are being distributed to equipment operators.

Part numbers for the affected interconnect shaft assemblies are listed below:

SERVICE BULLETIN Page 1 of 12

NUMBER: 10.8/103

121113-1200 121113-2000 121113-3500 137666-100

121113-1300 121113-2400 121113-3900 137666-400

121113-1400 121113-2600 121113-4100 137666-500

121113-1500 121113-3000 121113-4300 137666-700

121113-1600 121113-3101 121113-4400 137666-800

121113-1700 121113-3201 121113-4500 137666-1000

121113-1900 121113-3300 121113-4600

The tables below lists the consumable items required for installation of each interconnect shaft:

Table 2 Interconnect Shaft P/N 121113-1200

Consumable Items P/N Description Quantity

903261C1 Seal, O-Ring (SAE 265) 1

950781C1 Seal, O-Ring (SAE 276) 1

950403C1 Seal, O-Ring (SAE 261) 2

129829-1 Gasket, Access Cover 1

Table 3 Interconnect Shaft PIN 121113-1400 and -1500

Consumable Items P/N Description Quantity

908061C1 Seal, O-Ring (SAE 281) 1

908153C1 Seal, O-Ring (SAE 275) 2

950781C1 Seal, O-Ring (SAE 276) 1

130277-1 Gasket, Access Cover 1

Table 4 Interconnect Shaft P/N 121113-1300, -1600, -1700

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring (SAE 275) 1

950781C1 Seal, O-Ring (SAE 276) 1

130277-1 Gasket, Access Cover 1

Page 2 of 12 SERVICE BULLETIN

NUMBER: 10.8/103

Table 5 Interconnect Shaft P/N 121113-1900

Consumable Items P/N Description Quantity

950781C1 Seal, O-Ring (SAE 276) 1

950403C1 Seal, O-Ring (SAE 261) 2

960400C1 Seal, O-Ring (SAE 265) 1

129829-1 Gasket, Access Cover 1

Table 6 Interconnect Shaft P/N 121113-2000

Consumable Items P/N Description Quantity

960400C1 Seal, O-Ring (SAE 265) 1

950403C1 Seal, O-Ring (SAE 261) 2

129829-1 Gasket Access Cover 1

Table 7 Interconnect Shaft P/N 121113-2400

Consumable Items P/N Description Quantity

955970C1 Seal, O-Ring (SAE 275) 1

960400C1 Seal, O-Ring (SAE 265) 3

130161-1 Gasket, Access Cover 1

915931C1 Adhesive A/R

955224C1 O-Ring 2

Table 8 Interconnect Shaft P/N 121113-2

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring 3

962359C1 Seal, O-Ring (Parker 5-495) 1

Table 9 Interconnect Shaft PIN 121113-3000

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring (SAE 275) 2

950781C1 Seal, O-Ring (SAE 276) 1

952876C1 Seal, O-Ring (SAE 378) 1

130277-1 Gasket, Access Cover 1

SERVICE BULLETIN Page 3 of 12

NUMBER: 10.8/103

Table 10 Interconnect Shaft P/N 121113-3101

Consumable Items P/N Description Quantity

130161-1 Gasket, Access Cover 1

908153C1 Seal, O-Ring (SAE 275) 2

952876C1 Seal, O-Ring (SAE 387) 2

964587C1 O-Ring (Bulk) A/R

Table 11 Interconnect Shaft P/N 121113-3201 AND -3300

Consumable Items P/N Description Quantity

130161-1 Gasket, Access Cover 1

908058C1 Seal, O-Ring (SAE 263) 1

908153C1 Seal, O-Ring (SAE 275) 1

964587C1 O-Ring (Bulk) A/R

952876C1 Seal, O-Ring (SAE 378) 2

Table 12 Interconnect Shaft P/N 121113-3500

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring (SAE 275) 1

955970C1 Seal, O-Ring (SAE 257) 1

952876C1 Seal, O-Ring (SAE 378) 2

955970C1 Seal, O-Ring (SAE 257) 1

Table 13 Interconnect Shaft P/N 121113-3900

Consumable Items P/N Description Quantity

908061C1 Seal, O-Ring (SAE 281) 1

950001C1 Seal, O-Ring (SAE 460) 1

Table 14 Interconnect Shaft P/N 121113-.4100

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring (SAE 275) 3

952876C1 Seal, O-Ring (SAE 378) 1

130277-1 Gasket, Access Cover 1

Page 4 of 12 SERVICE BULLETIN

NUMBER: 10.8/103

Table 15 Interconnect Shaft P/N 121113-4300

Consumable Items P/N Description Quantity

903240C1 O-Ring 1

955970C1 Seal, O-Ring (SAE 257) 1

962253C1 Seal, O-Ring (SAE 366) 1

Table 16 Interconnect Shaft P/N 121113-4400

Consumable Items P/N Description Quantity

908061C1 Seal, O-Ring (SAE 276) 1

908153C1 Seal, O-Ring (SAE 275) 1

952876C1 Seal, O-Ring 1

Table 17 Interconnect Shaft P/N 121113-4500 and -4600

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring (SAE 275) 1

915931C1 Adhesive, Silicone GERTV615 A/R

962253C1 Seal, O-Ring (SAE 366) 1

903239C1 Seal, O-Ring (SAE 152) 2

Table 18 Interconnect Shaft P/N 137666-100

Consumable Items P/N Description Quantity

950001 Seal, O-Ring (SAE 460) 1

137651-1 Gasket, Adapter 1

137650-1 Gasket, Cover 2

Table 19 Interconnect Shaft P/N 137666-400

Consumable Items P/N Description Quantity

130161-1 Gasket, Access Cover 1

903271C1 Seal, O-Ring (SAE 920) 1

908153C1 Seal, O-Ring (SAE 275) 3

950781C1 Seal, O-Ring (SAE 276) 1

964587C1 O-Ring 1

SERVICE BULLETIN Page 5 of 12

NUMBER: 10.8/103

Table 20 Interconnect Shaft P/N 137666-500

Consumable Items P/N Description Quantity

130161-1 Gasket, Access Cover 1

908153C1 Seal, O-Ring (SAE 275) 1

908280C1 Seal, O-Ring (SAE 262) 1

964587C1 O-Ring .139 Diameter Bulk A/R

952876C1 Seal, O-Ring (SAE 378) 2

Table 21 Interconnect Shaft P/N 137666-700

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring (SAE 275) 1

952876C1 Seal, O-Ring (SAE 276) 1

Table 22 Interconnect Shaft P/N 137666-800

Consumable Items P/N Description Quantity

908153C1 Seal, O-Ring (SAE 275) 2

952876C1 Seal, O-Ring (SAE 378) 2

Table 23 Interconnect Shaft P/N 137666-1000

Consumable Items P/N Description Quantity

903222C1 O-Ring (SAE 014) 1

917361C1 Silicon Rubber RTV 732 Bulk A/R

950781C1 Seal, O-Ring (SAE 276) 1

952876C1 Seal, O-Ring (SAE 378) 2

903239C1 Seal, O-Ring (SAE 152) 1

Action Required:

When maintenance requires removal of engine-to-compressor interconnect shaft, proceed as fol-

lows. Ensure that the required gaskets and O-ring seals listed in the Operation and Maintenance

Instructions Manual are available prior to initiating disassembly.

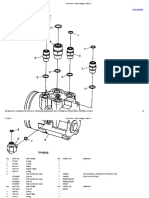

Removal of Input Drive Shaft Assembly (Figure 1)

This is a typical procedure, different dash numbers may require slightly different procedure.

Page 6 of 12 SERVICE BULLETIN

NUMBER: 10.8/103

1. Remove hex-head bolts (17), washers (18,19) and locknuts (20) attaching top cover (12)

to bottom cover (11).

COVER HALVES ARE FABRICATED OF ALUMINUM. USE CARE WHEN

SEPARATING TO AVOID DAMAGE.

NOTE

It is not necessary to remove access covers (13), gaskets (14), bolts (15)

and flat washers (16).

2. Separate the matched cover halves by tapping ends of dowel pins protruding through

holes in cover halves. It may be necessary to insert a thin blade between the cover halves

to break the adhesive seal. When cover halves have been separated, remove and discard

O-rings (10).

3. Matchmark driver coupling (7) to the key phaser notch on driver hub-(1).

4. Remove locknuts (9) and bolts (8) attaching driver coupling (7) and driven coupling (25)

to drive shaft (21). Leave two sets (bolts and nuts) installed on each end to prevent shaft

from dropping.

DRIVE SHAFT (21) WEIGHS APPROXIMATELY 19 POUNDS (8.5KG). DO

NOT REMOVE FINAL TWO SETS OF ATTACHING HARDWARE UNTIL

SHAFT HAS BEEN SUPPORTED.

5. Loosen remaining locknuts (9) and bolts (8) to allow shaft to separate from couplings,

but still support drive shaft to keep it from falling.

DO NOT REMOVE EXISTING TRIM BALANCE SCREWS (34).

NOTE

Shaft is scribed at the factory with a single line on the forward (driver) end

and double lines on the aft (driven) end. If shaft ends are not identified,

SERVICE BULLETIN Page 7 of 12

NUMBER: 10.8/103

scribe or matchmark to establish the shaft position and orientation prior to

removal.

6. Support drive shaft (21) and remove remaining bolts (8) and locknuts (9); tighten jacking

screws to separate drive shaft from couplings (7, 25) and remove shaft.

7. Carefully slide driver coupling (7) off driver hub (1), being careful not to damage splines.

NOTE

Matchmark forward adapter (3) to driver hub (1) prior to removal.

8. Remove bolts (5) and lock plates (4) from forward adapter (3).

9. Remove forward adapter (3) from driver hub (1) and remove and discard O-rings (2,6)

from adapter.

10. Remove bolts (22), bolt retainer (23), and retainer-ring retainer (24) from driven hub

(33).

11. Carefully slide driven coupling (25) off splines of driven hub (33); extract retainer ring

(26) from coupling.

NOTE

Matchmark aft adapter (31) to driven hub (33) prior to removal.

12. Remove lockwashers (28), flat washers (29), and bolts (27) from aft adapter (31).

13. Remove aft adapter (31) from driven hub (33); remove and discard O-rings (30,32).

Installation of Input Drive Shaft Assembly

1. Remove sealant and clean mating surfaces of forward adapter (3) and aft adapter (31),

and top and bottom halves of matched cover assembly (11, 12).

2. Lubricate O-rings (30, 32) and install on aft adapter (31); align bolt holes and slide

adapter into compressor housing around driven hub (33).

3. Lubricate bolts (27); install bolts, lockwashers (28) and flat washers (29) through flanges

of aft adapter (31) into bearing housing of compressor. Tighten bolts to a torque value

of 13 ft-lb (18 N•m).

Page 8 of 12 SERVICE BULLETIN

NUMBER: 10.8/103

RETAINER RING (26) IS INSTALLED TO LIMIT END FLOAT OF THE

INTERCONNECT SHAFT ASSEMBLY. IF RING IS NOT SECURE AND

FIRMLY SEATED IN GROOVE OF COUPLING (25), THE ENTIRE SHAFT

ASSEMBLY CAN MOVE AFT, DISENGAGE FROM THE INPUT DRIVER

HUB, AND CAUSE SEVERE DAMAGE.

4. Install retainer ring (26) in groove in inside of driven coupling (25). Then slide coupling

on splines of driven hub (33, Fig. 2).

5. Position retainer-ring retainer (24, Figure 1) and bolt retainer (23) on driven hub (33);

install bolts (22) and tighten to a torque value of 25 ft-lb (34 N•m).

6. Secure bolts (22) by bending flange of bolt retainer (23) up against flat on head of each

bolt.

7. Lubricate O-rings (2,6) and install on forward adapter (3). Align bolt holes in flanges of

adapter with corresponding holes in driver hub.

8. Lubricate bolts (5); install bolts through lock plates (4) and flanges of forward adapter

(3) and thread into driver hub (1). Tighten bolts to a torque value of 13 ft-lb (18 N•m).

9. Secure hex-head bolts (5) by bending long flanges of lock plates (4) up against flat side

of each bolt head.

10. Locate and position matchmarks, aligning drive shaft (21) with key phaser notch on

driver hub (1). Slide driver coupling (7) on splines of driver hub (1).

DRIVE SHAFT BOLTS (8) AND LOCKNUTS (9) ARE WEIGHT

CONTROLLED FOR BALANCE. SUBSTITUTION MAY RESULT IN

EXCESSIVE VIBRATION WHICH COULD CAUSE DAMAGE TO BEAR-

INGS.

11. Orient matchmarks on drive shaft (21) with matchmarks on forward and aft drive shaft

couplings (7, 25). Install bolts (8) and locknuts (9) in forward and aft flanges to connect

drive shaft to couplings. Tighten bolts to a torque value of 25 ft-lb (35 N•m).

12. Cut two pieces of bulk O-ring stock (P/N 964587C1) to the appropriate length to fit slots

in mating surfaces of top and bottom halves (11,12) of matched shaft cover assembly.

13. Use cover assembly gasket or apply a bead of adhesive (P/N 915931C1) to bottom cover

mating surface extending from O-ring to edge of cover. Orient dowel pin holes on upper

SERVICE BULLETIN Page 9 of 12

NUMBER: 10.8/103

and lower cover halves and position covers around shaft with ends mating with forward

adapter (3) and aft adapter (31).

14. Install bolts (17), washers (18,19) and locknuts (20) to attach cover halves together;

tighten bolts and locknuts in an alternating pattern applying 75 in-lb (8.5 N•m) torque

to complete interconnect shaft assembly and installation.

Table 24 KEY TO FIGURE 1

1. Driver Hub 18. Flat Washer

2. O-ring 19. Flat Washer

3. Forward Adapter 20. Locknut

4. Lock Plate 21. Drive Shaft

5. Hex-Head Bolt 22. Hex-Head Bolt

6. O-ring 23. Bolt Retainer

7. Driver Coupling 24. Retainer-Ring Retainer

8. Hex-Head Bolt 25. Driven Coupling

9. Locknut 26. Retainer Ring

10. O-ring 27. Hex-Head Bolt

11. Bottom Cover 28. Lockwasher

12. Top Cover 29. Flat Washer

13. Access Cover 30. O-ring

14. Gasket 31. Aft Adapter

15. Hex-Head Bolt 32. O-ring

16. Flat Washer 33. Driven Hub

17. Hex-Head Bolt 34. Trim Balance Screws

Page 10 of 12 SERVICE BULLETIN

NUMBER: 10.8/103

Figure 1 Interconnect Shaft Assembly (Typical)

SERVICE BULLETIN Page 11 of 12

NUMBER: 10.8/103

Page 12 of 12 SERVICE BULLETIN

NUMBER: 10.8/103

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Manual de Partes Komatsu 930 SE4 PDFDocument708 pagesManual de Partes Komatsu 930 SE4 PDFRodrigo Andres Merellado BustosNo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument16 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Chapter 1-8: Industrial Gas Generator Illustrated Parts CatalogueDocument18 pagesChapter 1-8: Industrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Komatsu 730e-10 Mining Truck Parts ManualDocument740 pagesKomatsu 730e-10 Mining Truck Parts Manualspeedstar_no1100% (5)

- CH11008Document1 pageCH11008pilotNo ratings yet

- Altronics AGV5 SRVC MNL 11-2003 PDFDocument18 pagesAltronics AGV5 SRVC MNL 11-2003 PDFSMcNo ratings yet

- TXD3E PartsDocument2 pagesTXD3E PartsCarlos Rafael Rondon AbreuNo ratings yet

- CS-280E Chain Saw: Parts CatalogDocument16 pagesCS-280E Chain Saw: Parts CatalogГоран СтанишићNo ratings yet

- Sec6 8035Document355 pagesSec6 8035Benmorsli AhceneNo ratings yet

- Blackmer Parts List Pump Model: Xl3B: Discontinued Models: Xl3A-N, Xls3A-NDocument2 pagesBlackmer Parts List Pump Model: Xl3B: Discontinued Models: Xl3A-N, Xls3A-NJuan David Triana SalazarNo ratings yet

- SEC6Document408 pagesSEC6hectdgNo ratings yet

- Blackmer Parts List Pump Models: Txd3E Tx3E: (Double Ended Shafts) (Single Ended Shafts)Document2 pagesBlackmer Parts List Pump Models: Txd3E Tx3E: (Double Ended Shafts) (Single Ended Shafts)Felipe Ignacio PaillavilNo ratings yet

- Blackmer Parts List Pump Models: Txd3E Tx3E: (Double Ended Shafts) (Single Ended Shafts)Document2 pagesBlackmer Parts List Pump Models: Txd3E Tx3E: (Double Ended Shafts) (Single Ended Shafts)Sebastian Espinoza100% (1)

- Agv5 SM - 11 03Document18 pagesAgv5 SM - 11 03Luis GonzalezNo ratings yet

- Table of Contents - ManualDocument4 pagesTable of Contents - ManualRich KennedyNo ratings yet

- Blackmer Parts List PUMP MODELS: SGL1.25A, SGRL1.25A, SGL1.5ADocument2 pagesBlackmer Parts List PUMP MODELS: SGL1.25A, SGRL1.25A, SGL1.5AJackNo ratings yet

- B15S-5 SB1086 E18 PDFDocument412 pagesB15S-5 SB1086 E18 PDFGORDNo ratings yet

- Parts Catalog: 0CR10-M56600ENDocument25 pagesParts Catalog: 0CR10-M56600ENEdward De La CruzNo ratings yet

- Armado de Transmision 924G - 101803Document30 pagesArmado de Transmision 924G - 101803linko estradaNo ratings yet

- NP1 5Document2 pagesNP1 5Elinton De Jesus SarmientoNo ratings yet

- Ambition 135 PDFDocument127 pagesAmbition 135 PDFSANTOSH KUMAR71% (7)

- GEX450-268-9868.Catalogue PiècesDocument81 pagesGEX450-268-9868.Catalogue PiècesIgor Assoumou MatambaNo ratings yet

- M18 061 eDocument3 pagesM18 061 eFalgon IslamNo ratings yet

- John Deere - Parts Catalog - Frame 5 PDFDocument2 pagesJohn Deere - Parts Catalog - Frame 5 PDFJorge Mendoza100% (1)

- John Deere - Parts Catalog - Frame 5Document2 pagesJohn Deere - Parts Catalog - Frame 5Jorge MendozaNo ratings yet

- RG125F - 92-94 Vues EclateesDocument125 pagesRG125F - 92-94 Vues EclateesJacquetNo ratings yet

- NP4Fparts103 A05Document4 pagesNP4Fparts103 A05Leandro Gabriel GuerreroNo ratings yet

- Xtz125e Parts CatalogueDocument57 pagesXtz125e Parts CatalogueGábor Esetleg75% (4)

- Winco - 60700 106 - 40ptoc 4 D - 40fptoc 4 D - 45ptoc 17 D - 45fptoc 17 D - PLDocument8 pagesWinco - 60700 106 - 40ptoc 4 D - 40fptoc 4 D - 45ptoc 17 D - 45fptoc 17 D - PLnash RosalesNo ratings yet

- Bomba Blackmer GX2.5Document4 pagesBomba Blackmer GX2.5Arturo VillenaNo ratings yet

- Honda Goldwing gl1100 1980 To 1982 Honda Parts Manual PDFDocument195 pagesHonda Goldwing gl1100 1980 To 1982 Honda Parts Manual PDFnuno araujoNo ratings yet

- B15T-5 Sb1065e20Document676 pagesB15T-5 Sb1065e20GORD100% (1)

- 1275AC-681 Sec6Document254 pages1275AC-681 Sec6John SuarezNo ratings yet

- Ambition - 135 Apr 2004Document127 pagesAmbition - 135 Apr 2004Sourabh TiwariNo ratings yet

- Honda Supra Fit NewDocument23 pagesHonda Supra Fit Newpsmp100% (2)

- Kidde WHDR Part ListDocument20 pagesKidde WHDR Part ListAhamed KyanaNo ratings yet

- GEX450-523-9868.Catalogue PiècesDocument76 pagesGEX450-523-9868.Catalogue PiècesIgor Assoumou MatambaNo ratings yet

- Dawn (Apr, 2013) 2Document92 pagesDawn (Apr, 2013) 2Kishonkumar KishonNo ratings yet

- SAA4D95LE-5D S N 521394-UP (For PC130-8) - Peças Motor pc130Document157 pagesSAA4D95LE-5D S N 521394-UP (For PC130-8) - Peças Motor pc130GustavoOliveira100% (1)

- T20000 SeriesDocument11 pagesT20000 Seriesandrés florentin pizarro lazarteNo ratings yet

- 580M Siii Carcasa de La Transmision 4WDDocument3 pages580M Siii Carcasa de La Transmision 4WDALEX DIEGONo ratings yet

- Service Parts Are Available For Pilot Valves Work ToolDocument8 pagesService Parts Are Available For Pilot Valves Work ToolAdal VeraNo ratings yet

- Blackmer Parts List Pump Model: Gnx2A, Gnxh2A: Mechanical SealsDocument2 pagesBlackmer Parts List Pump Model: Gnx2A, Gnxh2A: Mechanical Sealsventas1No ratings yet

- Blackmer Parts List: Models: Txd2.5A TX2.5ADocument2 pagesBlackmer Parts List: Models: Txd2.5A TX2.5AMARCO HernándezNo ratings yet

- Blackmer Parts List Pump Models: Txd2.5A, Txsd2.5A TX2.5A, TXS2.5ADocument2 pagesBlackmer Parts List Pump Models: Txd2.5A, Txsd2.5A TX2.5A, TXS2.5ACarlos RinconNo ratings yet

- PC Legenda PDFDocument61 pagesPC Legenda PDFGufron AsroryNo ratings yet

- YD110 Parts CatalogueDocument47 pagesYD110 Parts CatalogueHazim JunaidiNo ratings yet

- Katalog Suku Cadang Honda LegendaDocument38 pagesKatalog Suku Cadang Honda LegendaAmbri Bre Ginting NaNo ratings yet

- Mig Ta500 400500JDocument5 pagesMig Ta500 400500JandraNo ratings yet

- SEC6 Partes y PlanosDocument380 pagesSEC6 Partes y PlanosJohn Suarez100% (1)

- Blackmer Parts List Pump Model: X4BDocument2 pagesBlackmer Parts List Pump Model: X4Bcesar moraNo ratings yet

- SEC6 Lista de Partes, Manual Canrig - OmronDocument404 pagesSEC6 Lista de Partes, Manual Canrig - Omronpablo100% (3)

- Industrial Gas Generator Illustrated Parts CatalogueDocument23 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Sparepart ManualDocument364 pagesSparepart ManualEkoNo ratings yet

- 501 E01 PDFDocument2 pages501 E01 PDFsladjandjordjevicNo ratings yet

- Yanmar 3TNV76Document24 pagesYanmar 3TNV76BERNARDNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Instruction and Maintenance Manual Electronic Lung Ventilator Model 190Document12 pagesInstruction and Maintenance Manual Electronic Lung Ventilator Model 190moh12109No ratings yet

- Gas Fuel Suitability: GFS-89527: Caterpillar Confidential GreenDocument2 pagesGas Fuel Suitability: GFS-89527: Caterpillar Confidential Greenmoh12109No ratings yet

- UserGuides TNM-U-E-0081 SRP9130 Plus Brief GuideDocument2 pagesUserGuides TNM-U-E-0081 SRP9130 Plus Brief Guidemoh12109No ratings yet

- En List of Cars For CAN-BUS 1406Document10 pagesEn List of Cars For CAN-BUS 1406moh12109No ratings yet

- Land Cruiser Prado 150 Series: Year Model Features Winches Part NoDocument2 pagesLand Cruiser Prado 150 Series: Year Model Features Winches Part Nomoh12109No ratings yet

- 19 +ECU+Power+Source+CircuitDocument5 pages19 +ECU+Power+Source+Circuitmoh12109100% (1)

- General Purpose Transistor: Semiconductor 2N2907ASDocument5 pagesGeneral Purpose Transistor: Semiconductor 2N2907ASmoh12109No ratings yet

- Service Bulletin: Continental Aircraft EngineDocument3 pagesService Bulletin: Continental Aircraft Enginemoh12109No ratings yet

- Rear Final DriveDocument150 pagesRear Final DriveDidier MartinezNo ratings yet

- Fuel Pump Timing Rta72Document7 pagesFuel Pump Timing Rta72Dilawar AliNo ratings yet

- TC Fls Sihi LPH 75000 Mag enDocument7 pagesTC Fls Sihi LPH 75000 Mag enGenrry EchaccayaNo ratings yet

- Pipe Fitters HandbookDocument306 pagesPipe Fitters HandbookAto Kwamina AndersenNo ratings yet

- CP 31-1996 Stand by GeneratingDocument42 pagesCP 31-1996 Stand by GeneratingHtoo Kyi Wynn80% (5)

- Granpac Maier DP 13209usDocument20 pagesGranpac Maier DP 13209uslycannoctus5592No ratings yet

- The Coupling Handbook - II - CouplingsDocument7 pagesThe Coupling Handbook - II - CouplingsGerman ToledoNo ratings yet

- HBS Annual Inspection Report Sample NewDocument6 pagesHBS Annual Inspection Report Sample NewhgmNo ratings yet

- White Paper Encoder Mounting 9-4-13Document4 pagesWhite Paper Encoder Mounting 9-4-13baaakNo ratings yet

- M.engineering - Piping SystemsDocument55 pagesM.engineering - Piping SystemsKordalhs KyriakosNo ratings yet

- UG-5.7, UG-8, UG10 Governor: Product Manual 54042 (Revision D, 3/2000)Document13 pagesUG-5.7, UG-8, UG10 Governor: Product Manual 54042 (Revision D, 3/2000)dg_cd7340100% (2)

- 518 Centrifuge IOM Manual Rev.c PDFDocument120 pages518 Centrifuge IOM Manual Rev.c PDFRobert Andrei100% (2)

- Chery Arrizo 7 QR525MHE+TRANSMISSION PDFDocument60 pagesChery Arrizo 7 QR525MHE+TRANSMISSION PDFRostam DastanNo ratings yet

- Levo821380wb enDocument116 pagesLevo821380wb enSusanto Hidayat100% (1)

- Verderpro Brochure UkDocument32 pagesVerderpro Brochure UkSavalia HardikNo ratings yet

- 3rd - EimDocument2 pages3rd - EimKenneth MoralesNo ratings yet

- Encoder Allen BradleyDocument4 pagesEncoder Allen Bradleywendy souza britoNo ratings yet

- D MDocument9 pagesD MMuthu KumarNo ratings yet

- Fluid CouplingsDocument20 pagesFluid CouplingsMd Mehbub SamratNo ratings yet

- t19 (Scope of Work) 1436846899Document4 pagest19 (Scope of Work) 1436846899Mohammad Safdar SadatNo ratings yet

- CF-R 520 Manual - Compressed PDFDocument51 pagesCF-R 520 Manual - Compressed PDFSebastian Nicușor PărăoanuNo ratings yet

- 5351a PDFDocument487 pages5351a PDFRolando GonzalezNo ratings yet

- Vi Semester MechanicalDocument18 pagesVi Semester MechanicalAshvanee GargNo ratings yet

- 135MW CFBC OperationDocument148 pages135MW CFBC OperationDebabrata Ghosh100% (1)

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- ZF Selection GuideDocument270 pagesZF Selection GuideAnh Nguyen100% (3)

- Some Rudder Terminology - Wartsila Marine EncyclopediaDocument7 pagesSome Rudder Terminology - Wartsila Marine EncyclopediaAVINASH ANAND RAONo ratings yet

- April 2014Document86 pagesApril 2014Delian KurniawanNo ratings yet

- Energies 11 02687Document17 pagesEnergies 11 02687Lucas ErburuNo ratings yet

- Catalogo General VictaulicDocument220 pagesCatalogo General VictaulicDaniela CeciliaNo ratings yet